DIGITAL FABRICATION | 3D Printing

Brief

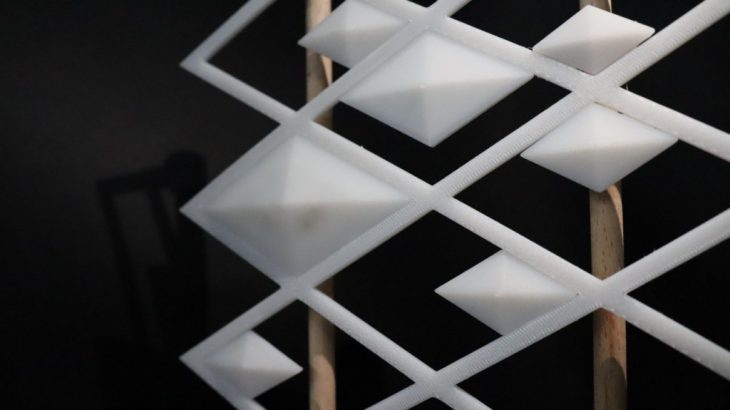

The project aimed to fabricate a prototype of the Maison Van Cleef & Arpels facade using 3d printer to represent multiple nodes and joinery connections. The project was made in 3 days of the Digital Fabrication seminar at IAAC, Barcelona, 2020.

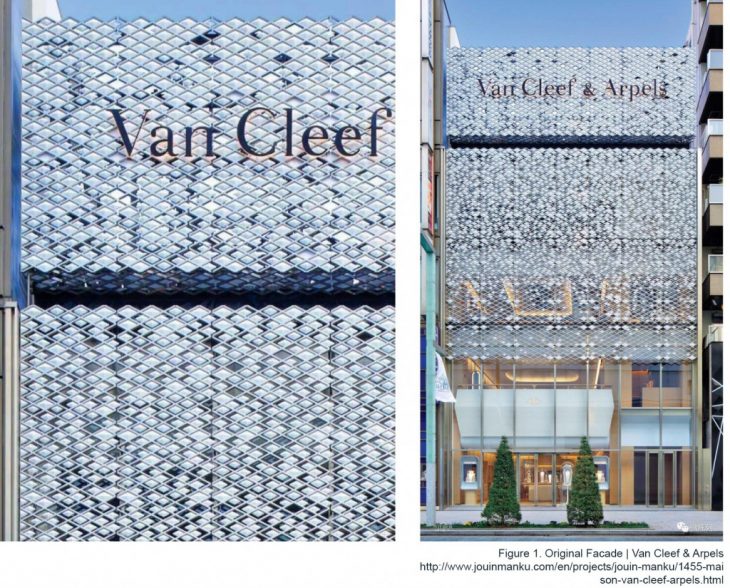

Original Facade | Van Cleef & Arpels

Area: 430 m2

Architect of record: AXE Design (Japan)

Facade: Asahi Building-Wall (Japan)

? Flagship, Tokyo / Ginza

? Mars 2016

Jouin Manku:

Jong Kim, Mio Shibuya, Martin Kloeckner, Xiao Lin, Charles Pons, Julien Lizé

The stained-glass facade is partially shaded with the metal-grid frame, containing thousands of diamonds which randomly fit the openings. LED-embedded lozenges partially fill the screen’s latticework in painted sand-cast aluminum.

Fabrication Strategy

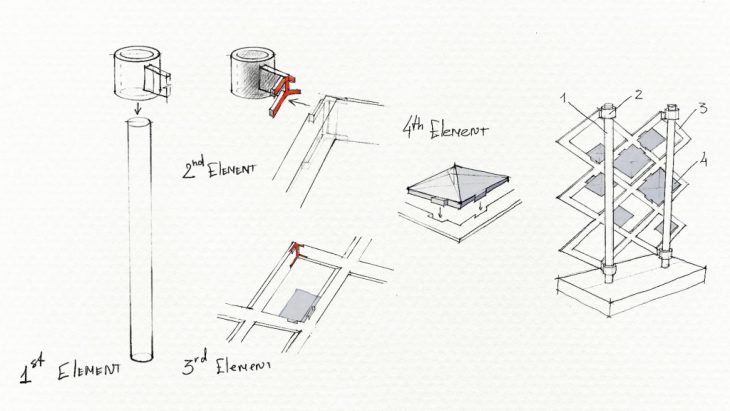

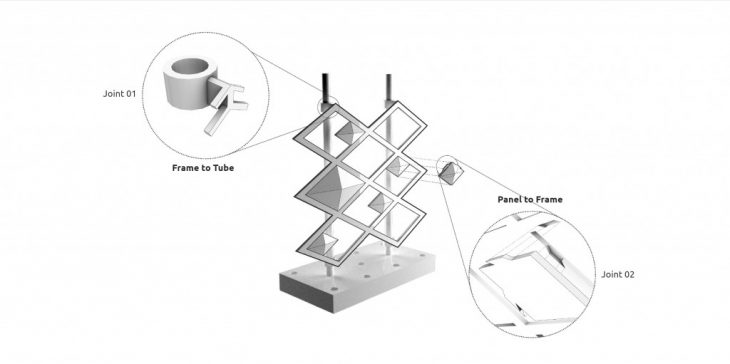

We were inspired by traditional Japanese wood joinery techniques, where no external fasteners required. To successfully assemble our prototype we had to focus on tolerance of the joints.

MATERIALS: Wood – base and columns; plastic (3d printer) – frame, joints, diamonds.

Sketch

3d model

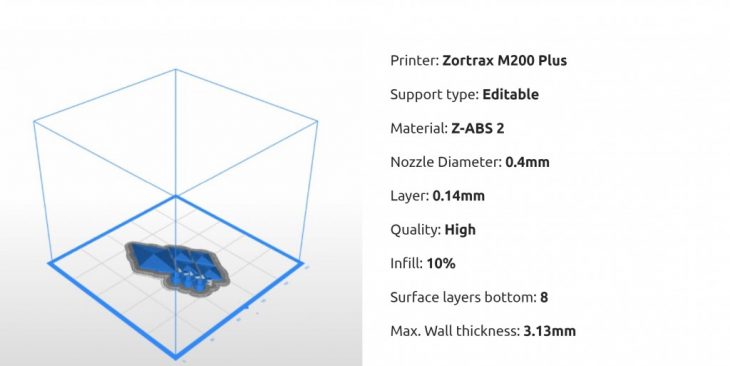

3d Printing Parameters

Video

</p>

Parametric Skins // Maison Van Cleef & Arpels is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master of Advanced Architecture 2020/21 by

Students: Ziying Zeng, Victoria Fedorova, Amandeep Singh Sasan,

Faculty: Ricardo Mayor Luque, Lana Awad, Shyam Zonca