Project Brief:

This series of digital fabrication exercises were developed based on the principle of recursive growth. We have explored the potential of the different 3d fabrication processes from designing the base geometry in softwares to the manipulation of the real world materials’ quality. As a result, we have obtained valuable experiences in translating the visions of parametric designs to physical projects.

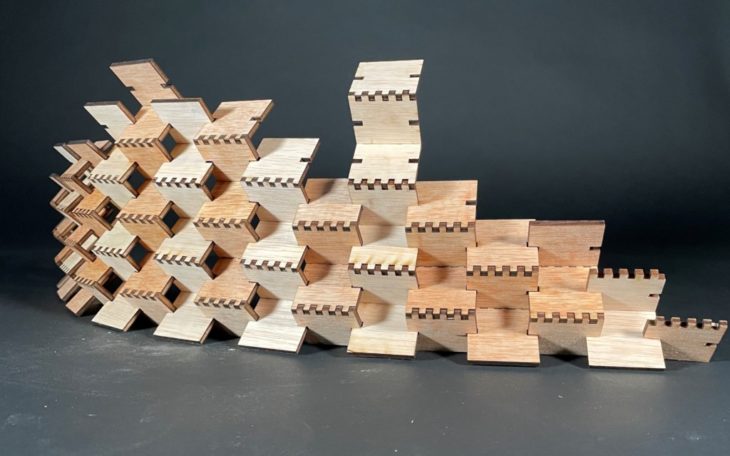

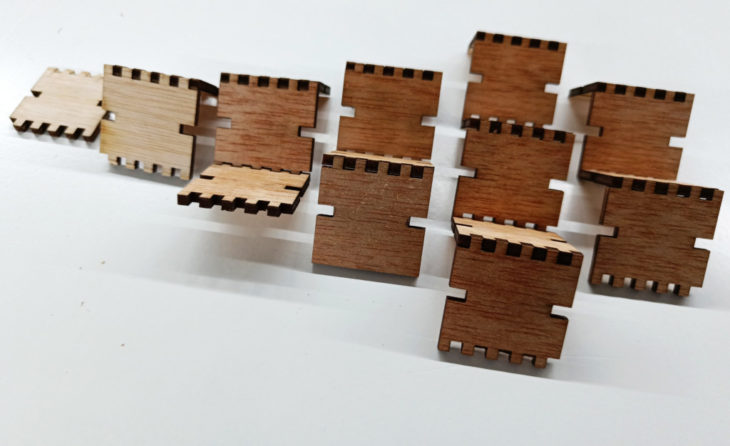

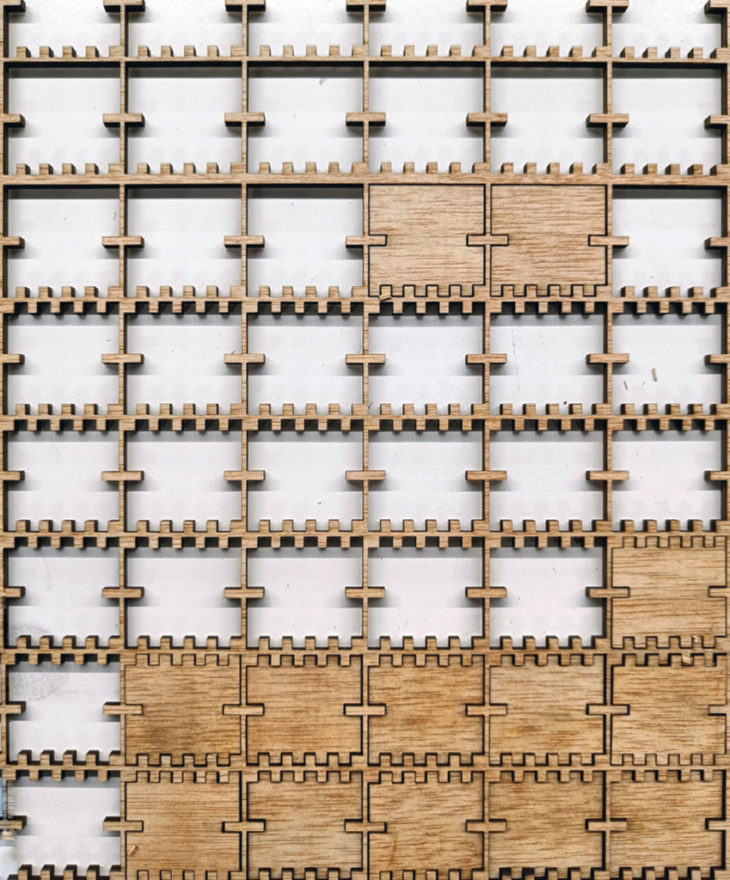

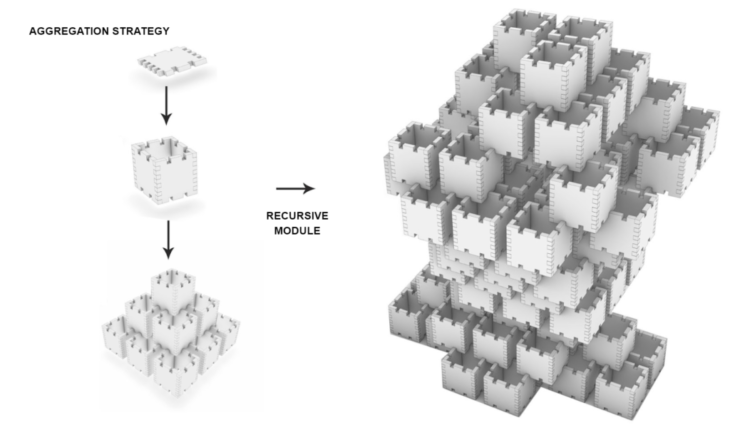

Exercise 1: Laser Cutter, the Mechanical Joints

In this session we explored two types of joinery: box joints and half lap joints. We used two types of joints as we wanted to explore the laser cutter machine accuracy and possibilities in our exercise. We started from two different pieces (end pieces and middle pieces), and by joining them we created a recursive structure. The structure’s shape can be manipulated through different compiling patterns between the pieces.

Basic Modules:

Cut Sheet:

Fabrication Parameters:

Material: 4mm Plywood

Technique: Mechanical joints

Joint type: Finger Joint

Machine: Rayjet 500

Working Parameters: Speed = 180, Power = 42

Aggregation Strategy:

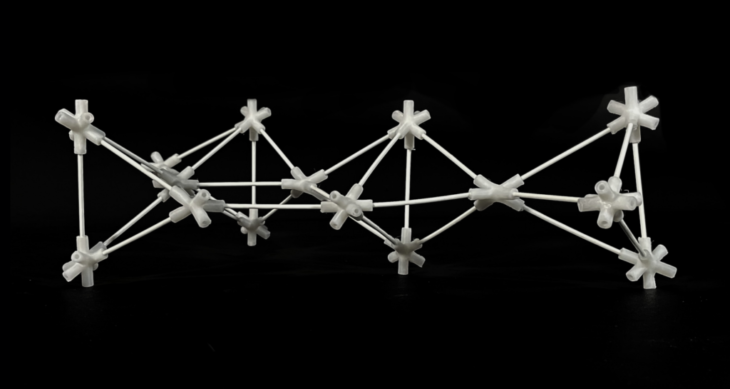

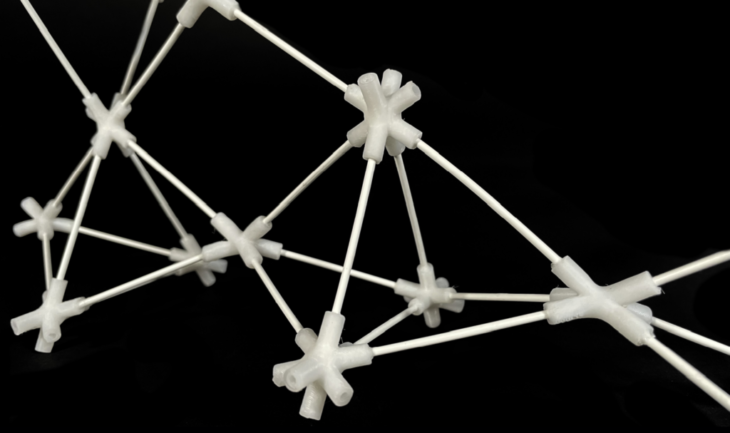

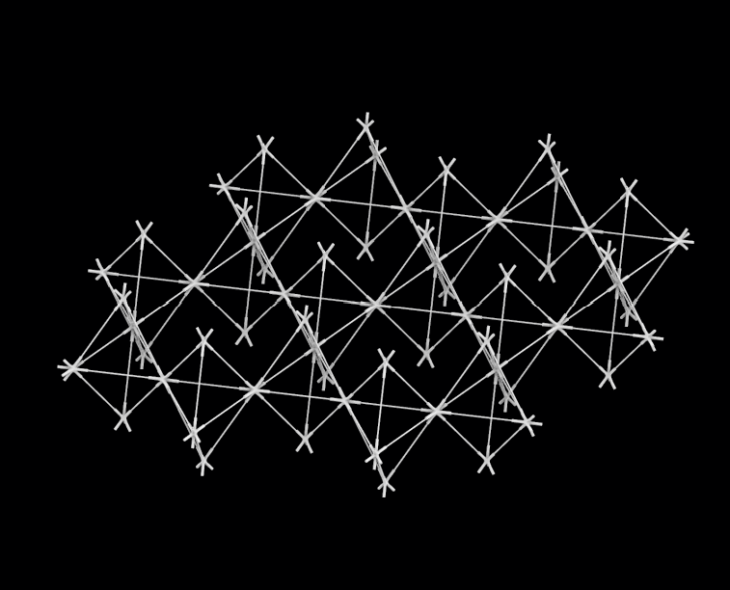

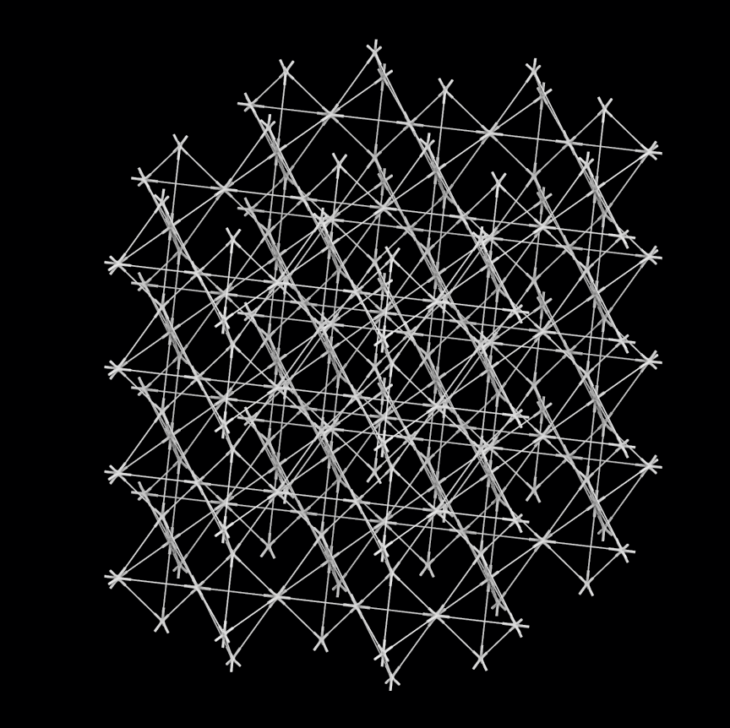

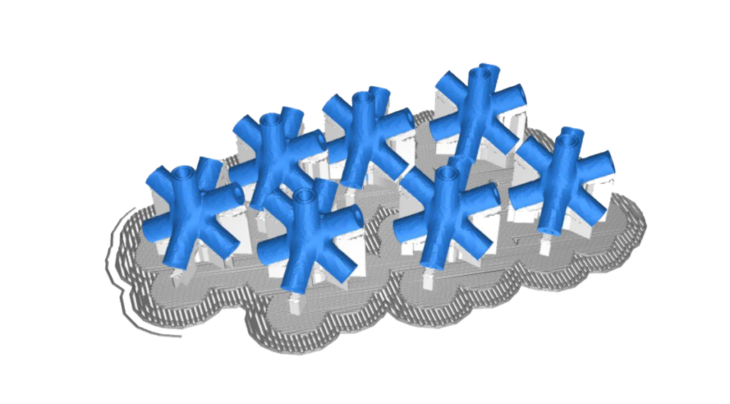

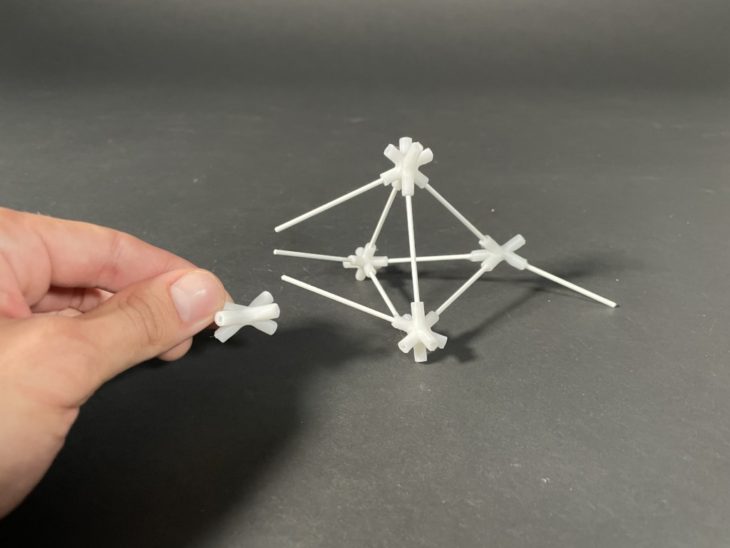

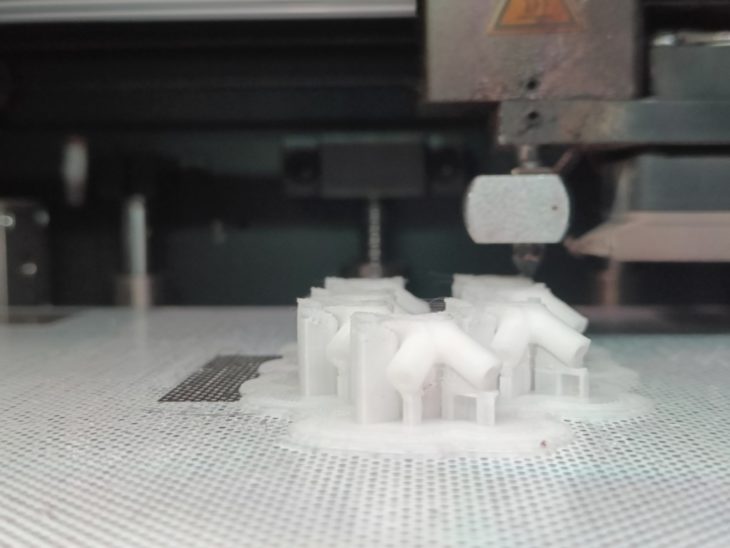

Exercise 2: 3D Printing, Massing Geometry

In this session we explored a node system based on two different geometries. One of them has eight pods, and the other with six. Together, they can generate an endless series of volumetric networks.

The two types of nodes:

Aggregation Strategy:

Fabrication Parameters:

Node A (with six pods):

Totalnumber of nodes: 3

Total print time: 51 minutes

Total Material Usage: 2.24m (5g)

Material: Z•ABS

Machine: ZORTRAX M200

Nozzle Diameter: 0.4mm

Quality: High

Infill: 20%

Node B (with eight pods):

Totalnumber of nodes: 7

Total print time: 2hr 34minutes

Total Material Usage: 6.13m (15g)

Material: Z•ABS

Machine: ZORTRAX M200

Nozzle Diameter: 0.4mm

Quality: High

Infill: 20%

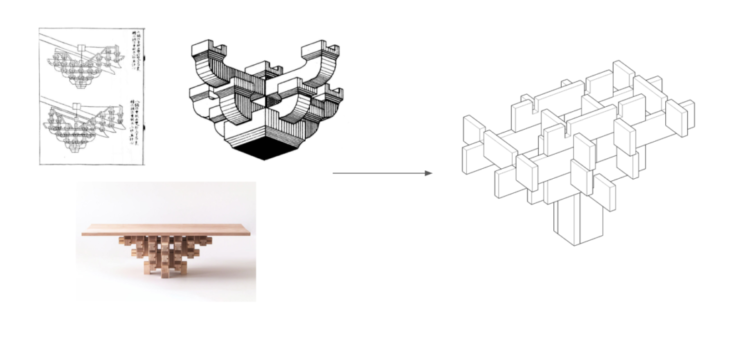

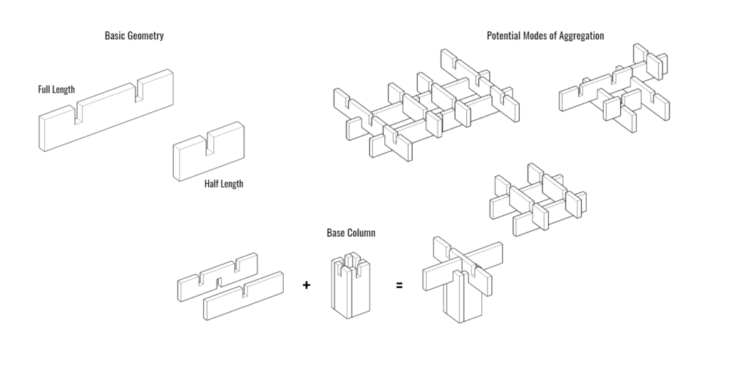

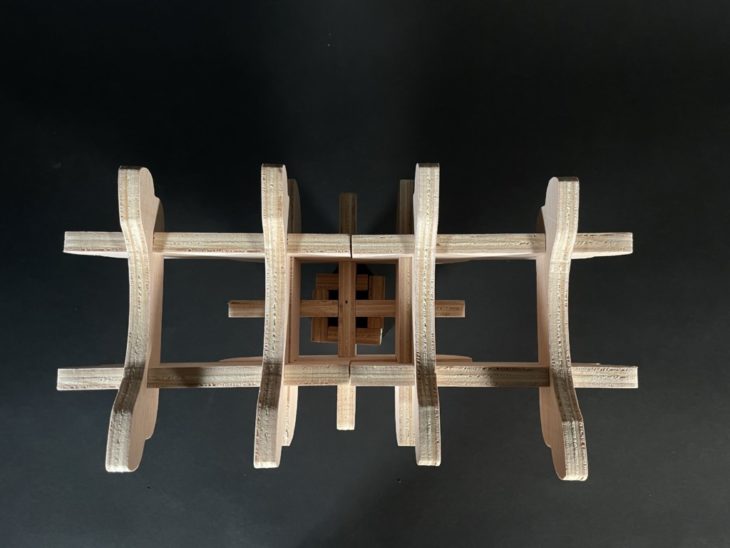

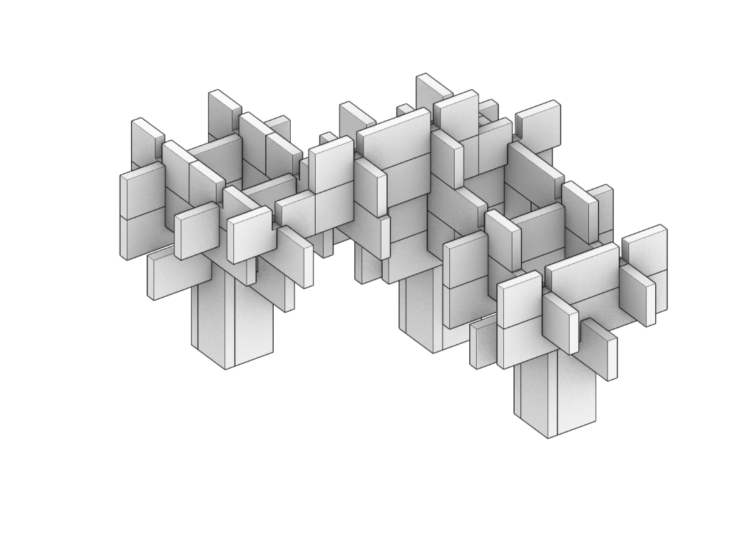

Exercise 3: CNC Milling, Vertical Bracket

In this session, we only used the basic 2 axis flat milling strategy. We intended to explore the differences between the fabrication methods of the laser cutter and the CNC milling. The result is a vertically aggregating system that balances its center of gravity on a single column, inspired by the traditional Asian Architecture.

Developing Concept:

Fabrication Process:

Final Result:

The final output of this session was given an ornamental shape rather than maintaining the basic geometric format.

Aggregation Strategy:

Fabrication Parameters:

Material: 12 mm Plywood

Machine: Shopbot(p59)

Post Processor: Shopbot_MTC

Workpiece volume: 470mmx600mmx12mm

CNC Milling strategies:

2 ½ Axis Profiling

Upcut Mill

Flute: 1

Diameter: 4

Spindle Speed: 12000

Cut Direction: Upcut

Stepover Control : 0%

Total mill time: 16.73 minutes

Engraving

Upcut Mill

Flute: 1

Diameter: 4

Spindle Speed: 12000

Cut Direction: Upcut

Total mill time: 1.72 minutes

Credits:

INTRODUCTION TO DIGITAL FABRICATION | GROUP 3 TERM REPORT is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master of Advanced Architecture 2021/22 by

Students: Enlin Guo/ Alexandru Girtan/ Martin Gomez/ Pragati Vpk

Faculty: Ricardo Mayor Luque, Lana Awad, Shyam Zonca