Diamonds in the Sky – 3-Axis CNC Milling

2021/22 Introduction to Digital Fabrication, Final – Neha Jayanth Pattanshetti, Alessandra Weiss, Luca Wenzel

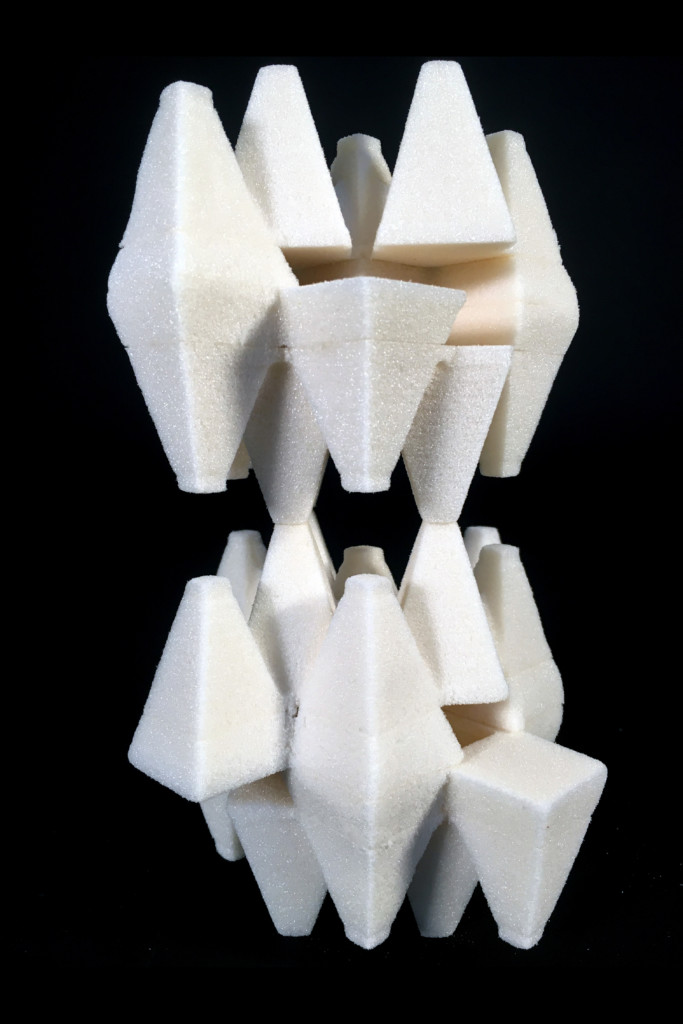

Diamonds in the Sky is an exploration of pyramidal forms, aggregated, rotated, and inverted in space. The intent was to understand the advantages and limitations of the CNC milling process, as well as the chosen material, polyurethane foam. Through this, the following factors were considered: the relationship between solids and voids, how these geometries were designed, could be stacked, milled, and assembled, to create an aggregation in space that could theoretically continue indefinitely.

Final Model

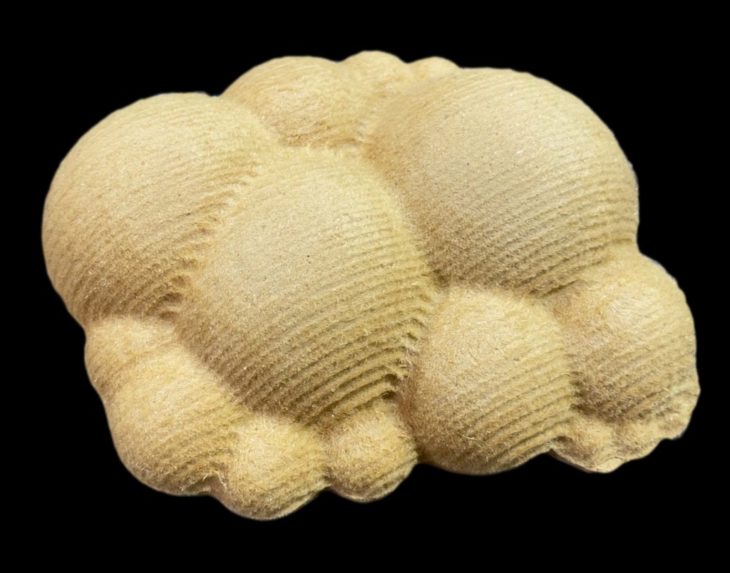

Crash Course

The design for the final project originated in the crash course project. 3-axis milling was used to create a pattern of connected spheres. Horizontal roughing removed the bulk of material with a larger flat bit, parallel finishing with a smaller round bit to give final shape to the geometry. 2-/2 axis profiling and bridges were used to keep the spheres connected to the base during the cutting process.

Crash Course Model

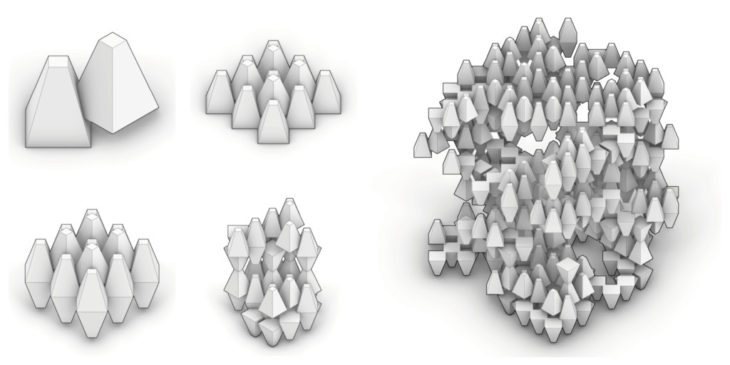

Stacking Diamonds

The Final Geometry began with two pyramidal shapes rotated and intersected, then arrayed and flipped on the vertical axis, subsequently stacked and randomly subtracted to create a perforated geometry with empty spaces in between. The relationship between solids and voids was explored, and how this type of aggregation of forms could be achieved using a CNC milling process.

Diamond Stack and Array

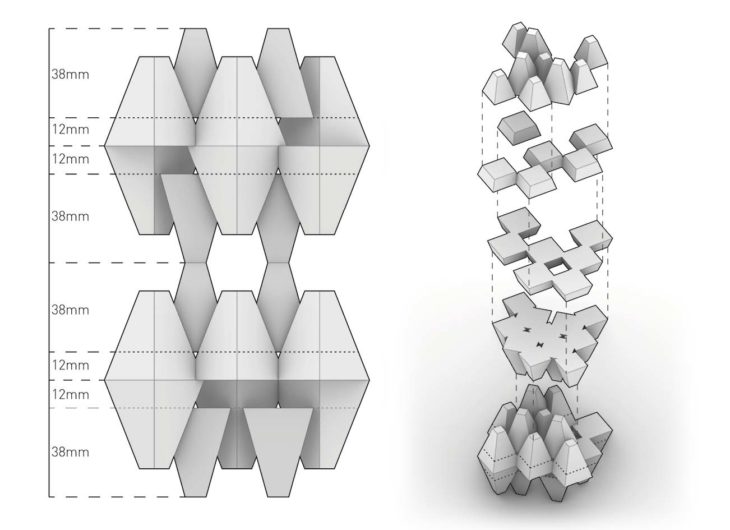

Front View and Assembly of Layers

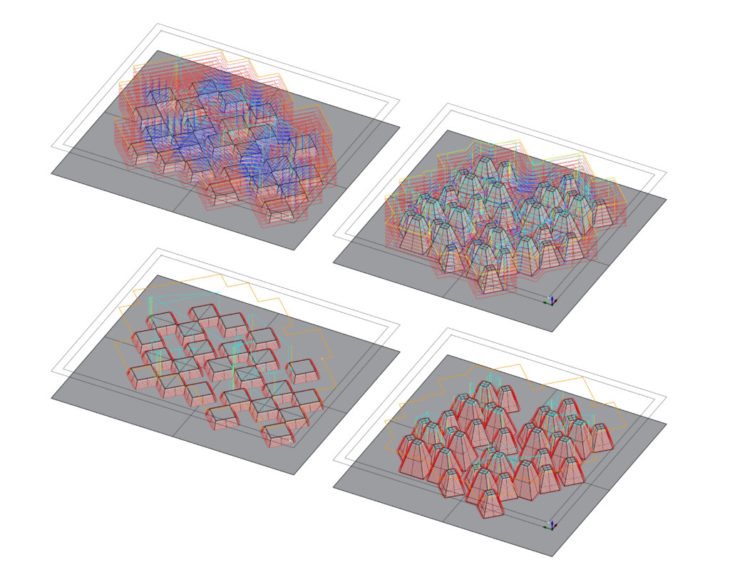

File Preparation

The slicing of the model and layout was critical in considering the seams, ease of assembly and efficiency of time. The logical starting point to section it was from each of the ends as well as the center of the model, the maximum height was specified at 38mm for the 40mm material (leaving 2mm attached at the base). The remaining sections were then evenly divided starting from the vertical axis flips. Two files were created for the milling plan, one for the taller geometries and one for the shorter ones.

Milling Paths

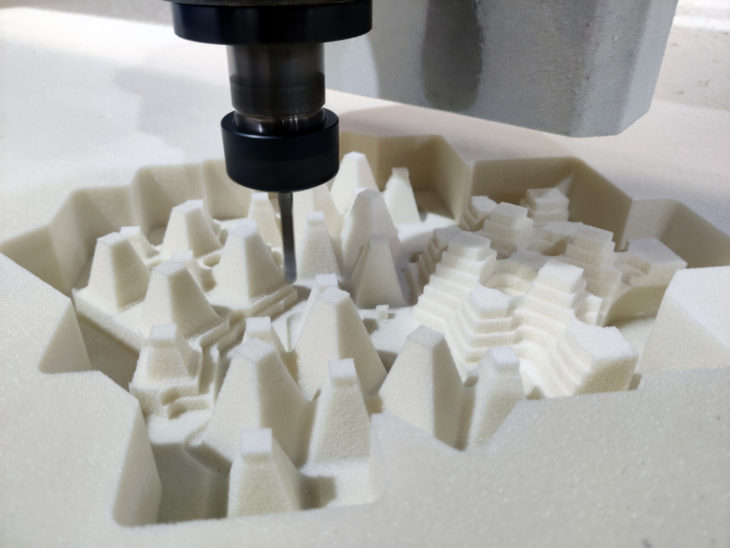

Milling Process

To decrease the milling time and ease the assembly, polyurethane foam was chosen instead of MDF for the Diamond Aggregation. The Raptor X-SL 3200/S15 CNC machine was used, which allowed to increase the spindle speed substantially compared to when milling MDF (from 12000 to 18000).

Horizontal Finishing

Assembled Layers

Technical Data:

- Material: Polyurethane Foam

- Machining Strategy: 3-Axis

- Post Processor: Raptor X-SL 3200/S15

- Workpiece volume: 120 x 120 x 200 mm

Horizontal Roughing

- Flat Drill Bit

- Diameter: 10 mm

- Spindle Speed: 18000

- Cut Direction: Downcut

- Stepdown Control (dZ): 50%

- Stepover Distance: 75%

- Total mill time: 22 minutes

Horizontal Finishing

- Ball Drill Bit

- Diameter: 6 mm

- Spindle Speed: 18000

- Cut Direction: Downcut

- Stepdown Control (dZ): 25%

- Total mill time: 14 minutes

Credits

Diamonds in the Sky is a project of IAAC, the Institute for Advanced Architecture of Catalonia, developed during the Master in Advanced Architecture (MAA01) 2021/22 by students: Neha Jayanth Pattanshetti, Alessandra Weiss, Luca Wenzel; faculty: Shyam Francesco Zonca

Inspiration: Rihanna