Introduction

In this 1 week workshop the aim was to establish a relation between the robotic craft of assembly with aggregation as a digital design tool.

First there was a manual hands on exploration to understand on one side the material and building blocks it self (wood blocks (27mm x 27mm x 200mm or 300mm)) on the other side to get an understanding of the aggregation design strategies.

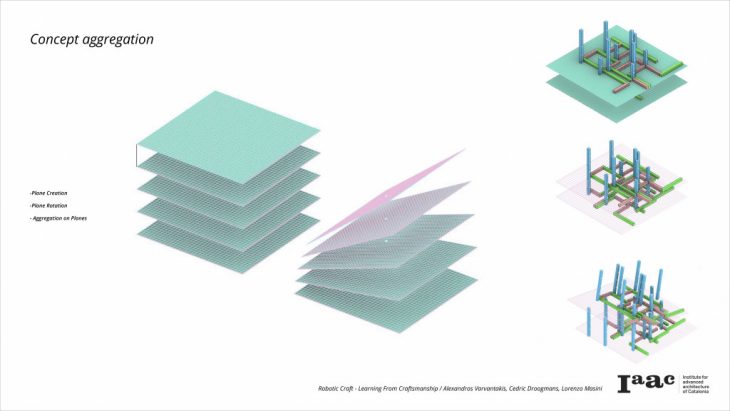

The concept

Resulting in the goal to create a system then can rapidly grow in vertical space, create an unique emerging pattern and to be able to control this system in different ways, using only the two building blocks.

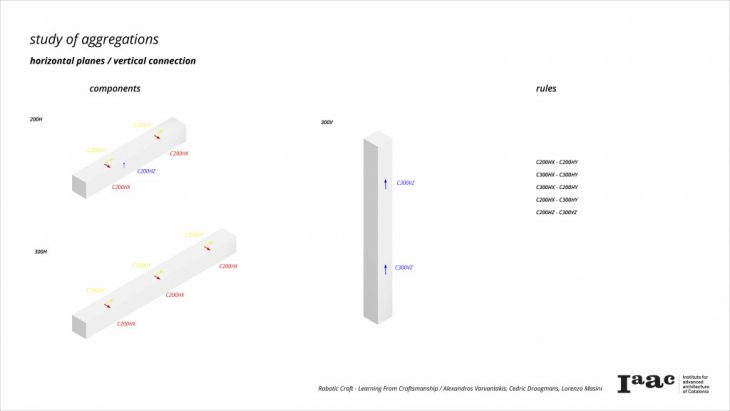

The aggregation system

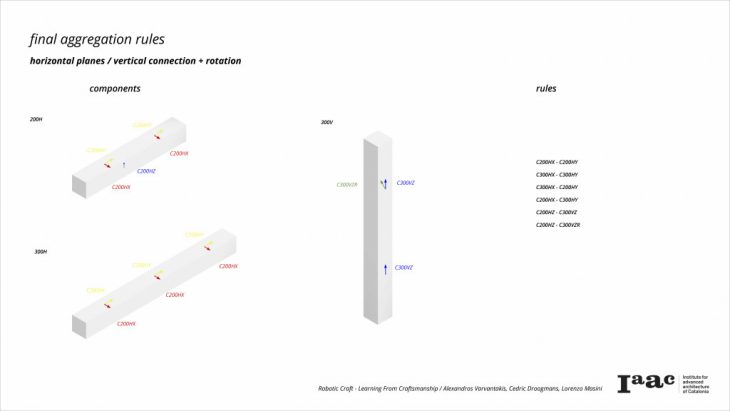

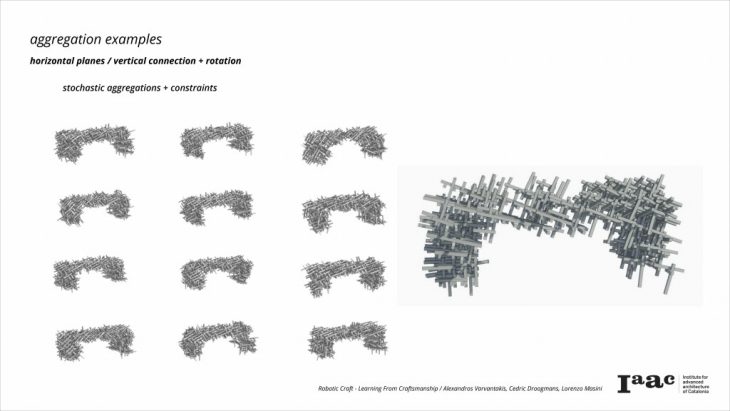

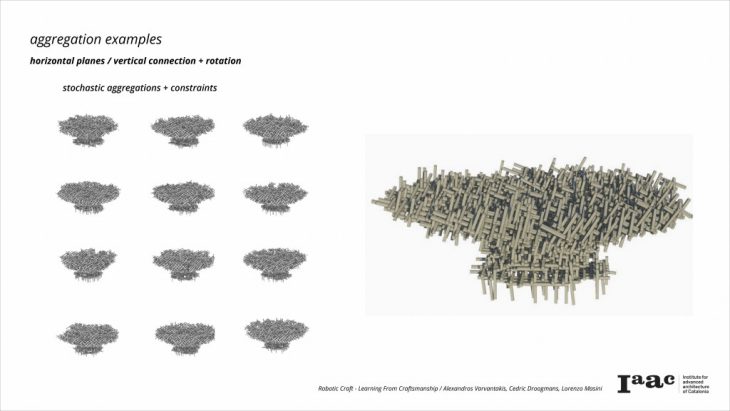

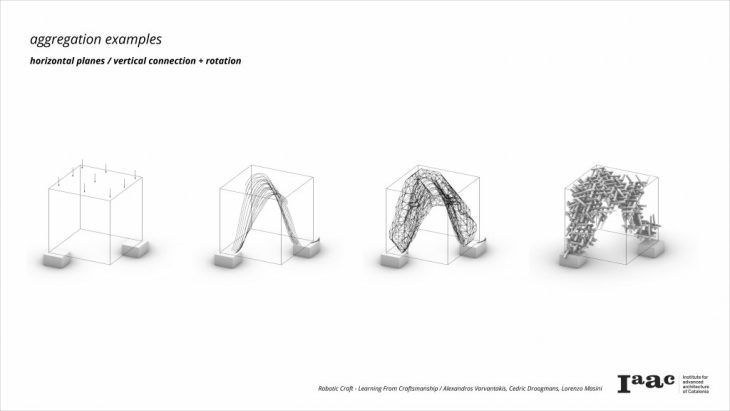

To combine the goals that we set ourselves we created an aggregation system that creates planes with vertical connections, to separate each plane from each other. To add the possibility for a pattern to emerge we embedded in the vertical connection a chance to rotate the next plane.

To form the aggregation a structural analysis was used to create stress-lines from a given load to given supports.

These stress lines where used to guide the path of the aggregation. Leaving enough freedom for the system to be able to grow according to its own rules.

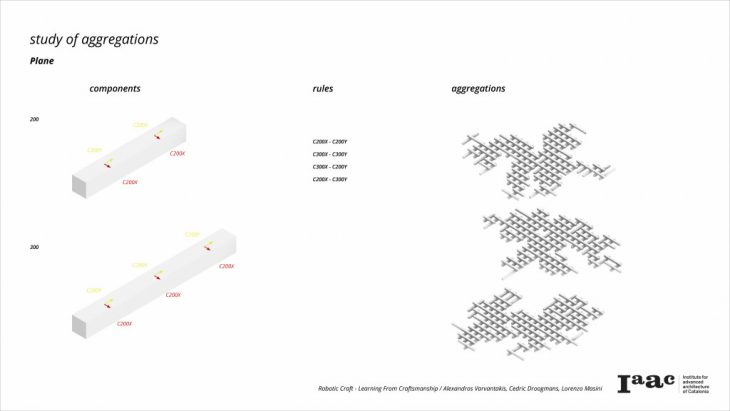

first set of rules:

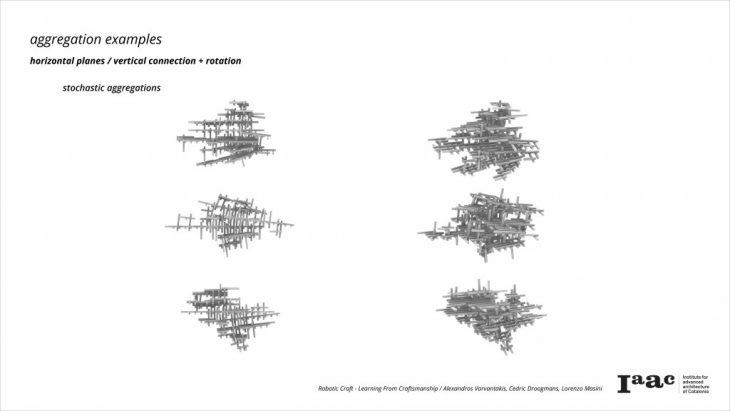

results of stochastic aggregation

final set of rules with rotation

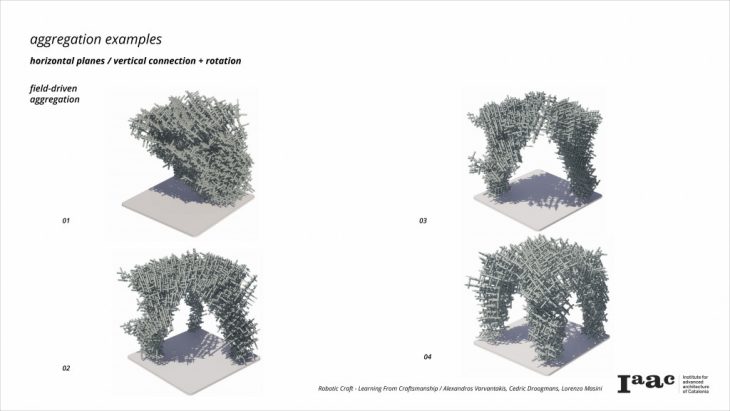

samples of aggregation

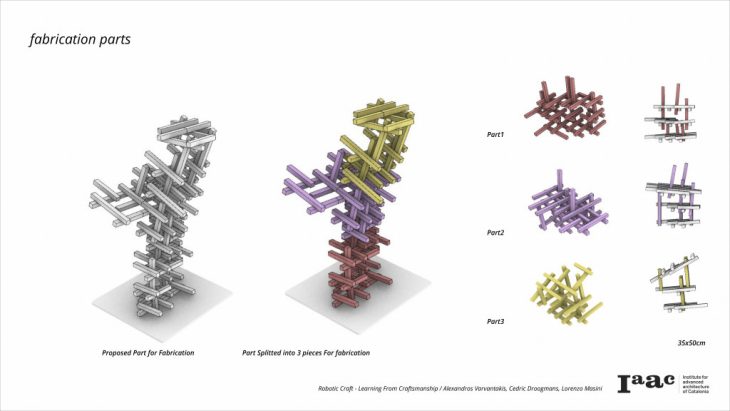

Fabrication

To assemble the resulting aggregation different techniques where explored.

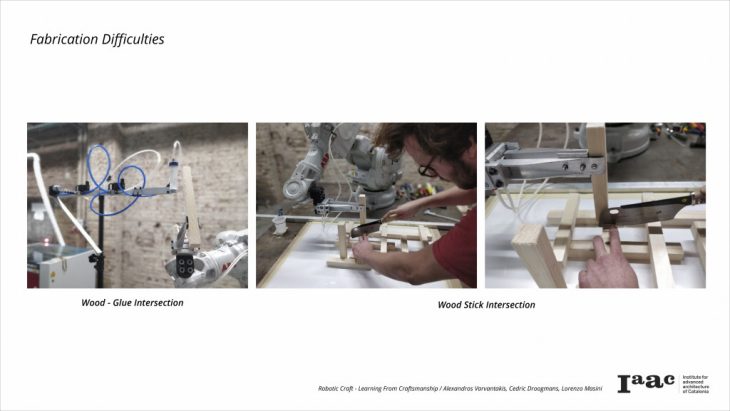

At first we used an ABB robot to fully automatically build the prototype. The process was split into separate steps: take the wood block, apply glue and assemble the pieces in the right order. Because of the complex nature of the aggregation this proved itself to be difficult to achieve in one week.

first try to robotic assembly

The robotic process underlines different issues, first of all the impossibility to avoid some collision between elements for the density of the system and the impossibility to rotate the platform for reaching the right place from the best angle.

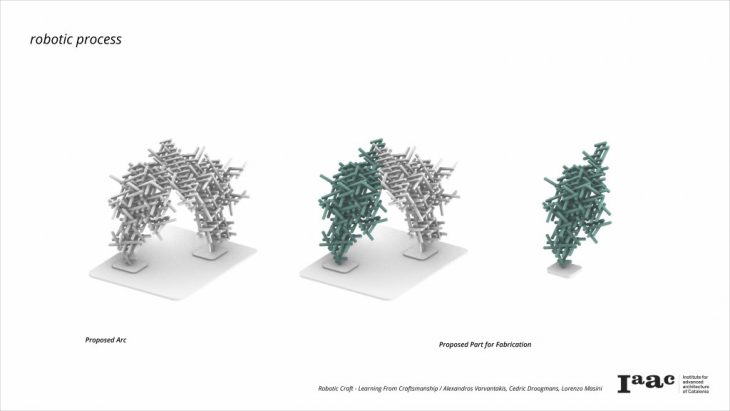

robotic process simulation

The robotic process underlines different issues, first of all the impossibility to avoid some collision between elements for the density of the system and the impossibility to rotate the platform for reaching the right place from the best angle.

sample of collision

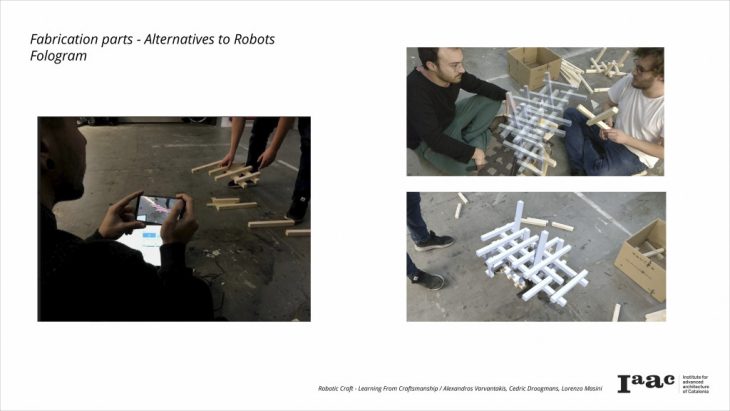

So we decided to use augmented realty to assemble a rapid prototype of the desired part of the aggregation.

Possible applications

The designed system is highly flexible and adaptive to given constraints by the designer which makes it a unique tool to use if needed. As shown in the example we designed a pavilion with this technique showing the light pattern that results out of the aggregated pattern.

Plane aggregation is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction in 2019 by:

Students: Alexandros Varvantakis, Cedric Droogmans, Lorenzo Masini

Faculty: Pablo Zamorano, Aldo Sollazzo, Raimund Krenmueller

Faculty Assistants: Soroush Garivani, Hazal Yilmaz