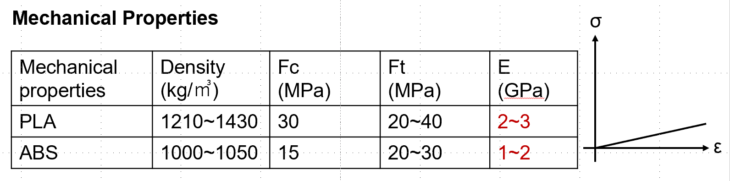

Materials used for 3D printing

For 3D printing, two materials are mainly used. Polylactic acid (PLA) and Acrylonitrile butadiene styrene (ABS). PLA has biodegradability so this material can be related to carbon neutral. And ABS is used in toy and household items, because it has relatively low harmful effects on humans.

This is mechanical properties of PLA and ABS. Most of them are related to geometry and temperature, it could be said to entire 3D printing materials due to its degree of freedom in shape. One of the important thing is they have lower stiffness than building materials, while it has high capacity in tension and compression as much as them.

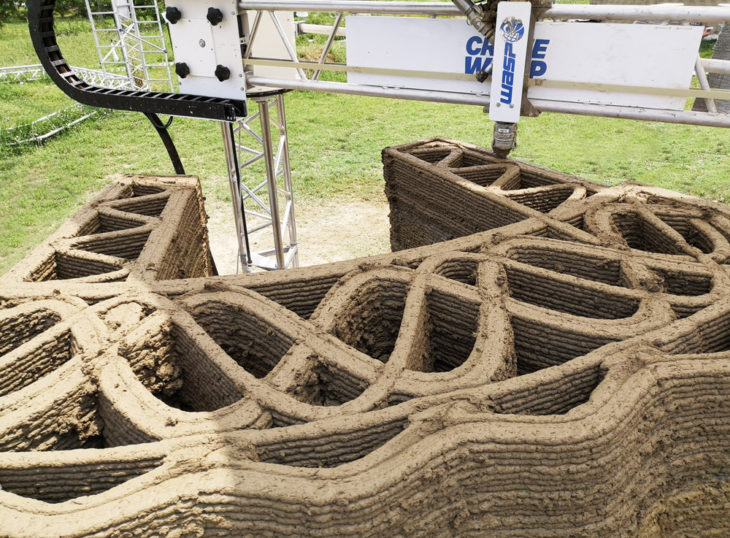

Round Houses of raw earth

This is the first 3D printed raw earth house. Constructed in Italy. The structure was made of double doom which has 350 layers of 12mm, 150km extrusion, and 60 cubic meters of earth. This is an example 3D printer simplified process, minimized resources and reduced construction time. It was printed in 200 hours.

https://www.archdaily.com/956854/round-houses-of-raw-earth-3d-printing-sustainable-homes-in-200-hours?ad_medium=widget&ad_name=navigation-next

3D printed house

In Netherland, 3D printed concrete house was constructed. The 24 elements were printed at a factory. 3D printing enable concrete to be placed only where it is needed, without wasting materials.

https://www.archdaily.com/961135/the-future-is-now-3d-printed-houses-start-to-be-inhabited-in-the-netherlands

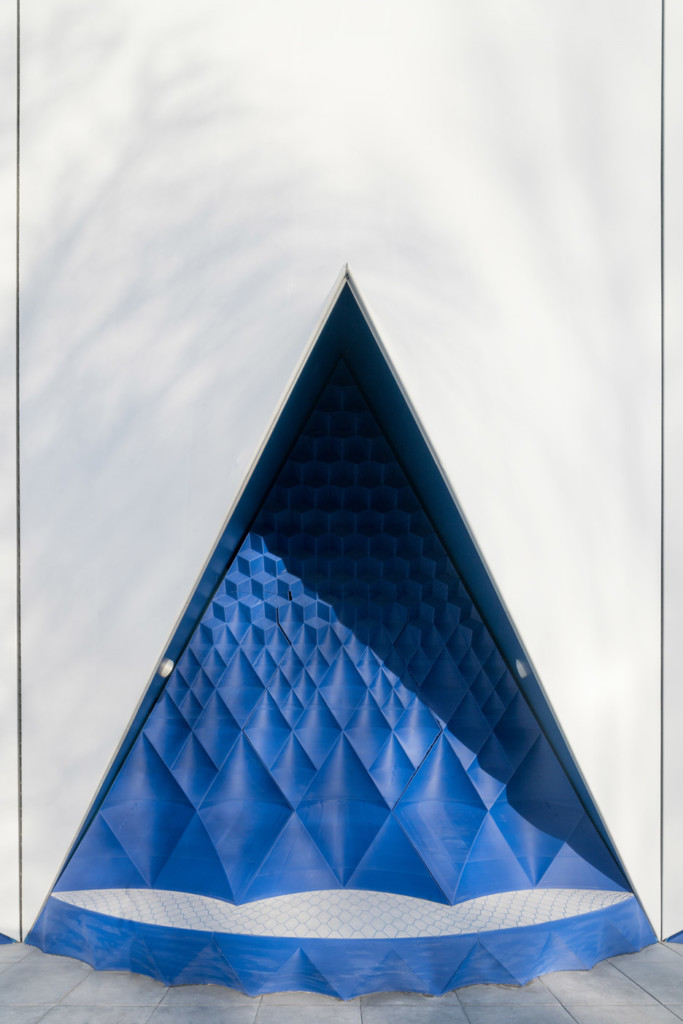

Plastic 3D pavilion

This is a hybrid structure made of steel and 3D printed plastic panels. It has 52-meter length and 26-meter width. The scheme took 6 years from initial research and development for plastic printing to this large scale demonstration.

https://www.archdaily.com/960939/beyond-the-geometry-the-worlds-largest-modified-plastic-3d-printing-architecture-archi-union-architects

ICD/ITKE Research Pavilion 2012

This is a pavilion made of carbon and glass fiber components, using more than 30kilometer length. The entire structure has 8meter in diameter and 3.5 meter in height. Despite its large size, the weight of the structure was less than 320 kg. robot arm and temporary steel frame enable construct this pavilion.

https://www.itke.uni-stuttgart.de/research/icd-itke-research-pavilions/icd-itke-research-pavilion-2012/

A façade combining tensile fabric and 3D-printed bioplastic

Bio-based filament was used in a façade of this building in Netherlands. It was a temporary façade and can be recycled. The blue bench on left image is 3D printed bio based filament.

https://www.dezeen.com/2016/01/12/european-union-3d-printed-facade-dus-architects-holland/

Discussion

The materials used in 3d printers have high capacities, but vulnerable to deformation due to its low stiffness. 3D printer enable constructors to make various shape with high degree of freedom, and even weak materials can be applied depending on its shape.

Currently, PLA and ABS are probably not widely used as structural materials but interior or ornaments. I thought PLA and ABS could be used as structural materials depending on future research with the advantage of biodegradability.

Structural Material and 3D printing is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master In Advanced Computation For Architecture & Design 2021/22 by Students: Takeaki Sakakibara | Faculty: Jane Burry