E.M.R.A.C. – ECOLOGICAL MATERIALS REIMAGINED BY AUTOMATED CRAFTSMANSHIP / Passive Cooling Column // W.1.1 WIRE’N’CLAY

The team of E.M.R.A.C. – Ecological Materials Reimagined by Automated Craftsmanship created a column-like passive cooling object from wire-cutting clay extrusions which were kindly sponsored by Toni Cumella from Ceramica Cumella for this workshop-week of the MRAC-20/21-program. During the week Amadeo Tierno Rodríguez from Altair Spain introduced Computational Fluid Dynamics Analysis Solutions (CFD Hyperworks, Virtual Wind-Tunnel) and supported with the investigation of the cooling dynamics by visualizing the air-flow around this passive cooling column.

Workshop Overview

The focus of this intense workshop week was to investigate passive cooling systems based on examples in traditional terracotta facades and contemporary cooling installations.

The aim was to explore the characteristics of clay, the use of wire-cutting to subtract and re-aggregate the prefabricated given shapes and the possibilities of combining these with the precision of robotical fabrication and finally create a 1:1 scale prototype from clay extrusions usually known from the use as façade cladding.

Manual Approach

First steps: down-scaled 1:3 versions of the available clay baguettes were extruded by hand and the process cutting clay with a wire manually was explored.

Clay Extrusion

Manual Approach

Digital Approach

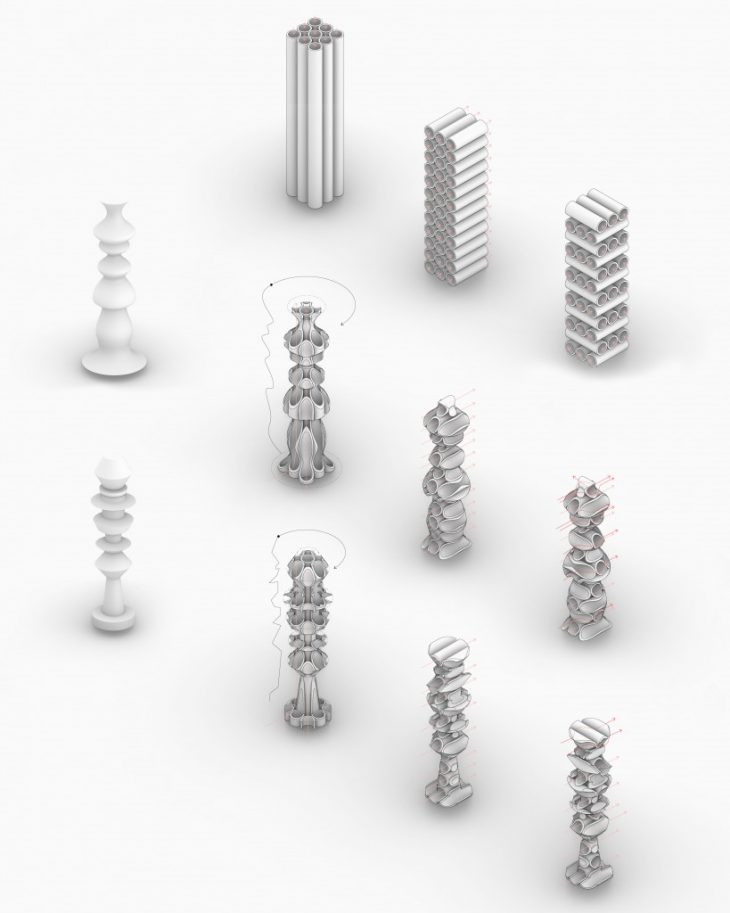

During the design phase, lot of possibilities were explored. Trials on Square, cylindrical and combination of both clay extrusions stacking horizontally and vertically with several slicing designs were investigated. Further to which, the best functional and aesthetical design was chosen. Intention of the design is to maximize the cooling effect in the maximum area around the element.

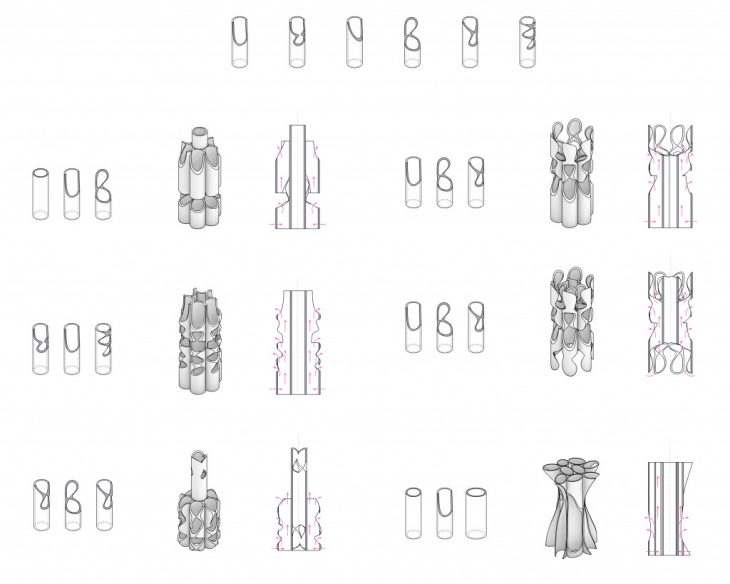

Diagram of Early Aggregations

Tool Customization

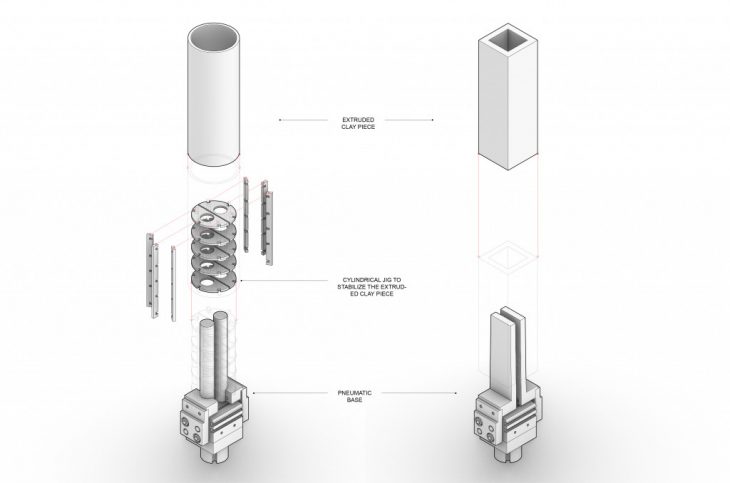

In order to create precise cuts using robotic wire cutting on clay extrusions, the clay elements need to be stable and the cutting tool on the robotic arm need to have enough approach area so as to avoid any clashes with the target.

Base design concept

– Circular extrusion gripper:

For keeping the clay extrusion in place, the existing base with 3d printed gripper was upgraded with a 2 part semi circular CNC add-on (below image). The circular wooden gripper works as an additional accessory and increases the hold of the previous gripper over the extrusion.

– Square extrusion gripper:

To hold the square extrusion firmly, existing base was upgraded with a 3d printed gripper accessory resulting in better grip (reference image)

Tool Diagram

Tool Path and Endeffector

The target to cut clay extrusions bigger in size than previous tests, the pre-existing wire-end-effector assembly for the robotic arm had to be upgraded with better strength, increased possible cutting area and maximum flexibility in potential robot movement without any clashes. Keeping the above as the vision, the tool was upgraded successfully. As a result the tool length was increased from 150 mm to 250 mm and the depth increased from 100 mm to 150 mm.

Robot Simulation

Computational Approach

The geometry of the column is based on stagging several clay extrusions first and start substracting from the extrusions along ruled surfaces following a specific profile polar arrayed around its centre. The chosen profile for the final column is the result of choosing from dozens of digitally created forms.

Studies before Application of Manufacturing Parameter

Final Design and Performance Assumption

The final design is driven by

– the manufacturing process and certain rules set up to allow for the robot wire-cut

– an optimized air-flow around and within the form

– a multiplication of surface area for the vaporization performance

Schematic Air-Flow

Robot Setup

Post design finalization, grasshopper was used to define the new tool, create path for the robotic arm to execute cutting over all the 32 numbers of cylindrical clay extrusions.

Assembly of base-gripper and wire-cut end-effector attached to robot

Fabrication

The code of the tool path was created using the grasshopper robots plug-in. The design required 32 numbers of cylindrical clay extrusion to be sliced for even amount of air circulation throughout. Also 4 numbers of cylindrical pieces were used as a passage for continuous water flow.

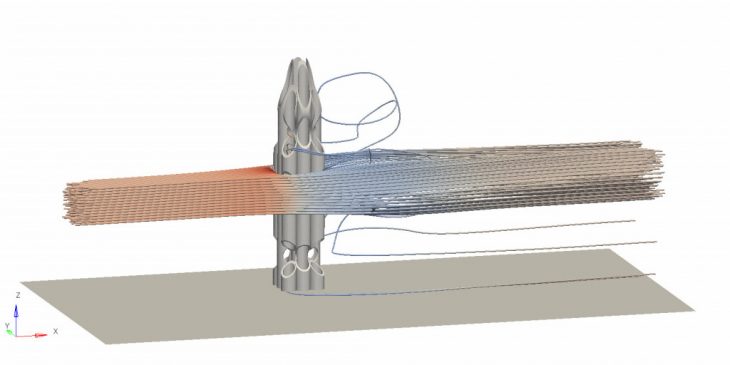

Computational Fluid Dynamics Analysis

With the kind support of Altair and excellent software’s like Hyper works, Hyper works CFD and Virtual Wind Tunnel from Altair. CFD analysis was carried on the design to understand how air passes through the design and performance of the element in terms of cooling effect. Below reference image is a sample output of the CFD analysis software’s

Virtual Wind Tunnel Simulation

Assembly of the Cooling Column

Post completion of clay slicing by the robotic arm. All the elements were assemble using clay as the bonding agent. The central unsliced extrusion was main adhering element around which the balance sliced pieces were bonded. The whole system was assembled in 4 part and later stacked one over each other to create the final assembly.

The assembly procedure focuses on keeping the sliced holes in exact location as per design in order to keep the design intention alive in the final output so that air circulation works inline with the CFD and gives optimum cooling effect in the maximum area around it.

Final Object

The assembled column-like structure is supposed to not be seen as pure ornamental object, rather an ancient alternative to modern air-conditioning. The centre tube can be filled with water and through the porosity of the clay the entire column will be a water cooled surface and by channeling the airflow through the openings and volumes of the structure it will have a cooling effect to its surrounding.

Sectional View

Jury Presentation

The Jury was able to see the 1:1 scaled prototype of an wire-cut passive cooling column fully assembled. By touching the not yet totally dried clay, the surface was already acting as a cooling device which is humidifying the interiors.

Photograph of Scale-Model 1:1

Photograph of Scale-Model 1:1

Photograph of Scale-Model 1:1

Application Context

This typology of water-holding terracotta pots is known from the driest places on earth. A thinkable location to adapt the PASSIVE COOLING COLUMN is shown below. One Example is the Alhambra Palace in Spain and the other one is a typical courtyard in Marrakesh, Morocco.

Visualization – Passive Cooling Column

Documentation

Link to the video below click HERE or on the image below.

E.M.R.A.C. – Ecological Materials Reimagined by Automated Craftsmanship / Passive Cooling Column // W1.1 Wire’n’Clay is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction Workshop 1.1 in 2020/2021 by:

Students: Hendrik Benz, Helena Homsi, Arpan Mathe, Aslinur Taskin

Faculty: Kunaljit Chadha

Faculty Assistant: Anna Batallé Garcia, Soroush Garivani, Ashkan Forughi Dehnavi

In collaboration with: Toni Cumella / Ceramica Cumella

Supported by: Ant Studio, Altair

Workshop Participants:

Shahar Abelson, Hendrik Benz, Alberto Eugenio Browne Cruz, Charngshin Chen, Michael DiCarlo, Helena Homsi, Arpan Mathe, Juan Eduardo Ojeda Valenzuela, Orestis Pavlidis, Aslinur Taskin, Alexandra Timageni,