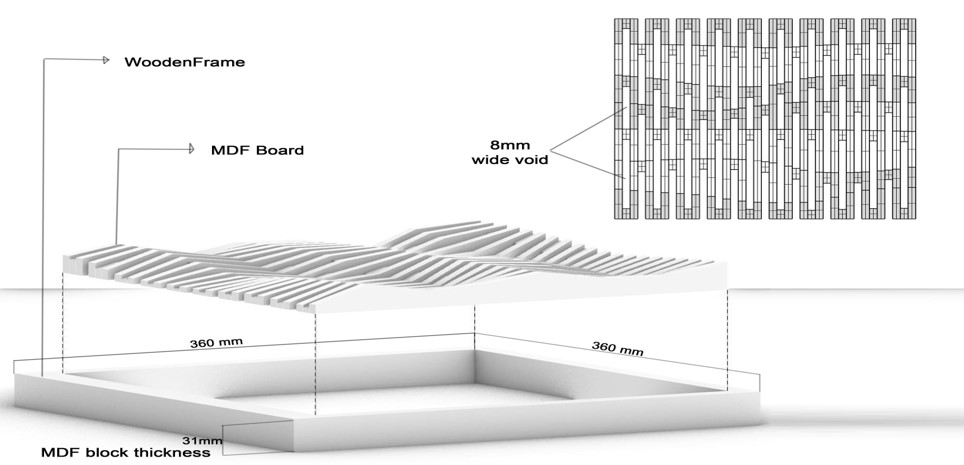

The prototype is inspired by the facade of Port Moresby Small House also known as Brise Soleil House, fabricated using a CNC milling machine ( SHOP BOT ) for a work piece volume of 360 x 360 x 30mm and the material used for milling is MDF to utilize a system of complex joints and high degree of surface articulation.

REFERENCE FACADE

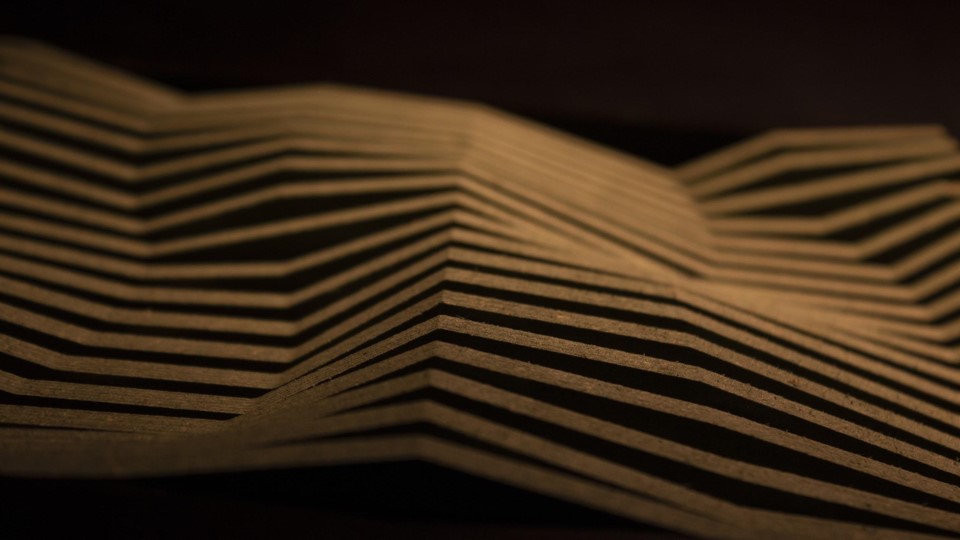

The Brise Soleil House is a compact 2-bedroom, 173SQM dwelling situated at the top of a steep, west-facing block near Port Moresby Harbour overlooking a former cargo terminal. The house is a cast-in-situ concrete building partially clad in an undulating wave-like timber wrapper which provides shading, privacy, and ventilation to the master suite. The wrapper flattens as it continues around the building to become a full-height operable screen for the upper level gallery to control the western sun and capture views to the Coral Sea beyond.

Architects: Studio Workshop Project: Port Moresby Small House Location: Port Moresby, Papua New Guinea Year 2017 Photographer: Peter Bennetts

From a design perspective, the wrapper pays homage to local traditions of timber craftsmanship seen in the lowland stilt houses and intricately carved canoes (lakatoi). Furthermore, the design of the wrapper engages a broader discussion of screens and veils in equatorial architecture found in the canon of Modern and 20th century works by Ossipoff, Ferrie, Rudolf, and others.

FABRICATION PROCESS

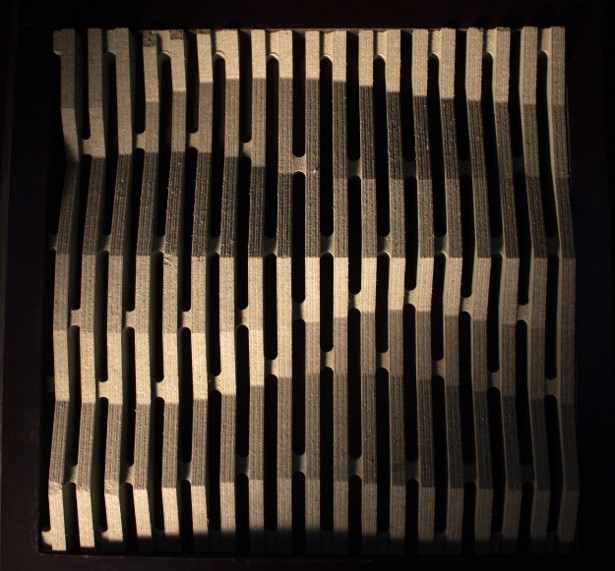

For understanding the facade and the design strategies to be incorporated in the final prototype, a smaller prototype of 150 x 150 x 28mm was first fabricated. Although, the strategies and the techniques for the final prototype were different but the smaller prototype proved helpful, such that, it allowed a deeper understanding of the various tools and the diameters that were important to be implemented in the final prototype.

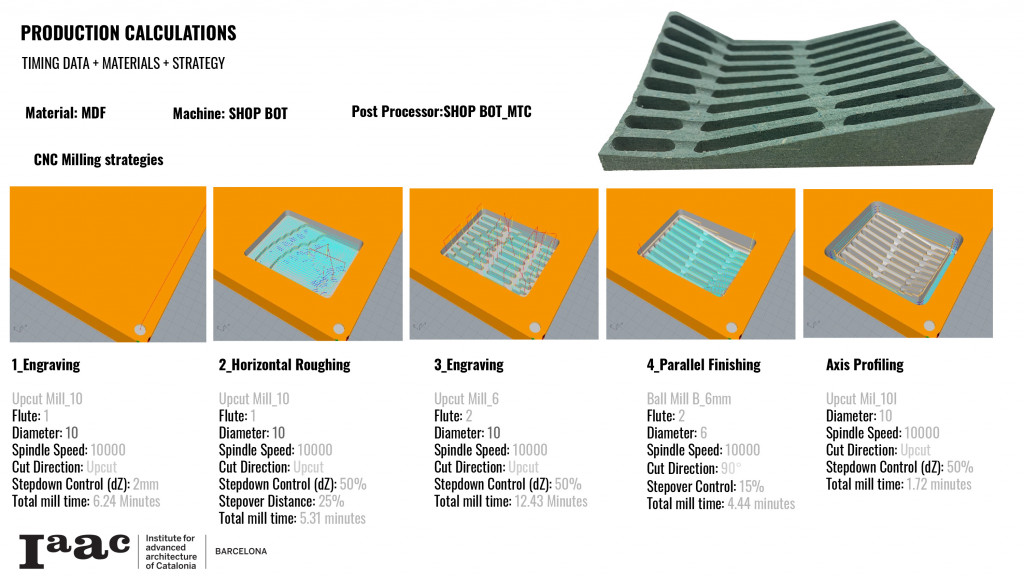

The production time for the smaller prototype was 31 minutes and the milling strategies used were – engraving, horizontal roughing, parallel finishing and axis profiling.

Smaller Prototype 150 x 150 mm

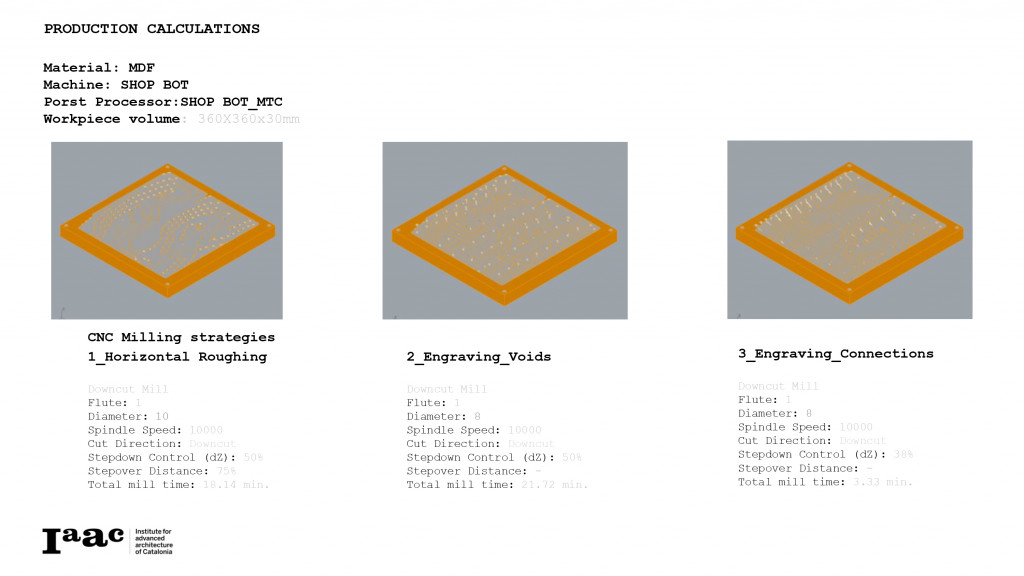

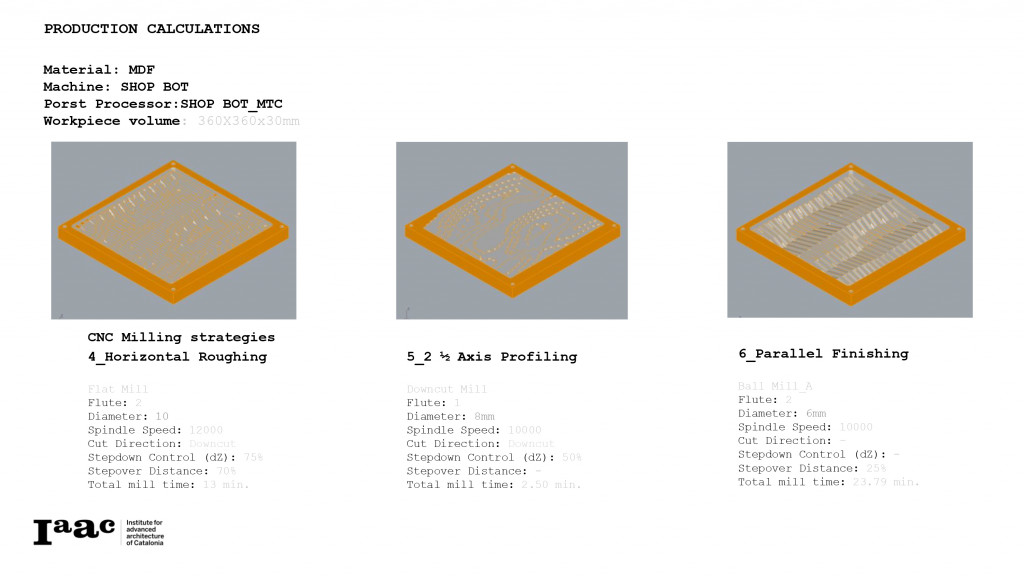

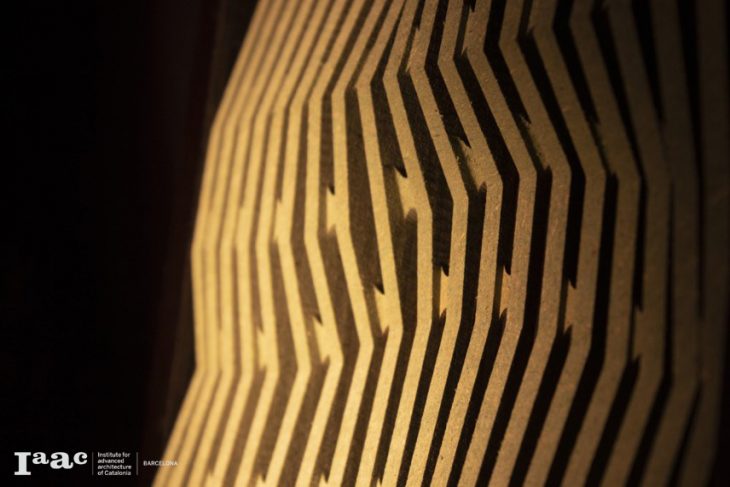

The fabrication process for the bigger prototype took approximately 1 hour and 25 minutes. The prototype was removed from the frame with the help of Axis profiling that made it easy to separate the prototype from the MDF board. Also, the wavy facade prototype was later mounted on a plywood base of 31 cm.

CNC Milling strategies and production data

CNC Milling strategies and production data

Prototype Assembly

FINAL MODEL

Final Prototype

Final Prototype

Parametric Skins – Port Moresby Small House : is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master of Advanced Architecture 2020/21 by Students: Abrar Ali, Daniel Sorial, and Rosamary Machado and Faculty: Ricardo Mayor Luque, Lana Awad and Shyam Zonca