The Wall Challenge

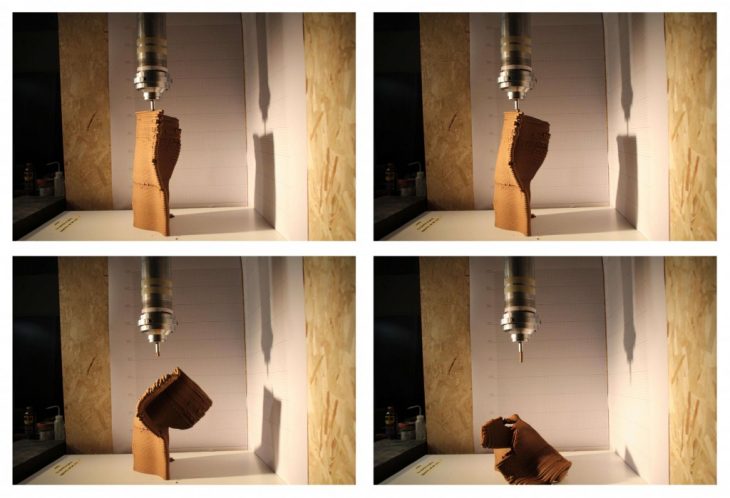

As part of the Open Thesis Fabrication program workshops were being held, the third workshop was about a challenge to 3d print a wall to look at its structural performances. The pieces consists only of one thinly printed surface to explore the relationship between the geometry and the structural behaviour in adobe printing. An important aspect to look at was the structural integrity during the printing process, that is while the material is wet and uncured. As soon as the geometries were dried and cured, vertical loads were subjected to the pieces.

In order to design the geometries there are some crucial elements to take into consideration. Firstly to look at the external balance, the single surface need to be designed in such a way that the support systems do not allow the structure to move. Secondly, the internal balance,the condition that occurs in a section or a portion of the structure, guaranteeing the structural strength.

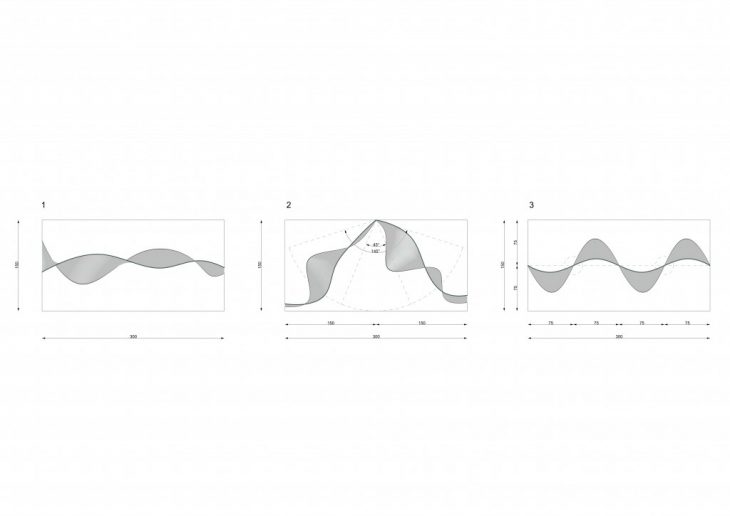

To come up with the right design a catalogue of shapes was created to see which shape would perform best. The selected shape was then printed and both physically and digitally tested.

Altogether 3 catalogues were made and 3 pieces created. Together with the Catalan structural engineers of Windmill, we tested how the pieces performed digitally and where the weak parts of the structures are.

Parallel to the digital testing, 3d printing showed how the structures were prone to movement, considering we were looking for the most challenging wall design.

The structural deformations due to the relationship between stresses and stiffness can affect the final form of the balance of the structure when applying loads. Buckling is a movement that needs to be prevented. This happens when a straight and slim structure is subjected to compression or movement.

Many conclusions could be drawn from this informative workshop. For instance, the greater the stiffness is, the less deformation you have. It is best to avoid stress on weak parts like corners as well to avoid straight lines in the middle of the geometry. Adding up: more contact surface means better balance, weight should be balanced (stability), most stiffness should be at the bottom, frequency is important at edges, center of gravity needs to be on (or close to) the center of the model and always make use of 3 or more surfaces.

Through these exercises we were able to optimize geometries through the freedom of 3D printing and scientific measuring of both the digitally and physically testing prove to be a valuable design tool for future design tasks of the OTF program.