A Gradual Flow

Reference

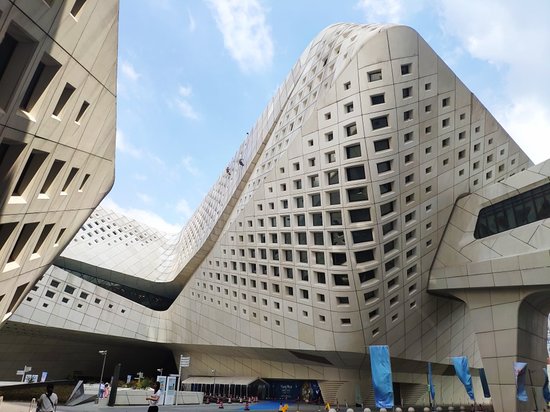

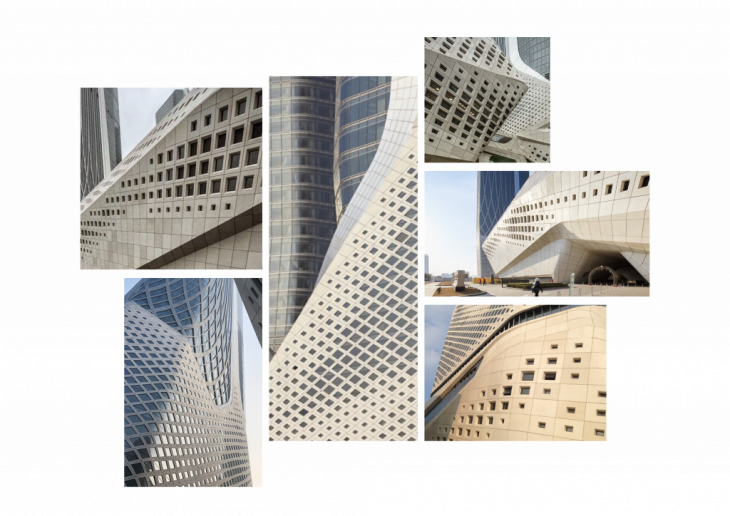

The Facade reference used is the Nanjing International Youth Cultural Centre by Zaha Hadid Architects.

The Nanjing International Youth Cultural Centre is located on the river in Hexi New Town; Nanjing’s new central business district (CBD). The project includes a 106,500 m2 conference centre, two towers totalling 258,500 m2, 100,000 m2 of basement areas and the plaza that terminates the CBDs main axis on the riverfront.

Credits to Archdaily

Reference found on ArchDaily

About the Facade

At the interface among the tower and platform, the glass facade gradually changes into a grid of rhomboid fibre-concrete panels, giving the enormous surfaces of platform and meeting focus a strong and sculptural appearance; underlining the dynamic character of the structure and enhancing the daylight to the interior spaces.

The Objective

The project focuses on the production of the existing facade through two different stages.

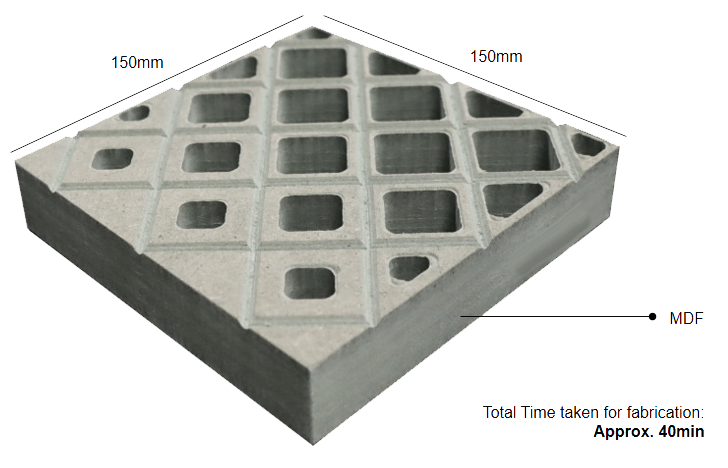

- The first stage focuses on a prototype developed on a 15 x 15cm scale MDF panel.

- The second stage focuses on the final proposal developed on a 30 x 30cm scale MDF panel.

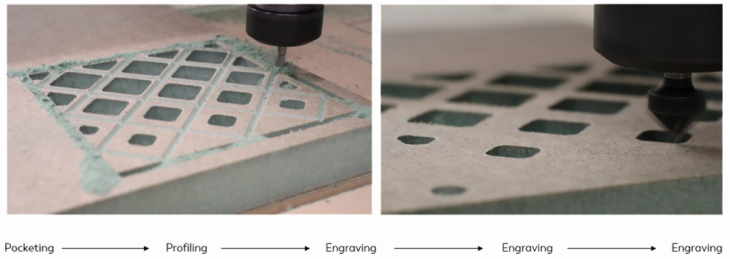

First Stage – Prototype

Number of days: 01

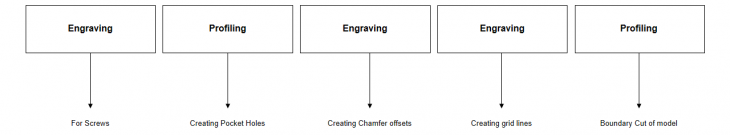

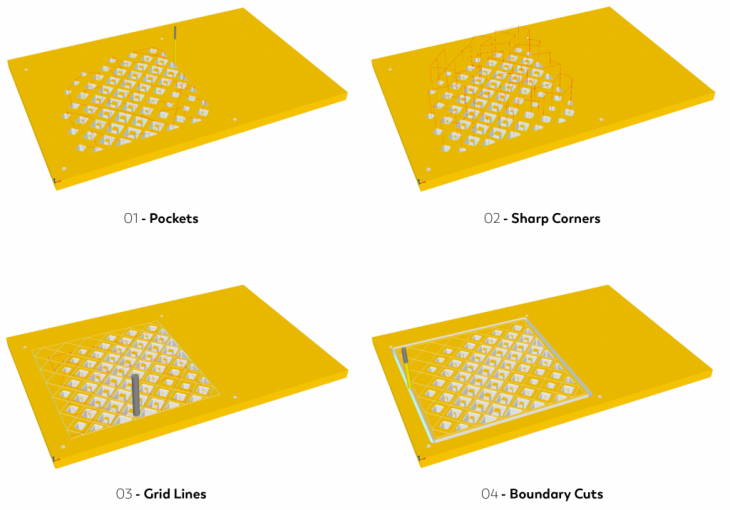

This developed an understanding of the concept of CNC and an experimental phase on the different strategies that can be used to mill the model. The operations that were used in the first stage were:

- Pocketing (to create the holes through the panel)

- Profiling (to crease the corners of the hole)

- Engraving (to provide an offset on the corners of the hole)

- Engraving (to create the grid lines on the panel)

- Engraving (to create the boundary cut of the prototype)

Finished Prototype:

Time taken for fabrication of the prototype: 40min

Second Stage – Final Proposal

Number of days: 01.5

After understanding key concepts and operations from the prototype stage, we were able to determine an efficient strategy to work with the operations better on RhinoCAM.

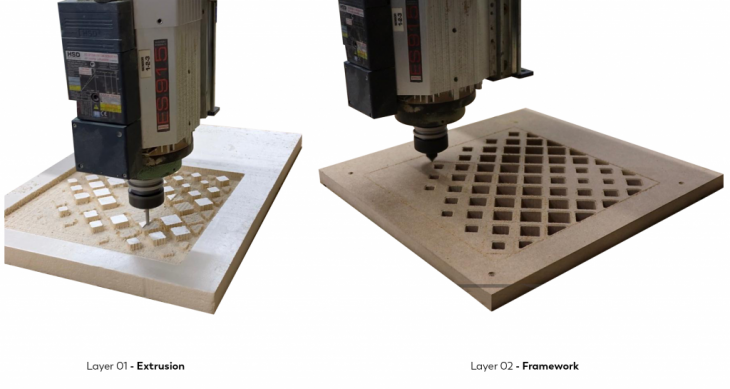

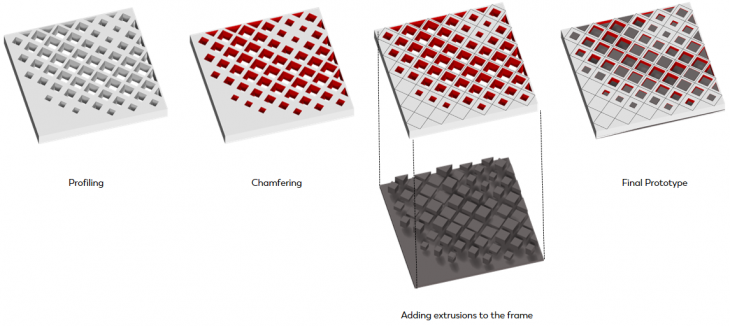

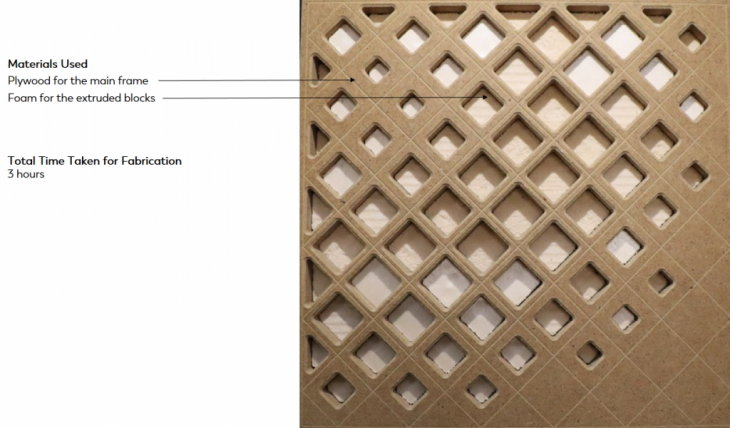

We had also proposed creating a two-layer CNC milled model which would consist of a Framework and an Extrusion block as we wanted not only the framework to have the gradient effect but also the blocks which extrude outside to have it as well, based on the same parameters.

Design Development

The following illustration explains the connections of the two layers from the CNC milling.

Material Selection

Plywood and Foam were used for the final proposal, as we wanted to form a smooth contrast between the two layers when attached together.

Time taken for fabrication of the final proposal: 03 hours

Visuals

Credits

A Gradual Flow // CNC Milling Fabrication is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master of Advanced Architecture (MAA01) 2020/21 by Students: Amandeep Singh Sasan, Victoria Fedorova, Ziying Zeng and Faculty: Ricardo Mayor Luque, Lana Awad and Shyam Zonca