Material (data) Intelligence | Towards a Circular Building Environment

Framework

Site demolition produces a significant amount of waste. All material that is derived from from demolished sites ends up in landfills, without any attempt to be sorted on reusable and non-reusable pieces which can later be used in new structures. This project is a continuation of “Digitizing material collation from pre demolition sites”.

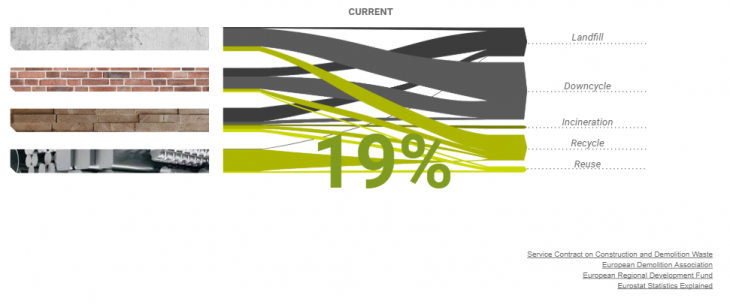

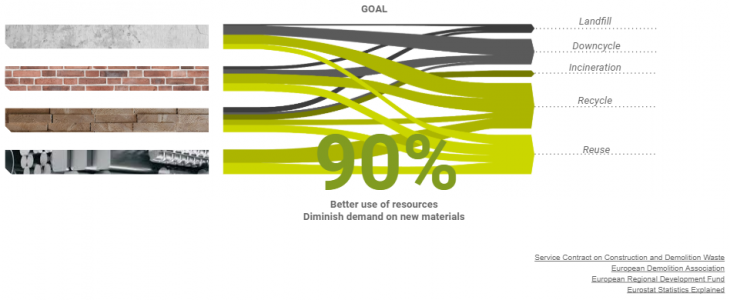

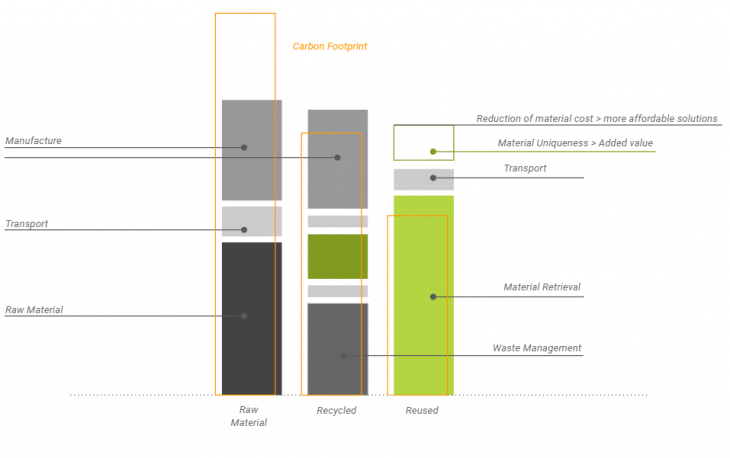

In construction, four materials are commonly used: concrete, masonry, wood and metal, these will also be the focus throughout this project. The graph below showcases the current life cycle of the materials as well as how much of them are being wasted by land-filling or down-cycling.

The aim is to increase the amount of material recycled and reused, which will also lead in decreasing the quantity that is being down-cycled or resulting in the landfills.

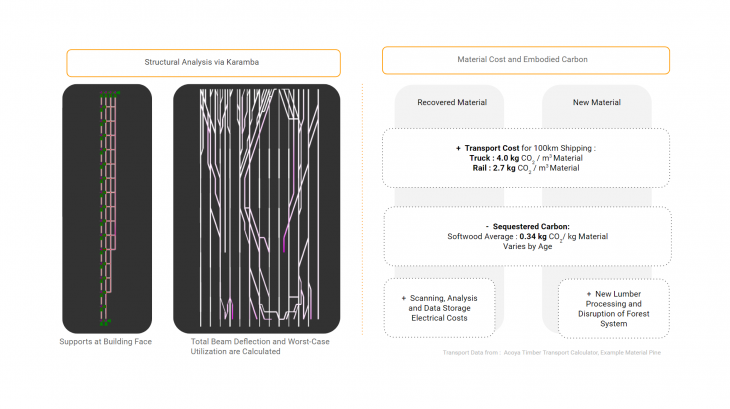

A broader impact of this process is the reduction of carbon footprint, which is a significant amount when we compare to what is produced by the raw material to that of the reused one.

Proposal

The research has a focus on understanding which technological advancements can be applied to better inform design decisions from pre-demolition resources. Three solutions are being proposed aiming to support the process of materializing a more circular building environment. By doing so, we expect to reduce the embodied energy in buildings, reduce the amount of greenhouse gas emitted to the atmosphere and the construction waste generation.

The objective of the project is to showcase how matching algorithms along with generative design and digital fabrication can be used to integrate materials retrieved from pre-demolition sites to develop new structures, while minimizing waste and maximizing efficiency.

Methodology

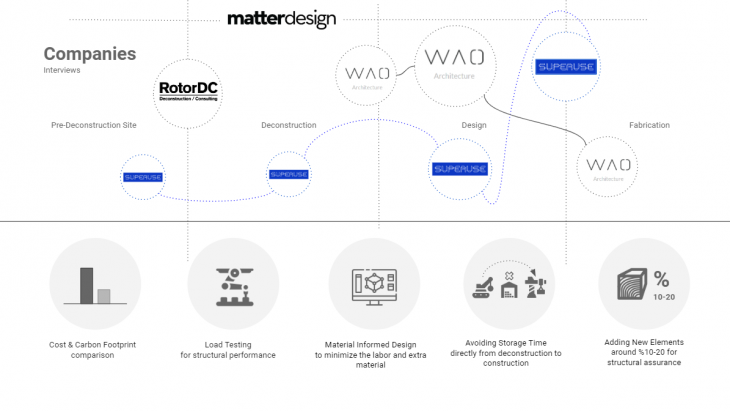

Current Market Analysis

We examined current market solutions that provide similar services to what we are developing and conducted interviews with some of the companies (listed in the figure below) to get more information on how they approach the topic of recycling and reusing materials and what processes they employ. These companies are compared and classified based on data related to the following: cost and carbon footprint comparison, load testing and structural performance of materials, ability to develop material aware designs, ability to avoid the process of storing the material-which is a cost additive factor, and lastly, the ability to fully engage recycled material in the design by limiting a quantity of 10-20% of new material to be added so structural performance is ensured.

Steps

From collecting material found on pre-demolition sites to making it ready for new use, there is a range of processes involved and a set of data collected. With this research we sought to manage data about material, make it easy to understand for any user, engage several users in a design process that increases awareness on how elements are utilized in a structure and how latest fabrication technologies can support new construction solutions for repurposed materials.

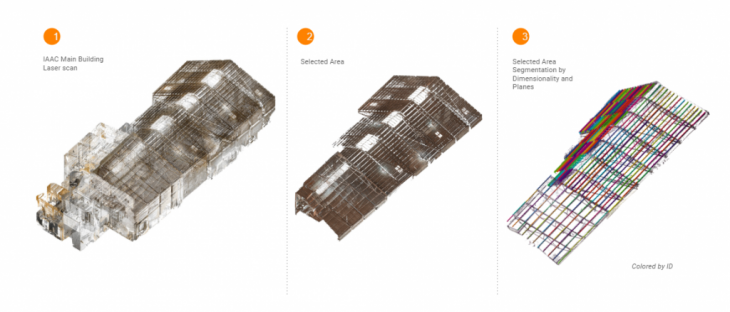

Digitalize and Automate the process of creating the material dataset

This step involves the scanning and collection of information which occurs during pre-demolition. The process and details are further explained here and here

Building Inspection

Building Inspection

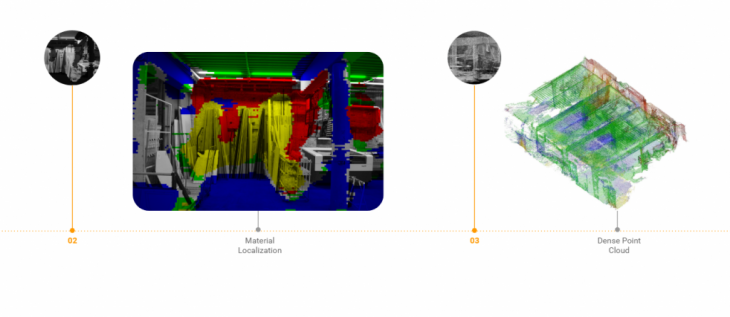

Classification and Localization

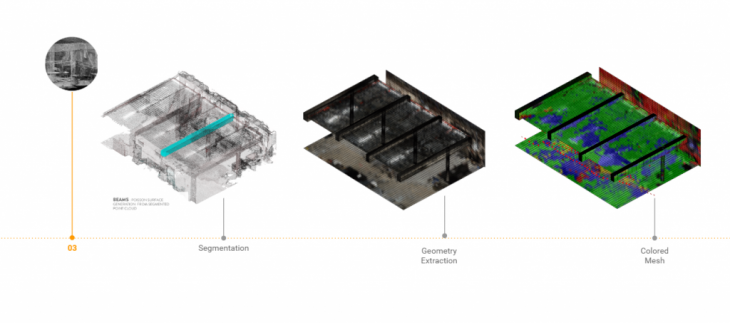

Geometry Reconstruction

Collaborative Design Tool | Human-Machine Interaction

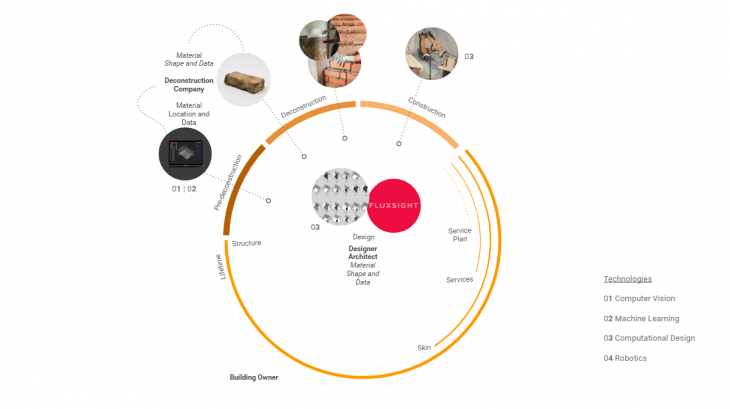

FluxSight is a design tool in augmented reality that helps architects and designers to create objects in a wide variety of scales using reclaimed resources. This process explores free-form modelling from hand tracking and gesture detection in the early design stage, taking into account resources availability and combining it with performance criteria like solar radiation. The main objective of this tool is to promote and create awareness of the importance of material re-usability, potentially reducing the environmental and economical impact of our constructed environment. Technical details here.

Material Language | Best Fitting Function for Element based in Material Properties

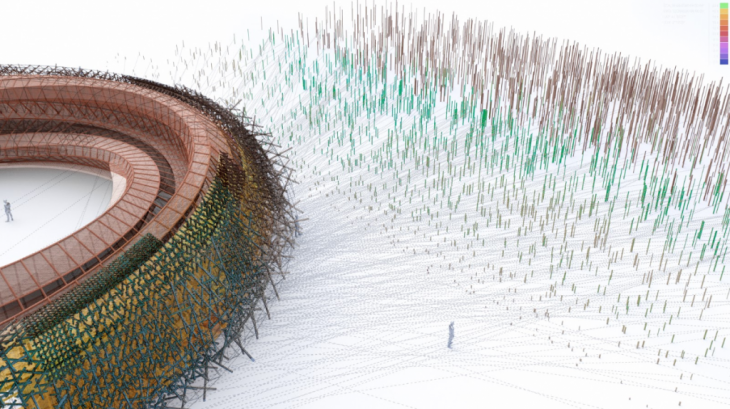

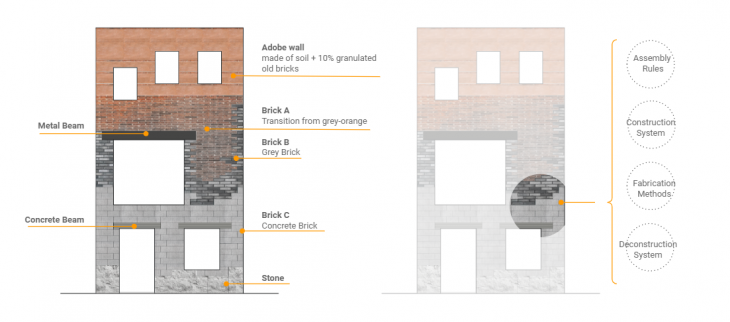

When developing any design with reused material it is important to know the material’s potential. The diagram below demonstrates different elements visualized on a facade, and the importance of being aware of the capabilities related to the integrity of the material, dimensions and possible construction systems. Fabrication techniques related with the design and how new technologies could support the assembly of the elements are taken into account. Design for disassembly solutions should also be consider in order to facilitate future recovery of the material at the end of its life.

The development of the matching system will be implemented on a facade.

Case Study

Material Dataset

Data acquisition | IaaC Main Building

Properties Definition

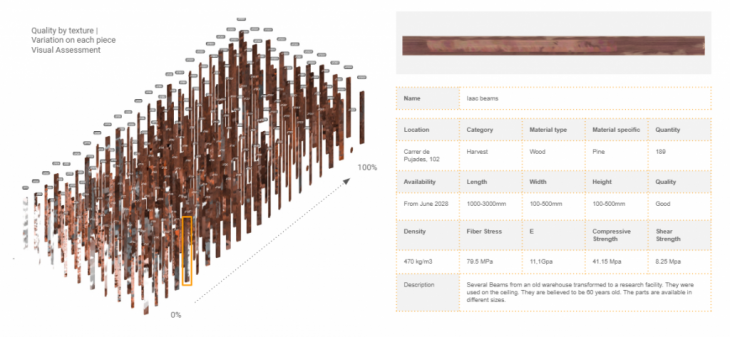

Based on the elements we got from the roof assembly, we create a catalogue of pieces, which add up to a total of 220 individual elements.

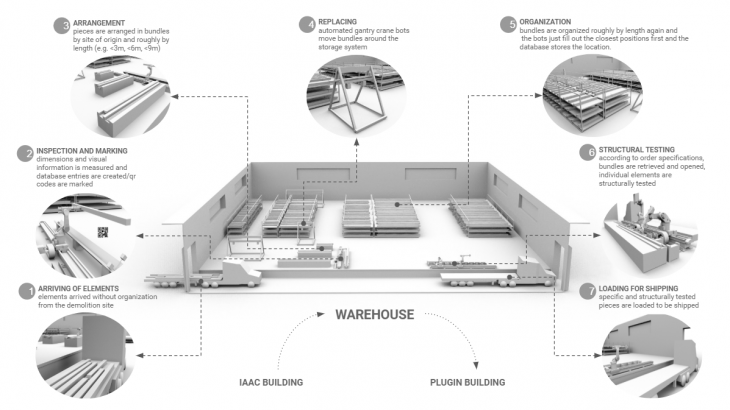

Warehouse | From Iaac IAAC Pujades 102 to Plug in Barcelona

Once the material has been properly scanned and collected, it arrives to the warehouse. A set of steps follow, as shown below, between receiving the material from the demolished site and making it ready for shipment where it will find use again to a new design.

Storage and Logistics

Elements are marked at the time of demolition with the date and new id within the database, using methods that are resistant to possible damage during transport and storage. The dimensional information is entered into a SQL database with other relevant data for later access by the designer.

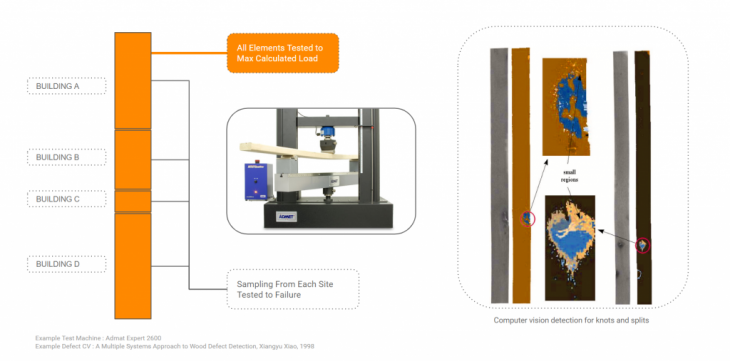

Initial Structural Testing

Specifically, all elements are tested structurally using standard techniques against the greatest loads expected from the current design, along with a visual analysis for major defects. A sampling of the elements from each source site is also tested to failure to set an estimate of damage over time.

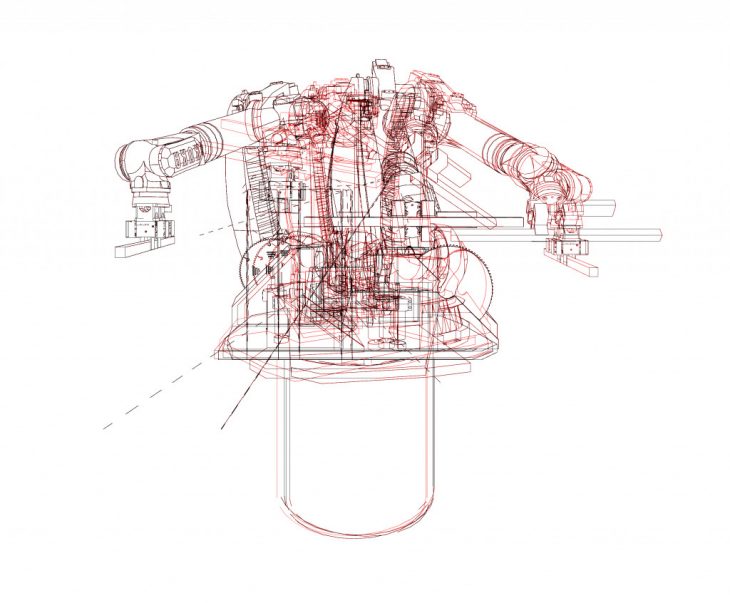

Design Workflow

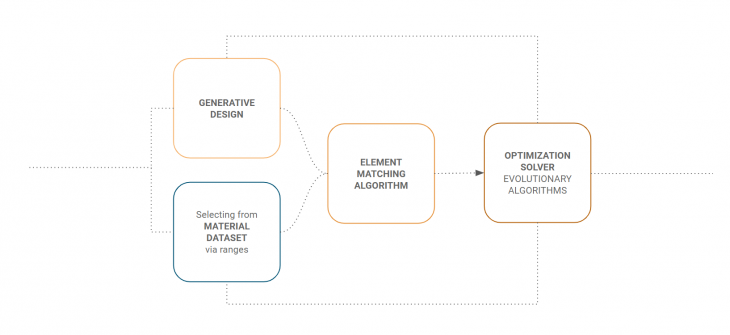

Critical for an optimal density of re-used material, the designs should feature a degree of flexibility and adjustment by parameter. When an iteration of the design is submitted to the system, the materials calculated for its construction are matched up with available items from the material dataset. The efficiency of this mapping, along with a resulting structural simulation of the resulting structure, is used as a guiding fitness value for gradually adjusting and optimizing the design.

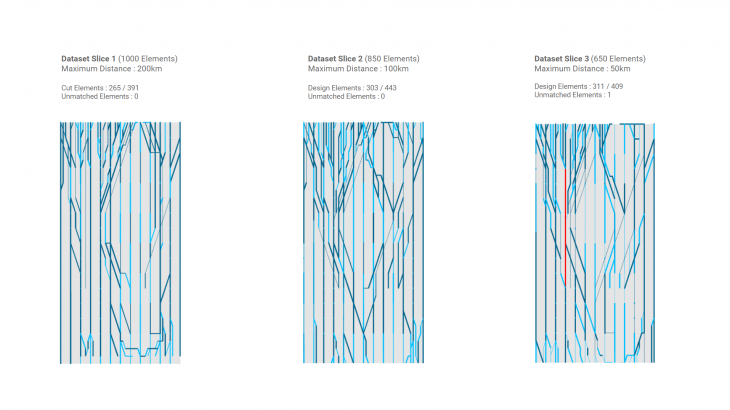

Material Dataset

The design can choose specific ranges of data to use in their design, taking a specific slice out of the material dataset.

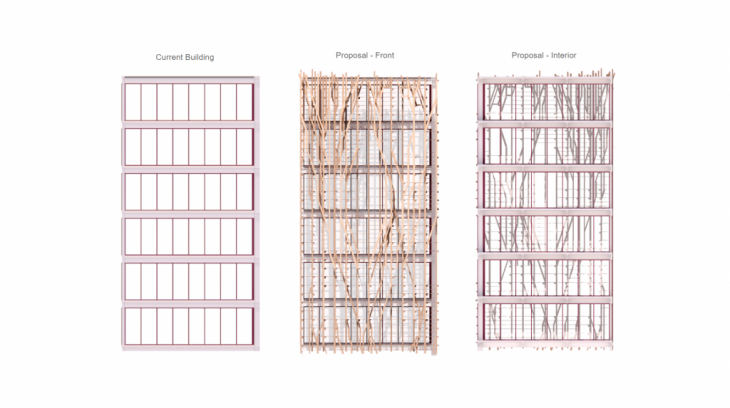

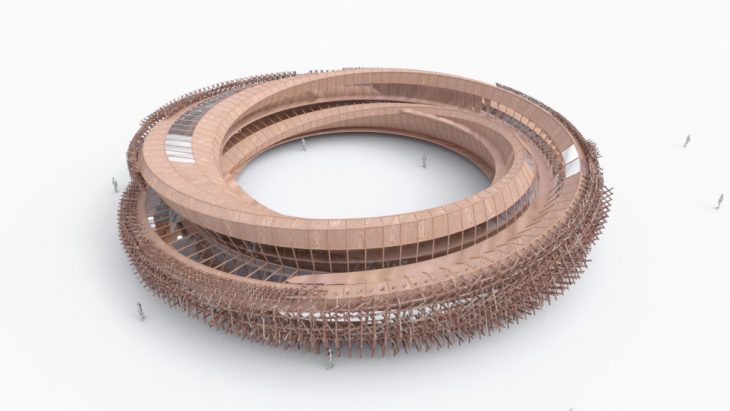

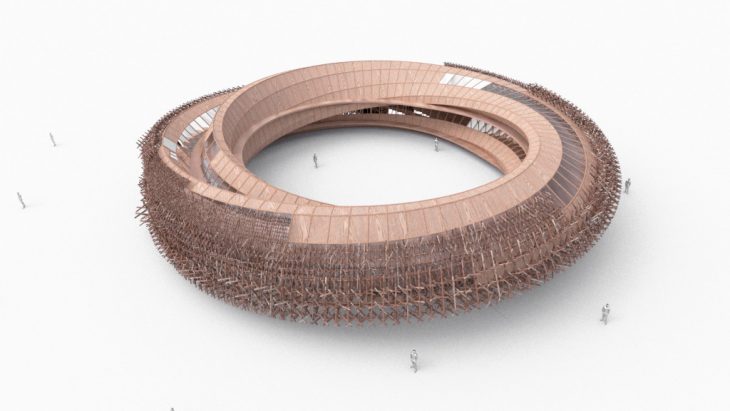

Discrete Wood Elements

We are using the pieces we retrieved from the IaaC main building roof demolition to generate a facade solar protection for the Plug-in building, from Mias Architects. The basic principle is to add a screen-like element in front of the already existing glass facade, which will create a more interesting visual aesthetic both for the street as well as for the users of the building. Yet, it is simple enough to show how the matching of pieces occurs and how they assemble to serve e new purpose.

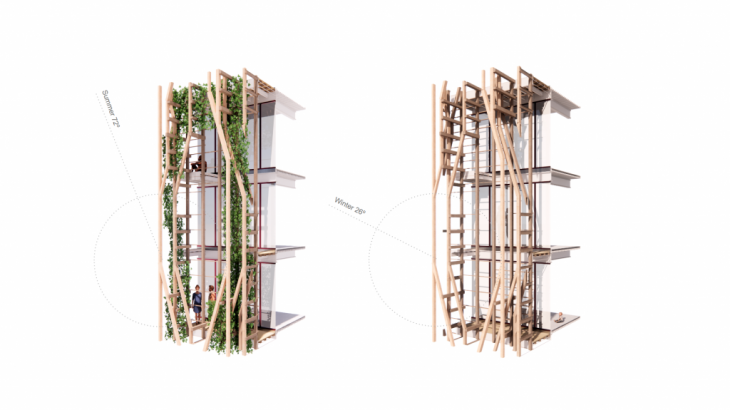

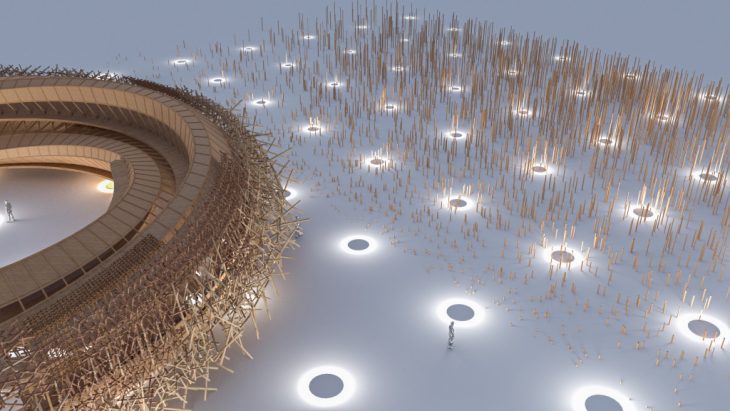

Design Strategy | Solar Performance

The modification will add to the building a new relationship with the environment. It will create a transition between the inside and the outside while improving the thermal behavior of the building. The design approach is simple, yet flexible enough to facilitate different functionalities in different parts. This study showcases a few scenarios that can occur by manipulating the geometry through the connections or combinations of pieces in a systematic way.

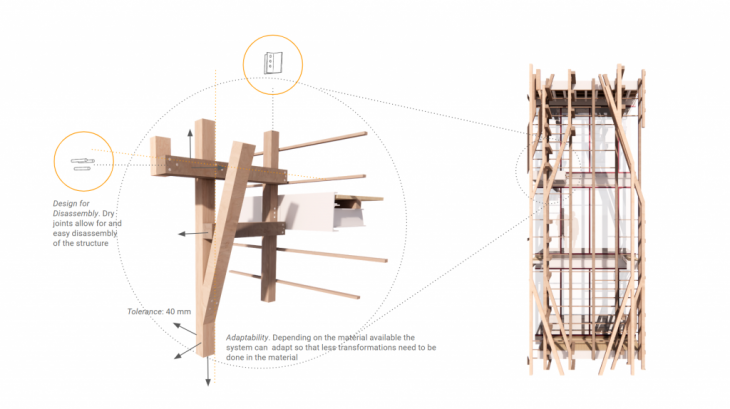

Construction System | Tolerances and adaptability

Furthermore, the design of the facade is taking into account the possible variability of the material and design for disassembly strategies. The construction system is developed such that different sizes of the recovered material can fit without having to apply major transformations. The most restrictive dimension is the length that it can be easily cut during the assembly process. All the joints are dry joints so if any of the elements needs to be changed or recovered it will be an easy task.

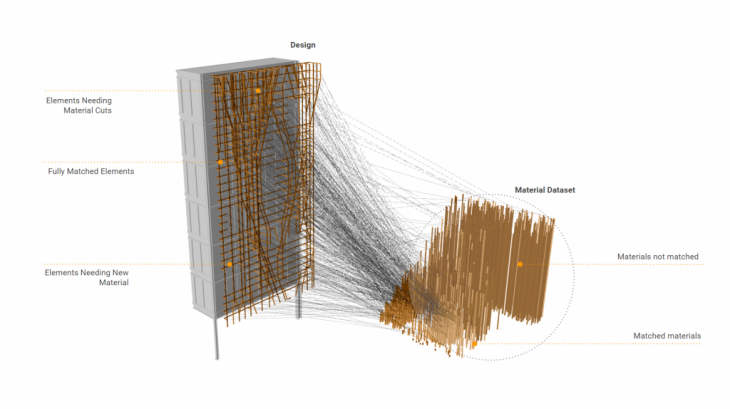

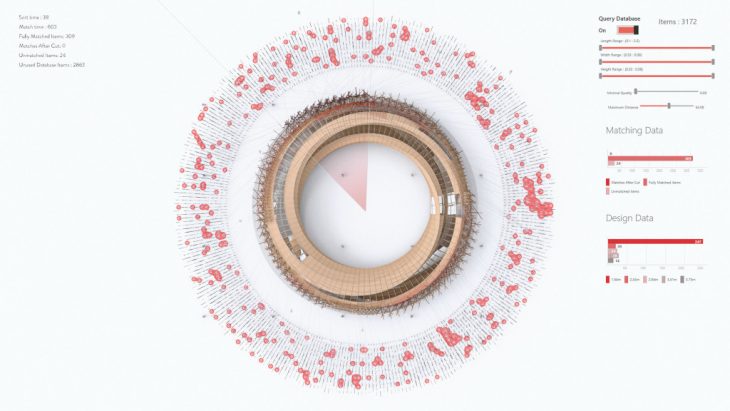

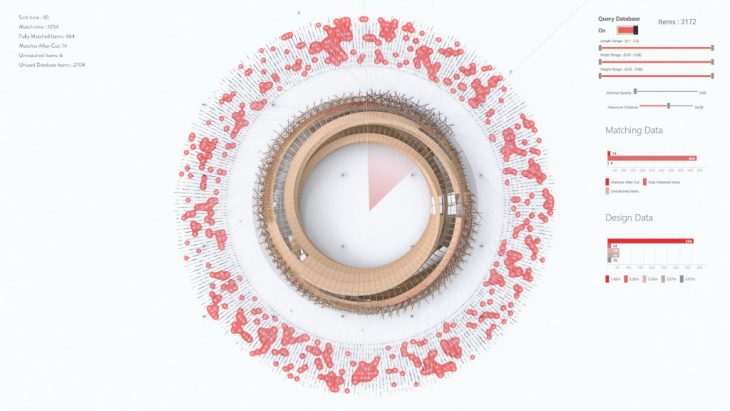

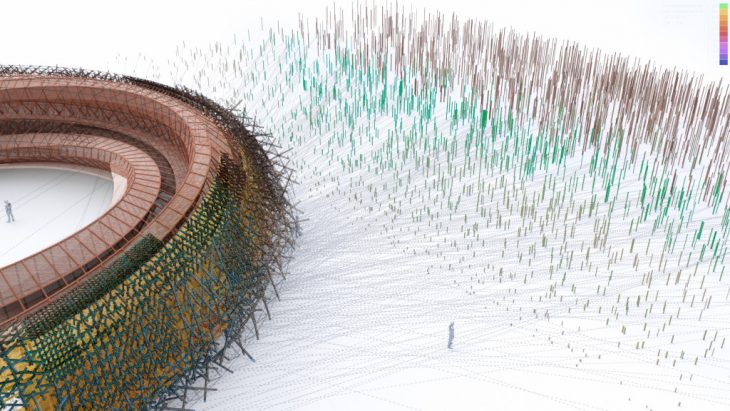

Matching Algorithm | Best Fitting

The material dataset is integrated to the design. The following figure shows how the retrieved pieces find their place on the proposed facade. In addition, the algorithm shows which elements will need to be cut, which ones are fully matched and which ones are insufficient will be needing more material to complete the design.

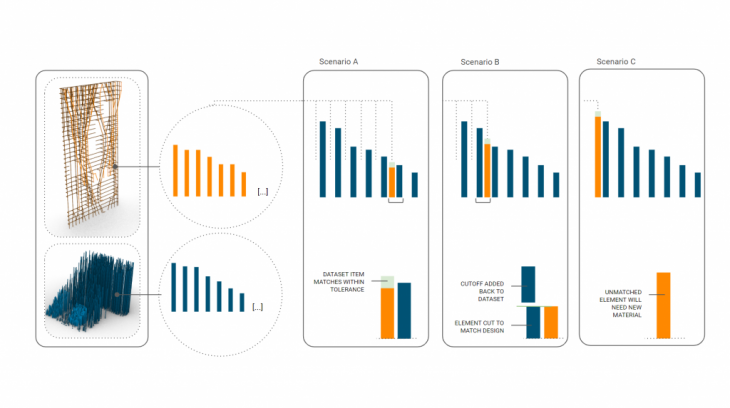

Matching Algorithm | Sorted Elements

As each element in the design is compared with the dataset, there are three possible results. First, it may find a direct match within a certain tolerance. Alternatively, a larger piece may need to be cut down to match, and the resulting cutoff added back to the dataset. Finally, the dataset may be unable to provide the necessary element and a new-stock element will need to be procured.

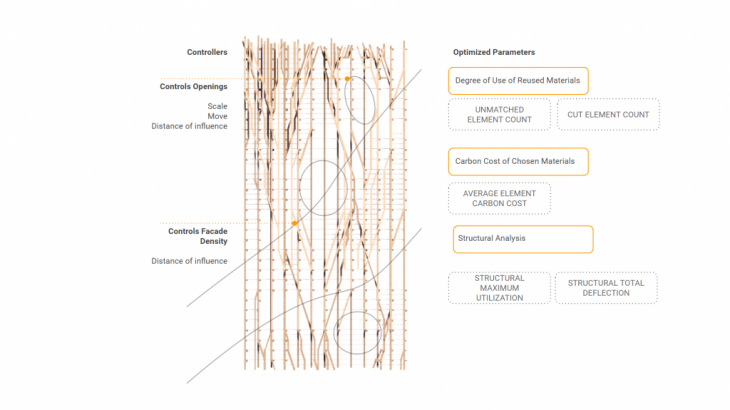

Optimization Solver | Parameters

As each element in the design is compared with the dataset, there are three possible results. First, it may find a direct match within a certain tolerance. Alternatively, a larger piece may need to be cut down to match, and the resulting cutoff added back to the dataset. Finally, the dataset may be unable to provide the necessary element and a new-stock element will need to be procured.

Design Analysis

Design Optimization

A genetic algorithm applies small translations to the geometric inputs of the facade, and minimizes a total fitness value calculated from the previous analysis. Inputs are weighted to favor efficient reuse first, with the structural results only disqualifying an iteration if the system proves to be very unstable.

Design Optimization | Design Results From Dataset Choice

Building the design with different available materials will produce variations on the final built outcome, while maintaining the main design intentions (in this case, balcony placement)

Prototype Fabrication

Material Properties | Unloading and Sorting

Prototype Fabrication : Checking Dimensions and Sorting by Order of Construction

Transformation | Milling and Assembly

Prototype Fabrication : Cutting to Size, Milling for Joinery, and Position

Final Product

Localize, Collate and Design is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Masters of Robotics and Advanced Construction in 2019-2020 by Students: Anna Batallé, Irem Yagmur Cebeci, Matthew Gordon, Roberto Vargas, Faculty: Alexandre Dubor, Aldo Sollazo