INTRODUCTION

Introduction to Digital Fabrication course is focused on learning the use of three different machines: CNC Milling, Laser Cutting and 3D Printing. The objective was to fabricate different recursive geometries with the help of the machines. We focused not only in the geometrical design but fabricated a functional piece based on the characteristics of each machine.

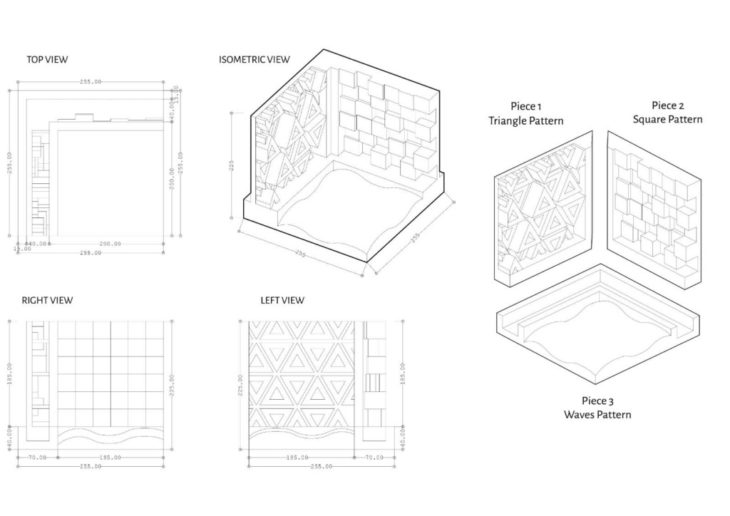

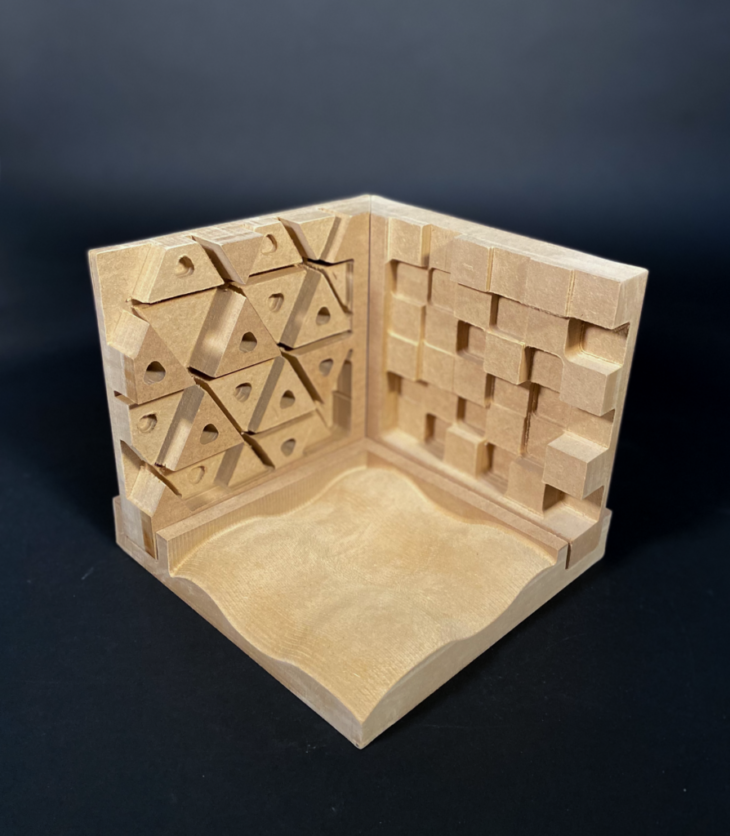

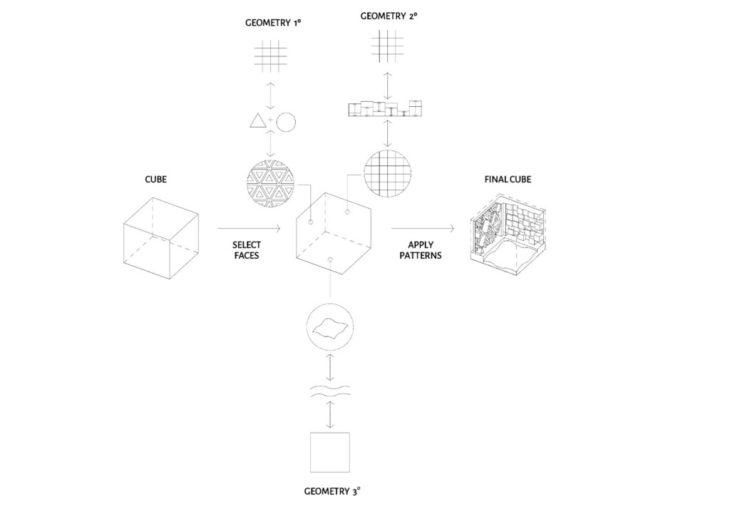

CNC MILLING

Our objective was to create a model with basic geometrical shapes to be able to use as much machine operations as possible.

Strategies

Horizontal Roughing

Flat Mill 6mm

Flute: 2

Diameter: 10

Spindle Speed: 12000

Cut Direction: Upcut

Stepdown Control (dZ): 50%

Stepover Distance: 75%

Total mill time: 26 minutes

Horizontal Finishing

Ball Mill 6mm

Diameter: 6mm

Spindle Speed: 12000

Cut Direction: Upcut

Stepover Control: –

Total mill time: 5 minutes

Parallel Finishing

Ball Mill 6mm

Diameter: 6mm

Spindle Speed: 12000

Cut Direction: Upcut

Stepover Control: –

Total mill time: 13 minutes

Pocketing

Flat Mill 10mm

Flute: 2

Diameter: 10 mm

Spindle Speed: 12000

Cut Direction: Upcut

Cut Depth Control: 5%

Stepover Distance: –

Total mill time: 4 minutes

Profiling

Flat Mill 10mm

Flute: 2

Diameter: 10 mm

Spindle Speed: 12000

Cut Direction: Upcut

Cut Depth Control: 5%

Stepover Distance: –

Total mill time: 13 minutes

Clear Flat Tops

Flat Mill 10mm

Flute: 2

Diameter: 10 mm

Spindle Speed: 12000

Cut Direction: Upcut

Cut Depth Control: 5%

Stepover Distance: –

Total mill time: 18 minutes

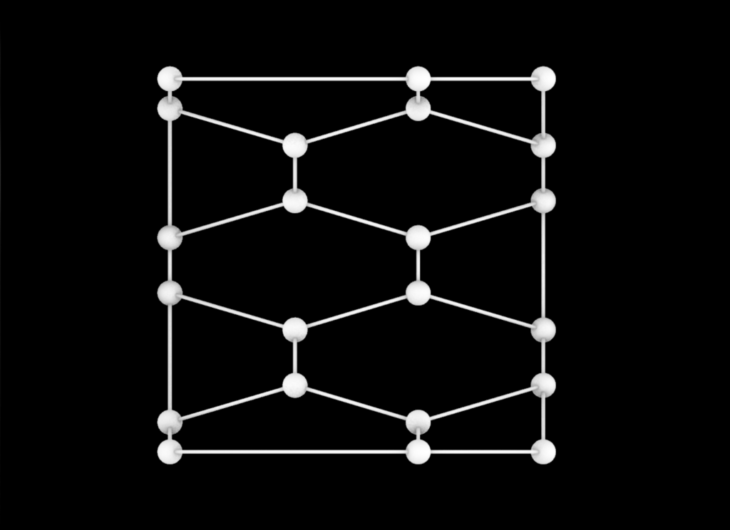

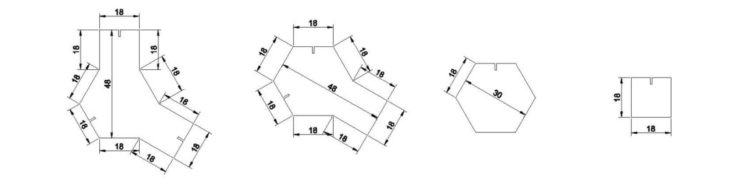

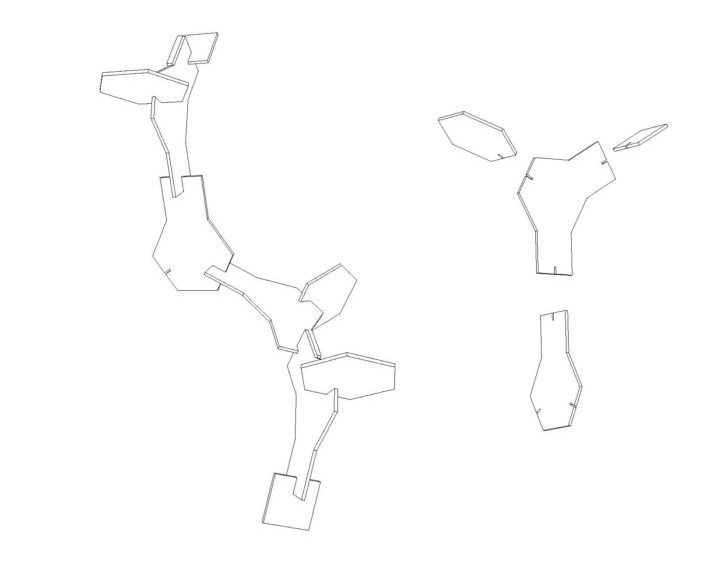

LASER CUTTING

By using a basic geometric structure of squares and hexagons, we created a piece with the multiple configurations. Each piece has a different work in the structure.

Strategies

Material: Polypropylane 1.2mm

Black Speed 3.5 | Power 48 White Speed 3.5 | Power 60

Duration:

Black 12 minutes White 12 minutes

Technique: Interlocking

Tolerance: 0.8mm

Joint Type: Halved

Machine: RayJet 500

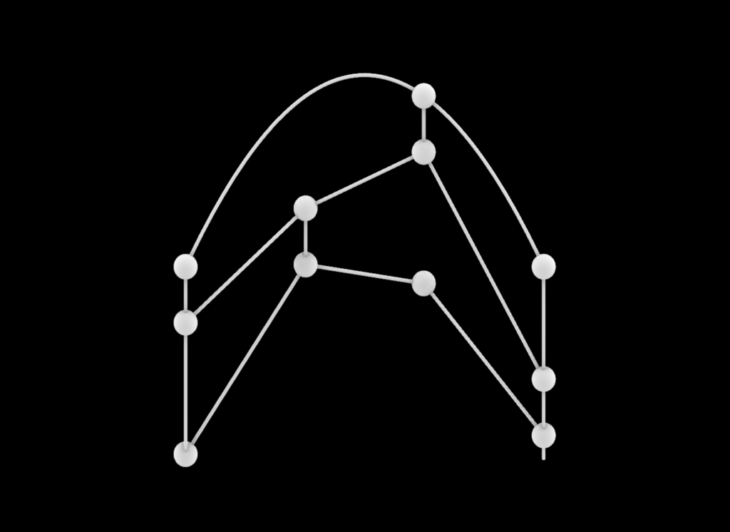

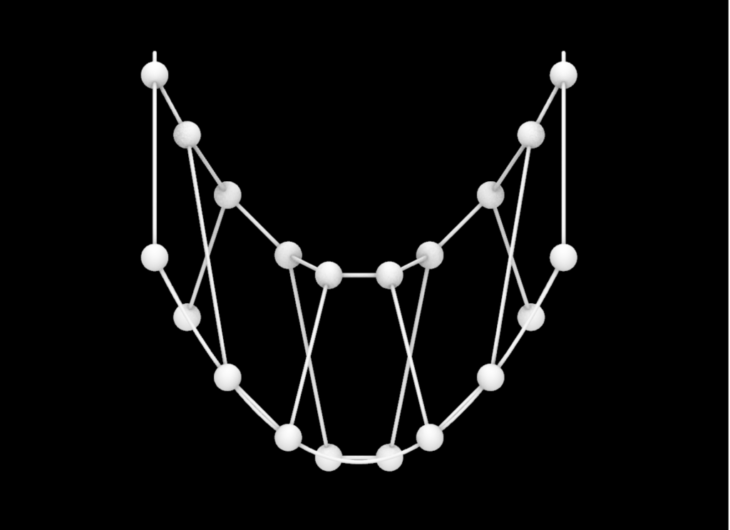

3D PRINTING

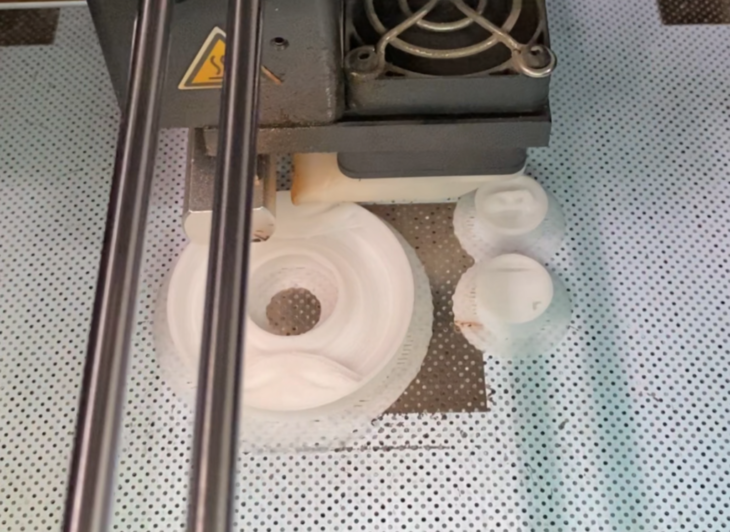

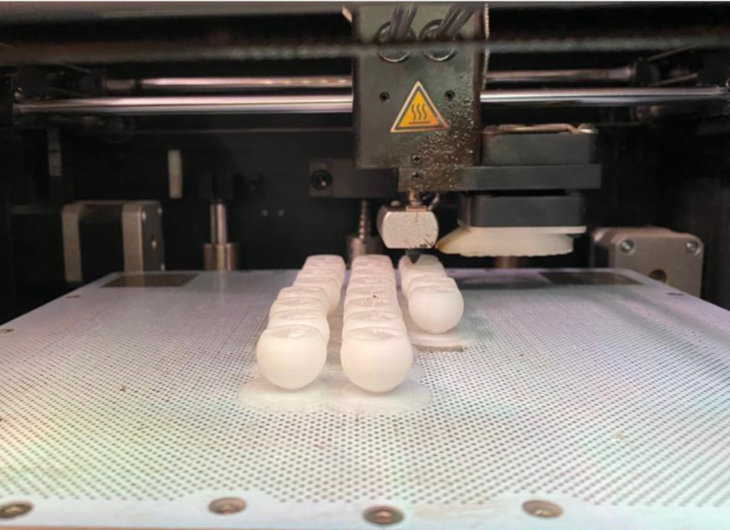

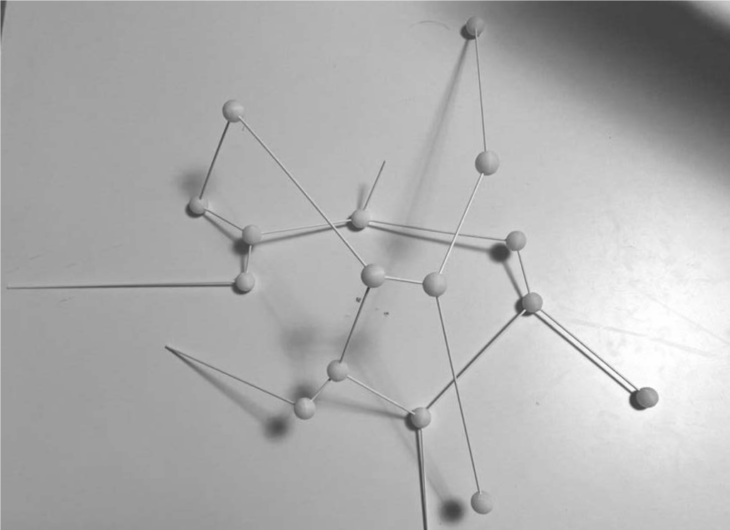

The objective was to design 3D printed nodes to join wire rods and create a geometrical piece. All the nodes have the same diameter but each one has unique holes.

Strategies

Number of Nodes: 20

Printing Time: 4 hours

Tolerance: 2.3 mm

Printer: Zortrax 200M

Material: Z-ABS

Supports: None

Infill Density: 0

Layer Thickness: 0.19

Print Quality: High

Introduction to Digital Fabrication – Recursive Geometries is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2021 by Students: Arunima Kalra, Brian Woodtli and José Manuel Asensio and faculty: Shyam Francesco Zonca, Lana Awad and Ricardo Mayor