Introduction

The Digital Fabrication Introductory course focuses on utilizing production techniques by learning the use of three different machines: CNC Milling, Laser Cutting and 3D Printing. The focus of the course was to fabricate different modular recursive geometries with different fabrication techniques along with the learning-by-doing manifesto. Through this course we learned the safety protocols for using each machine, and how to set up each machine for fabrication.

LAZER PRINTING

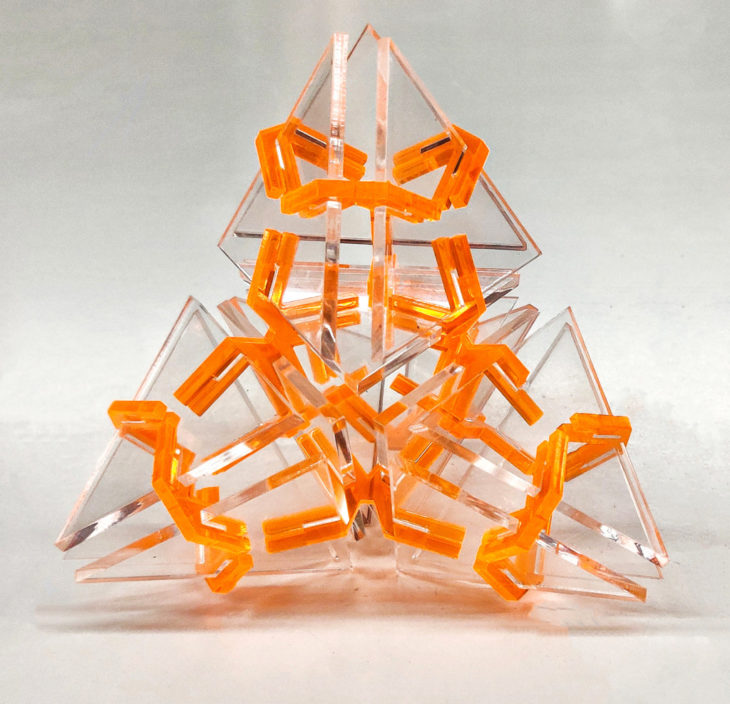

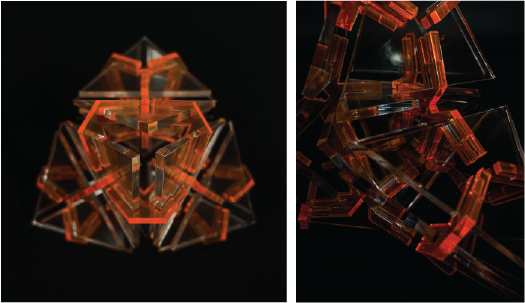

In the laser cutting fabrication method, we aimed to create an abstract tetrahedron in an exploded look by combining 4, 6x6x6cm triangles with interlocking technique. In order to keep the shape of these modules and the tension between them, we decided to use three different types of press fit joint. Moreover, we used 2 different colored acrylics that are 3mm thickness. One of them is in transparent the other one is fluorescent colored.

// Technical

Material: Acrylic 3mm transparent/ fluorescent

Technique: Interlocking

Joint type: Press Fit Joint

Machine: Epilog 75(p59)

Speed: 7

Power: 100

Frequency: 5000

// Singular Geometry

// Final Recursive Geometry

// Digital Recursive Growth

3D PRINTING

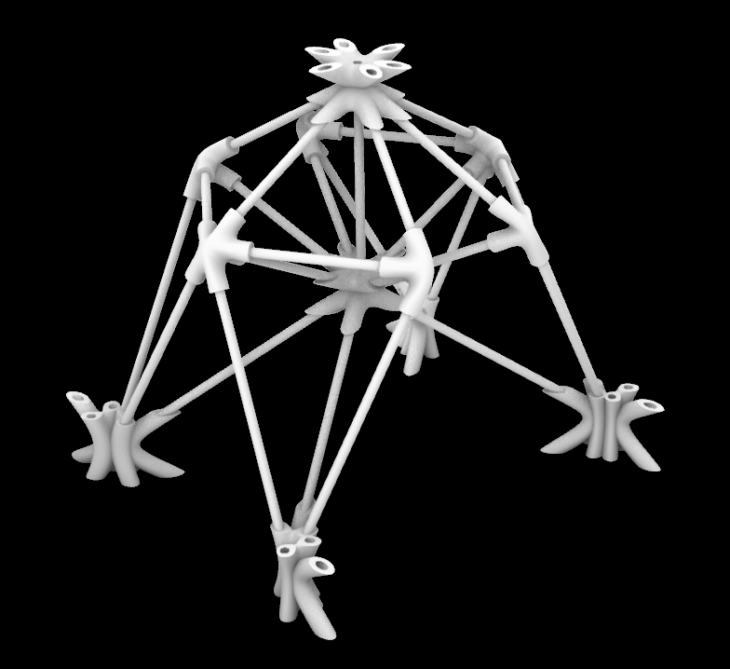

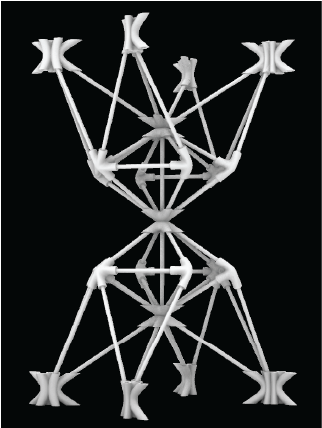

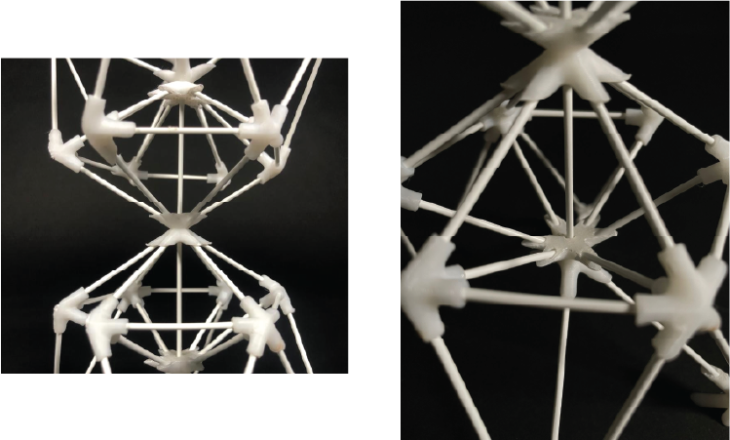

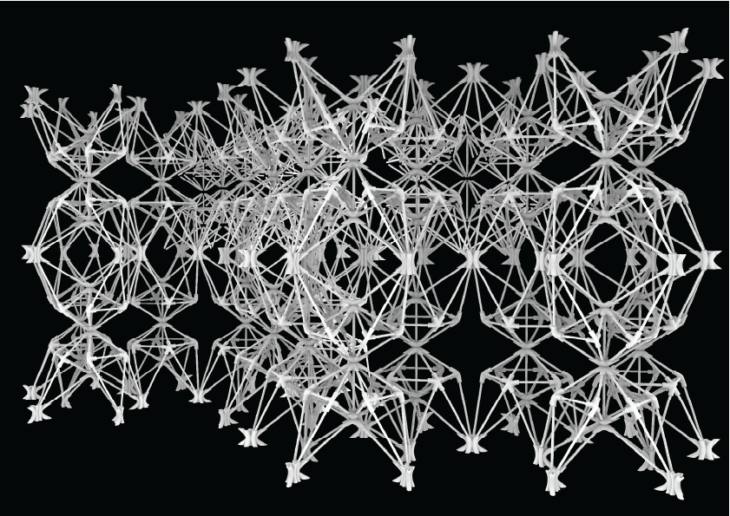

We created a recursive geometry with nodal joinery systems. Six node variations were designed and fabricated. Between the joints, we worked with 2mm rods. One of the most important part of this fabrication is to focus on how to optimize the model in the software to reduce the time and material usage.

// Technical

Material type: Z-ABS

Machine specifications: Zortax M200 plus

Layer thickness: 1 mm

Support type, angles, and specifications: Automatic, 20°, Smart Bridges_ Lite

Supports required: Yes

Infill type, percentage, & pattern: Normal, 30%, Pattern 0

Print Quality: Normal

Total number of nodes: 23 (6 node variations)

Total print time: 4h

Total material quantity: 5.41m (13g)

// Singular Geometry

// Final Recursive Geometry

// Digital Recursive Growth

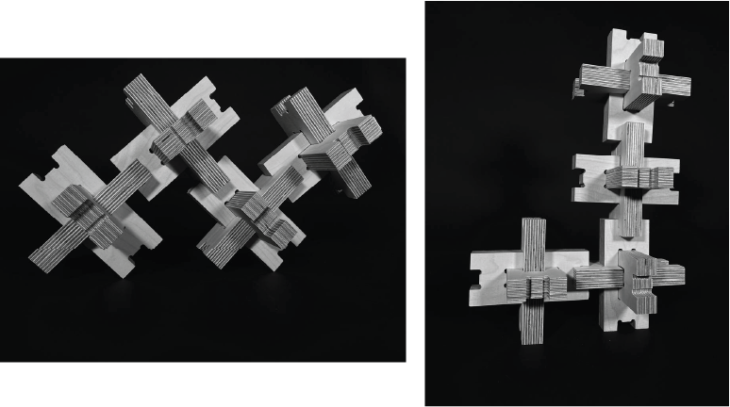

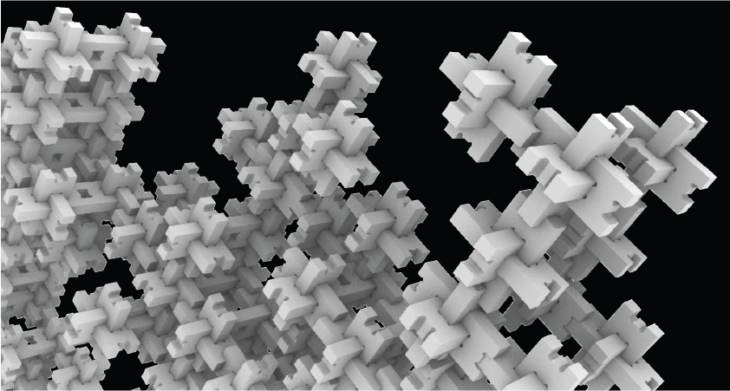

CNC MILLING

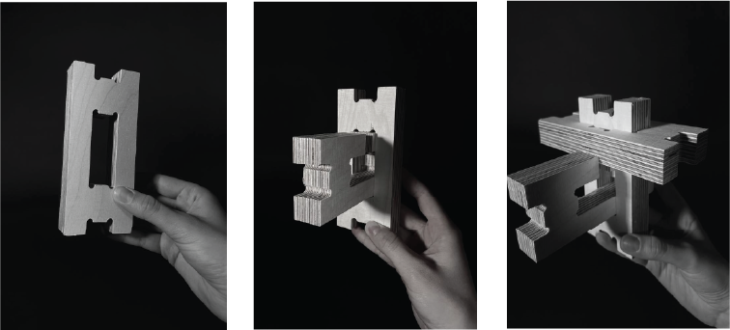

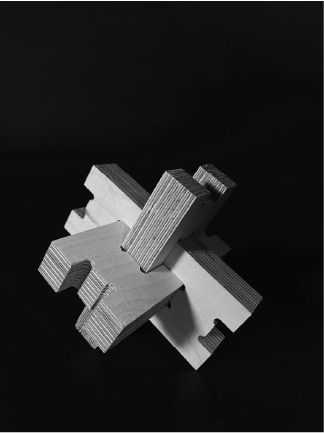

The aggregation of recursive geometry in CNC Milling was quite challenging. We used 3 different shapes interlocking each other in the center.

// Technical

Material: Plywood 24mm

Machine: 2 Axis

Post Processor: Raptor(p102)

Workpiece volume: 200 cm x 200 cm x 200 cm

Total mill time: 38.1 minutes

Engraving for Screws, Pocketing and Profiling:

Flute: 2

Diameter: 6 mm

Spindle Speed: 18000

Cut Direction: Upcut

Stepover distance: 75%

Stepdown Control(dZ): 70%

// Singular Geometry

// Final Recursive Geometry

// Digital Recursive Growth

Introduction to Digital Fabrication – Recursive Geometries is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in (2021) by:

Students: Gizem Demirk?ran, Mara Muller-De Ahna , Aishwarya Arun

Faculty: Ricardo Mayor, Lana Awad, Shyam Francesco Zonca