This course had the purpose of introducing us to several digital fabrication methods. The course was divided into 3 parts that each focused on a different machine: Laser cutter, CNC machine, and 3D printer. The first session of each part was a crash course on the machine that would be used along with a quick fabrication exercise. The students would then have a week to develop a recursive design and fabricate the objects. At the end of each mini term, the teams would present their design in front of the fabrication professors and the rest of their classmates.

3D PRINTING

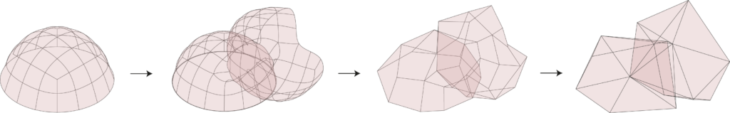

This exercise started with a geodesic dome as the base geometry. This was then simplified in terms of curvature of the mesh by triangulating it. The base of the geometry went from a circle to a pentagon and the mesh went from small and several triangles, to bigger and less, therefore decreasing the curvature and number of intersections to optimise the fabrication process in terms of time. The nodes were designed based on the intersection of the vertices. Aggregation could be achieved from the x, y, and z axis when adjusting the design digitally and the final aggregated geometry forms different dome-like spaces in the above mentioned directions.

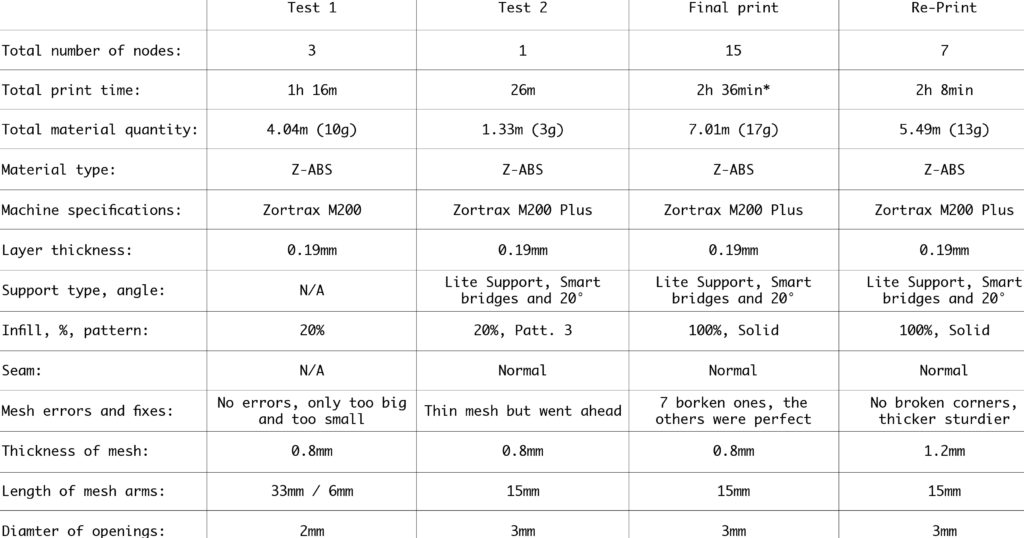

// Production file, time and material data

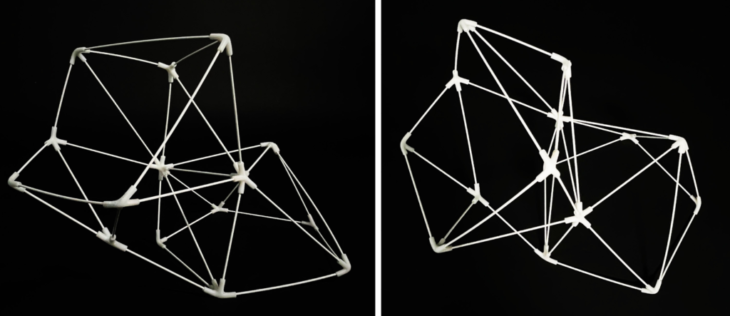

// Assembled geometry

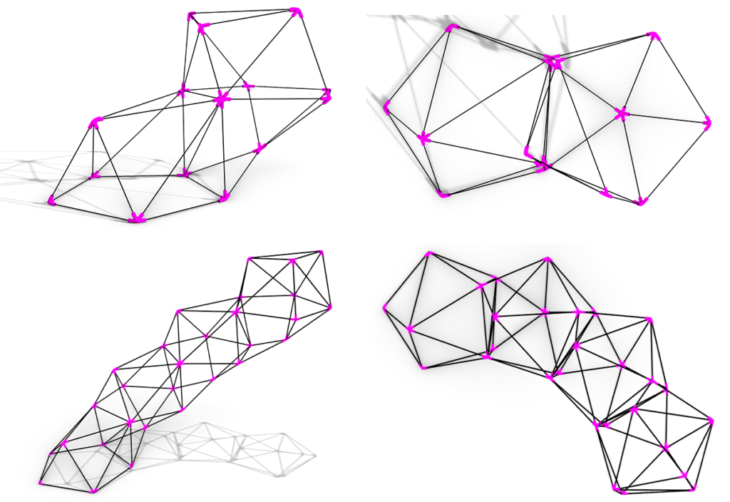

// Digital aggregation

CNC

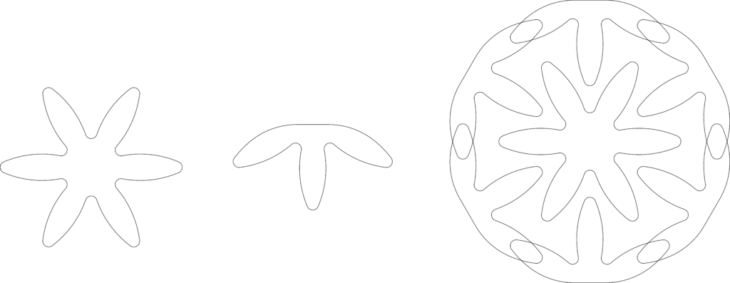

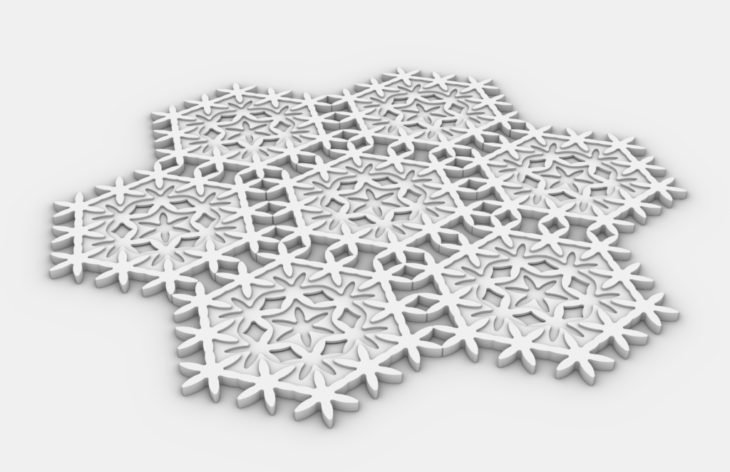

The CNC milling project was inspired by the recursive geometry patterns found on the local Barcelona tiles. The aim of the milling was to achieve a single replicable tile. This tile can be used to develop spaces enclosed by walls and ceilings using the tile as a modular element. The design began with a six-pointed flower geometry and was eventually iterated into three layers of geometric shapes which is showcased in the final output.

// Production file, time and material data

// Production file, time and material data

Material: MDF Tablero 40mm

Machine: Raptor X-SL

Post processor: CNC_STEP_BCN Raptor

Workpiece volume: 200mm x 200mm x 200mm

Pocketing

Upcut mill: 6A

Flute: 2

Diameter: 6mm

Spindle Speed: 18000

Cut direction: Upcut

Step down control (dZ): 40%

Stepover distance: 3.175mm

Total mill time: 18.14 mins

Engraving

Upcut mill: 6A

Diameter: 6mm

Spindle speed: 18000

Cut direction: Upcut

Stepover control: 40%

Total mill time: 0.0 mins

// Assembled geometry

// Digital aggregation

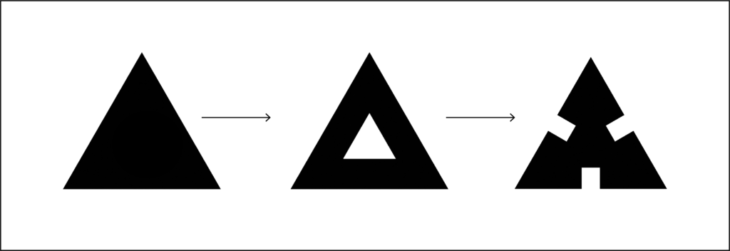

LASER CUTTING

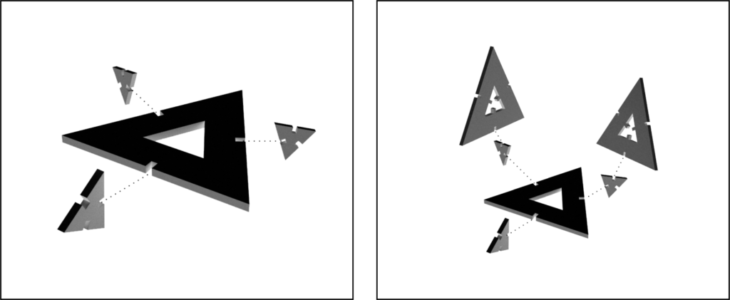

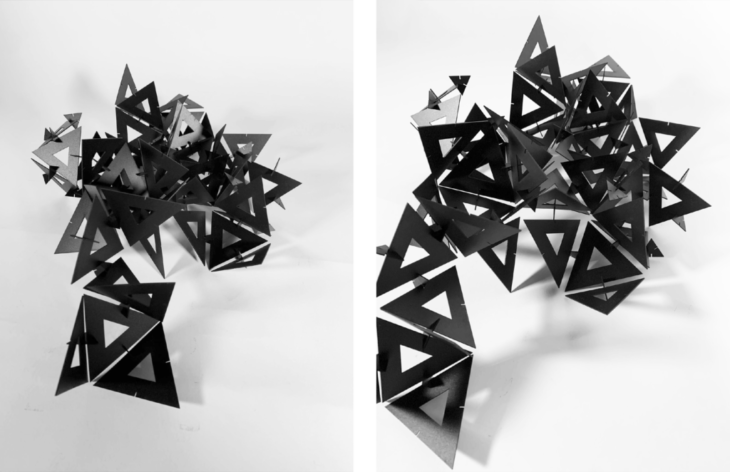

Laser cutting was the last exercise in this seminar. The design involved two different types of triangles that were joined together. The second set of triangles were used as joineries and were cut off from the first set of triangles. Each of the triangles have extra nooks on the side to facilitate the stability of the pieces. The form can aggregate in all directions and form different pavilions.

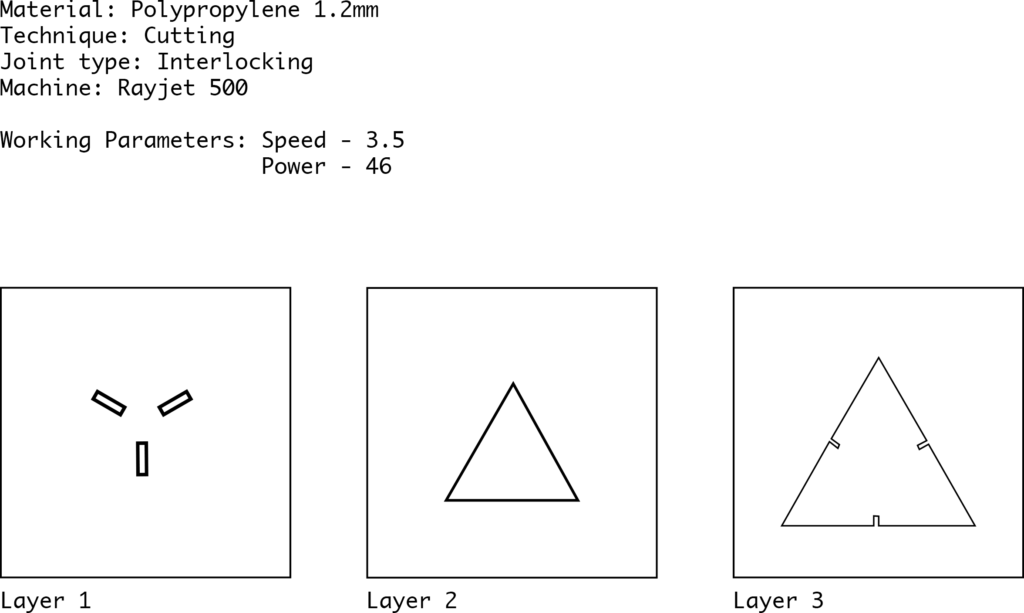

// Production file, time and material data

// Assembled geometry

// Digital aggregation

Introduction to Digital Fabrication – Recursive Geometries is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2021 by Students: Ariadna Giménez, Preetam SP and Rahma Hassan and faculty: Shyam Francesco Zonca, Lana Awad and Ricardo Mayor