Introduction

The introduction to digital fabrication course focuses on the use of computer aided manufacturing in order to make things faster, better, cheaper, and more efficient. Our group created recursive geometries during this course, which were subsequently produced using a laser cutter, 3D printer, and CNC machine. We learned how to use the machines, how to pick which machine is best for particular task, how to optimize our design for construction, and so on. As a result, we acquired the fundamental skills needed to turn complex designs into reality.

3D Printing

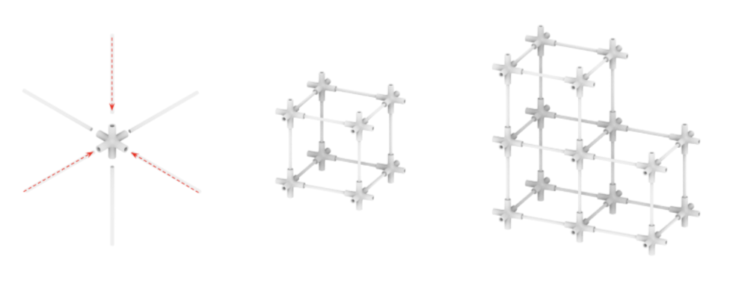

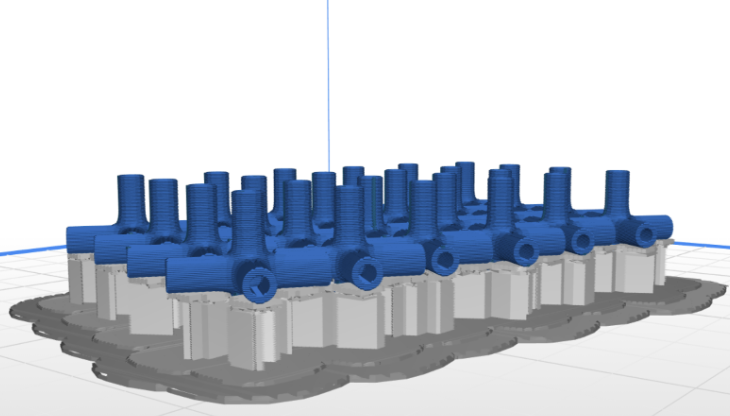

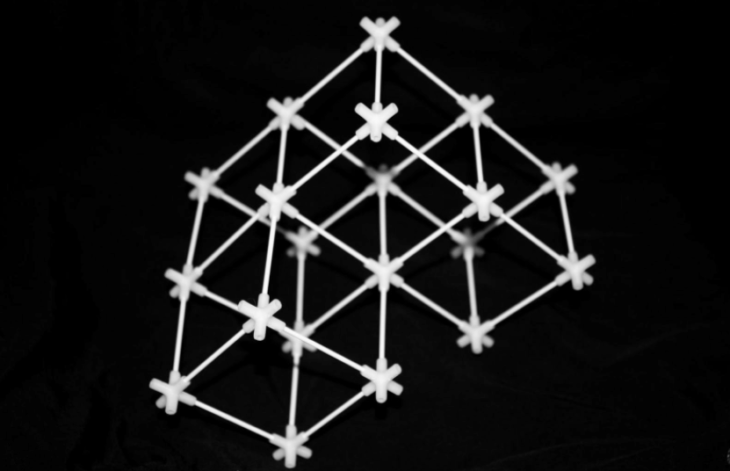

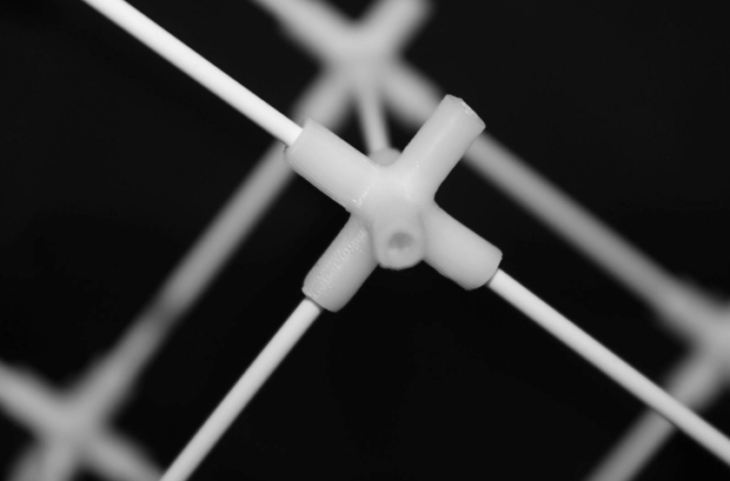

The team designed a pixelated recursive geometry based on the idea of using a single node geometry to test the 3D printing technology. The nodes are constructed with six directions in mind, enabling for the building of wire boxes with minimal tolerance holes that keep the 2mm wire in place.

Technical Parameters

Machine specifications: Zortrax M200

Material type: Z-ABS

Total number of nodes: 24

Layer thickness: 0.19 mm

Support type, angles and specifications: Editable, 20%

Infill type, percentage, & pattern: Normal, 30%, PATT. 0

Seam: Normal

Mesh errors and fixes: No errors

Total print time: 3 hours 53 minutes

Total material quantity: 27 gr

Final Model

CNC Milling

Our team decided to use the same geometry used in 3D printing when fabricating with the CNC Milling machine, as it created a simple yet effective universal node that can be put together like lego blocks in order to create a recursive pixelated cube structure.

Technical Parameters

Material: 30mm MDF

Machine: 2 Axis

Post Processor: CNC_STEP_BCN

Work-piece volume: 300 X 300 X 30

Engraving:

Mill Type: Flat Mill

Flute: 2

Diameter: 6mm

Spindle Speed: 12000

Cut Direction: Upcut

Total mill time: 0.27 minutes

Axis Pocketing:

Mill Type: Flat Mill

Diameter: 6mm

Spindle Speed: 12000

Cut Direction: Upcut

Stepover Control: 25%

Stock : 0.1

Total mill time: 10:20 minutes

Axis Profiling:

Mill Type: Flat Mil

Diameter: 6mm

Spindle Speed: 12000

Cut Direction: Upcut

Bridges: 2 per cube

Stock: 0.1

Total mill time: 18:01 minutes

Final Model

Laser Cutting

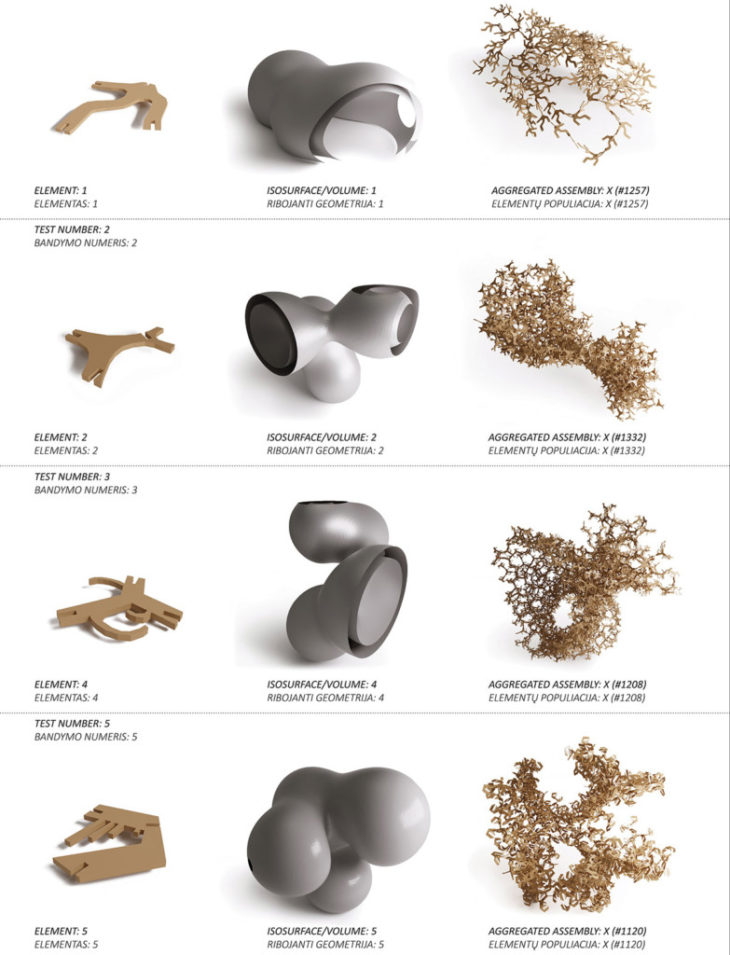

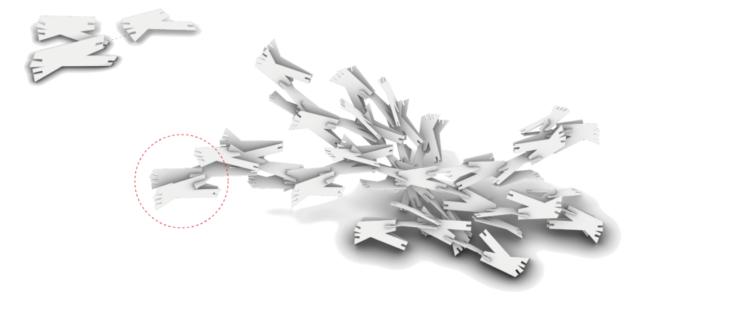

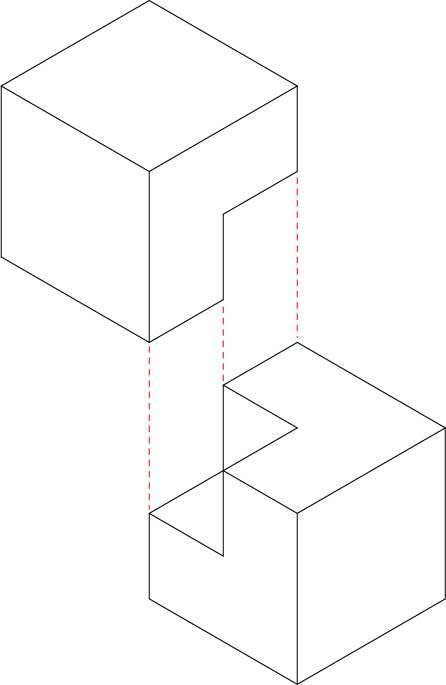

We used the Fox plug-in in laser cutting to see how one 2D shape can be aggregated together to generate a complicated 3D structure. The illustration below is an inspiration that guided us through the design process.

Technical Parameters

Work piece : 500mm x 200mm x 400mm

Machine: Epilog 50-75W

Material: Acrylic 3mm

Speed: 90%

Power: 50%

Total prints: 120 units

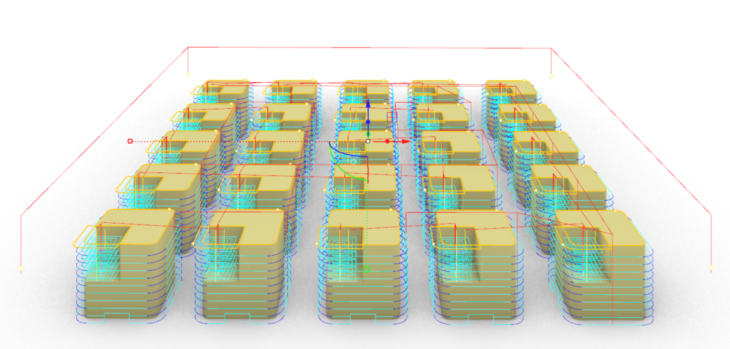

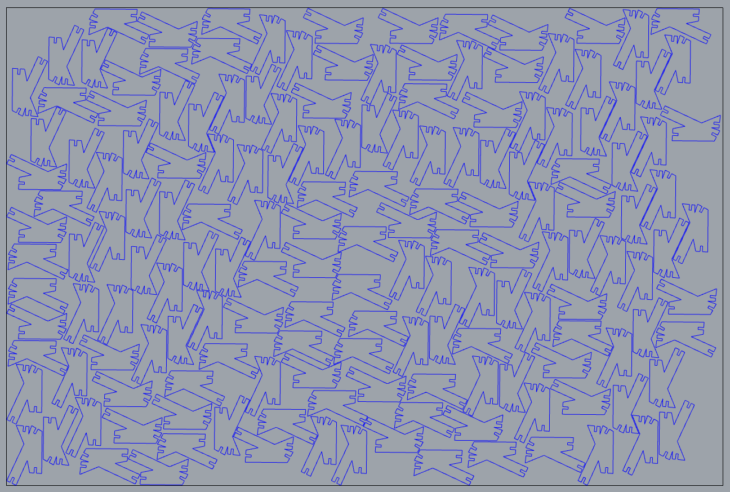

Print File

To save time, the team decided to optimize the nesting of the print file using grasshopper. This helped us to reduce waste while speeding up the printing process.

Final Model

Introduction to Digital Fabrication – is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2021

Students: Muhammad Taimur Mian, Harshul Pareshbhai Goti and Miran Calmanovici

Faculty: Shyam Francesco Zonca , Lana Awad and Ricardo Mayor