This Blogpost is a Short summary of my practical chapters of my thesis. For more in depth you are welcome to view the presentation or contact me directly.

Enjoy!

HYB[RE]DESIGN – MERGING PHYSICAL AND DIGITAL CRAFT IN ARCHITECTURAL PRACTICE.

</p>

0.Abstract

Importance.

The architectural community considers the physical model-making practice a valuable design exploration tool. As a result of the dominant market demand for digital deliverables in increasingly shorter intervals, architectural firms are deprecating analog practices, mainly volumetric, and sculptural nature crafted models, due to the inefficiency in integration to the digital platforms. The current prototyping methods prefer Geometrical accuracy over speed (i.e. desktop 3d printers). this relocates the act of making a prototype a visualization aid for clients rather then a inner-profession communicative tool.

This phasing out causes a growing concern in the design community about the preliminary design quality.

“ It is tragic, indeed, that at the time in which our technologies offer multi-dimensional perception of the world and ourselves, we should throw our consciousness and capacities back to the Euclidean world “

Juhani Pallasma – The Thinking Hand:

Existential and Embodied wisdom in Architecture, 2009

Hypothesis.

This project examines how the integration of volumetric hand crafted physical model practice and with digital design tools could impact the creative productivity in the architectural preliminary design process. The aspects the will be examined are:

- Design Efficiency- Can the user produce more iterations in less time without harming the valid / Quality?

- Empowering Creativity – Do are users get a sense of empowerment? values such as Control, Design options, personal input.

- Mental Image – the perception of the designer’s regarding their work -How intuitive is their interaction with the designed object.

Methodology.

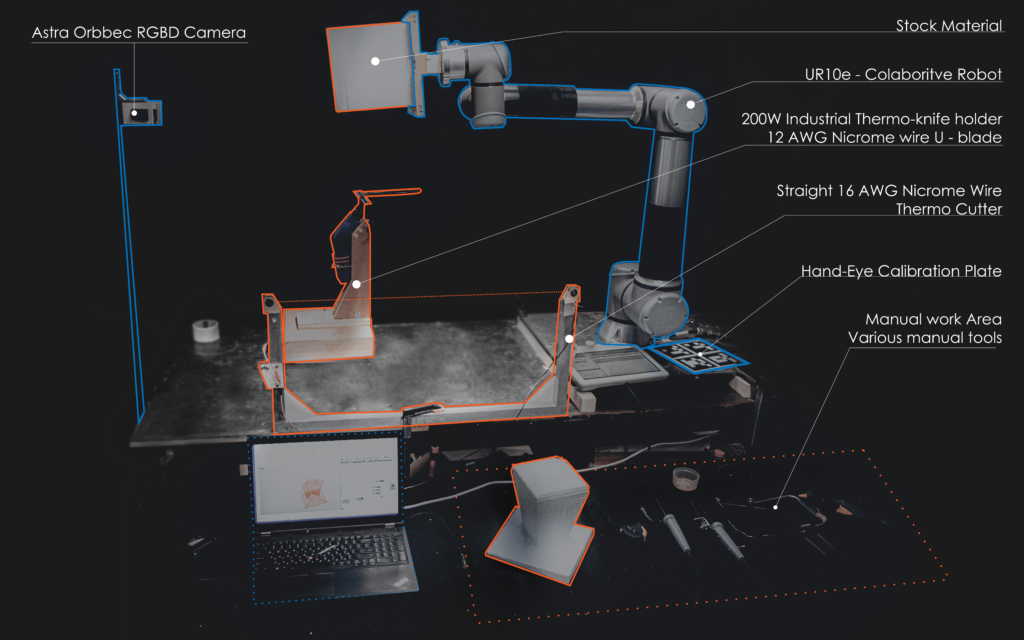

For the sake of the experiment, Two translational units were devised:

- Analog to Digital – Automated 3D scanning and surface reconstruction.

- Digital to Analog – Robotic fabrication protocol in EPS – thermo cutting and CNC.

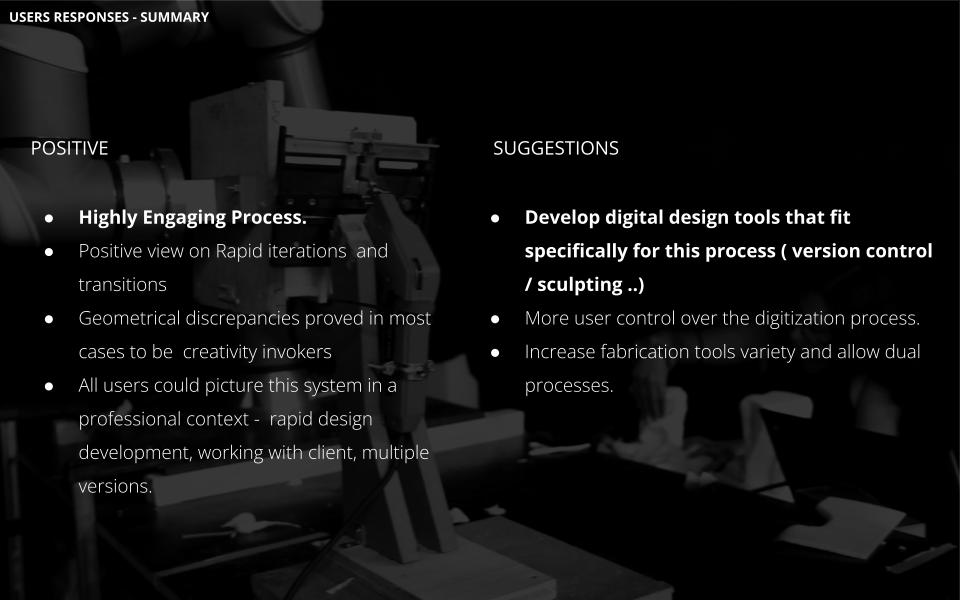

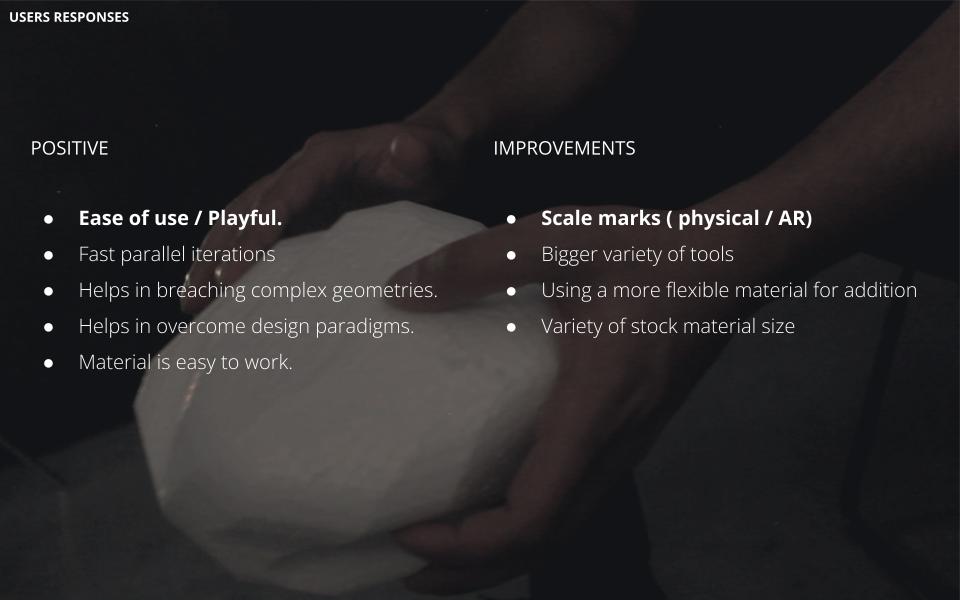

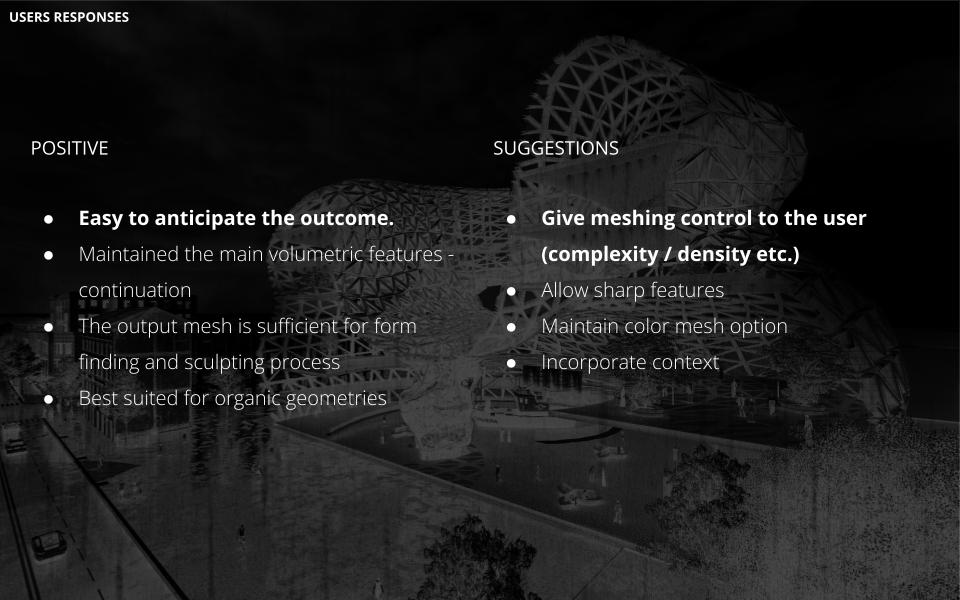

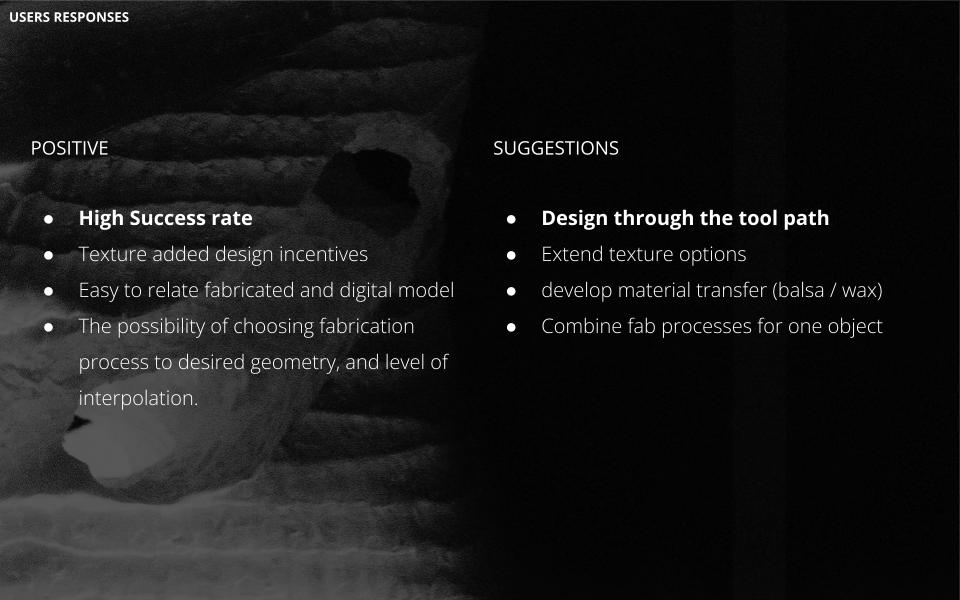

The experiment will comprise three design scenarios varied in scale and work time. In addition to a questionnaire that will assist in qualitatively estimating the user’s point of view in 2 categories:

- The user’s experience in the current system.

- Future potential – given more or improved features.

Impact.

If confirmed, This research could push for further development of analog-digital design tools, which potentially reinstate manual craftsmanship as part of the designers’ tool kit. Furthermore, designers could use the generated database to implement novel data processes such as fusing procedures to manage the digital-analog design, version control, data fusing, and AI.

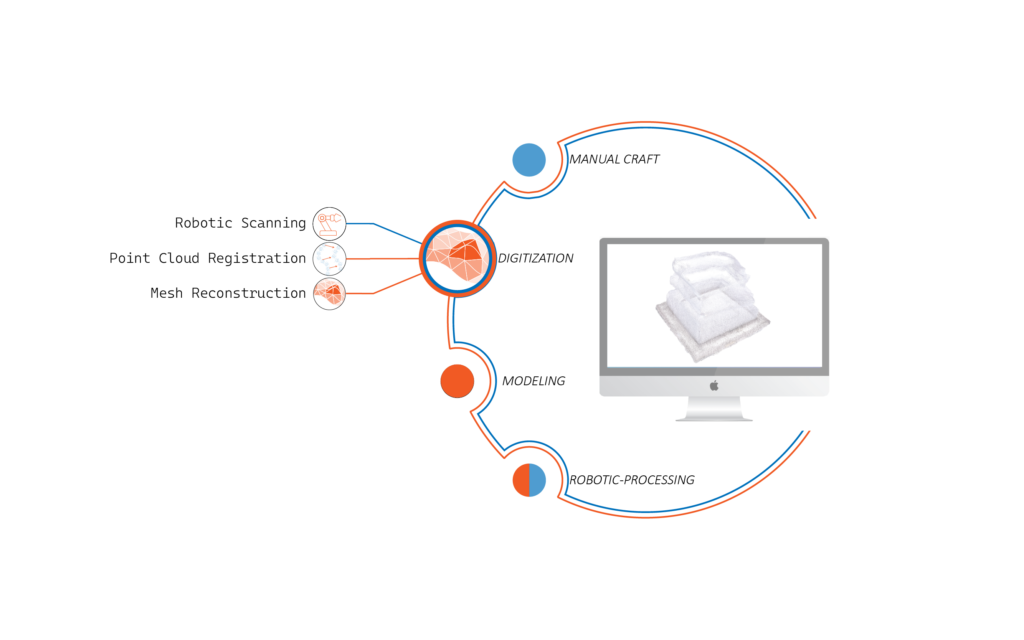

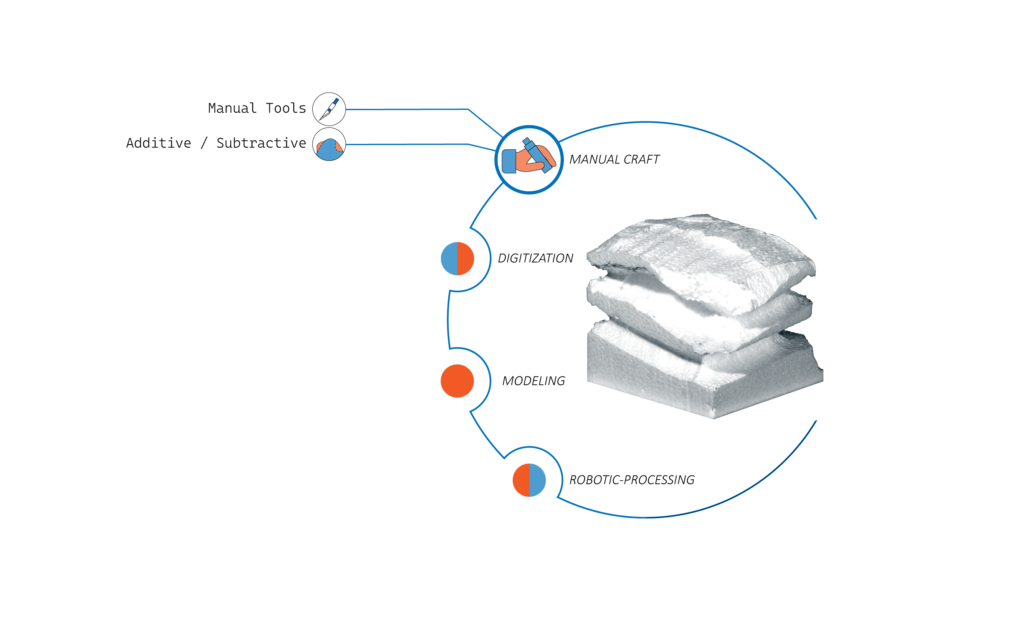

1.1 METHODOLOGY – PROCESS

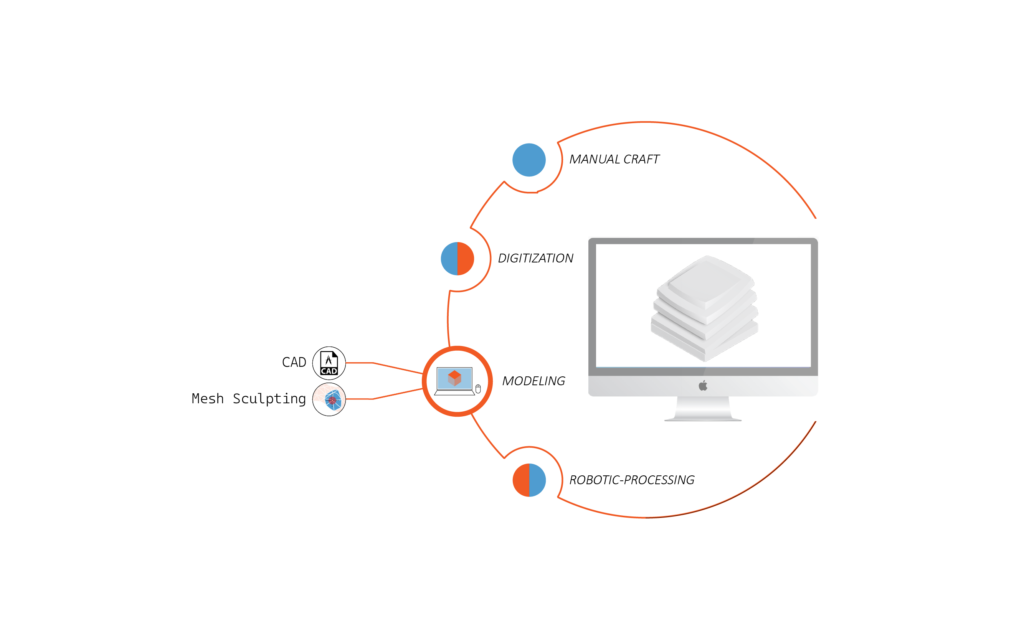

The Work flow consists of 4 iterative stages:

- Manual Craft – Where the user designing with MANUAL tools in additive or subtractive manners. – USER INPUT

- Digitization – a Robotic arms grabs the model, using an ASTRA RGBD camera, scans and reconstructs a mesh – AUTOMATED

- Modeling – Where the user designing with DIGITAL tools in his native envioerment – USER INPUT

- Robotic Processing – Robotic arms fabricates the developed models in one of 3 suggested protocols – AUTOMATED

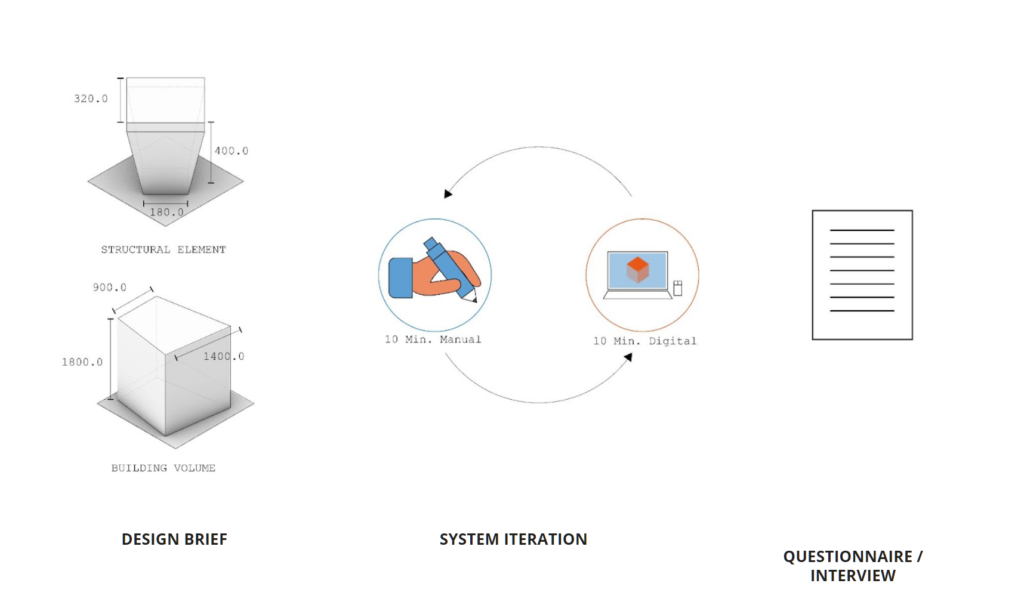

1.2 METHODOLOGY – EXPERIEMENT

To Validate the hypothesis – An experimental brief was assigned to 12 designers, all of architectural background with various level of experience (less then a year <->20 years) .

the brief consisted of :

- The Design Target -either a public building volumetric or a Structural element (column), with a bounding volume.

- Starting point – Digital or Physical – Either received the geometry as 3dm file or a cut block of foam.

- Iteration – each designer had 10 minutes to work in each manner (physical/ digital) , at the end of the 10 minutes he had to switch to other manner – total of 10*4 minutes.

- at the end a questionnaire was send to describe the experience, and several attended a deeper video interview.

2.1 Manual Craft

2.2 DIGITIZATION

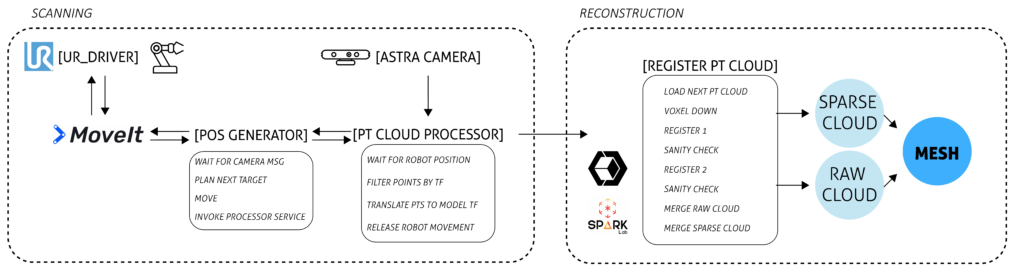

The Digitization process consists of –

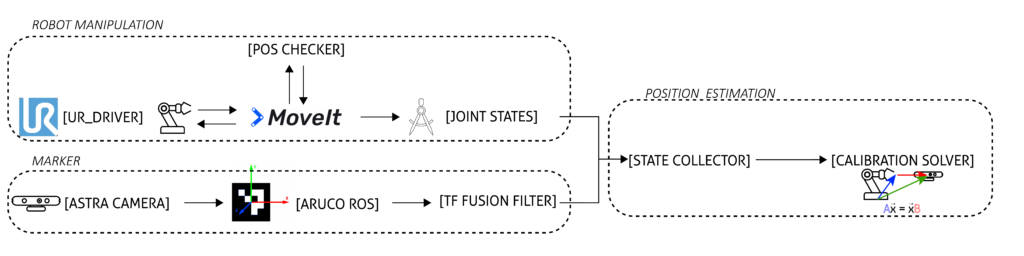

- Calibrating the camera and the Robot to the same coordination space

- Auto scanning – collecting filtered point from different perspectives (robot poses)

- Merging the Registering the point shots to one point cloud

- Meshing

CALIBRATION

PT CLOUD SHOTS

Once a Model was turned to mesh –

The Designer Could apply all verity of tools he is used to -from analytics to rendering.

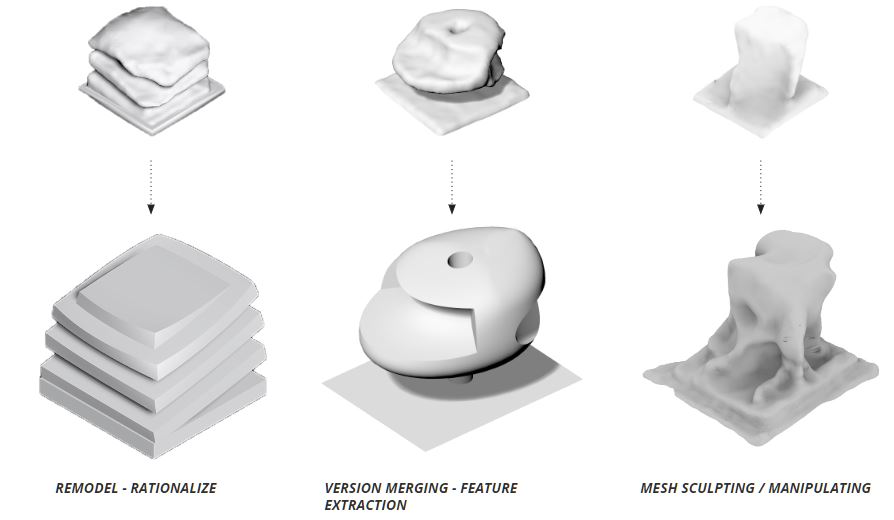

2.3 DIGITAL MODELING

The designers once presented with the mesh received 10 minutes to work on in their native workflow. The common choices were Rhino3D, Grashopper, and Blender.

DIGITAL MODELING STRATEGIS

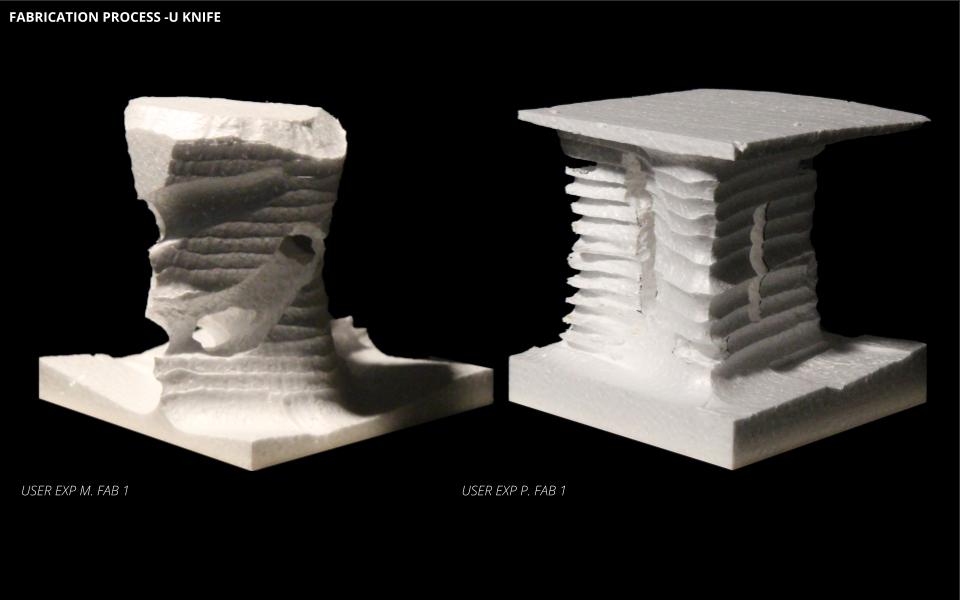

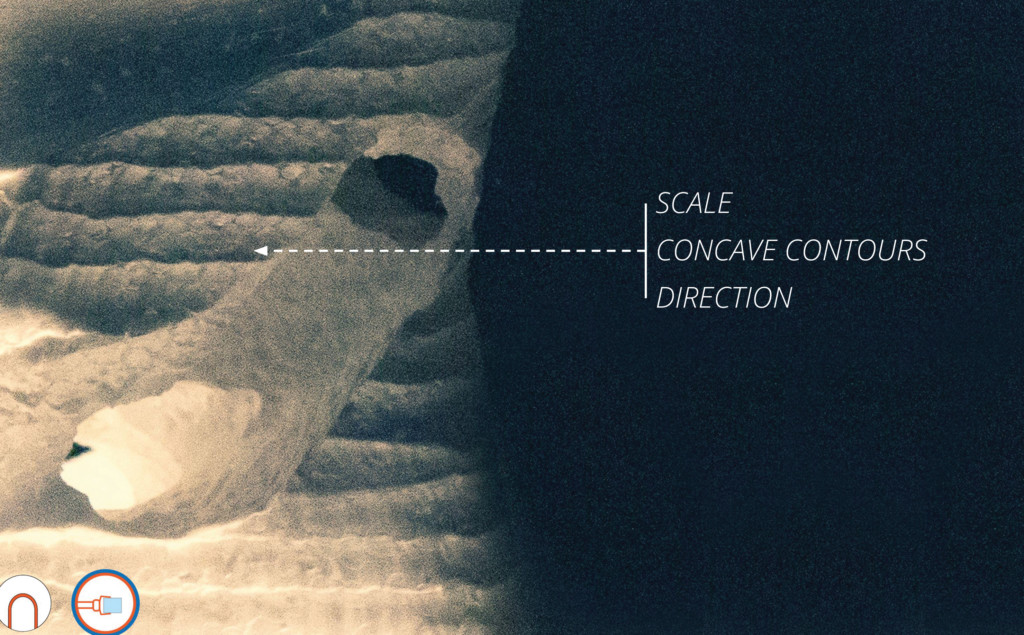

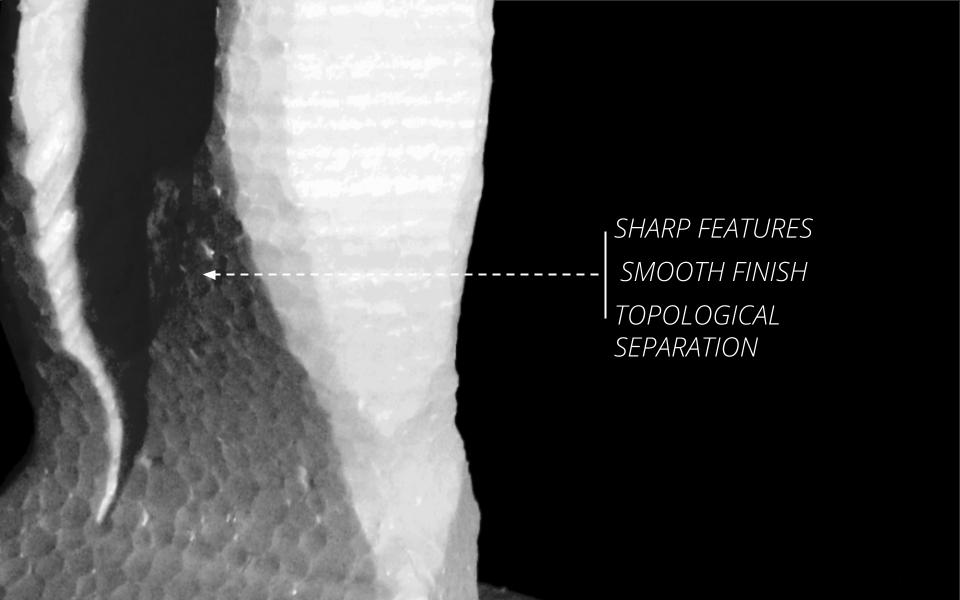

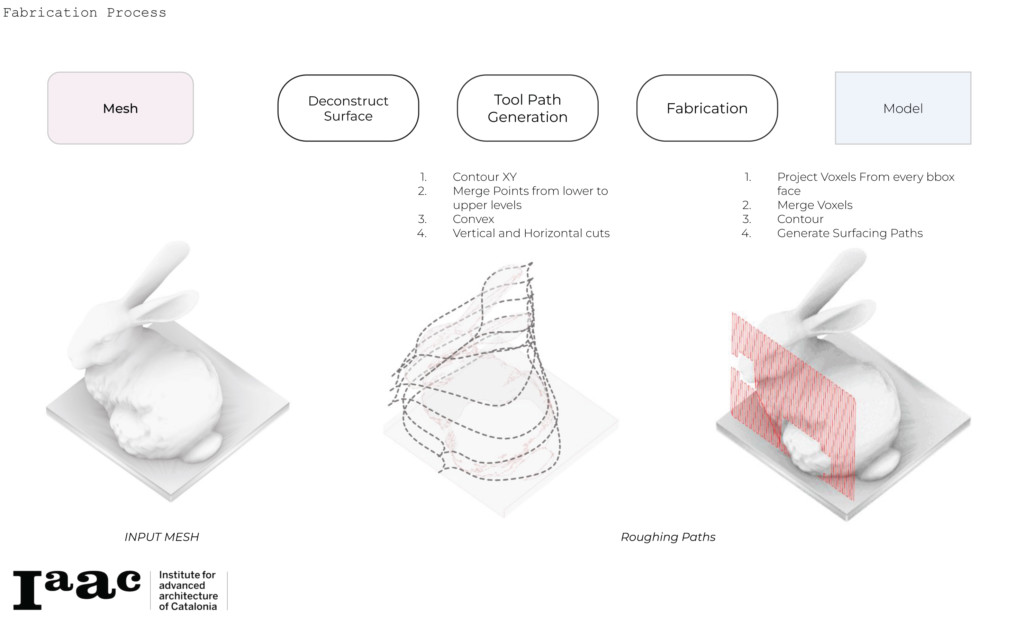

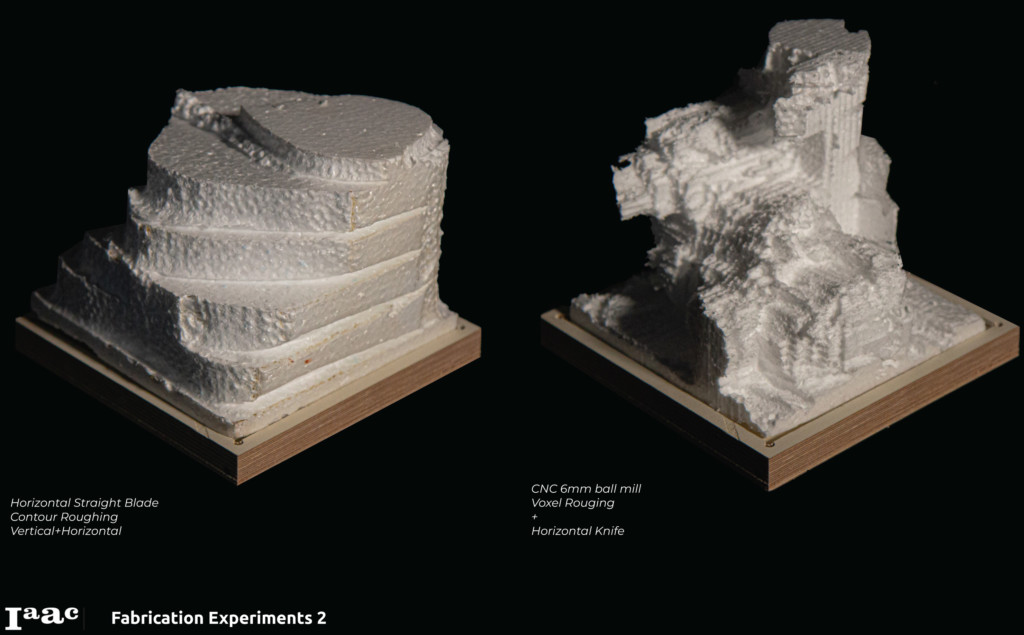

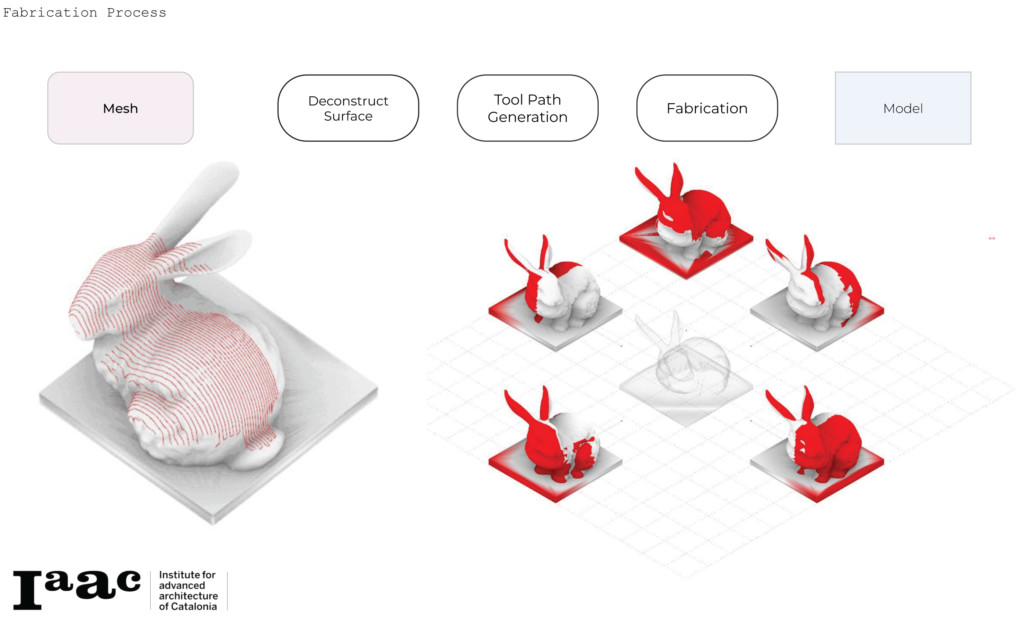

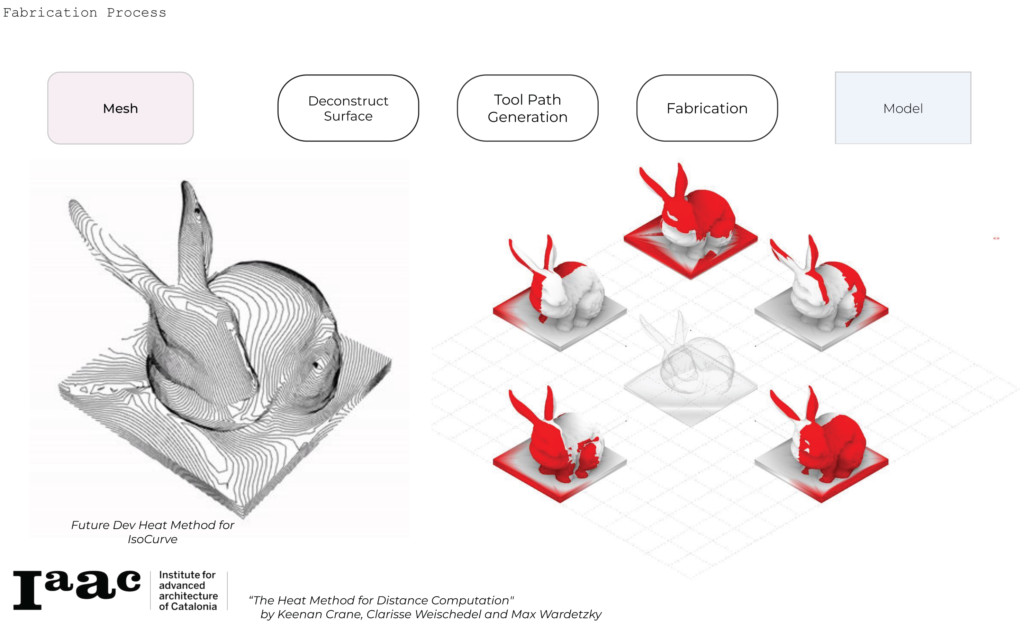

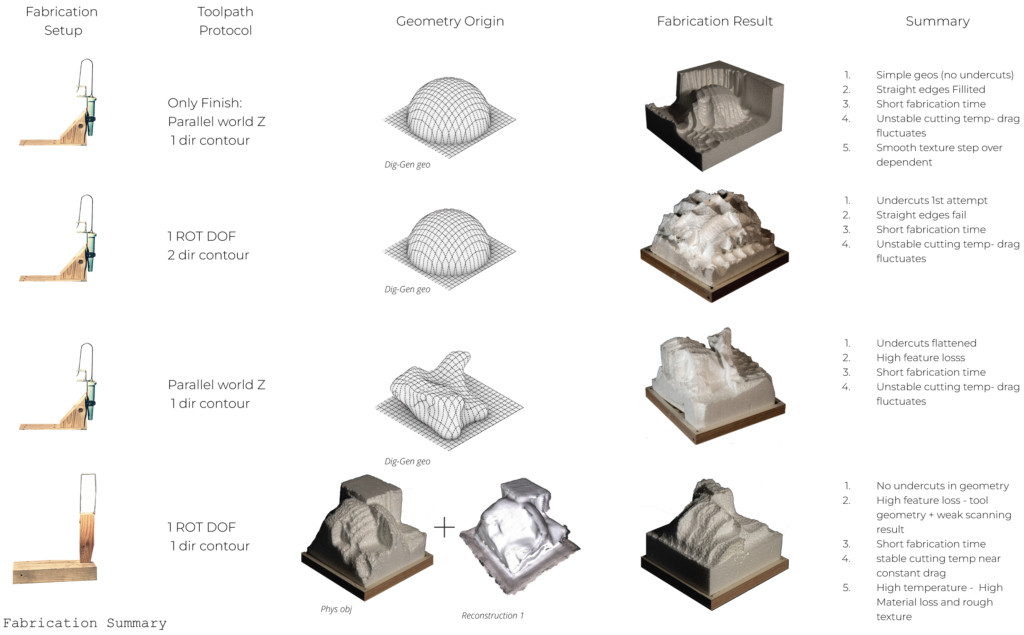

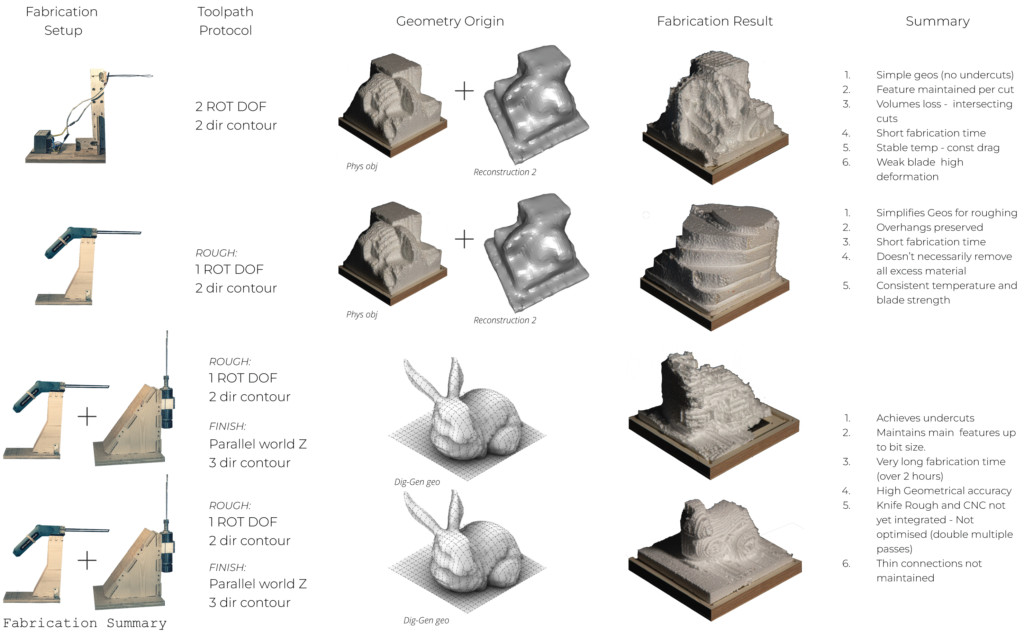

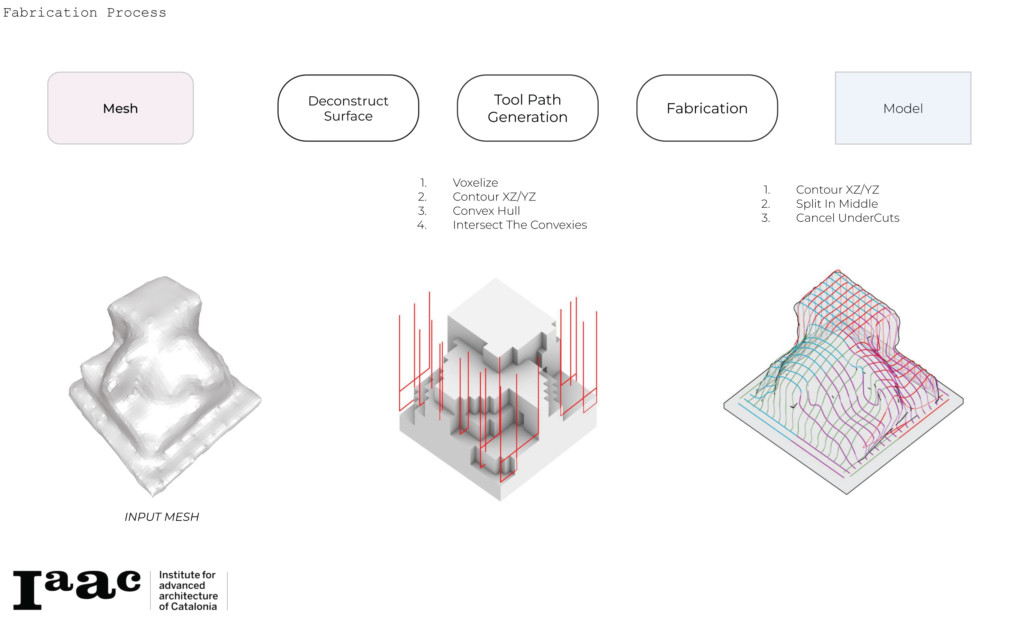

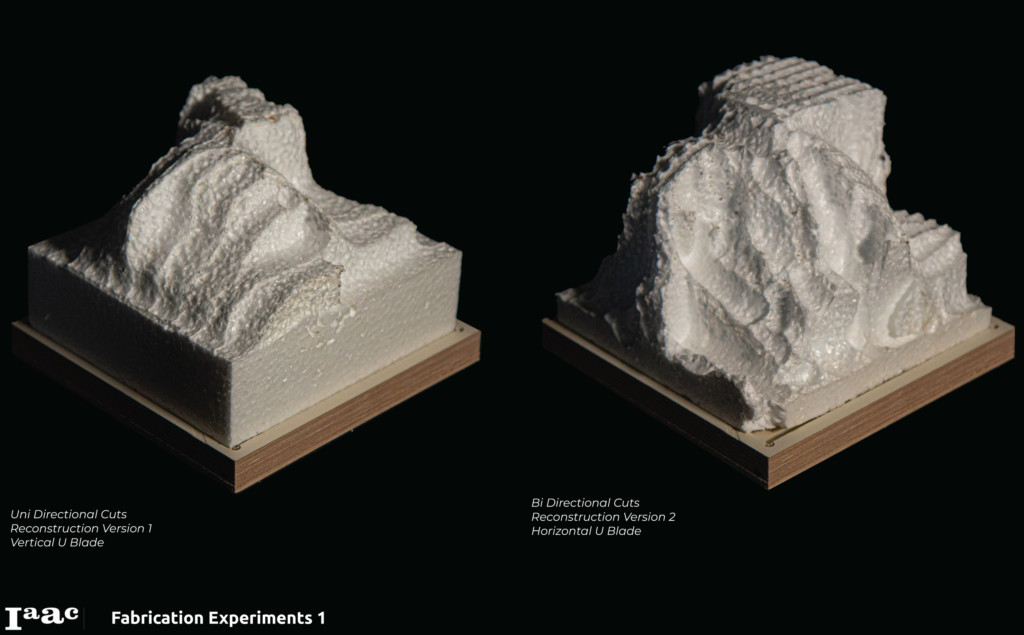

2.4 ROBOTIC PROCESSING

Once Finished the digital modeling phase, The designer chooses one of several processes developed for this project, according to tool or procedure best suites his design intentions.

all the procedures value speed over geometrical replication in order to achieve a smooth and fast transition between the different platform. this comes with a price/ gain – the procedures leaves a significant mark on the design process forces the designer to utilizes the fabrication process in his design process.

3.SUMMARY

4.APPENDIX – fabrication development

Hyb[RE]DESIGN // THESIS is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at the Master in Robotics and Advanced Construction in 2021/2021 by:

Students: Shahar Abelson

Faculty: ALEXANDRE DUBOR, ALDO SOLAZZO