Dimensions of Motion

Congruent Motion

3D Printing

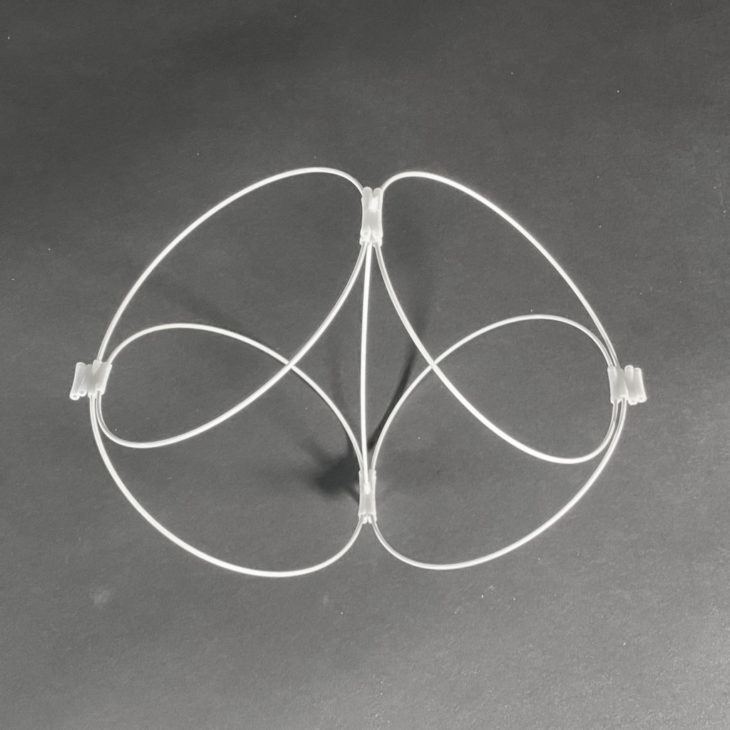

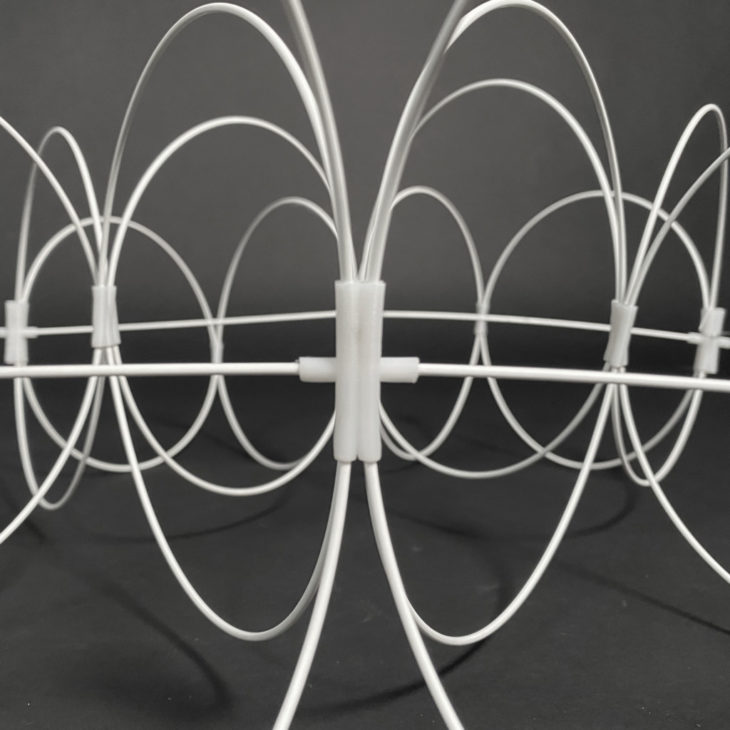

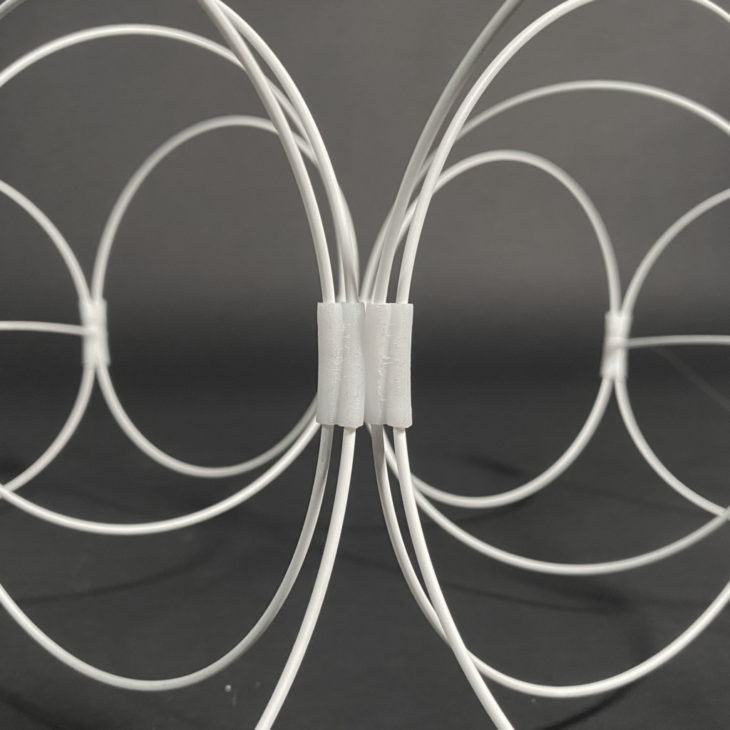

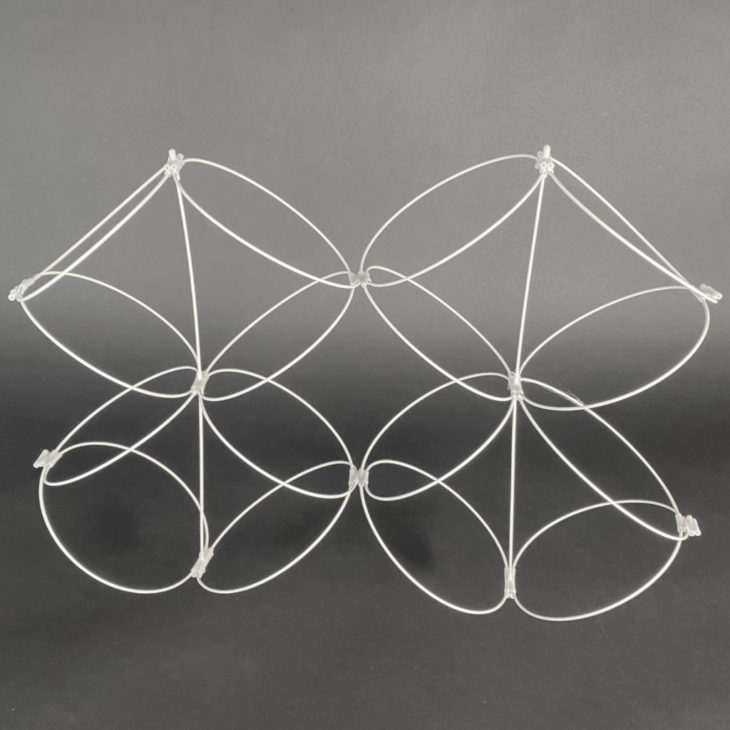

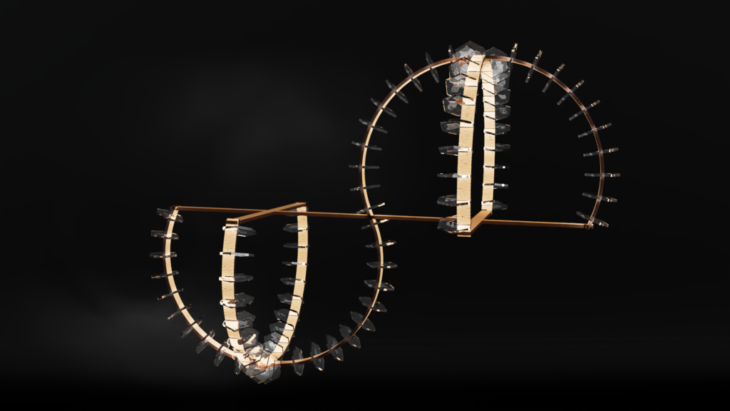

Congruent Motion was an experiment with fixed and moveable nodes. To achieve our goal we created two different types of nodes, one that is fixed at the axis points, the other allowing the rod to slide past. The recursive geometry has the capability to expanded or recede.

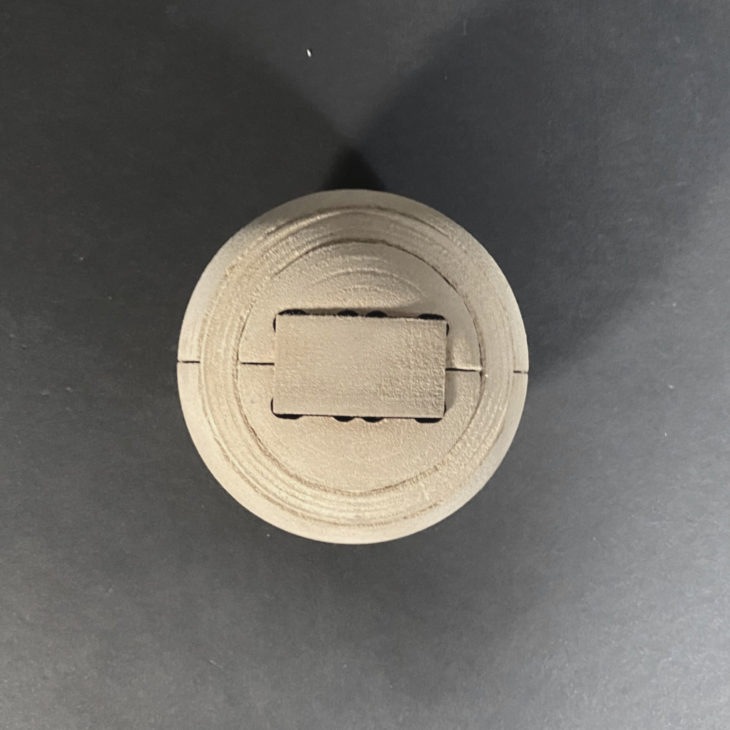

Congruent Motion – Singular Module

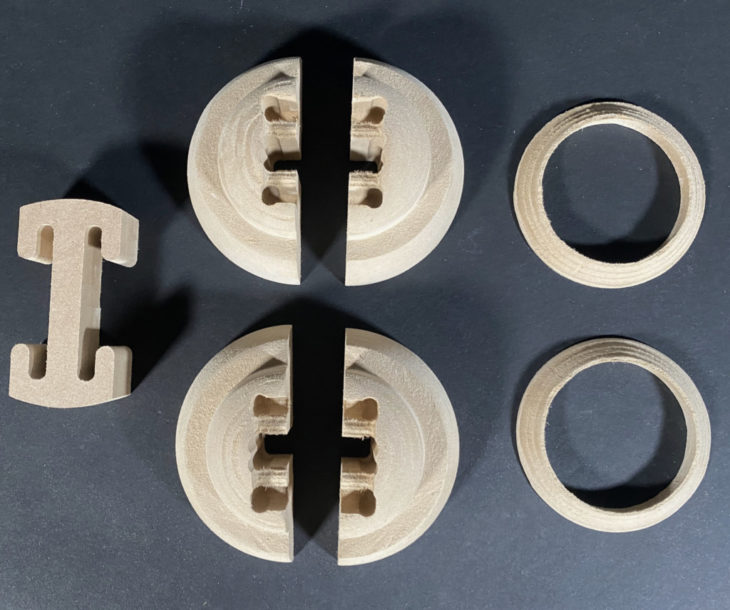

Congruent Motion -Axis Nodes

Congruent Motion – Sliding Nodes

TOTAL NUMBER OF NODES: 12 TOTAL PRINT TIME: 2h 58min TOTAL MATERIAL QUANITY: 8.19m (21g) MATERIAL TYPE: ABS MACHINE SPECIFICATIONS: ZORTRAX M200 LAYER THICKNESS: 0.19mm SUPPORT TYPE AND ANGLES: Light support <20° INIFILL TYPE, PERCENTAGE, & PATTERN: normal 50% MESH ERRORS AND FIXES: Error in 3D print diameter, fix was drilling wider holes with 2mm bit

Congruent Motion – 4 Modules

Visual Motion

Laser Cutting

Visual Motion was an exercise in laying images on top of each other to create a 3 dimensional optical illusion. Then the engraved acrylic applied to its movable framework would produce the visual effect of a moving object.

Visual Motion – Module

MATERIAL : 3 mm Acrylic & 4 mm Plywood MACHINE : Epilog 50W WORKPIECE VOLUME : 600 x 900mm ENGRAVED ACRYLIC Speed : 60 Power : 20 Frequency : 5000 CUT ACRYLIC Speed : 15 Power : 90 Frequency : 5000 CUT PLYWOOD Speed : 20 Power : 95 Frequency : 300

Visual Motion – Engraved Acrylic

Physical Motion

CNC

Physical Motion intent was to create an object that had the physical properties to be in motion. With its spherical shape, it allows the object to have the capability to travel.

Physical Motion – Module

Material: MDF Machine: CNC_Step_BCN Post Processor: .nc Workpiece volume: 300x1300x40mm Horizontal Roughing Flat Mill Diameter: 10 Spindle Speed: 12000 Cut Direction: Upcut Stepdown Control (dZ): 50% Stepover Distance: 40% Total mill time: 32 minutes Horizontal Finishing Ball Mill Diameter: 6 Spindle Speed: 12000 Cut Direction: Climb / Conventional Stepover Control: 31% Total mill time: 15 minutes Profiling Flat Mill Diameter: 6 Spindle Speed: 12000 Cut Direction: Upcut Stepover Control:0% Total mill time: 4 minutes

Physical Motion – Parts

Introduction to Digital Fabrication – Recursive Geometries is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2021/2022

Students: Victor Engelhard Suarez, Cansu Kilinc, Rachel Busche

Faculty: Shyam Francesco Zonca, Lana Awad and Ricardo Mayor