// Snowflake //

DATA / Material : Wooden plate 3mm thick – Technique : Laser cutting

CONCEPT / Starting from a rigid wooden plate measuring 150mm by 150mm, this project aims to use a specific laser cutting pattern in order to obtain a double curvature surface once applying some forces on each corner. For this purpose, the choice was to use snowflake shape cuttings combined with triangular cuttings in order to increase the path of remained wooden parts.

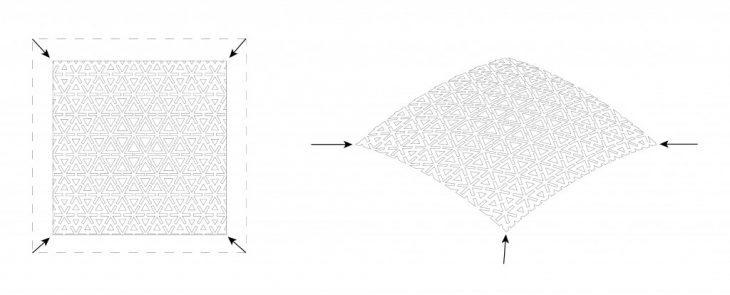

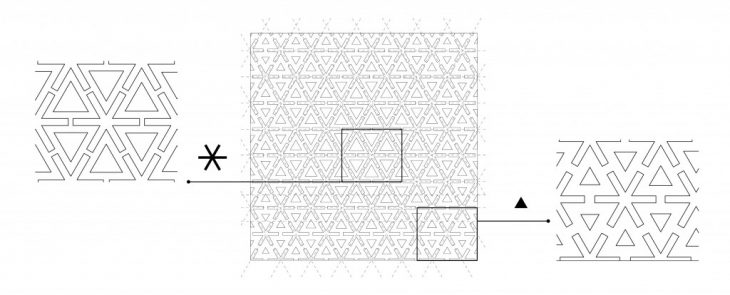

METHODS / In order to turn a rigid wooden plate in a smooth double curvature surface I used a triangular grid as the base of the pattern composition. By using the shape of snowflake applied on each node of this grid the triangle’s edges became weaker. Then, wishing an even more significant bending effect, I added an other layer of cutting pattern which was the triangles. The proportion of remained wooden parts are relating to the distance of the cut from the center of wooden plate. More the distance between the center and the cut is important more the remained wooden part will be important. This means that, once cut, the center of the wooden plate will be more flexible than the boundaries.

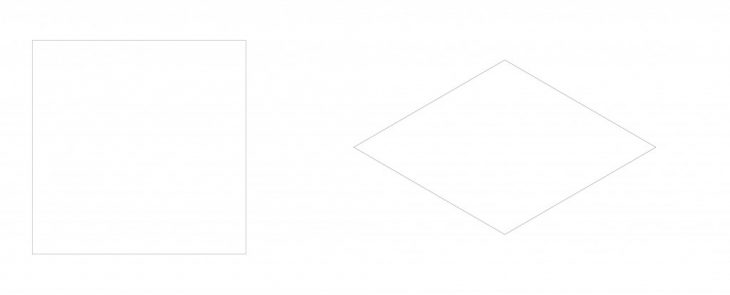

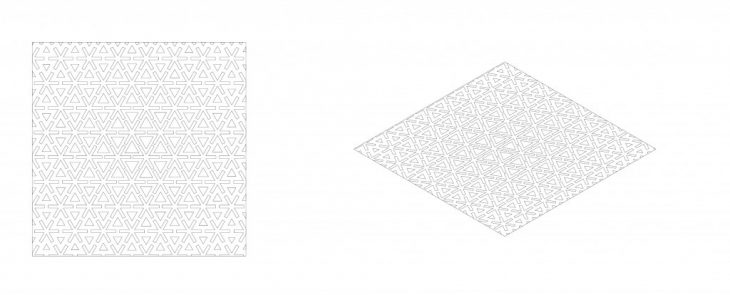

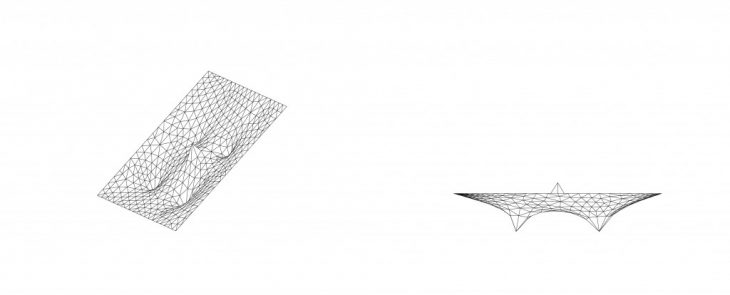

Rigid wooden plate 150mmx150mm

Snowflakes + triangles cutting pattern

according to the distance from the wooden plate center the remain wooden parts are more or less important making the center part weaker than the boundaries

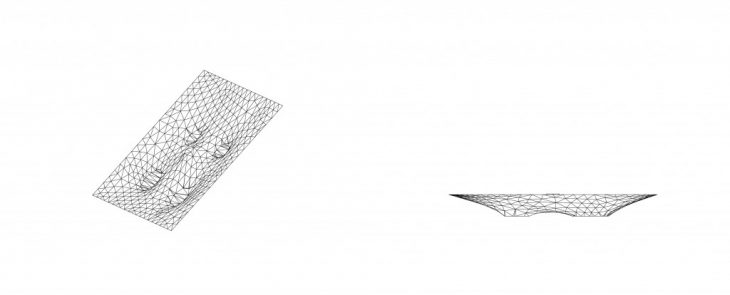

Double curvature surface obtained by applying forces

The final cutting pattern is the combination of 2 shapes inherited from the triangular grid

// Tense mesh milling //

DATA / Material : Foam slab – Technique : CNC Milling

CONCEPT / This project aims to creat a cast object by creating the mold in using the potential of the CNC milling and digital technologies. The mold will be sculpted within a foam slab following a trimmed tense triangular shape. The final cast object will appear with the gentelness of the tense shape and the hardness of triangular facets in which the shape is decomposed.

METHODS / The sape of the mold was obtained by creating a rectangular and squarish grid of points. Some points were moved in a lower position and one point was moved higher. Relating this bunch of point, we applied a Delaunay mesh tool in order to creat t triangular shape relating to those 3 dimensional points. Then a Kangaroo simulation was applied onto this from to obtained a tense triangular shape. This was trimmed in order to remove the sharp parts and obtained the wanted final result for the mold.

Rectangular grid of points

Rectangular grid of points

Make move some points up and down

Make move some points up and down

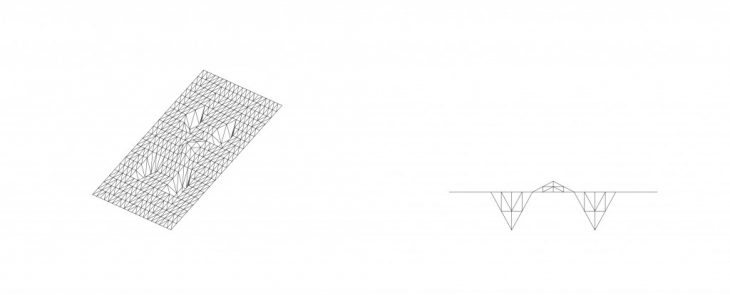

Delaunay Mesh relatind to those points

Delaunay Mesh relatind to those points  Apply Kangaroo simulation onto the mesh to get a tense shape

Apply Kangaroo simulation onto the mesh to get a tense shape  Trim the shape to erase sharp parts

Trim the shape to erase sharp parts

// Growing concrete mushroom //

DATA / Material : PVA + Resin molding – Technique : 3D printing

CONCEPT / This project aims to creat a cast object by creating the mold in using the potential of the 3D print and digital technologies. The mold will be built in PVA material following a shape obtained out of parametric process which is growing irregular shapes. The final cast object will appear as an organic concrete shape.

METHODS / The shape of the mold was obtained by creating a bunch of points following the base surface of the 3D printer board. Those points are used as the base points to creat some circles with random diameters. By using Anemone, circles are moving up and change they size onto several iterations. The series of circles created is going to be lofted and turned into meshes to give them some thickness.