1. What is it to dwell?

2. How does building belong to dwelling?

MARTIN HEIDEGER – Building Dwelling Thinking

The bridge swings over the stream with case and power. It does not just connect banks that are already there. The banks emerge as banks only as the bridge crosses the stream. The bridge designedly causes them to lie across from each other. One side is set off against the other by the bridge. Nor do the banks stretch along the stream as indifferent border strips of the dry land. With the banks, the bridge brings to the stream the one and the other expanse of the landscape lying behind them. It brings stream and bank and land into each other’s neighborhood. The bridge gathers the earth as landscape around the stream. Thus it guides and attends the stream through the meadows. Even where the bridge covers the stream, it holds its flow up to the sky by taking it for a moment under the vaulted gateway and then setting it free once more.

CHRISTIAN NORBERG SCHULZ – Genius Loci / Sense of PlaceThe bridge lets the stream run its course and at the same time grants their way to mortals so that they may come and go from shore to shore. Bridges lead in many ways. Now in a high arch, now in a low, the bridge vaults over glen and stream-whether mortals keep in mind this vaulting of the bridge’s course or forget that they, always themselves on their way to the last bridge, are actually striving to surmount all that is common and unsound in them in order to bring themselves before the haleness of the divinities. The bridge gathers, as a passage that crosses, before the divinities-whether we explicitly think of, and visibly give thanks for, their presence, as in the figure of the saint of the bridge, or whether that divine presence is obstructed or even pushed wholly aside.

TARGET GROUP

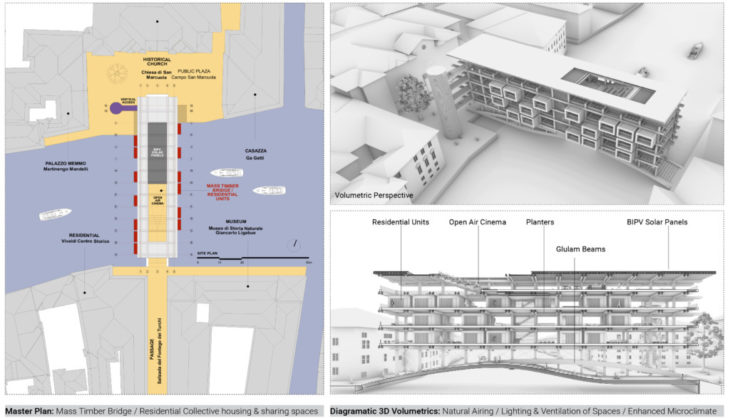

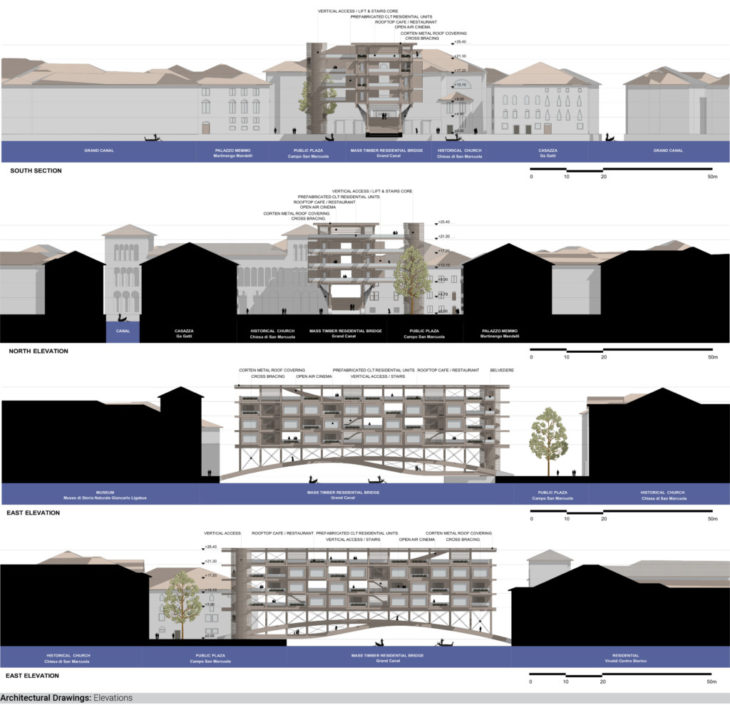

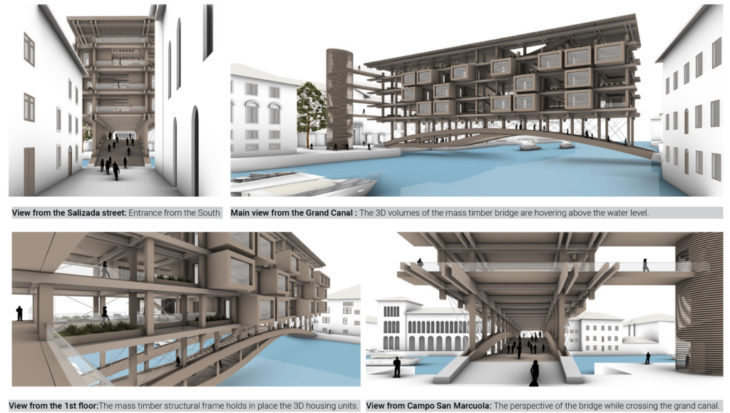

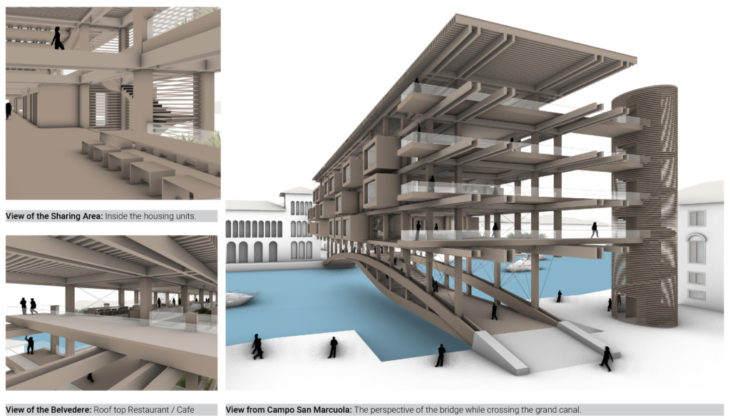

As the cultural context of Venice is almost connected with international exhibitions and schools related to art, architecture, painting, sculpturing and photography, we propose from the one hand a mass timber bridge – a fully reversible structure – to merge the two – currently unconnected sides of the urban fabric and on the other hand to create X32 energy self-sufficient ecological housing units of 45sqm, to be rented from visitors around the world who want to experience the living above the water as well as share common interests through the communal open spaces of the bridge’s platforms (dining, lounge, workshops, library).

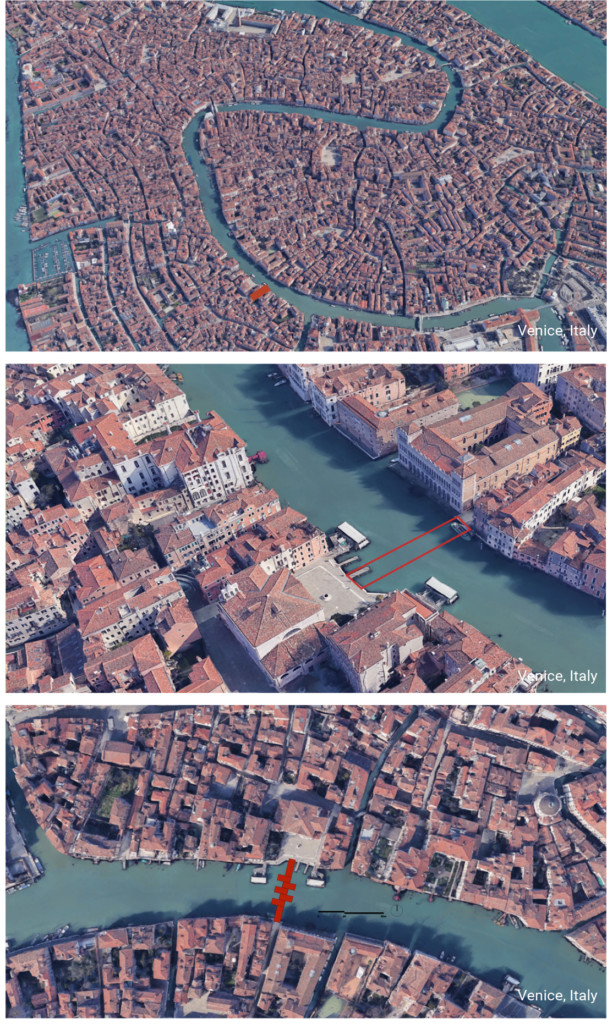

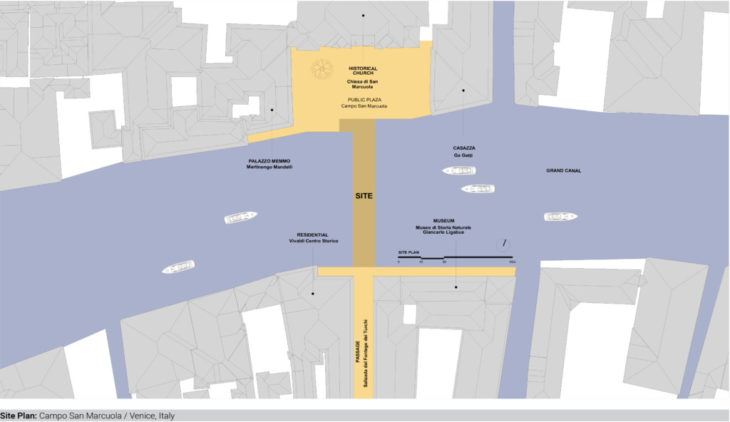

Many historic areas are integrated to the area of study, while the site is outlined at the grand canal and the adjacent shores.

The diagrams above show the urban fabric integration forces, sun orientation of the residential units on South East and SouthWest orientation, vegetation and water interconnection as well as traffic and circulation integration of the area of study to the overall city scale.

The masterplan of the residential complex is expanded through the grand canal while occupying different private and public activities as a gesture to share facilities to the city of Venice.

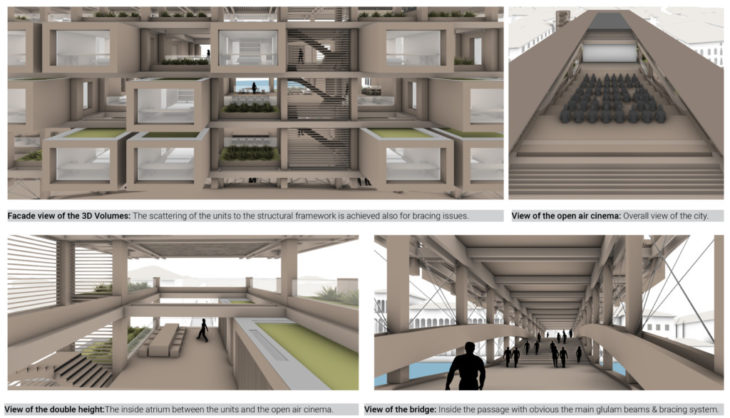

The main plans of each floor show the main bridge connection of the two shores at the ground level as well as the open-air cinema and restaurant on the 4th floor as public facilities while the three intermediate floors are related to the residential units.

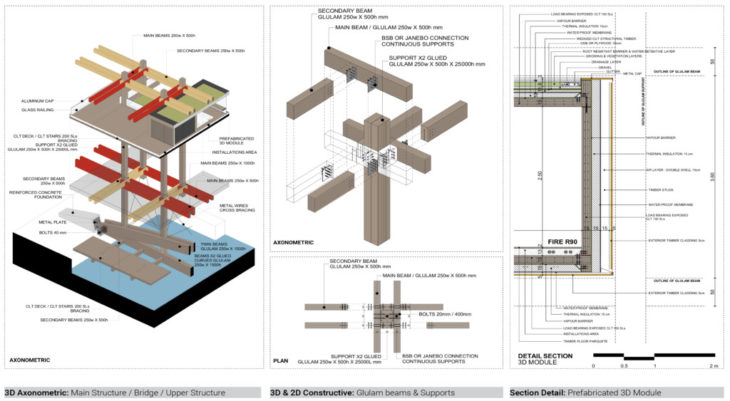

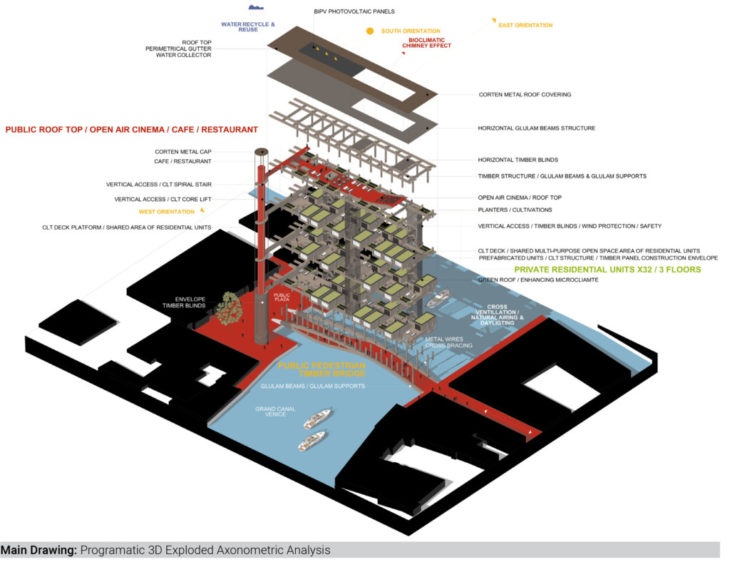

The 3D Axonometric Constructive Exploded anaylis diagram on the left shows the main connections of the glulam beams of the bridge to the concrete foundation as well as the secondary glulam beams which are connecting the two parallel sides of the bridge. The CLT decks are used for bracing. Regarding the upper structure, the direction of the main beams is shown in red while the secondary beams are shown in yellow. The direction changes from the second floor upwards to hold the cantilevers of the 3D Volumetrics. The 3D detail of the connection between the continuous beams with the main beams and columns is achieved with a BSB or Janebo system. Finally, on the right, a 2D detail of the 3D Volumetrics made of CLT panels exposed to the inside of the space is shown. An air gap is used in the facades to circulate the fresh air and lower the temperature of the facade. A green roof is implemented in each residential unit. The scattering of the 3D volumetric to the timber structural grid is used for bracing. For cross, bracing is also used the metal wires of the ground floor level of the bridge against lateral forces.

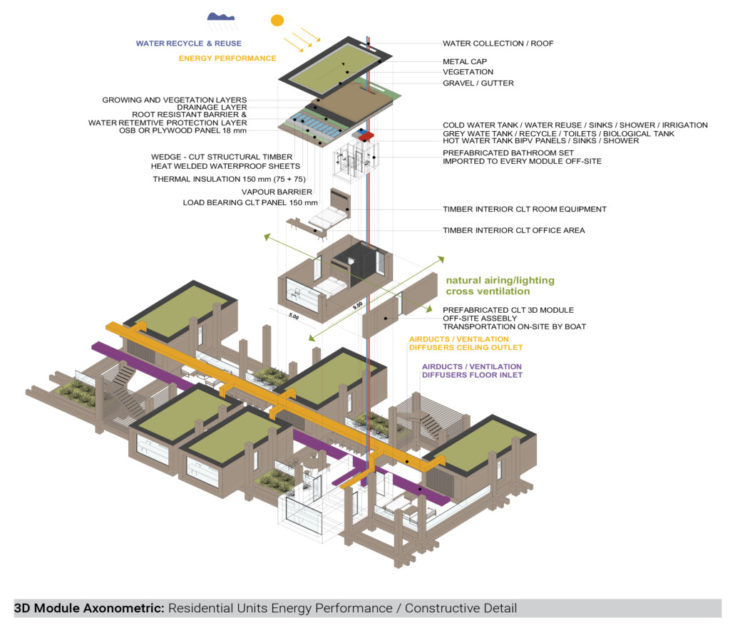

A sustainable building practice is to evaluate the use of wood components in sustainable prefabricated buildings as well as design and engineering challenges that wood can solve, discuss the advantages of building with prefabricated wood components in terms of speed and efficiency of construction, design flexibility, waste reduction, environmental performance, and improved life safety, while analyzing, through case studies, the different stages of wood building. In our case, we use water collection from roofs and terraces and reuse it for sinks, showers, and as reimported greywater for toilets. Inlet and outlet diffusers help maintain the microclimate for ventilation and air distribution. On the roof, there is an installation of BIPV Photovoltaic cells which are connected with the red water tanks to heat water for daily use. Green roofs enhance microclimate as well as the South East and South West orientations of residential units have the best performance regarding energy consumption and natural daylighting, while natural cross-ventilation and airing of each space of the residential units create a better energy performance of the housing complex.

Modular construction requires a significant shift in mindset and methods—not to mention the need to establish manufacturing environments. But it can be used to build aesthetically pleasing, sound structures—and deliver considerable efficiencies along the way.

Off-Site Manufacture (OSM)

Off-site manufacture is the manufacture of construction components or systems in a factory environment to be transported and assembled on-site.

Prefabricated (Pre-Fab Construction)

Prefabrication can cover off-site prefabrication of materials and parts, prefabrication of components and subassemblies as well as volumetric units or modules.

Modular Construction

Modularization of construction is a way to reduce complexity but still offer customized solutions. The Modular Building Institute defines modular construction as an off-site process performed in a factory setting, yielding three-dimensional modules that are transported and assembled at the building’s final location.

The programmatic exploded analysis shows the distribution of areas. With red color are shown the public spaces of the ground floor level of the bridge as well as the vertical connection of the cylindrical volume to reach the 4th level of the cafe/restaurant and the open-air cinema. On the roof, there is an installation of BIPV Photovoltaic cells to maintain the energy efficiency of the residential complex. The X32 3D Volumetrics residential units are developed at the 3 levels between offering views of the canal. 3D volumetric solutions are fully fitted-out units, which could constitute a room or part of a room, that can be assembled onsite like a series of Lego bricks. Onsite assembly involves lifting the modules into place and connecting services such as electrical and plumbing. Most of the work is done in a manufacturing facility offsite. A 3D volumetric approach delivers the potential for maximum efficiencies and time savings—but the trade-offs include transportation costs and size limitations. The maximum width for road transport that does not require a police escort is typically around 3.5 meters, but in our case, the size of 5m will be transported by ship to Venice. This either increases the cost of transporting larger units or limits the size of modules, making 3D volumetric most suitable for hotels, hostels, or affordable housing. It is also advantageous for rooms with more intricate finishing, particularly wet rooms such as bathrooms and kitchens. A 3D volumetric approach is most suitable for projects with a high level of repeatability and a high ratio of wet to dry rooms. It should be noted that repeatability does not mean all products need to look the same. Instead, a variety of standardized modules can be pieced together differently to produce a customized end result.

It is also possible to use a mix of 3D modules and 2D panels on a project or to combine those approaches with traditional site work (for instance, for the basement and first floor of a larger project). Typically, wet areas are manufactured as bathroom pods, while the remainder of the building is made from 2D panels. This optimizes the process for the two different areas of the building, bringing high-productivity improvements to the bathroom areas and maximum flexibility to all other areas. However, the manufacturing process required to deliver both solutions becomes more complex, as does the coordination of the supply chain. When evaluating the difference between these three options for an affordable housing unit of four floors, for instance, we found that a 2D solution could be 17 percent cheaper than a traditional approach, while a 2D and 3D hybrid solution lowers costs by 20 percent, and a 3D solution by 24 percent. This would vary by project, but these estimates indicate the scale of potential savings.

Modular construction can cut schedule by 20–50 percent and construction costs by 20 percent.

—

Bridge – Mass Timber Collective Housing is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Mass Timber Design in 2021/2022 by Student: Alexandros Kitriniaris. Faculty: Minna Riska, Dagfinn Sagen. Course: Project 2