“I do not want art for a few, any more than education for a few, or freedom for a few.”

(The Decorative Arts: Their Relation to Modern Life and Progress. )

William Morris

In recent years additive manufacturing has increasingly influenced industrial production and the way we manufacture products.

This paper aims to investigate the impact of AM in creating ceramic coatings and ornaments, explaining how, on the one hand, the renewed interest in ornaments and decoration after Modernism and the development of additive technologies for production on the other, can give new life to a productive sector halfway between industry and craftsmanship fabricating pices of high aesthetic value at an affordable price.

Ceramic 3D printing, together with polymers and metals three dimensional printing, are now the latest trends under the spotlight.

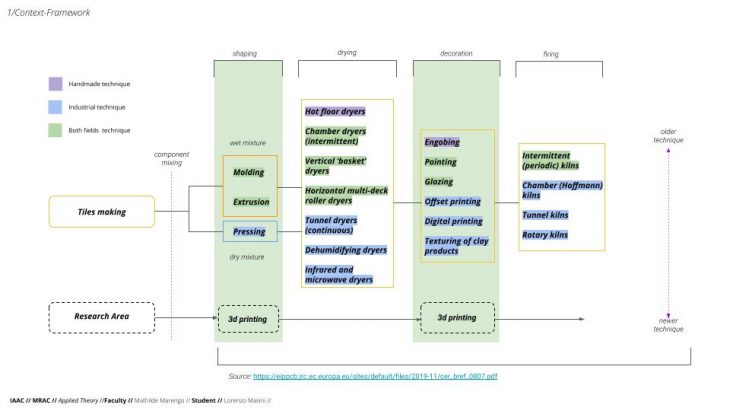

Thanks to the various excellent properties aforementioned, ceramics can be used in a wide range of applications, including chemical industry, machinery, electronics, aerospace and biomedical engineering. As a matter of fact 3D printing, also known as additive manufacturing (AM), has rapidly gained attention across the science and engineering communities since the 1980s, when it first emerged, and is now regarded as the true manufacturing evolution. Starting from a 3D CAD model digitally sliced into 2D cross sections, these new technologies are able to fabricate physical parts in a point-by-point, line-by-line or layer-by-layer additive manner that are difficult to realise using traditional fabrication methods such as casting and machining. Productivity also can be significantly increased thanks to AM as many units can be made in a single run. Nowadays, with the progress in materials and computer science, a variety of 3D printing technologies have been developed just for ceramic manufacturing. Depending on the form of the pre-processed feedstock, these technologies can be categorised into: slurry-based, powder-based and bulk solid-based methods. To date among the various technologies developed, Direct ink writing is the most widely spread in the field of coatings and ornaments in architecture, in terms of features and costs.