152 Travessera de Gràcia

CONTEXT

152 Travessera de Gracia project is an earth 3d printed high building located in Gracia, a high density neighborhood in Barcelona.

3D printing earth offers a rapid construction process and the freedom to address specific challenges unique to each site. The proximity to the material, possibility to recycle, and the precision of the technology make it a more sustainable construction process.

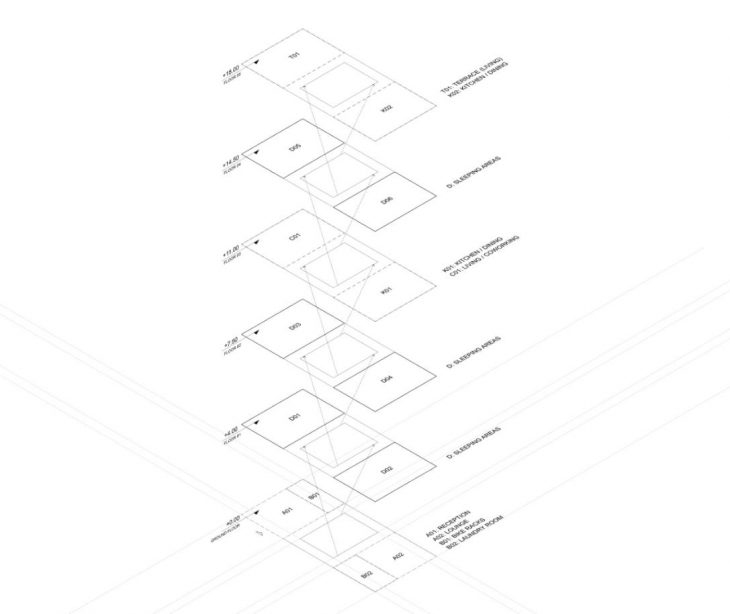

PROGRAM

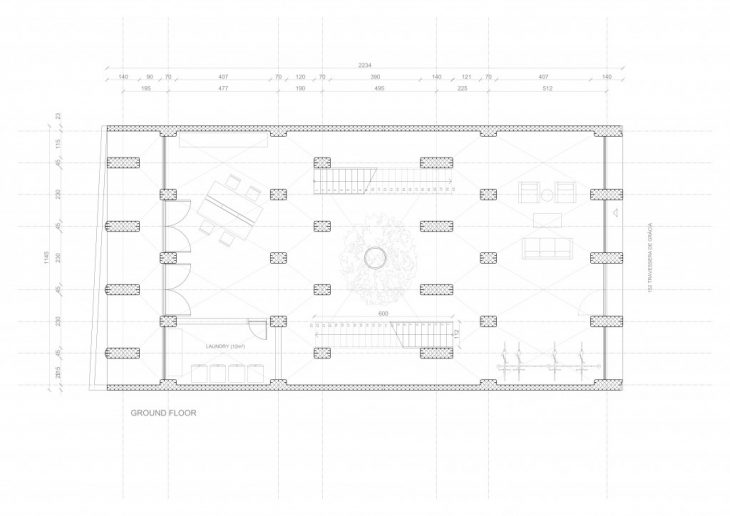

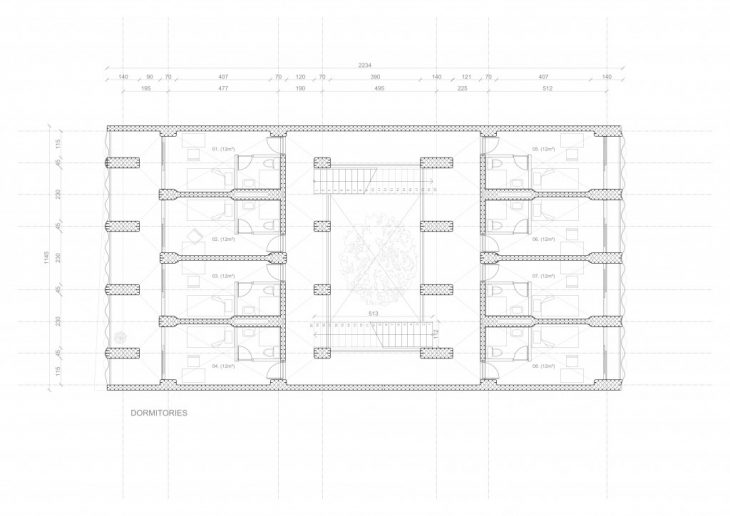

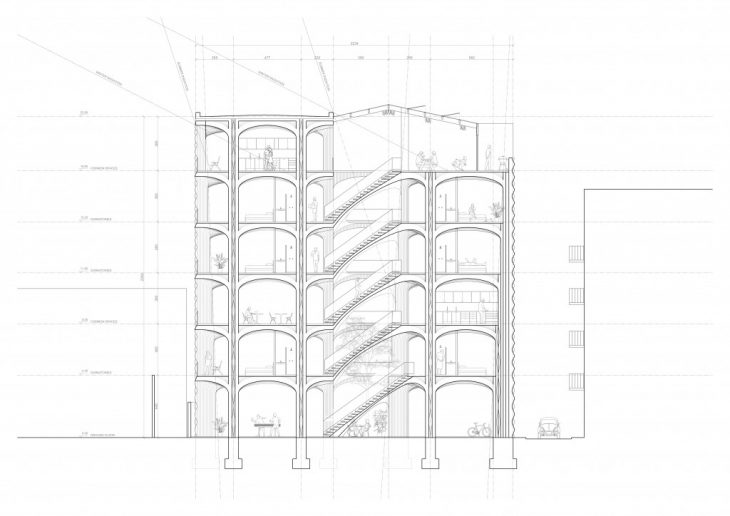

Barcelona is a city with an intense flow of students and workers seeking affordable and flexible housing conditions. This project provides housing for 28 students, with 28 dormitories distributed vertically in a 6 storey high building in the heart of gracia.

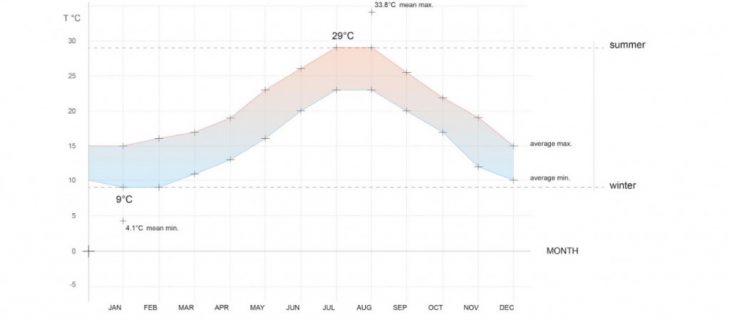

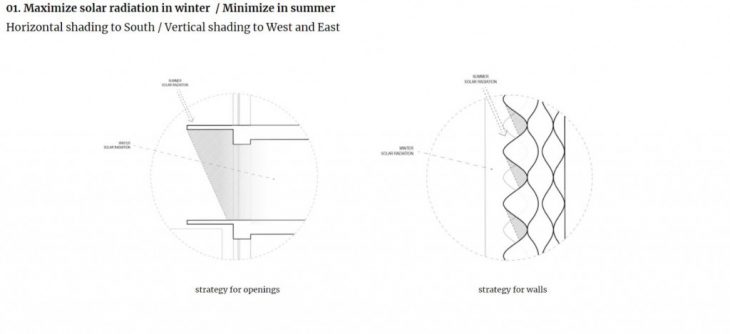

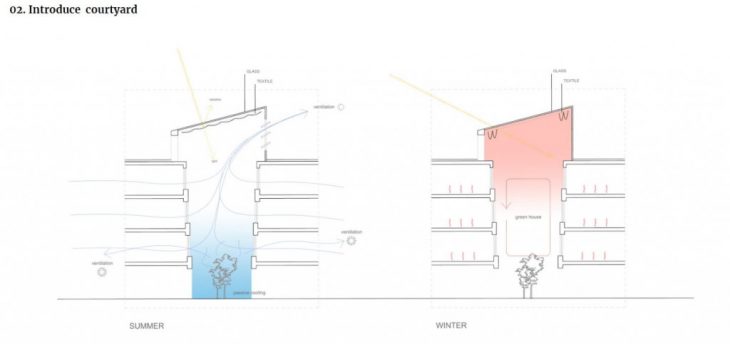

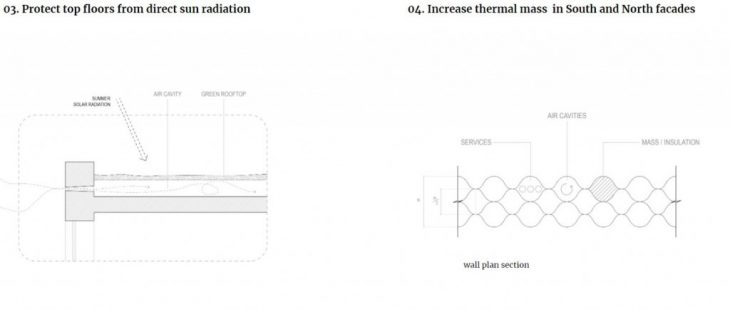

CLIMATIC STRATEGIES

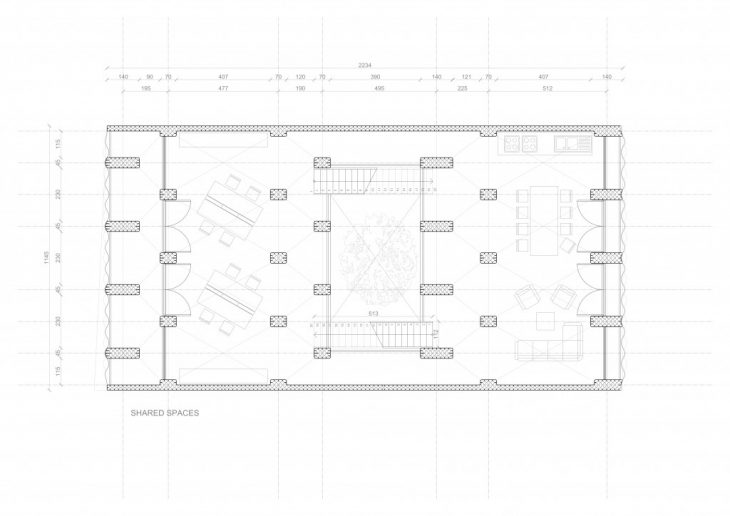

The biggest challenge when building in a Mediterranean climate is the different temperatures between summer and winter, and during day and night. To respond to these challenges, the project integrates different climatic strategies.

STRUCTURAL SYSTEM

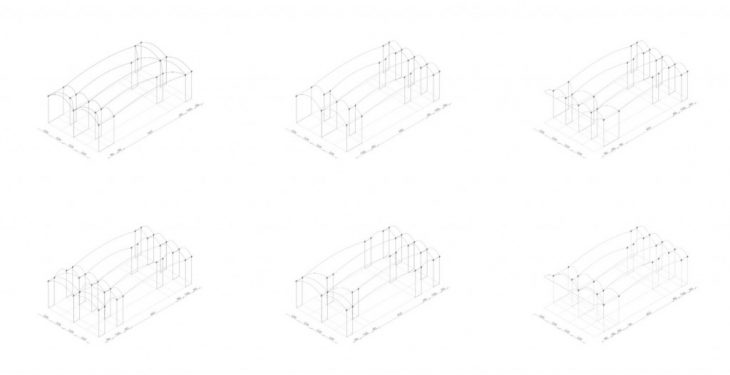

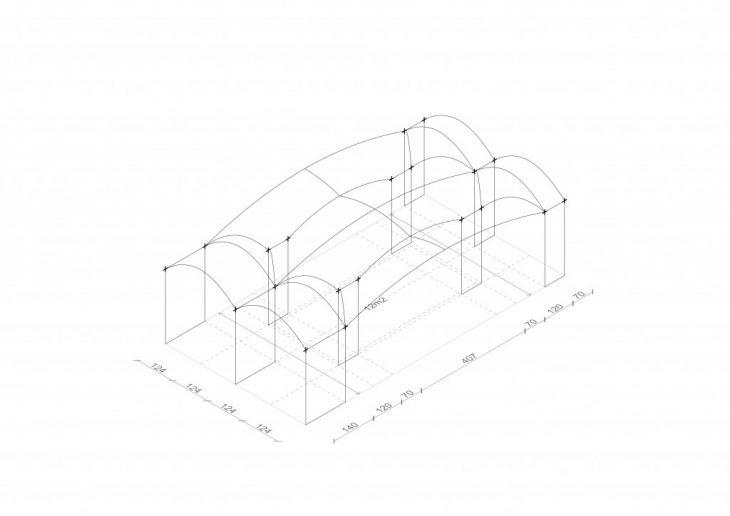

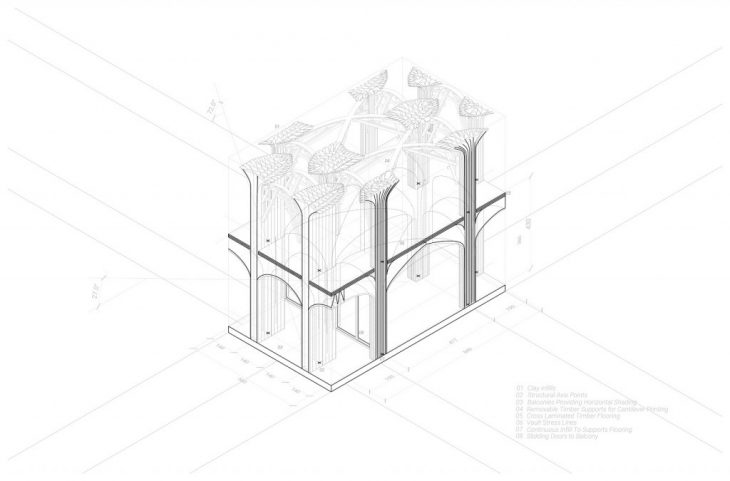

The structure of the building is based on a scheme of 3d printed horizontal and vertical elements. In most cases so far, given the limitations of 3d printing with clay, it has been limited to vertical extrusions. The support system derived from the research project allows us to print with cantilevers, and by doing that generating floor plans that can be explored in a building. Using a support system as such generates a typology which becomes unique to the technology and offers rich spatial experiences.

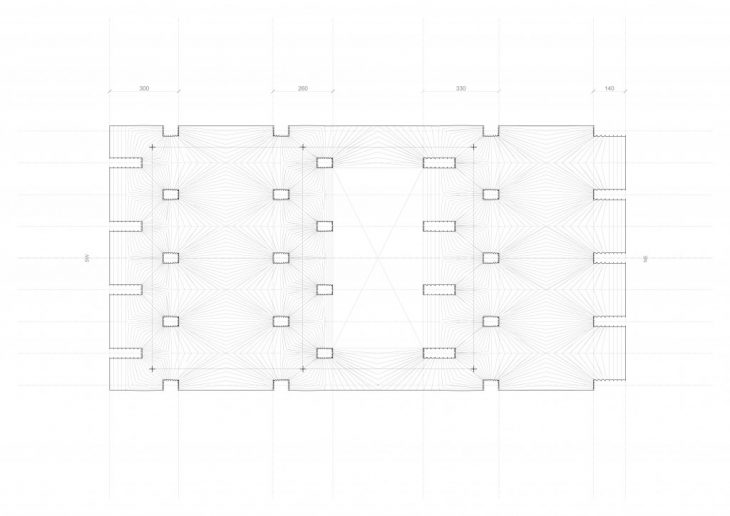

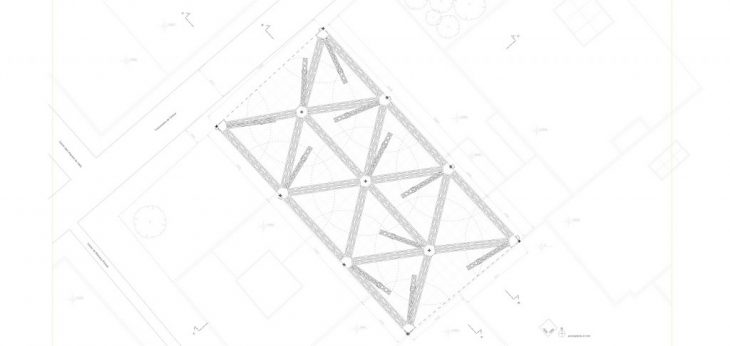

The final configuration of vaults and columns is selected to reduce the structural span, but creating spaces within columns that can accommodate an individual dormitory of around 12m square. The triangulation of the columns also opens the facades of the floorplan to circulation. The structural lines are generated by the vaults, branching from the columns. The displacement of these columns creates 4 structural segments. These segments respond to structure by reducing span while maintaining open spaces, but also tackle climatic issues by reducing the solar radiation entering the building specifically in summer, and allowing circulation around the courtyard and through the south facade.

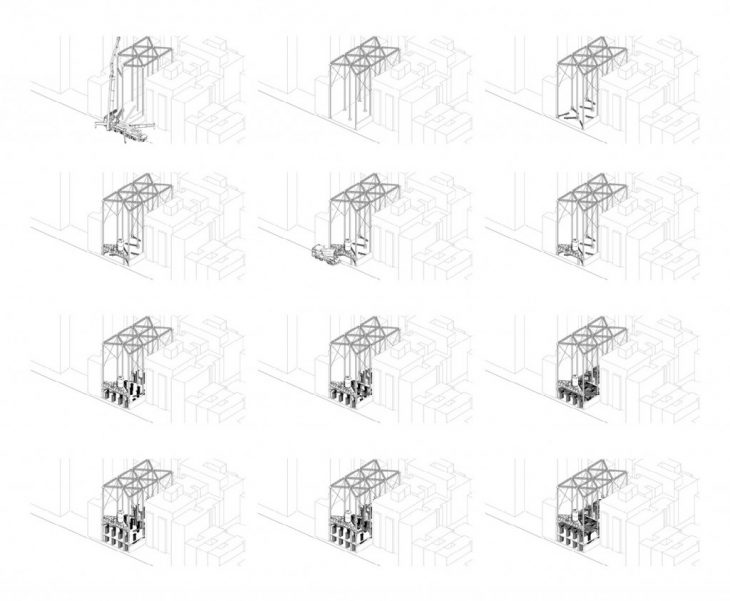

TECHNOLOGY

Crane WASP 3d printer is a modular 3D printing system. It reinterprets the classic building cranes.. It is composed of multiple synchronized units which can print simultaneously. Given its modularity and the constraints of the site, the machine was modified increasing the span and height of the machine to ensure its suitability for the site.

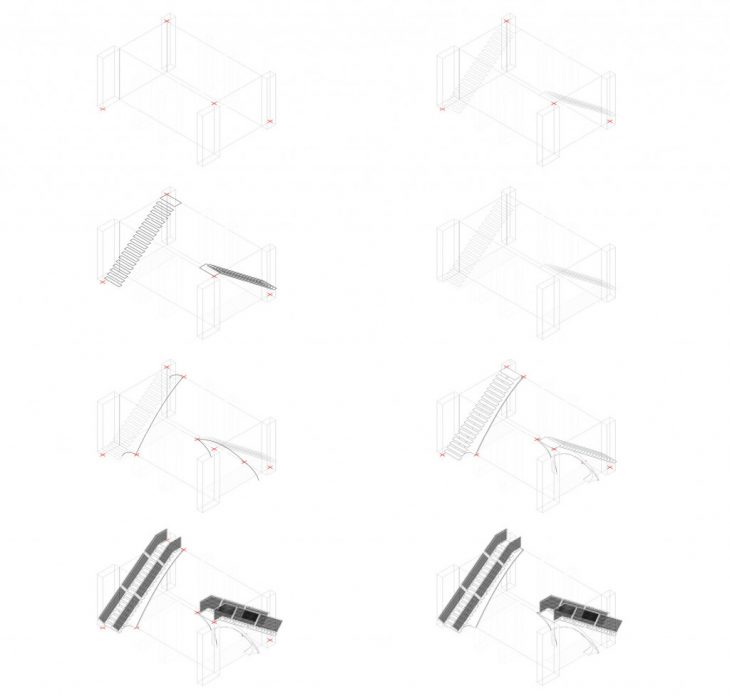

STAIRCASE

A central staircase integrates circulation, ventilation and light around the courtyard. The staircase also serves to provide structure through the vertical perforation of the building. Multiple iterations investigate the staircases in the courtyard and what it means to 3d print it, and how it connects to the structure.

The final staircase is connected to the columns on the edges of the courtyard in order to minimize the obstruction of light and ventilation. From the points and the lines of the vaults on both floors, we draw a surface which is 3d printed and offers support for the steps. These surfaces tie into the columns further rigidifying it.

CONSTRUCTION SEQUENCE

The printing process would be rather continuous with stops only to remove and reinsert the supports. When printing with earth, a rule of thumb from Wasp is to print 30cm a day which means a building such as this one would take 75 days to complete. It would be necessary for an operator to supervise the process while other teams such as programmers, carpenters and engineers would be working.

FLOORPLATES

SECTION

The section integrates climatic strategies with the vaults structural system and showcases the vertical distribution of the program, standard floor plates with individual dormitories, intercalated floor plates with shared spaces. In addition, a reduction on the size of the thicker columns from bottom to top, responding to the loads they receive. The same strategy is used to create a tapering of the interior south facade. The sun radiation informs the facades, the balconies to the south allowing sun inside the dormitories during winter, and blocking the sun during summer.

STRUCTURAL MODULE

The outcome of responding to the climate, technology and structural system the project provides is an ideal living scenario for students in Barcelona. With the use of a support system, a new architectural language is developed, enabling horizontal and continuous printing.

152 Travessera de Gràcia is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Open Thesis Fabrication in 2020/2021 by Students: Bruno Ganem Coutinho, Francesco Polvi and Zackary Bryson. Faculty: Edouard Cabay, Alexander Dubor, Kunaljit Chadha, Ashkan Foroughi Dehnavi