W4 – Seminar Workshop – Robotic Fabrication

< Fo_Arm_It >

Faculty: Kunaljit Chadha

SYLLABUS

SYLLABUS

<Fo_Arm_It> is a two semester long seminar which focuses on relation of design with old and new industrial manufacturing processes.

CNC machines were introduced in the middle 20th century into industry, changing the conception of the production of objects and hardware of machinery , majorly in the automotive industries.Recent advancements in CAD / CAM softwares has given a new identity to manufacturing and has compelled other fields to incorporate them for various enterprises.

The relation between machines and fabrication has always allured architects owing to its flexibility to mass customisation. This calls for a structured workflow from design to production.Hence, the focus on intelligent construction is desirable.

AIMS

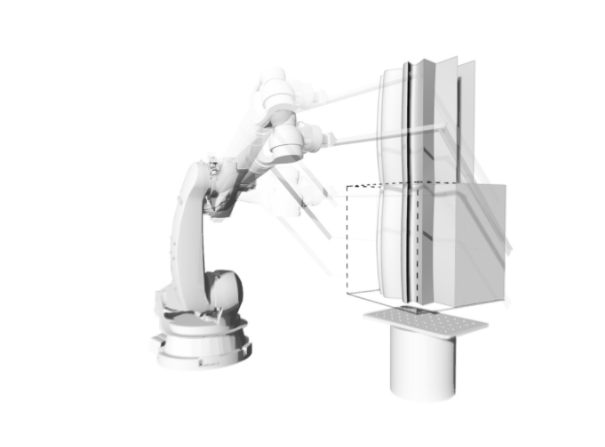

The aim of the seminar is to dumb down an industrial process of subtracting manufacturing in the first phase to understand and define workflow of of the manufacturing technique.The second phase involves usage of an industrial process to manufacture a prototype with mass customized components.This seminar is to explore design opportunities with six axes machining arising from two different processes of pre-profiled hot-wire cutting and CNC milling .The assignments will be ranging from designing a customised end-effector on the robot to using an existing industrial techniques.

By the end of the seminar, students will be well versed with the workflow from parametric modelling to production using the robot.This would allow students to integrate this knowledge in this respective studio projects.

EXERCISE

The first phase of the seminar would deal with designing a new pre-profiled hot wire section to attain a particular geometry with six axis tool path.The second phase of the workshop will be a team project where everyone will have a choice to elect a particular aspect in the project.The students are experience to:

– Creative tooling

– Fabrication with precise machining

Foam and end effectors will be provided by IAAC.

METHODOLOGY

The course will be divided into two 3 day workshops.

WORKSHOP Phase 02

The second workshop will be dealing with a specific topic about smart manufacturing. The students would learn:

– Master 6 axis machining for smart subtractive manufacturing

– Deal with the logistics and management of the project

– Understanding the vision of these processes for large scale manufacturing.

This phase of the workshop will be focused on a group project focusing freeform space frame structure.Assignment will be focused around smart construction of fabricating stable volume with an optimised material usage.

OUTCOME

– A final prototype installed in IAAC Atelier P59

– The workshop will conclude with a 100 word written document along with a presentation combining the knowledge from both the phases showing individual perception of these robotic processes.

– Blogpost