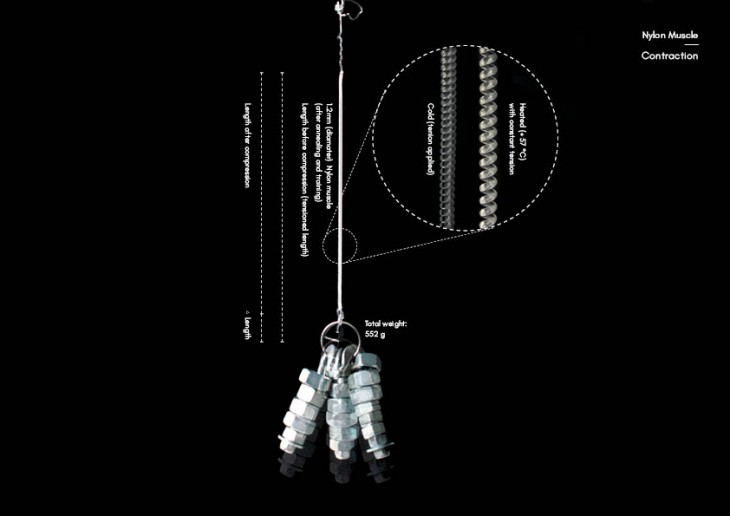

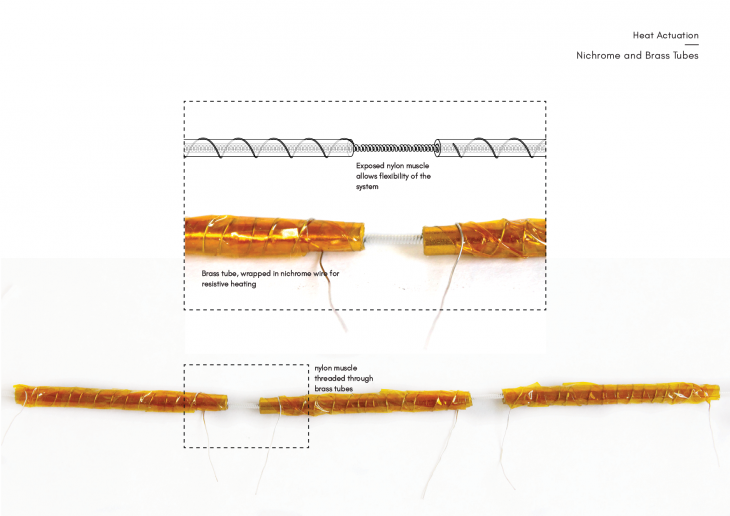

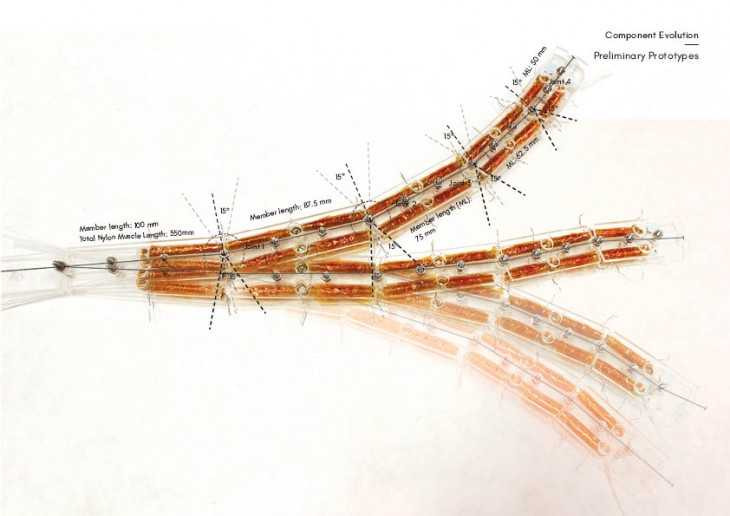

maNYforms explores the idea of a employing a unique smart material that can be created out of everyday objects onto an architectural system that is easily replicable anywhere on site. Heat actuated nylon muscles are cheap and quick to make, and have the capability to be produced en masse, for systems employing their character at various scales. Changing the parameters, or hacking the fabrication process results in a vast array of springs with different properties, suited for different tasks.

maNYforms explores the idea of a employing a unique smart material that can be created out of everyday objects onto an architectural system that is easily replicable anywhere on site. Heat actuated nylon muscles are cheap and quick to make, and have the capability to be produced en masse, for systems employing their character at various scales. Changing the parameters, or hacking the fabrication process results in a vast array of springs with different properties, suited for different tasks.

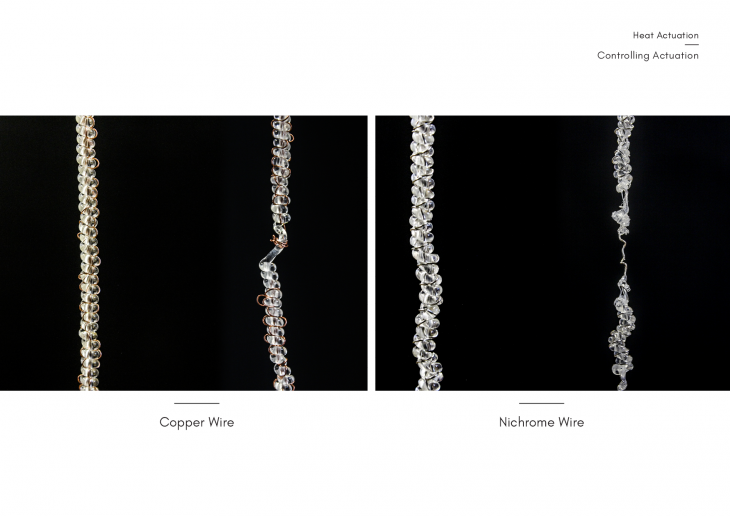

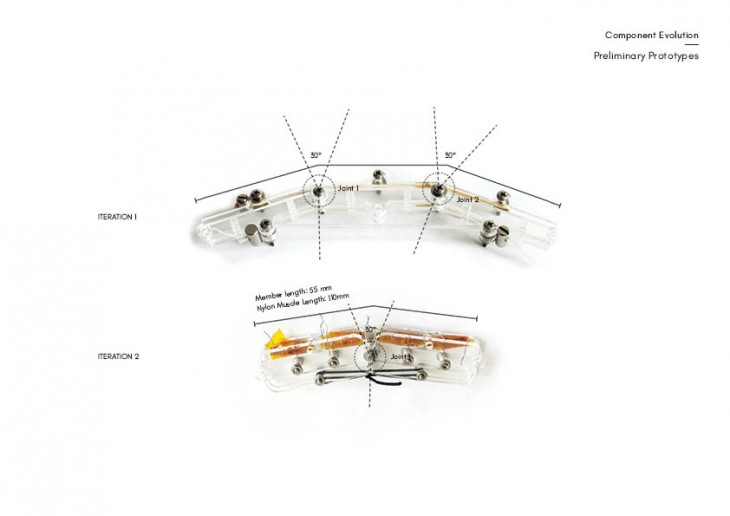

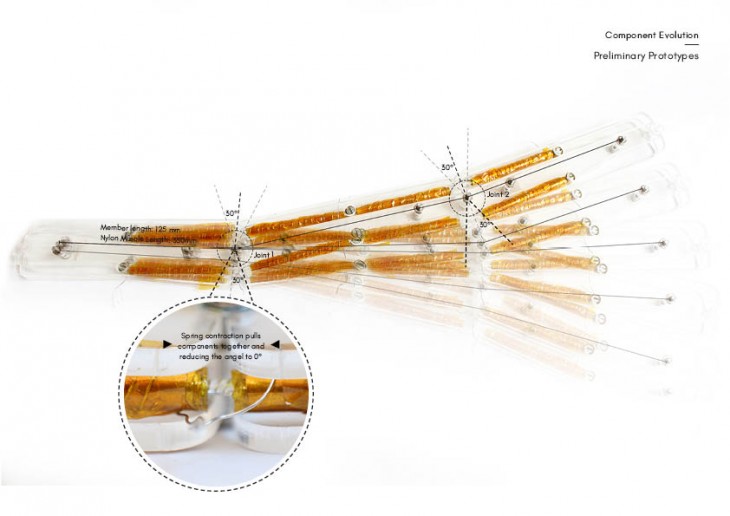

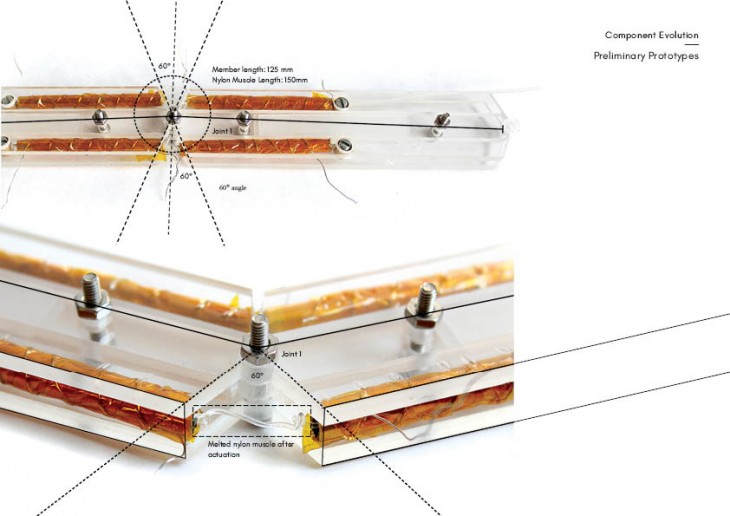

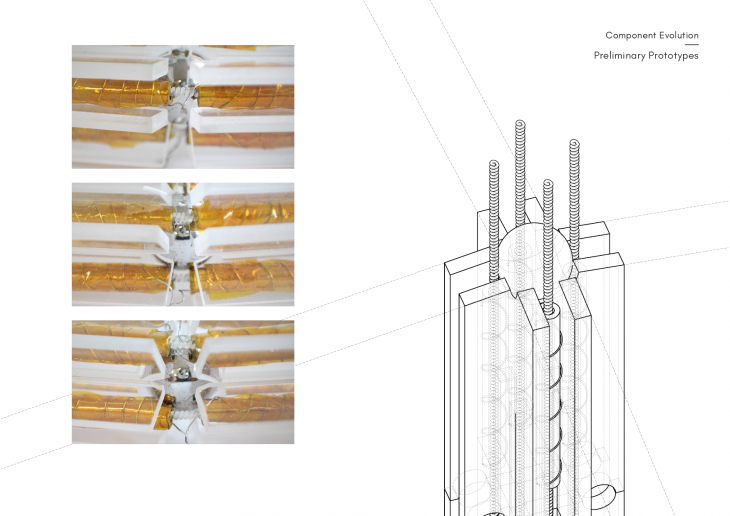

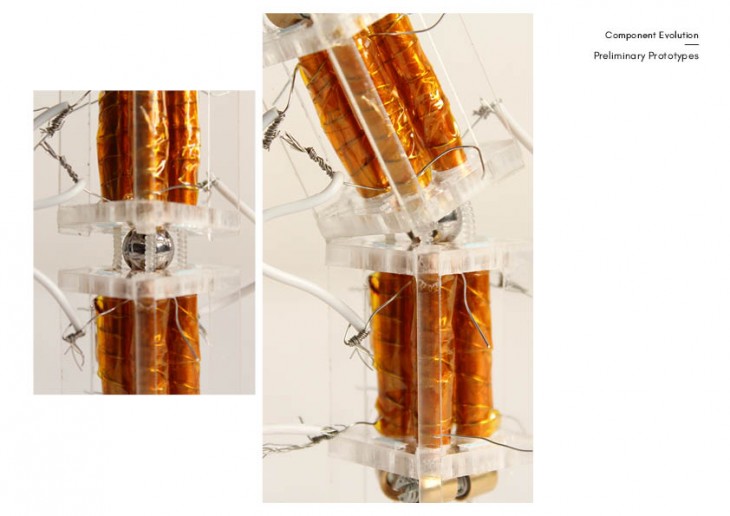

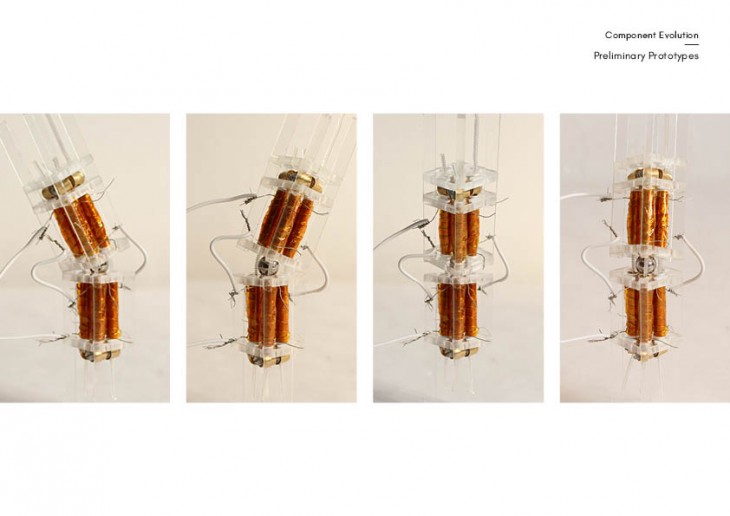

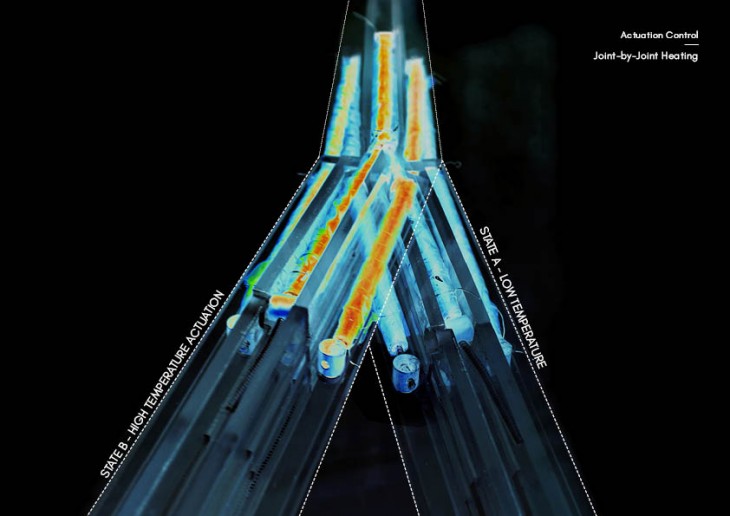

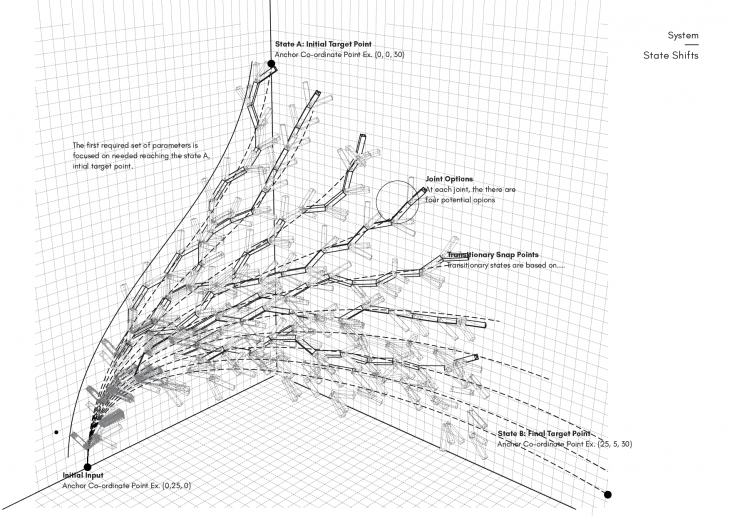

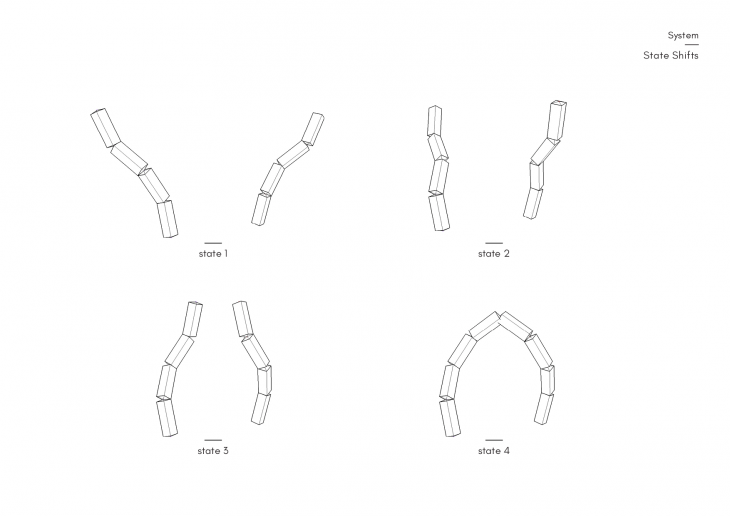

Actuated at 60-75°C, these muscles contract by up to 10% and are capable of carrying 700 times their own weight and have no reported loss of strength over multiple cycles, thereby making them ideal to use on an architectural scale. Since one of the preconditions for actuating these springs is a calibrated amount of tension, ma[ny]forms explores systems that work with a careful counterbalancing of forces by pairing the springs so they tense each other, and create movement when one is actuated. While optimizing the amount of work the muscle has to do, such systems add the capability to create a member that can be aggregated to twist, turn and lift – much like the human spine – in multiple axes and directions.

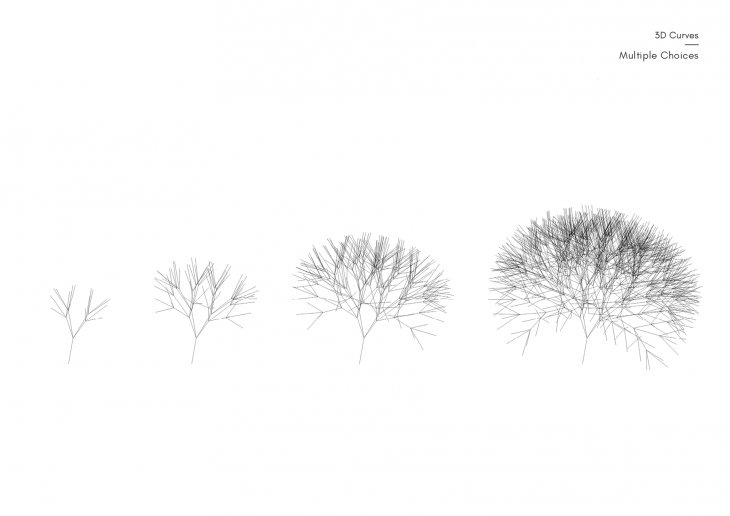

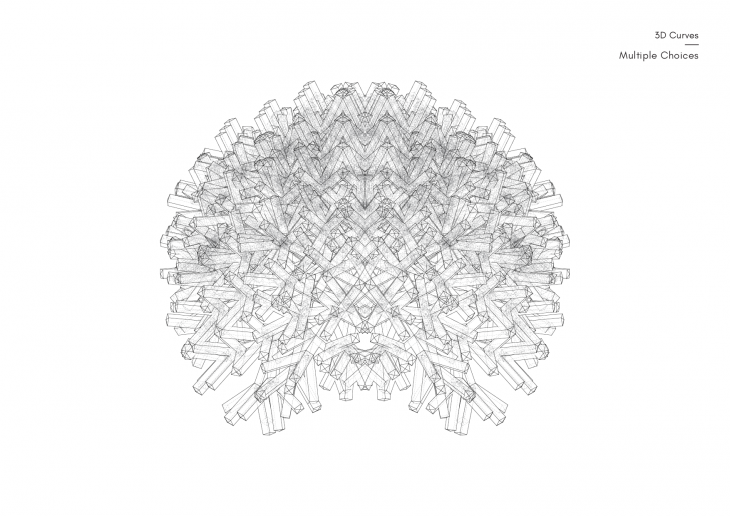

These can then create shape-shifting systems which can be controlled to span across spaces in a dynamic and configurable fashion, allowing a large degree of control over the creation, construction and use of these systems.

The phenomenal scalability that this material provides has been used to form different parts of the system. We can create members that can be carriers of compression or tension to form a larger dynamic system. The force flows that are created can be relayed live to tiny elements which hold the main struts together to create a dynamic system that feeds back on data from its own structural state, thus creating systems that are not only dynamic, but configurable to the extent of being capable of handling the fluctuating forces generated in dynamic architecture.

maNYforms is more than a product, it suggests a larger idea that can enable dynamic architecture systems at varying scales, over millions of cycles with a fabrication process that can be taken to any location, facilitating configurable, manipulated architecture.

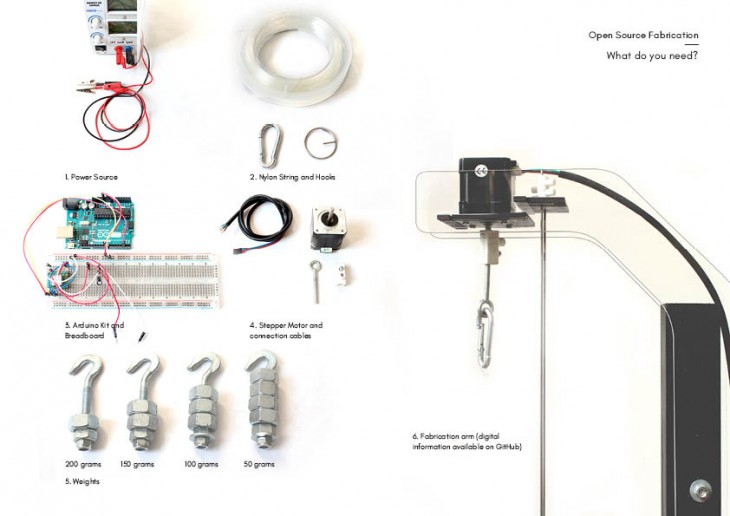

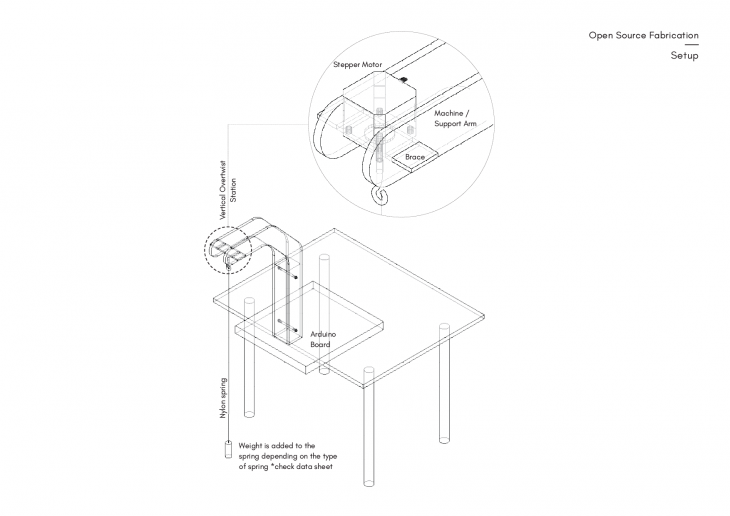

Fabrication Methodology

Actuation

Actuation

Component Evolution

System Explorations

Future Potential

maNYforms is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2016 by:

Students: Utsav Mathur, Jean Sebastian Munera and Connor Stevens

Faculty: Areti Markopoulou

Faculty Assistants: Alexander Dubor and Angelos Chronis