BANDSAWN CURVED LUMBER

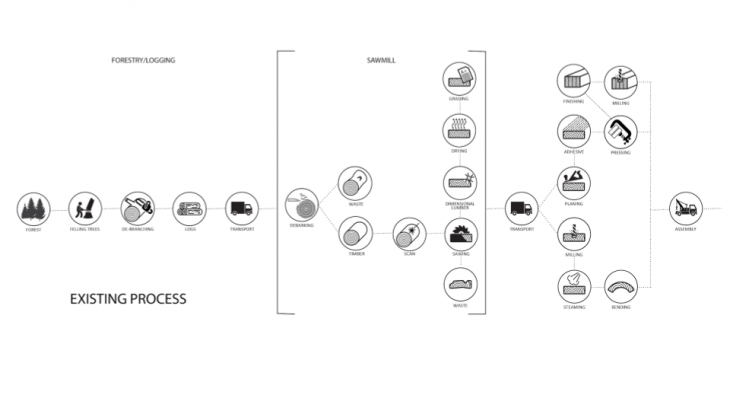

CONTEXT :

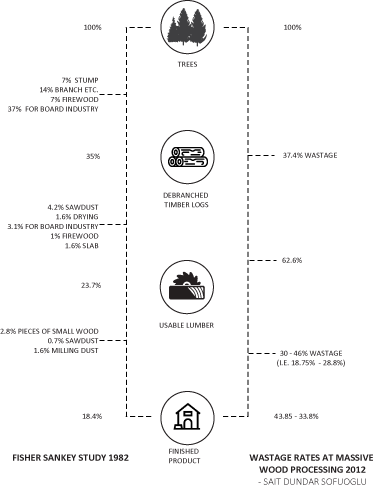

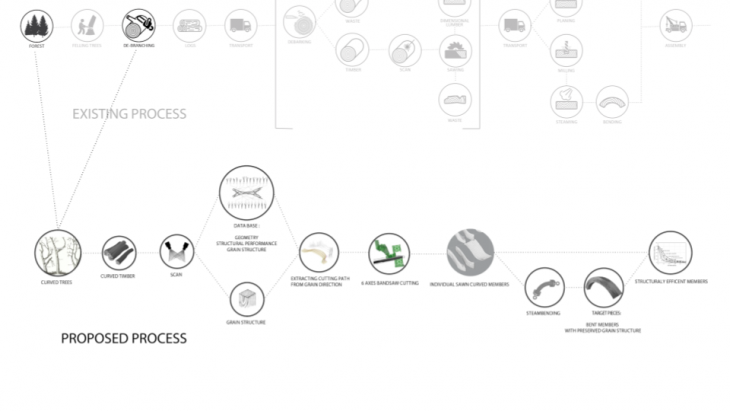

Understanding the wastage pattern from tree to lumber was key to developing the hypothesis for the project. Early studies conducted in 1982 showed that almost 80% of the tree was lost during the processing of the finished wooden product from a tree. Most recent studies pegged this number between 56 – 66%. This is primarily due to advancements of technology. Given that these figures are for straight trees, the number is expected to be far greater curved and crooked trees.

HYPOTHESIS

Can we introduce non-laminated structural lumber elements that are stronger and lighter than traditional curved wood members with the use of robotic fabrication informed by the material properties of wood?

MATERIAL PROPERTIES

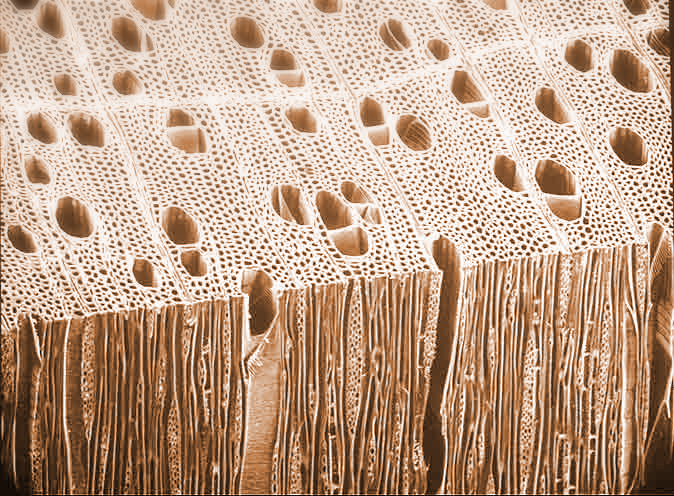

Wood is fibrous material, and the fibers are arranged in a matrix defining the directionality of the structure.

The wood grows following the stem, and the fibers are aligned parallel to the direction of growth. And as it grows it also grows outwards with different thicknesses of layers.

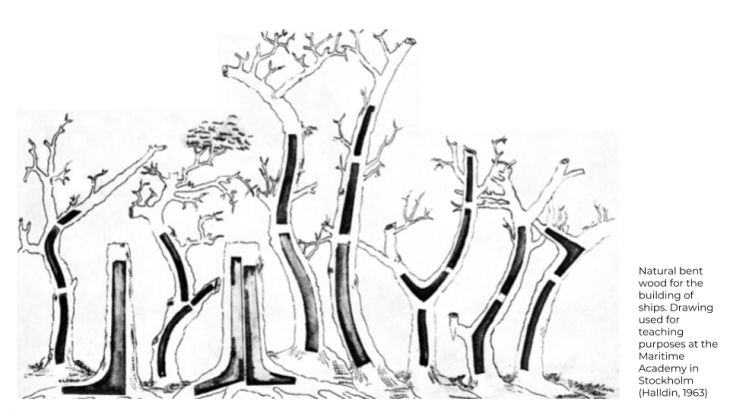

Change of topology of the grains happen in bifurcations by interlocking grains, Which is a counteracting mechanism from the tree to resist forces acting upon it.

Grain pattern responds to external forces, resulting in different grain grow patterns. (ex. Reaction wood)

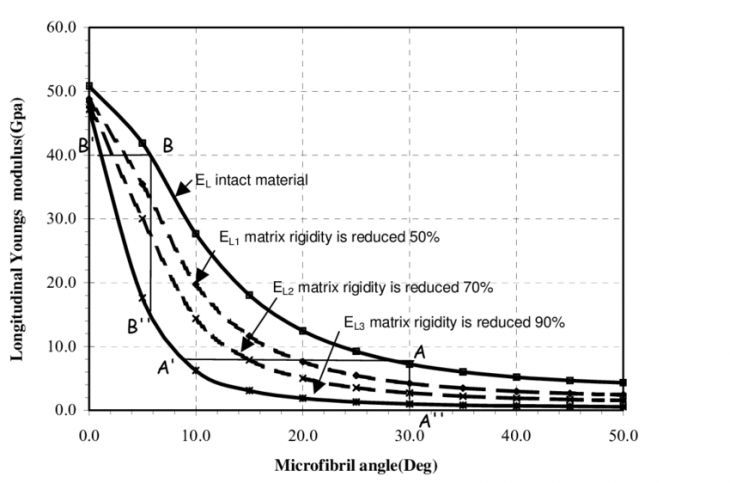

STRUCTURAL PERFORMANCE OF WOOD

Structural performance of the wood is relative to the orientation of the fibers, and the angle of the load. So the wood is strongest if the loads are in the direction of the fibers.

TENSION WOOD AND COMPRESSION WOOD:

Any tree of any age will form reaction wood when the woody organ (whether a twig, branch, or the trunk) is deflected from the vertical by more than one or two degrees.

This means that all non-vertical branches form considerable quantities of reaction wood. The type of reaction wood formed by a tree differs in softwoods and hardwoods. In softwoods, the reaction wood is formed on the underside of the leaning organ and is called compression wood. In hardwoods, the reaction wood forms on the top side of the leaning organ and is called tension wood.

In tension wood, the fibers fail to form a proper secondary wall and instead form a highly cellulosic wall layer called the G layer, or gelatinous layer.

In compression wood, the tracheids are shorter, misshapen cells with a large S2 microfibril angle, a high degree of longitudinal shrinkage, and high lignin content.

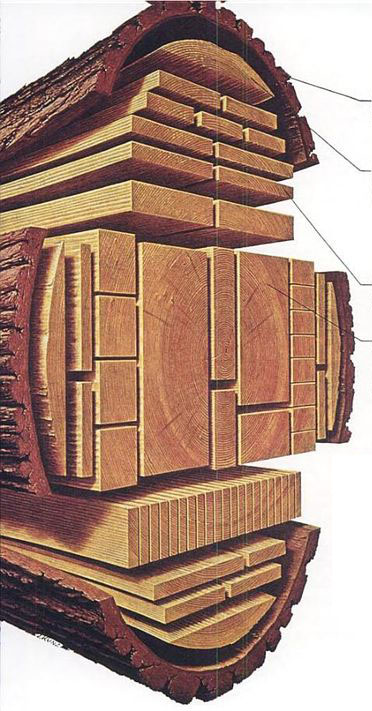

CUTTING PATTERN

PLAINSAWN

– Shrinks and swells less in thickness.

– Surface appearance less affected by round or oval knots compared to effect of spike knots in quartersawn boards; boards with round or oval knots not as weak as boards with spike knots.

– Shakes and pitch pockets, when present, extend through fewer boards.

– Figure patterns resulting from annual rings and some other types of figure brought out more conspicuously.

– Is less susceptible to collapse in drying.

– Costs less because it is easy to obtain.

QUARTERSAWN

– Shrinks and swells less in width.

– Cups, surface-checks, and splits less in seasoning and in use.

– Raised grain caused by separation in annual rings does not become as pronounced.

– Figure patterns resulting from pronounced rays, interlocked grain, and wavy grain are brought out more conspicuously.

– Does not allow liquids to pass through readily in some species.

– Holds paint better in some species.

– Sapwood appears in boards at edges and its width is limited by the width of the log.

CASE STUDIES :

GREYSHED

Project Title: Bandsawn Bands

Dates: 2012 (Initial Research)

2014 (First Publication)

Project Lead: Ryan Luke Johns, Nicholas Foley

Status: Ongoing

This project demonstrates an innovative technique for designing and fabricating freeform surfaces within the constraints of live-edged wood flitches. By 3D scanning a naturally curved tree section and designing into the available material that they are able to unfold a compact amount of wood into a smooth, continuous topological surface (i.e. furniture or architecture).

The process utilizes a robotically operated bandsaw to cut a series of curved strips which, when rotated and laminated, can approximate doubly-curved and digitally defined geometry.

ROBOTIC WOOD TECTONICS

Project Title: ROBOTIC WOOD

TECTONICS

Dates: 2016

Project Lead: PHILIP F. YUAN , HUA CHAI

Location:

The ‘Robotic Wood Tectonics’ project of 2016

DigitalFUTURE Shanghai explored the combination of robot wire-cutting technology and traditional woodcraft to produce geometrically complex wooden elements –without the immense material consumption of a CNC milling production process – in a full-scale wood pavilion.

In this case the project utilised a robotic bandsaw to cut curved sections of glulam which where used as structural elements for the project.

TEST 1 : MANUAL TEST WITH BANDSAW

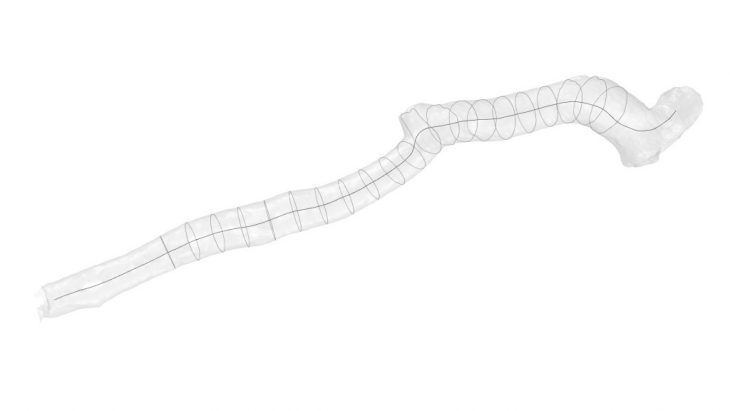

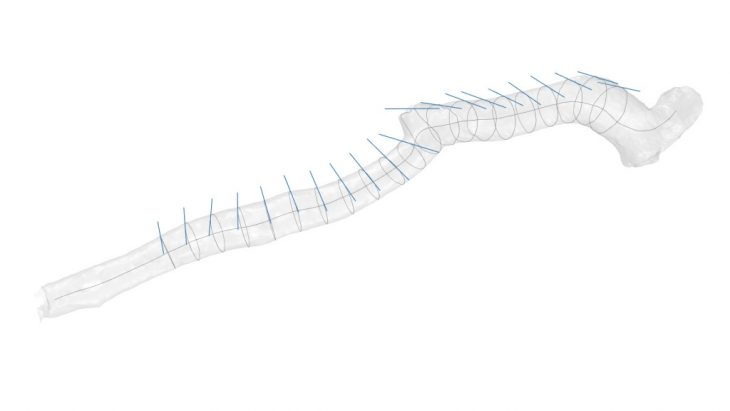

TEST 2 : MATERIAL AND GEOMETRY PRINCIPLES

SCANNING:

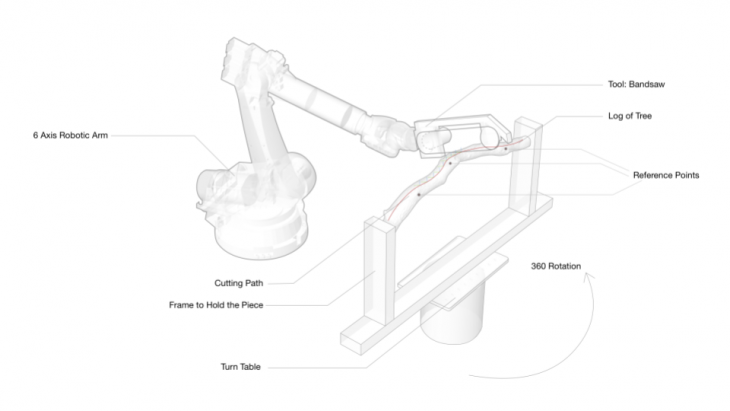

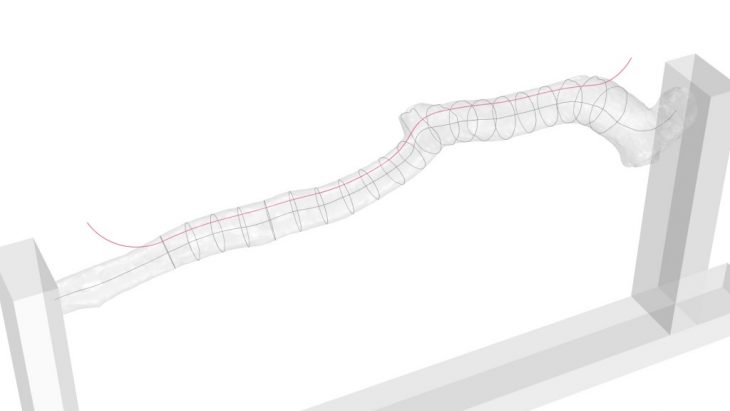

ROBOTIC SETUP

TOOL ATTACHMENT :

ROBOTIC PATH :

TEST 3:

FINAL PROTOTYPE :

STEAMING :

HEAT AND BENDING:

Reversible changes:

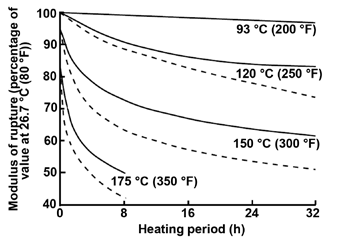

The mechanical properties of wood decrease when heated and increase when cooled. At a constant moisture content and below approximately 150 °C (302 °F), mechanical properties are approximately linearly related to temperature.

Irreversible change:

In addition to the reversible effect of temperature on wood, there is an irreversible effect at elevated temperature. This permanent effect is one of degradation of wood substance, which results in loss of weight and strength.

STEAM TEST 2: SPRING BENDING

BEFORE AFTER

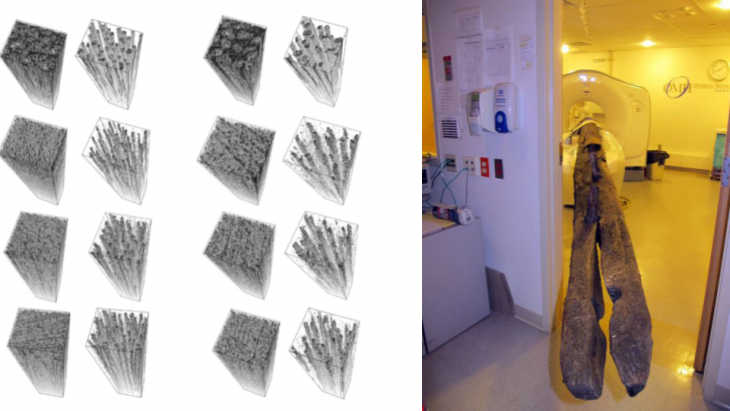

VISION : GRAIN PREDICTION

VISION : DATABASE OF THE FOREST

VISION : DATABASE OF THE CURT WOODEN PIECES

VISION : REAL TIME SCANNING AND FEEDBACK

VISION : BANDSAW VS ABRASIVE WIRE

BIBLIOGRAPHY + CREDITS :

– Walker, J. C. (2006). Primary Wood Processing: Principles and Practice.

– Hoadley, R. B. (2000). Understanding Wood: A Craftsman’s Guide to Wood Technology.

– Dinwoodie, J. M. (2000). Timber: Its nature and behaviour.

– Robotically Fabricated Wood Plate Morphologies – Tobias Schwinn, Oliver David Krieg, Achim Menges – RobArch 2012

– Rhino2krl – Tom Pawlofsky – RobArch 2012

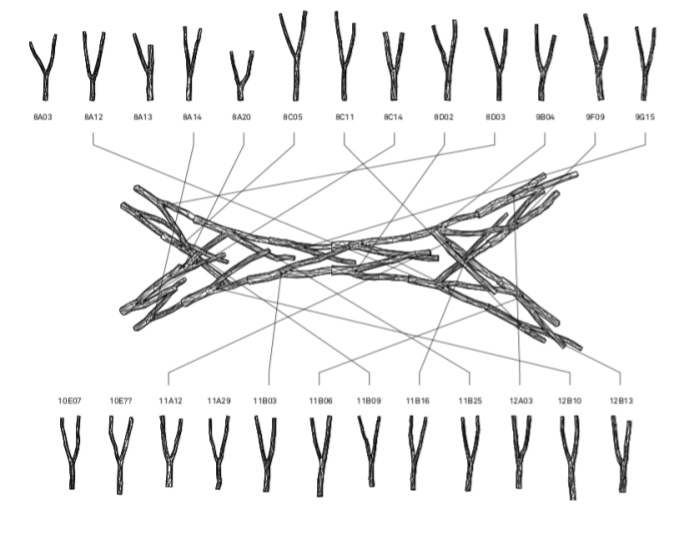

– Tree Fork Truss – Zachary Mollica and Martin Self – Advances in Architectural Geometry 2016

– X-ray micro-computed tomography in willow reveals tissue patterning of reaction wood and delay in programmed cell death – Nicholas Brereton et al. – 2015

– Vacuum Steam Technology for Rapid Plasticization and Bending of Maple – Robert S.Writght – 2011

– Designing Natural Wood Log Structures with Stochastic Assembly and Deep Learning – Kaicong Wu, Axel Kilian – RobArch 2018

BANDSAWN CURVED LUMBER is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction (M.R.A.C.) in 2018 by,

Students: Filip Biliecki, Jean Nicolas Dackiw, Soroush Garivani, Sujay Kumarji

Faculty: Dir. Alexandre Dubor, Raimund Krenmuller, Kunaljit Singh Chadha