VR Gamification // WORKSHOP 3.2

The project ‘VR Gamification’ aims to speculate about the introduction of gamification of manual labor processes. The question is if we can enhance a real-world fabrication process by the introduction of a game-like reward or score system to become more efficient? Can we bring more a more attractive work environment to processes that used to be boring repetitive tasks before? The use of an industrial robotic arm enforces many aspects of fabrication as being more precise and less likely for failures. Can we safely collaborate within a cyber-physical environment by introducing steps in which a human decision, intuition, or creativity can still be beneficial?

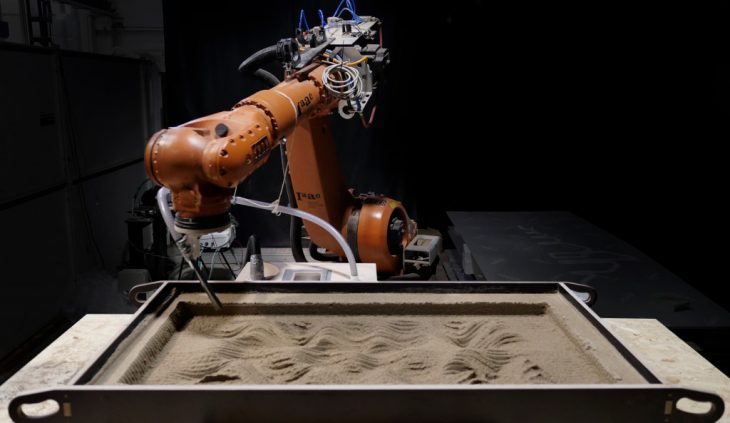

Robotic Fabrication Setup

The fabrication process we want to explore is based on the robotic setup used within our group’s 3rd term Studio Project – Sandcast. The robotic arm is used to extract from a box with compressed sand and forms a negative space used as a concrete mold for architectural scale panels.

Figure 1: Robotic Setup – Sandcast of concrete panels

Concept

The concept is based on observations made throughout the fabrication process of the sandcasts. The current robotic setup tends to be relatively slow due to certain facts, like; air-pressure of the vacuum used to extract sand, the humidity of the sand to allow for steeper designs, speed of the robot to not clog the system. While when the extraction tool is handled manually the human has an almost unbeatable perception of the speed and allowance of extraction to make sure not to clog the system.

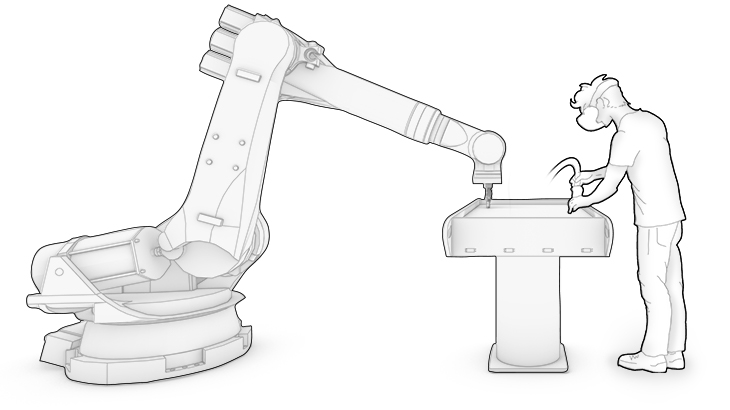

Figure 2: Fabrication Setup – Collaborative approach

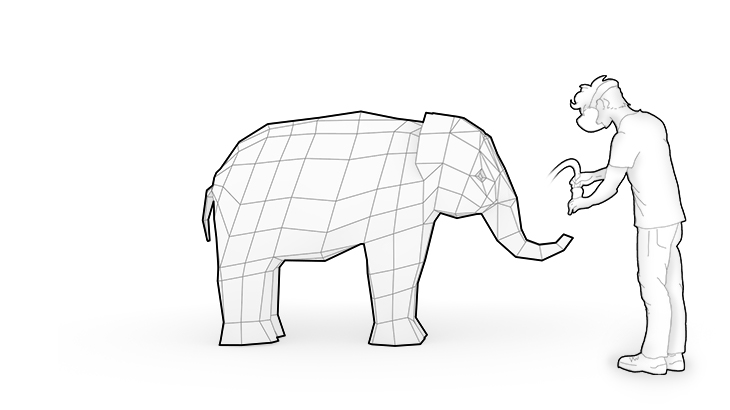

The idea is to do the roughening part (roughening = the removing of most of the sand before the final finishing) of the excavation by hand and use the robot only for the precise placement of contours and patterns which will be visible on the concrete panels once. This Sandcast project is ongoing and those roughening jobs need to be done for the fabrication of the prototypes in any case. Why not make the process fun and enjoyable? We came up with the idea to replace the robot with an baby elephant in an low poly game environment.

Figure 3: Virtual Replacement of the industrial robotic arm – a low-poly baby elephant

Virtual Environment

The low poly game is composed in Unity 3D. Besides some free accessible assets, like the rigged low-poly model of the elephant, the virtual environment is an arrangement of 3D assets partly prepared in Rhino 3D.

Figure 4: Virtual Environment

Besides the use of the HTC Vive Headset, a custom tool-handle was 3D-printed to allow the attachment of an HTC Vive Tracker to interact in-game.

Figure 5: VR Headset – VR Controller – VR Tracker-with-3D-printed-attachment

First Iteration

The goal within the first iteration of the game was driven by the idea to completely detach the fabrication process and the virtual reality game. Instead of the bed of sand in front of you you would see a baby elephant and instead of extracting something you have to follow the elephants trunk to feed the baby elephant.

Figure 6: First concept – Baby elephant feeding

Final Game

The second iteration was more related to the excavation process but reinterpreted within the same virtual space. We introduced a physics engine within the game, imitating the extraction and the potential behavior of the deformation of the sand. After pressing the in-game button peanuts are dropped into a box with the negative shape of a potential concrete panel.

Figure 7: Physics engine – Peanuts

The new goal is to excavate all the peanuts with the elephant’s trunk and entirely clear out the box to reveal the shape underneath. As this process is more closely attached to the physical process of extraction, an interesting observation is, that the sand and strength needed to collect it is acting like physical feedback comparable, for example, to a pneumatic chair for racing-games simulating the movement of a car.

Figure 8: VR Setup – HTC VIVE

Conclusion

Even if the story of the second iteration of the game is closer to the fabrication process, the outcome is not yet comparable to the robotic opponent’s excavation precision. Another interesting approach for further development would be to bring in the time needed to clear an area with our excavation tool compared to the time inside of the game to clear the same area of peanuts, as this is right now not calibrated. Another interesting aspect of gamification is the development of an in-game reward system to keep the interest on continuing for a longer time, like to achieve certain goals, to include a scoreboard, etc.

Figure 9: Comparison: Virtual vs. Reality

This one-week-long experiment and in-depth introduction to Unity allowed us to broaden the spectrum of ideas on where to apply VR, AR, and tracking of tools and robotic rigs within a fabrication environment. The fact of being able to precisely probe any object within the VR rig, have the system to self-correct, and kind of understand its own position in a loop of virtual-to-reality-to-virtual enables huge opportunities for the future.

VR Gamification // W.3.2 is a project of IAAC, Institute for Advanced Architecture of Catalonia

developed at the Master in Robotics and Advanced Construction in 2021 by:

Students: Hendrik Benz, Alberto Browne

Faculty: Ryan Luke Johns, Jeffrey Anderson

Faculty Assistant: Daniil Koshelyuk, Soroush Garivani

Workshop Participants: Shahar Abelson, Hendrik Benz, Alberto Browne, Charng Shin Chen, Michael DiCarlo, Helena Homsi, Arpan Mathe, Juan E. Ojeda, Orestis Pavlidis, Aslinur Taskin.