VOIDS

Objective:

To design a mould to cast six plaster bricks, using the CNC Machine, that would form part of a larger wall. The theme for the brick is privacy and the density is 60 percent solid, 40 percent void. Moreover, the collection of bricks needs to comply with the different structural issues when they are placed inside the general wall.

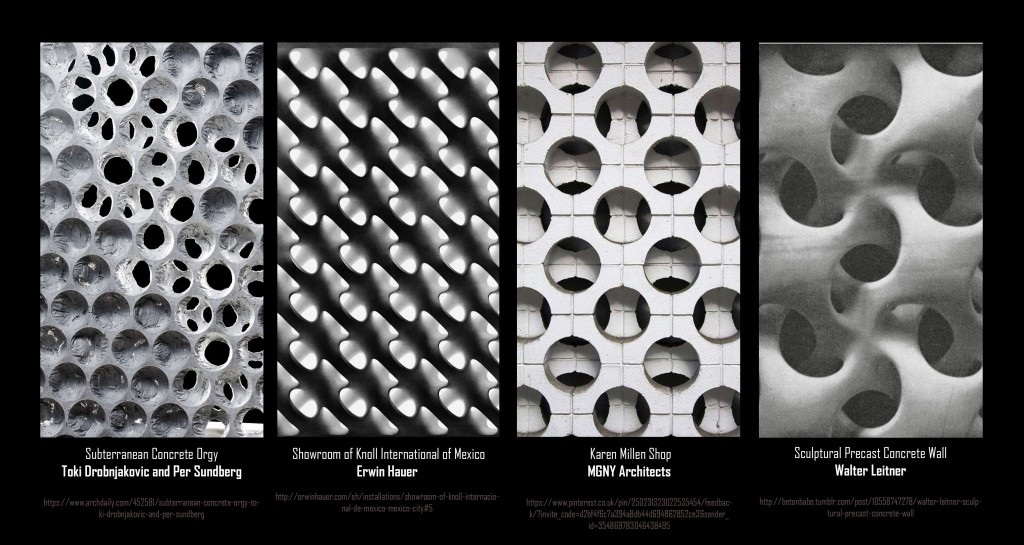

Inspiration and Concept:

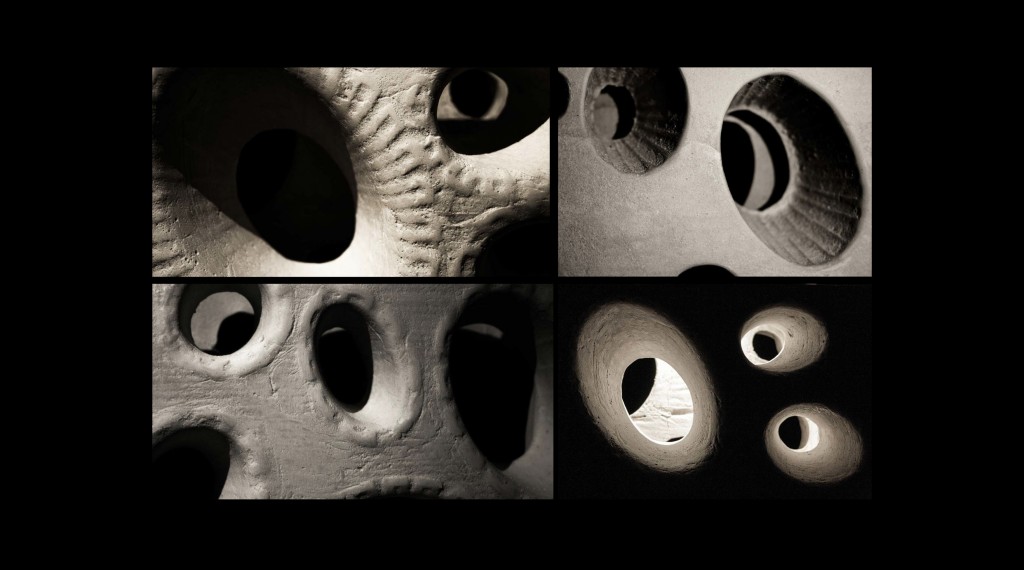

With the theme privacy, voids and layers became the key aspects to explore. To start with, research was done into how concrete could be perforated and layered to create voids.

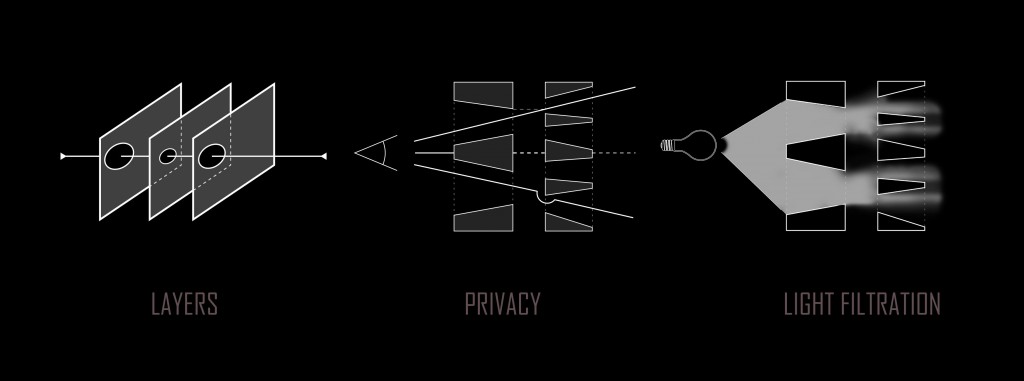

This would allow to distort and break up the view when looking through the brick, creating three lines of sights. Firstly, a direct line of sight, a line of sight that is stopped and finally, a distorted line of sight. In addition, light would add to the beauty of the brick, bouncing off the different voids.

Using these three key ideas, a design developed over the weeks that would finally produce a brick that encompassed all three ideas and respects the density of 60% solid, 40% void.

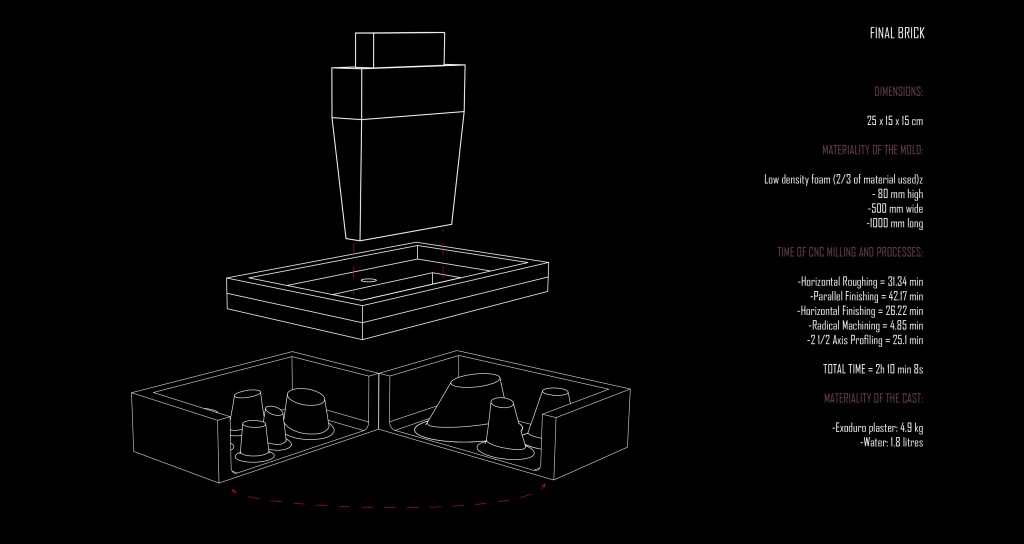

Designing the Mould:

To create the mould there are three key elements. First, the two sides that could each have a different design, and secondly, the centrepiece that would separate the two designs. One of the key challenges faced was how to connect the ‘individual layers’ so that the brick would not fall apart. The solution: a central insertion.

Design Process:

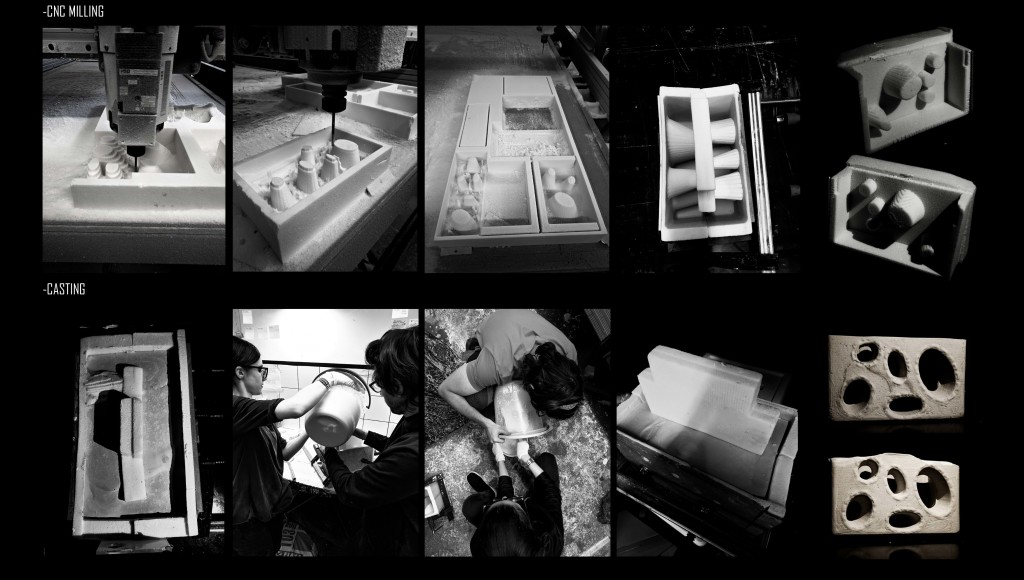

In order to speed up the CNC milling time, a medium density foam is the chosen material to cast in. This allows us to be able to CNC several elements in a timely fashion. However, to keep the texture for six casts would be the challenge. Each week, a method of casting was explored and tested.

WEEK 1: The idea of the central insertion was tested as well as the different edge finishes like fillet edge. The insertion was tapered on all sides in the hope that it could be removed easily. Success! With a little bit of force the brick was removed.

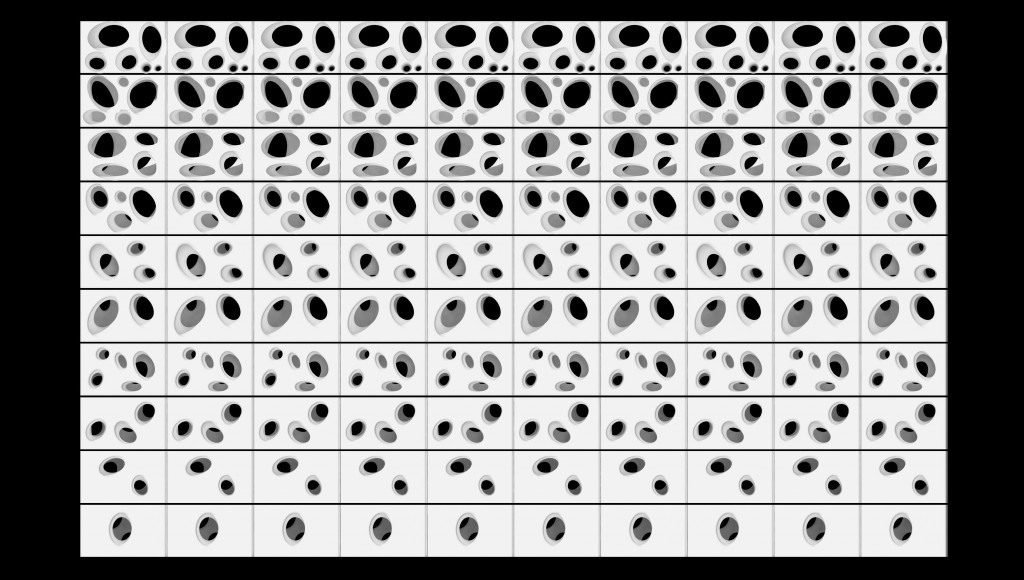

WEEK 2: This week, movable cones were tested. However, with this idea the centre insertion could not be tapered. Surprisingly, the movable cones worked! The benefit of this design is it would allow for many variations of brick.

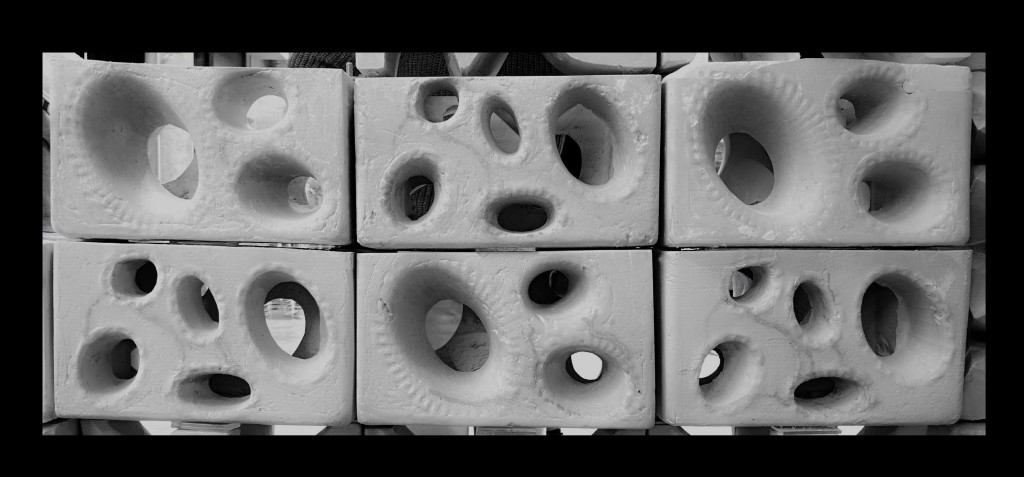

WEEK 3: For the final mould, half the mould has movable cones and the other half is static to allow for part of the centre piece to be tapered for ease of removing. Unfortunately this cast broke in several places due to the additional radial texture that was added. In order to avoid more issues, it was decided to remove the movable cones so that the insertion could be tapered in all directions and remove some of the texture.

With this design, all six bricks were successfully cast and the mould survived!

The approach taken to cast in could be applied to many different designs of the bricks. For the performance to be more structural, the number of perforations can be reduced. In the case of light filtration, this design already explores light, but by adding more perforations, the density could be reduced. The image below shows the possible variations.

Voids is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture, in 2018-2019 by:

Students: Daria Ciobanu Enescu, Fiona Demeur, Jose Isidro Pastor Tormo, Doruk Yildirim

Faculty: Alexandre Dubor, Ricardo Valbuena, Ricardo Mayor, Lana Awad, Sujal Kodamadanchirayil Suresh