Verticalize Earth House

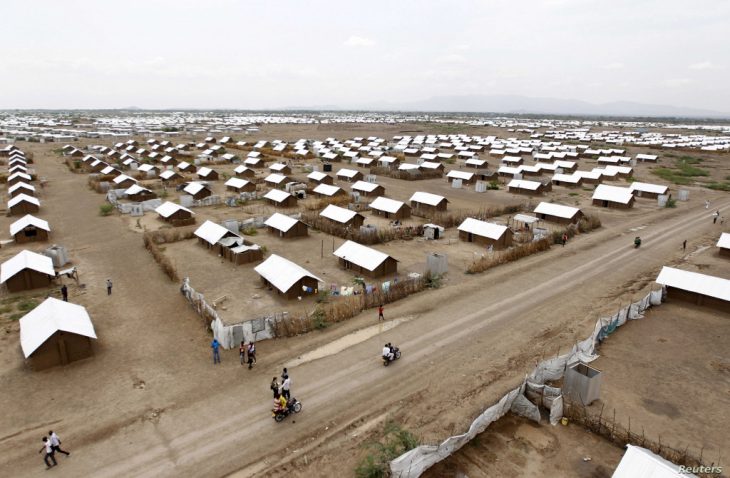

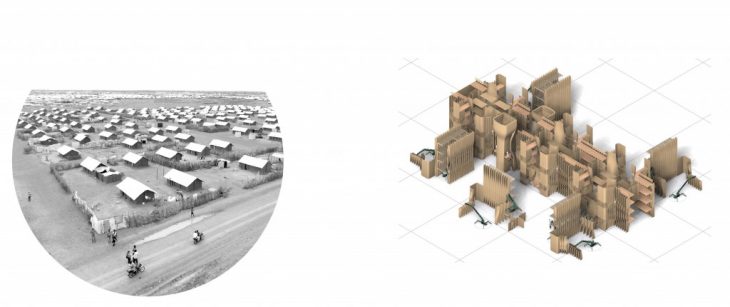

This is Kakuma, most people who lives here are refugees who escaped from the civil war. Some of them have lived here for 30 year. So Kakuma camp is no longer a temporary home. However,even they have diverse culture and different lifestyle, they can only stay in same type of shelter from beginning until now.Beside, Due to migration, the Camp has been saturated in the ground level. So we have 3 questions about this situation.

- How can we deal with this population explosion?

- How can we deal the urban sprawl?

- How can we provide customized housing for different demands?

In this situation 3d earth printing building can be good solution for the refugee camp.

- 3d printing building needs less time to construct building than conventional building. ( 1 house will take about 10 days)

- Also for printing building, only 3d printer machine, materials and people who can operate machine will be needed.

- Lastly, Earth house is almost zero environmental impact So after refugees leave, this camp. this city will be part of environment .

01_Proposal for Kakuma camp

Our proposal is that sustainable system for house in hot and dry weather condition by 3d earth printing. In Kakuma, there are not enough fuels and electricity so sustainable system is required. Second one is the verticalization for high density. High density will allowed more people to live in small area. It will prevent infra structures such as school, hospital and water tank to spread out. Third one is the customizing each building units based on environment and people’s needs. Concrete buildings or prefabricated building can make similar or same units. But 3d printing can customize each units by just different design data

In OTF, we developed the strategies to enhance 3 of the Performances of the building elements

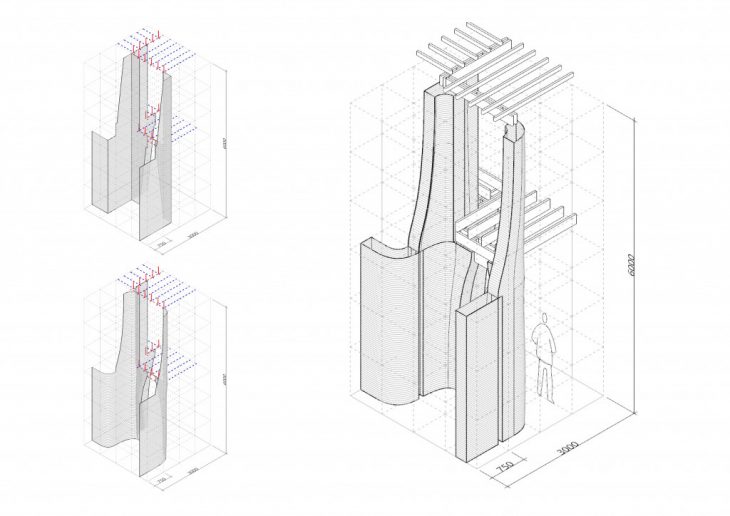

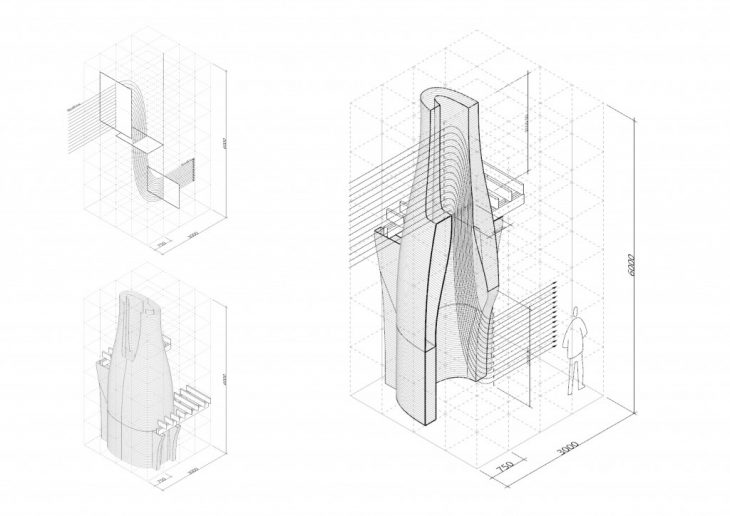

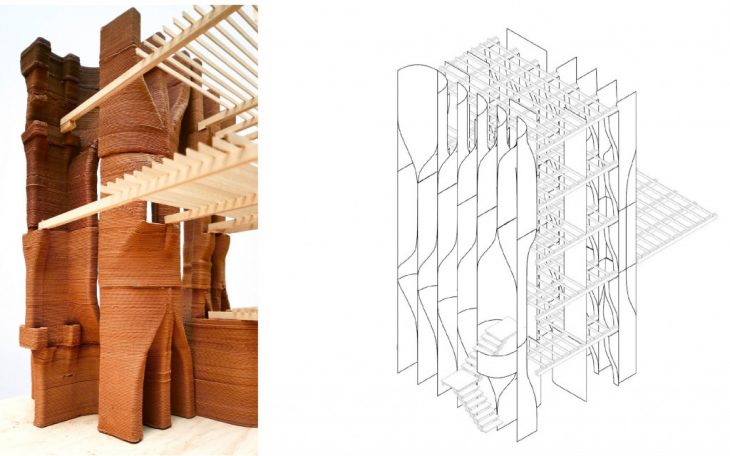

02_Partial Illustration of multi-story low rise clay structure

First portion of building element is for verticalization. By making support place for wood beam, this portion can have floor and roof. 3d printing building is strong to compressive force but weak to tensile force. So The strategy is combining wood and earth structure to improve strength against tensile force

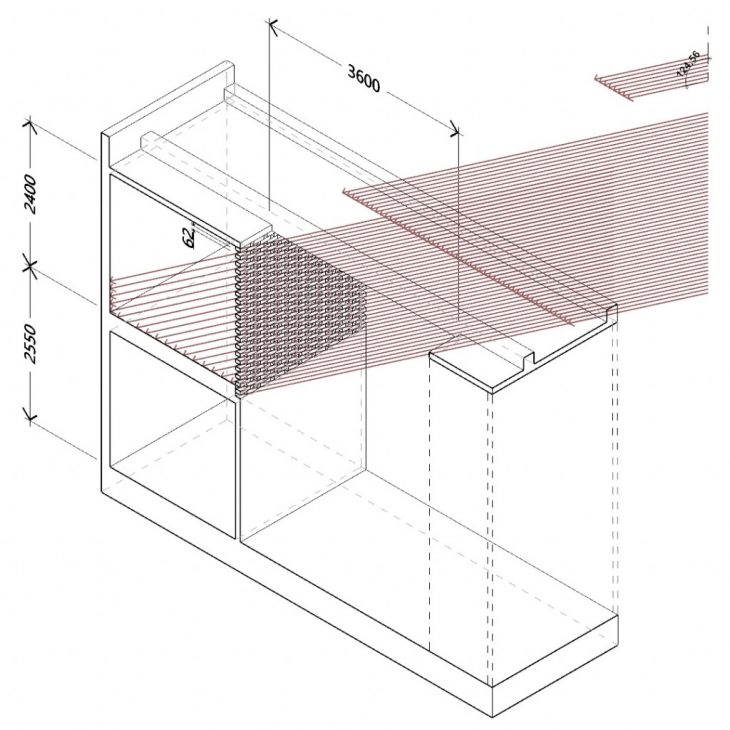

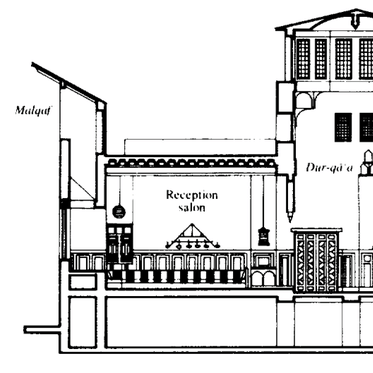

03_Partial Illustration of Sunscreen

This Reference is house in Vietnam. The bricks block the solar radiation and thermal radiation by control the size of opening.

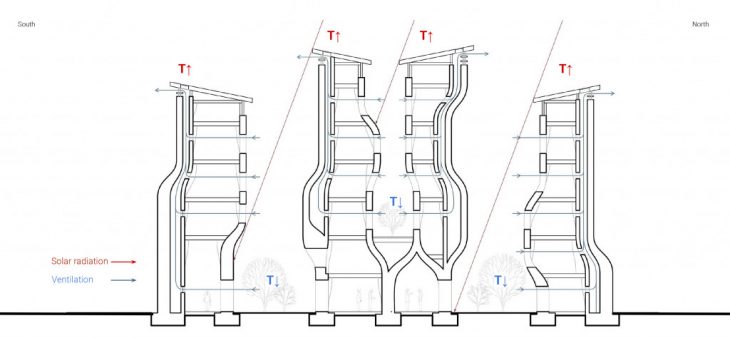

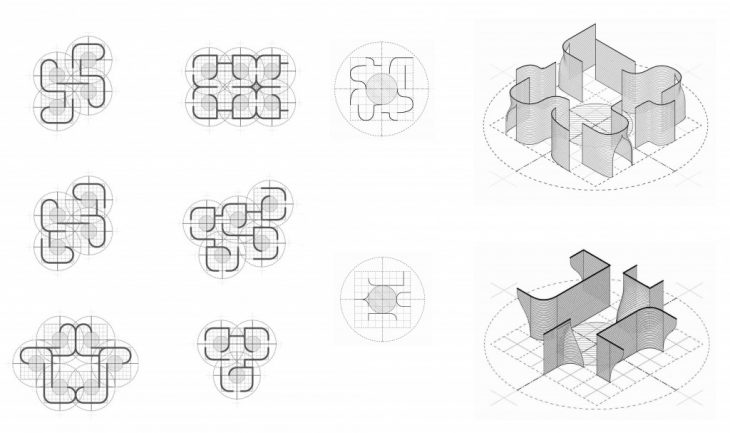

Curved wall would block direct solar radiation and also thick part will absorb heat and release it at cooler hours to balance the daily temperature difference because earth has higher inertia. In order to control the amount of the radiation pass to interior, the wall converge and diverge in various level height and angle to create different size and direction of openings. Merging wall is an advantage of 3d printing construction.

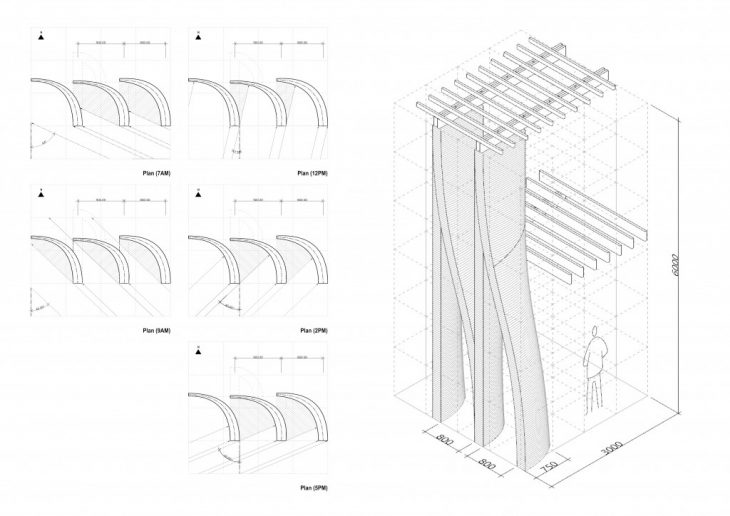

04_Partial Illustration of Sunscreen

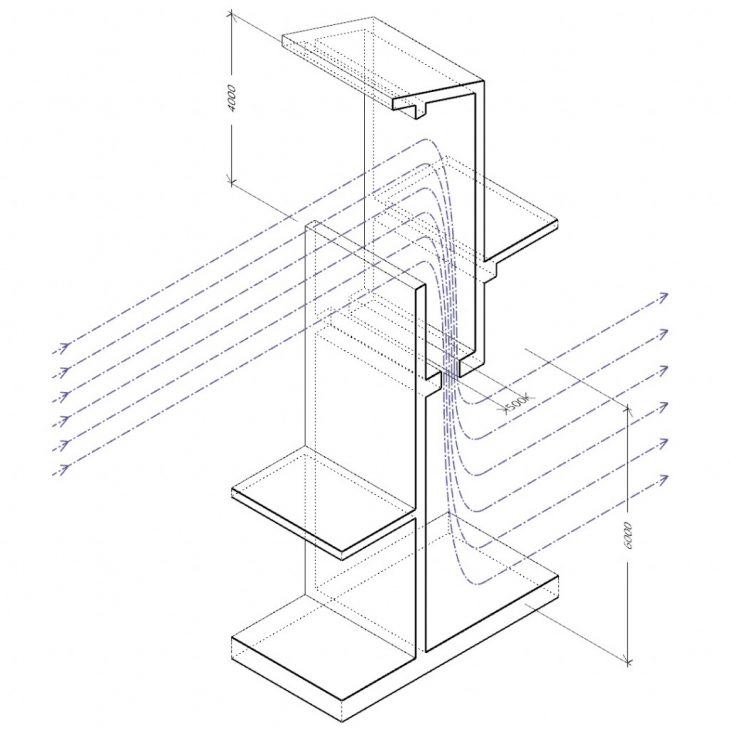

By using Venturi-Effect, wind capture system can provide fresh and cool air inside of house.

If there is no strong wind, we can put the transparent roof on the top . Solar radiation will heat up the air in the top part of chimney so temperature difference can make air flow. (Soalr-chimney Effect)

05_Macro Scale Performance

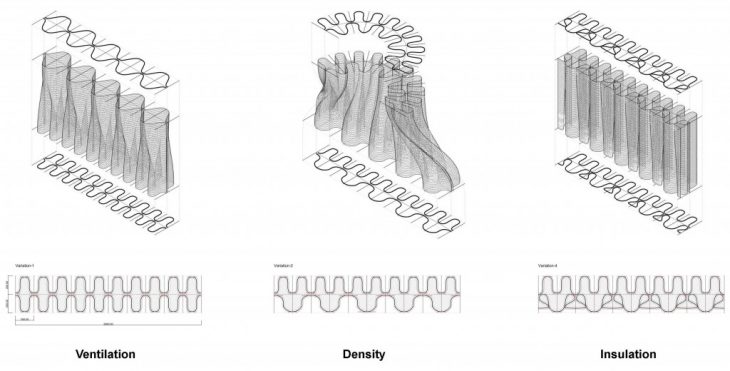

- While Portions are large scale performative building elements, infill will make small scale performance.

- Amount of tangency points: Structure Performance (amount of connection)

- Channel size and amount : Wall can have air channel for ventilation inside of wall

- Different size and amount cavities inner part and outer part – adjust the density of the print

- Air in the cavities – become heat insulation element

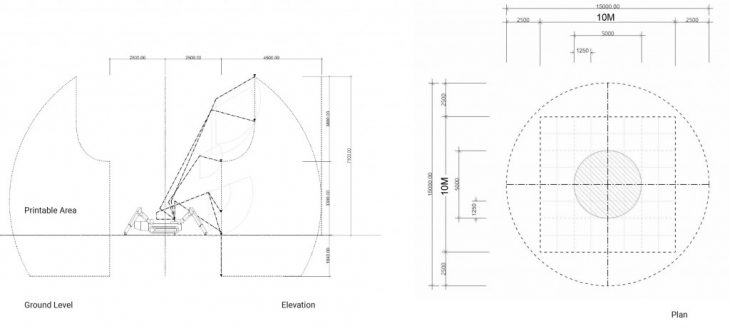

06_Construction Strategy

This machine can be folded 1m x 1.5m size so it optimize utilization in construction site. This machine is easy to be moved to another point – Reducing number of manual labor.

The printable range of his printer is 10mx10m and 3.8m height. We divided this printable range become 8 part to locate the portion of building elements. Compare to size of robot small machine but huge printable range. it works much more efficient than other robots

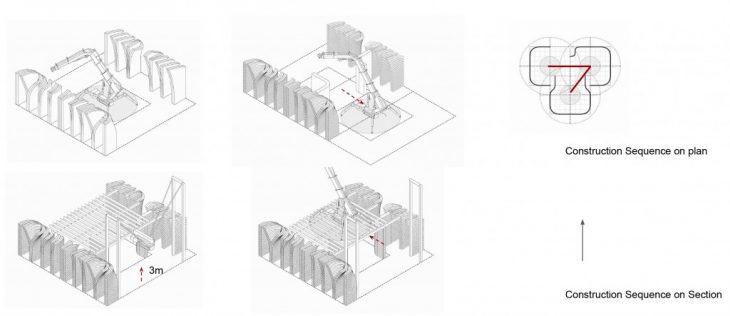

– Construction Sequence

Construction sequence is that after printing 3.8m height 6 partials, machine will be move to another position and continue printing. After finishing 1 floor, machine will be folded and lifted up to next floor.

07_Final Proposal

By combining earth and wood structure, multiple- story housing will be possible.

This housing has comfortable micro-climate environment. Shaded courtyards will provide cool air through solar chimney. Also converged and diverged openings at various height will filter sunlight for bright and mild temperature living environment. This sustainable ventilation and solar performance can be achieved by 3d printing construction

Space can be customized based on people needs. By combining printing range diverse plan can be printed.

We believe our proposal can be another option for refugee camp. This housing is not faster to be constructed than prefabricated shelters However,it would give more values such as participation of citizen in design process, transition from flat town to densive city .

Verticalize Earth House is a project of IaaC, Institute for Advanced Architecture of Catalonia

developed at Open Thesis Fabrication in 2019/2020 by:

Students: Jae Shin | Jingwen Chiou

Faculty: Edouard Cabay | Alexander Dubor | Kunaljit Chadha | Eugenio Bettucchi | Ashkan Foroughi Dehnavi