Introduction

The digital woodcraft seminar primarily looked into how digital tools have traversed old-age practices of wood construction. As part of the course, we had the opportunity to fabricate a joint system of our own and eventually use this joint as a basis for an overall complex structure.

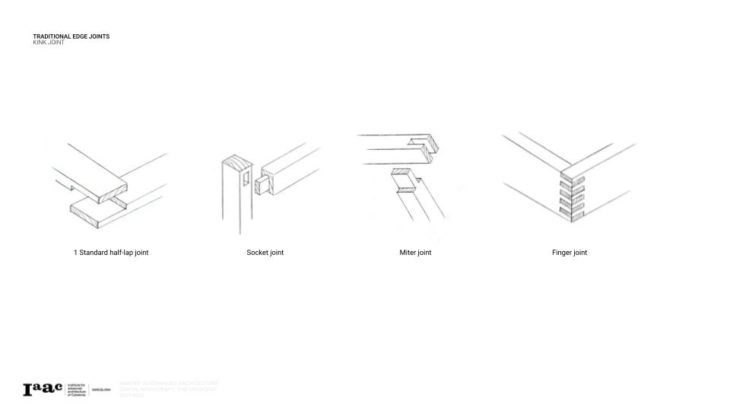

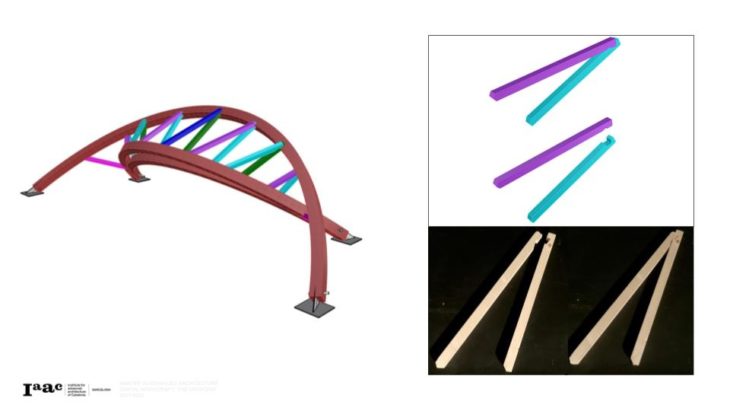

We explored the angled/edge wood joint. These edge joints have been concieved in a variety of ways in traditional wood construction depending on the application. Whether it is meant to be structural or unstructural depending on the design of the overall structural piece. We looked into how to use this joint as a structural element.

Traditional edge joints

We prototyped a simple butt joint to understand our material and fabrication sequences.

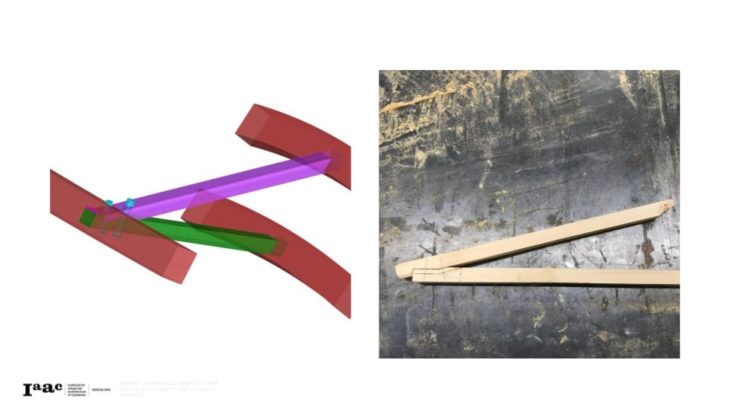

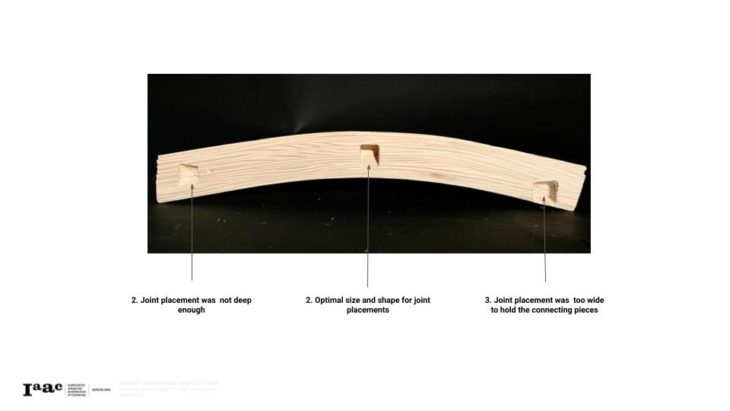

Machined edge Joint with self locking mechanism

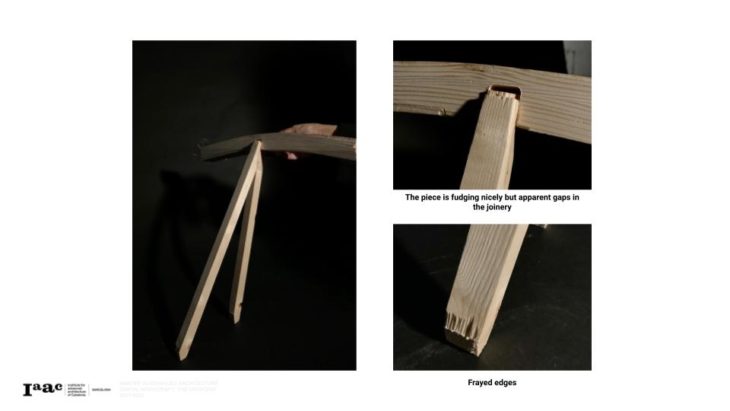

Initial prototyping

- showed that milling the wood inside-out created splinters to the wood on the edges which lowered the aesthetic quality of the wood.

- Milling along the grain is much preferable to against the grain to retain the structural qualities of the wood.

- We also noticed that for the self locking joints (japanese style joints) we needed to allow a larger surface area for contact otherwise pieces intended to hold the elements together would fail.

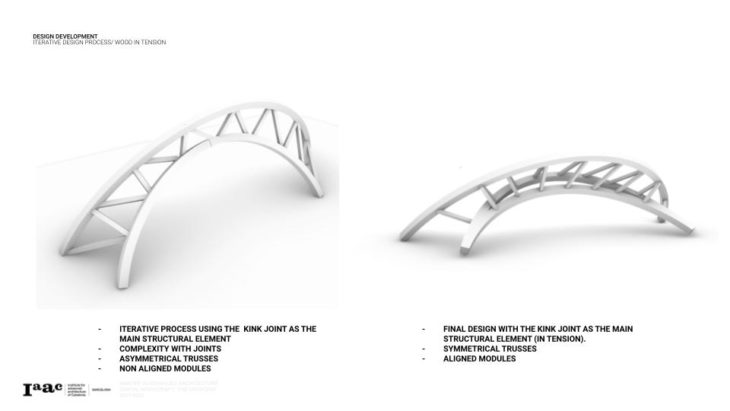

Designing

Cable bridges as Inspiration for woodcraft

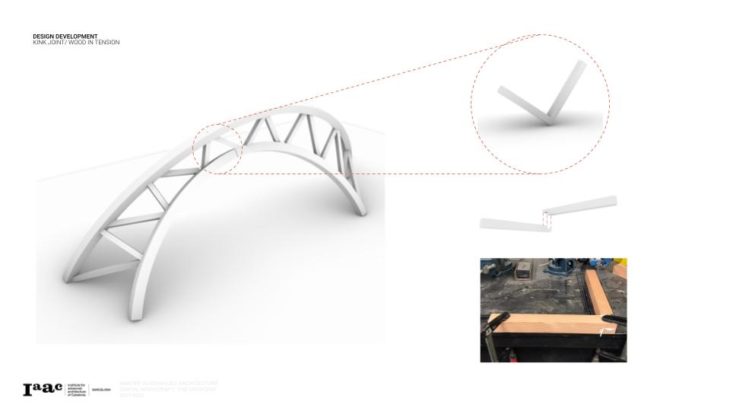

Using all the above as a basis, we proceeded to design an element based on the kink joint as a main structural part. We looked into cable structures as an inspiration and explored how we could harness the structural capabilities of wood in tension to create a similar structure.

(Image of wood grains showing strength along grain)

Fabrication Process

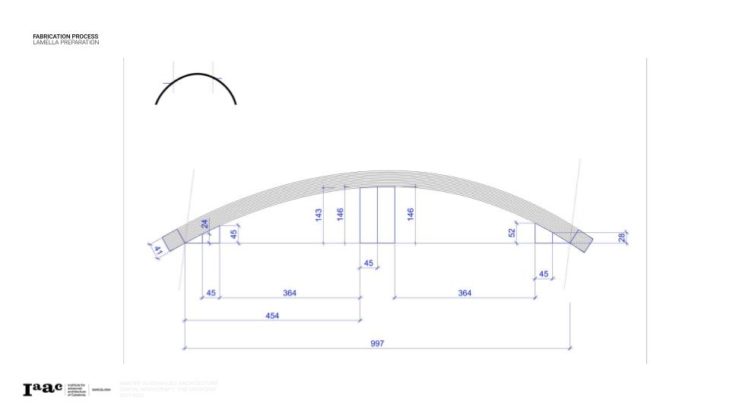

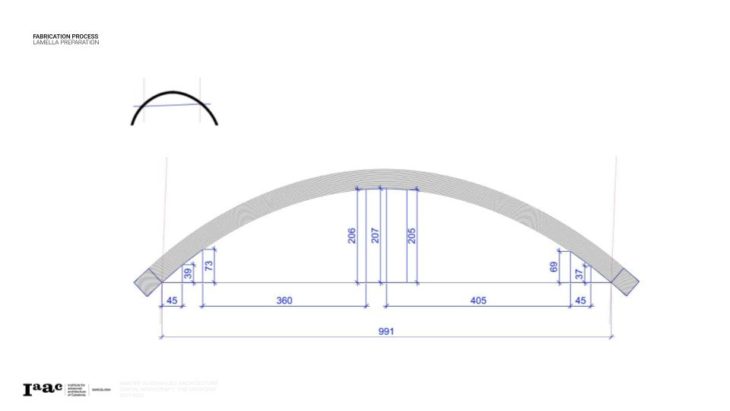

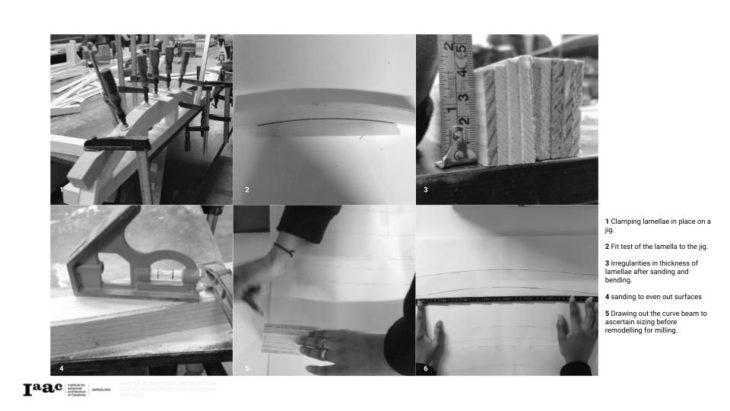

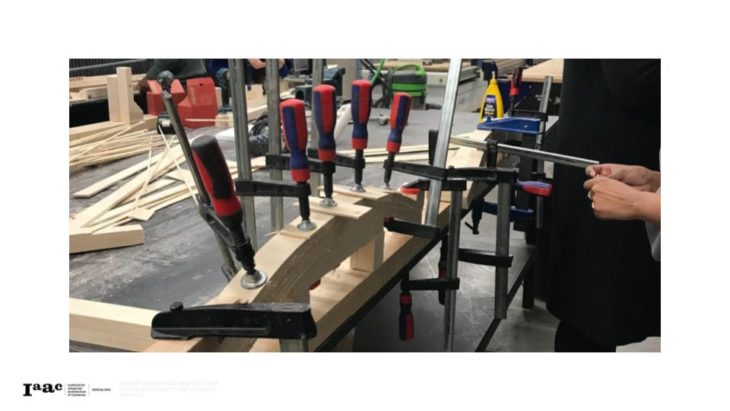

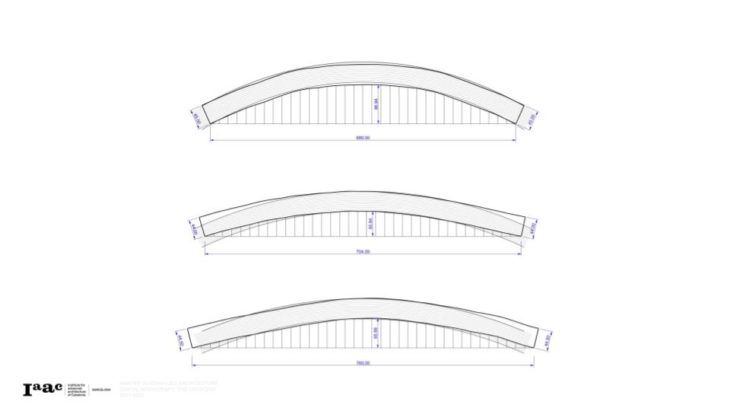

A. Fabrication process of the lamellas

-design and sizing of lamellas

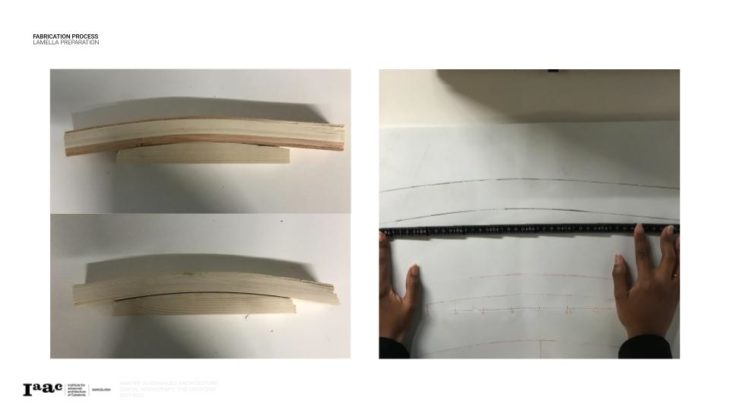

-Fabrication process

-fabrication of jig

-Slicing process & glueing of the lamellas

-checking for variation between the original computer design and the final prototype before milling.

Fit test prior to CNC milling to create accurate measurements of the glued wood pieces.

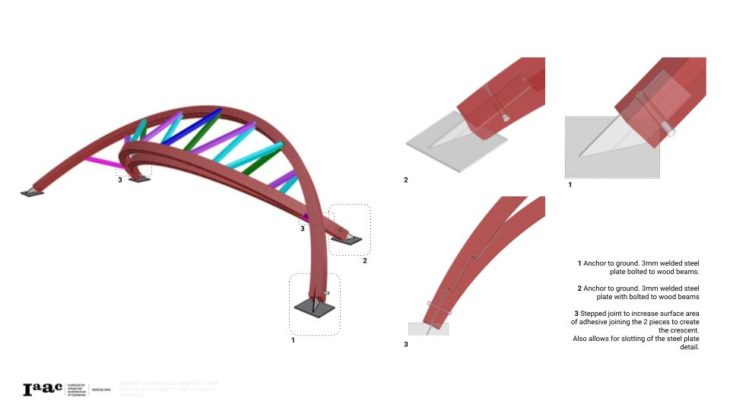

Design synthesis

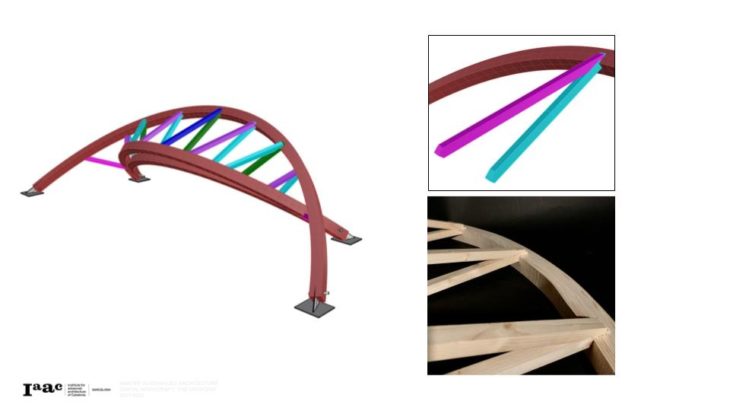

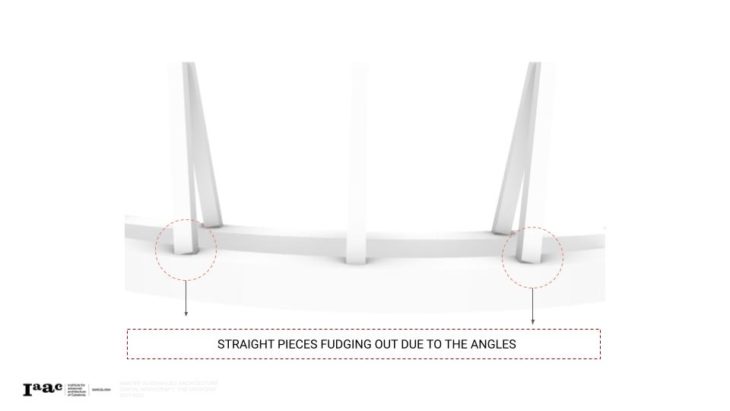

Wood is a rigid structure and an exploration into how to make it an element in constant tension was abit far-fetched. Our biggest challenge was to create a joint between a curved piece and a straight kink elements. And because the structure was a sort of reciprocal one, this created further complexity in that all the joints would vary from each other along the curved beams.

{The Underpass} is a project of IAAC, the Institute for Advanced Architecture of Catalonia, developed during the Master in Advanced Architecture (MAA01) 2020/21 by students: {Rahma Hassan, Tanvee Suhas Joshi & Jeremiah G. Oonyu}; faculty: {Tom Svilans, Marielena Papandreou, Shyam Zonca}.