Coming from no experience with a 6-axis machine, the team took the opportunity of the workshop to experiment and understand what

results it’s possible to obtain.

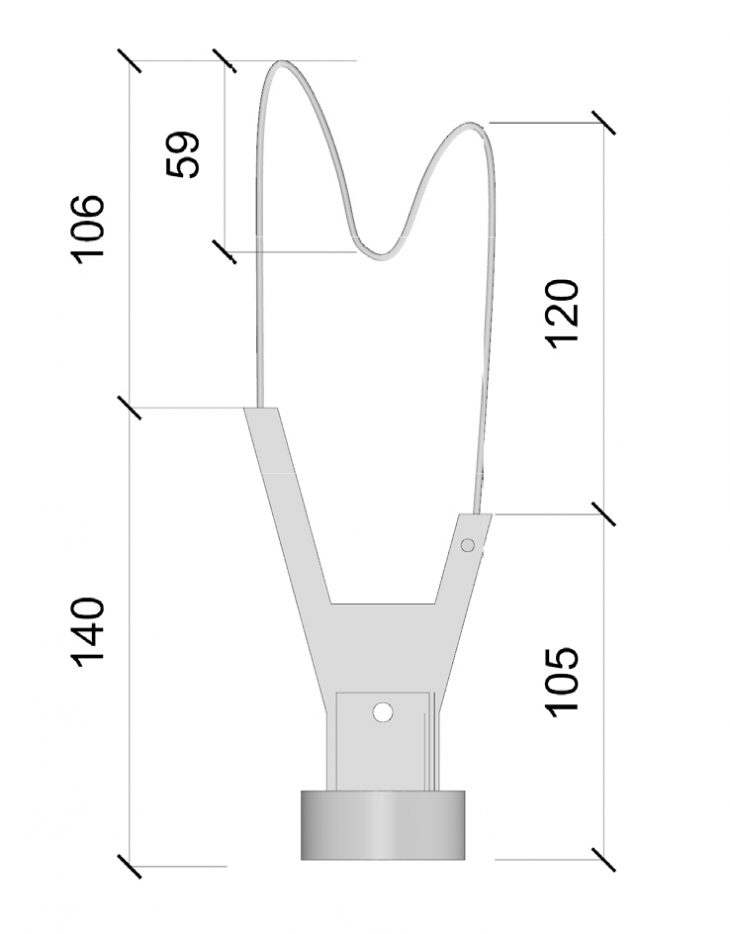

The team was asked to design their own tool, which was then laser cut, and used as the holding structure for the metal wire. The first decision was to design an asymmetric profile, playing with the length of the support legs.

The idea was to play also with the shape of the wire, which could be modeled in any shape. This shape was designed with Rhino and laser cut as well, so that it was possible for us to model the wire more precisely.

The wire was positioned on the profile, and heated up to carve the given Foam.

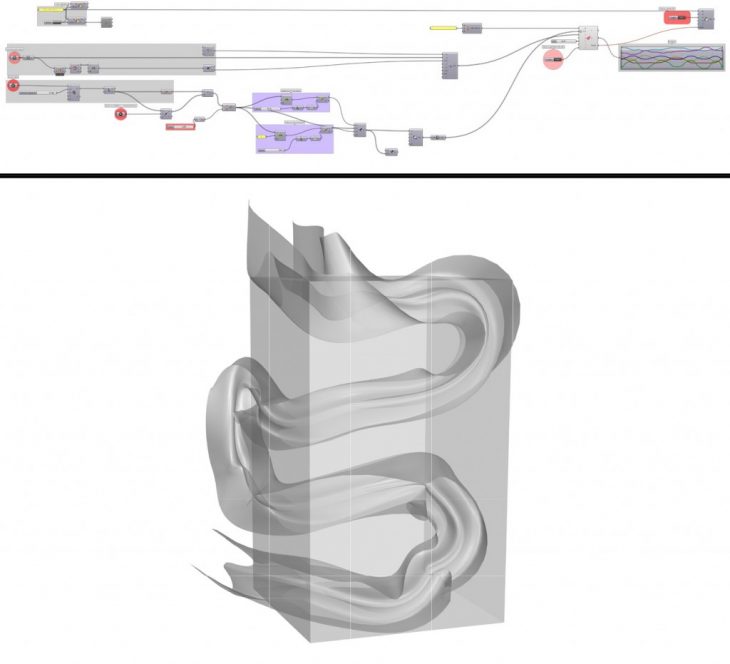

To explore the limits and the potentials of the specific geometry of the designed tool, three tests were run.

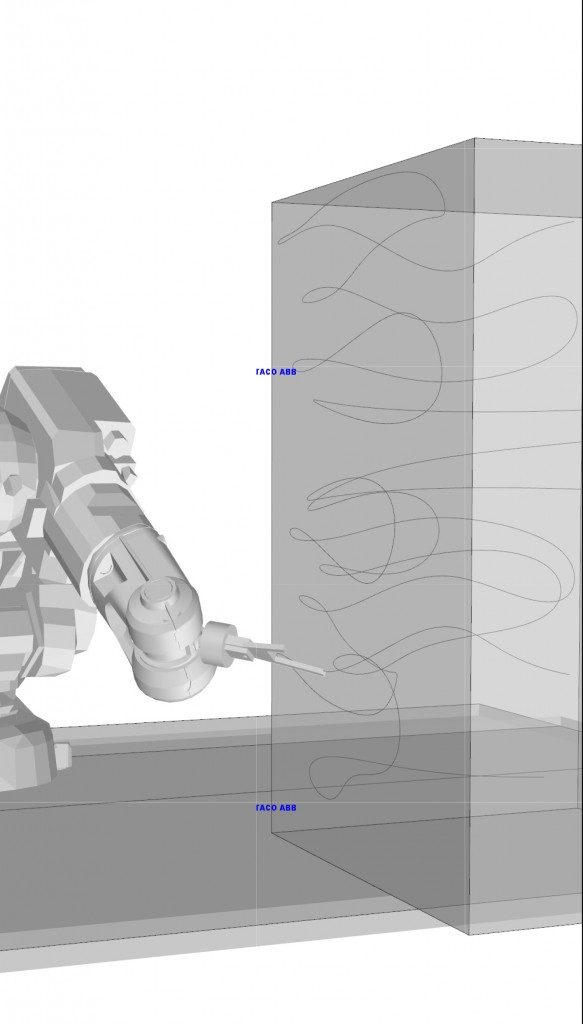

In the first test, the path was linear in x direction with different inclinations in the z direction. The second test was an opportunity to experiment with rotation of the z axis which resulted in an amplified amorphous form. Finally, the last test was exploring the capabilities of the the tool moving in x+y direction with a variety of indentations in z axis.

By assessing the results, the second test was chosen due to it’s potential to create a continuos effect connecting the two faces of the given box.

The main difficulty in applying the fabrication strategy was to prevent the clips attached to the tool from hitting the foam.

</p>

The Amorphous Corner is a project of IaaC, Institute for Advanced Architecture of Catalonia

developed at Master in Advanced Architecture, at the Robotic Workshop Seminar by:

Students: Camilla Franchini, Valerie Frey, Merve Savatli.

Tutors: Kunal Chadha.