THESIS STATEMENT

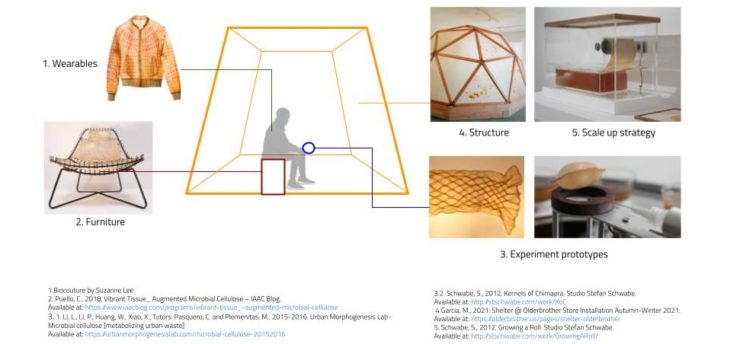

Tailored Landscape: Exploration of Design potential of Microbial cellulose in Biofabricated Architecture investigates practical options for the integration of consolidated material research of microbial cellulose (a.k.a. SCOBY – symbiotic culture of bacteria and yeast) developed and implemented by multidisciplinary designers into building skins solutions by exploring biofabrication techniques practiced in the fields of sustainable fashion/textile.

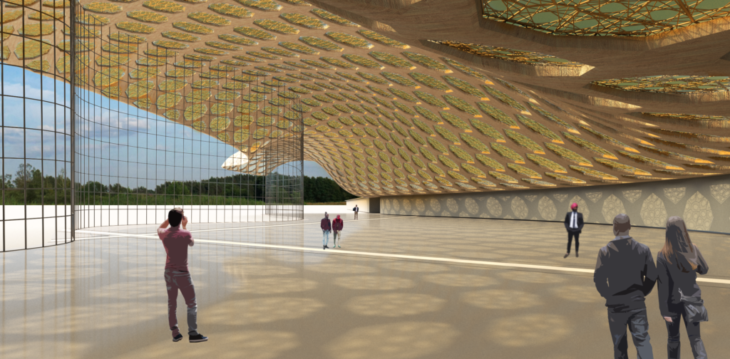

image credit: Elizaveta Veretilnaya

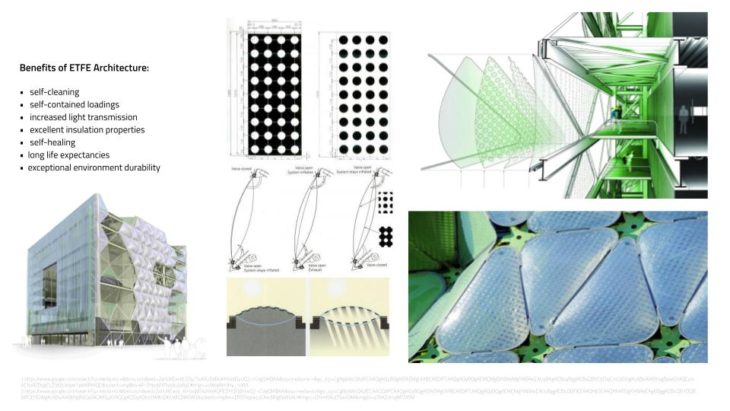

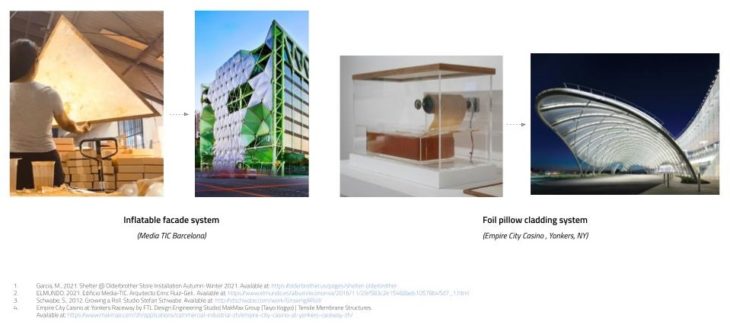

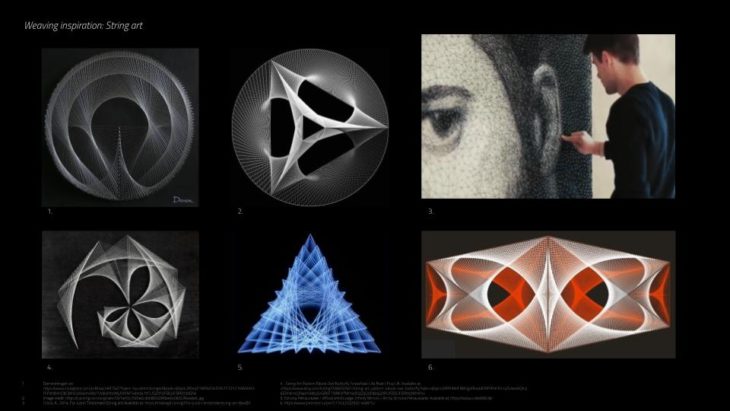

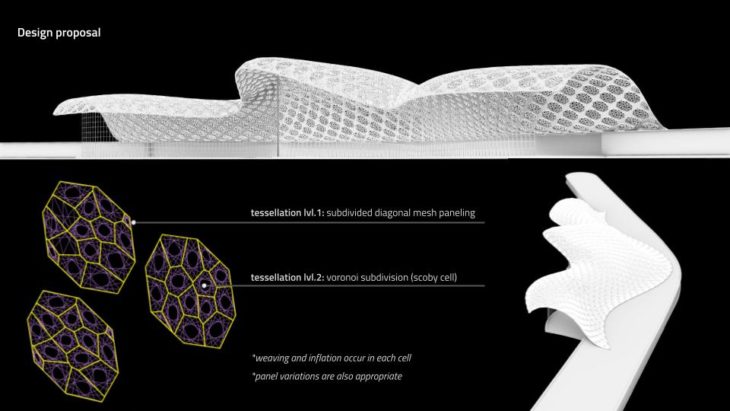

The thesis aims to develop a comprehensive design methodology through hybrid fabrication strategies using microbial cellulose as a primary shaping material for inflatable tensile membrane structures (skins) comprised of modular components with pre-woven tensioned threads (that act as fabric reinforcement and physical boundary for inflation).

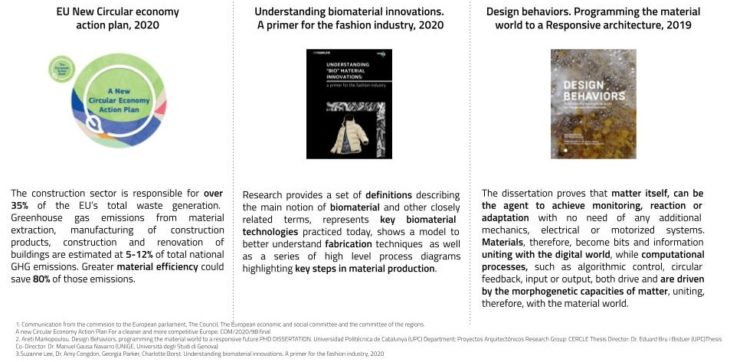

FRAMEWORK

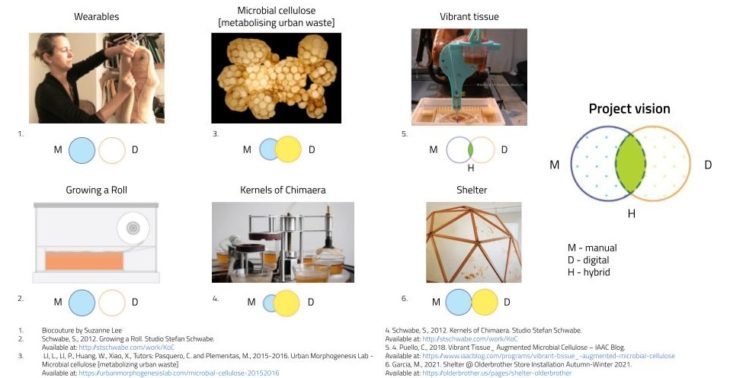

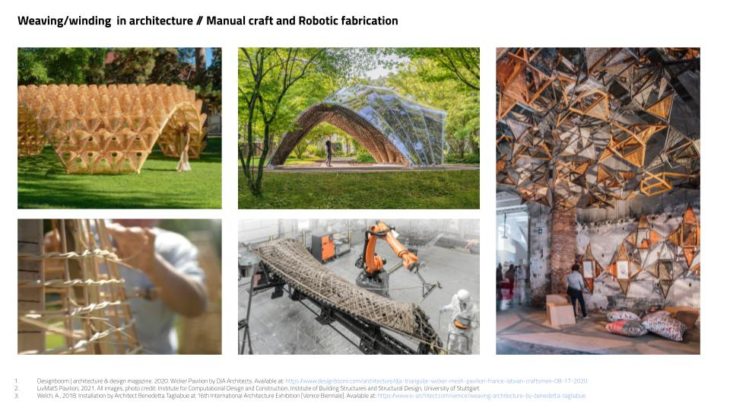

Biologically driven research in material-informed design introduces a different idea of the notion of ‘materiality’ in modern architectural practice, increasing designer’s awareness of the emerging role of ‘biomaterials’ (and all its subsets) in the field and paving a way for the development of new design methodologies that utilize multidisciplinary approach for their research.

Biologically driven research in material-informed design introduces a different idea of the notion of ‘materiality’ in modern architectural practice, increasing designer’s awareness of the emerging role of ‘biomaterials’ (and all its subsets) in the field and paving a way for the development of new design methodologies that utilize multidisciplinary approach for their research.

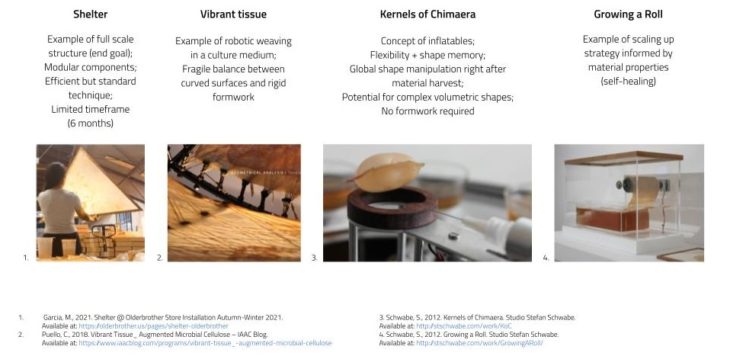

STATE OF THE ART

FABRICATION APPROACHES

IMPORTANCE AND LEARNINGS

SCIENTIFIC INTEREST

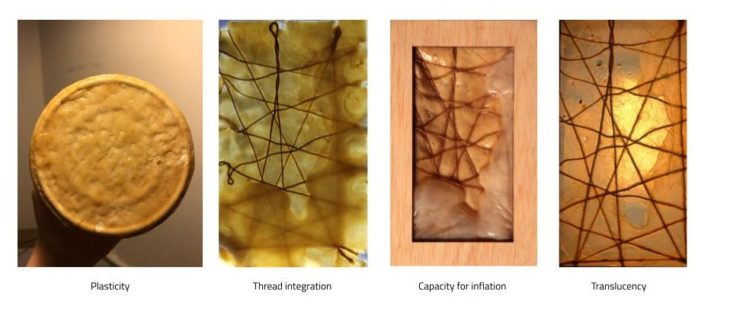

The most performative properties of microbial cellulose (plasticity, shape memory, self-healing, as well as capacity for inflation and compatibility with natural fibers) can be combined into one cohesive hybrid fabrication workflow to generate a comprehensive design methodology for biofabricated building skins solutions that are directly informed by these properties and operate within the limitations and possibilities of digital fabrication.

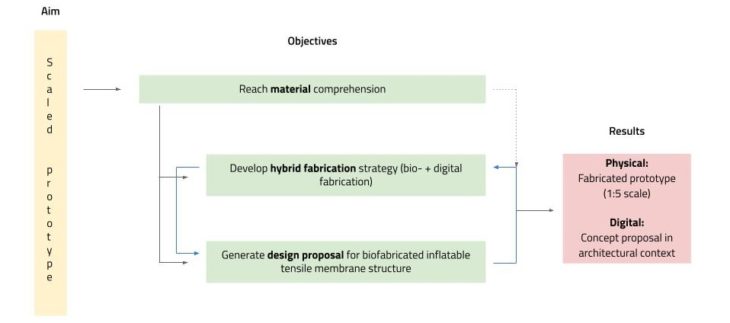

RESEARCH AIM AND OBJECTIVES

Practical ambition:

Practical ambition:

Using microbial cellulose as a main shaping material to build a scaled down building skin prototype composed of prefabricated inflated interconnected panels of microbial cellulose with pre-woven tensioned threads that act as as fabric reinforcement and physical boundary for inflation.

Bigger picture:

To prove that microbial cellulose can be utilized as a primary shaping material in an architectural context, thus expanding its application outside its usual context: food and textile industry, medicine, cosmetics, etc.

APPLICATION SCENARIOS// Biofabricated ETFEs

PHASE 01 // MATERIAL COMPREHENSION

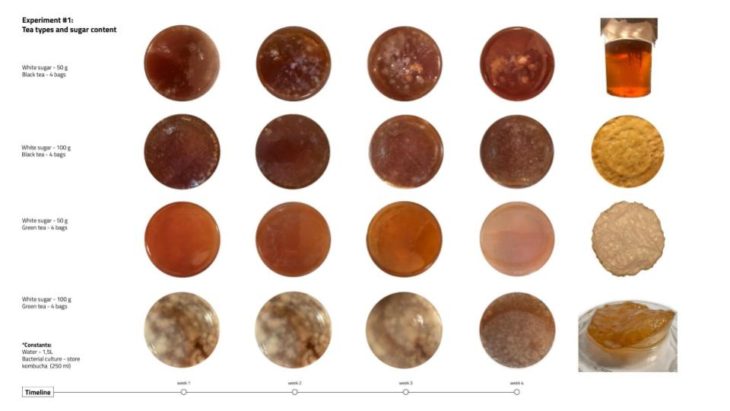

Points of investigation: growth speed, scoby thickness and texture

Experiment 1: Tea type (black/green) and Sugar content

Results: green tea based samples display better texture qualities; optimal sugar content – 7% of total liqud volume

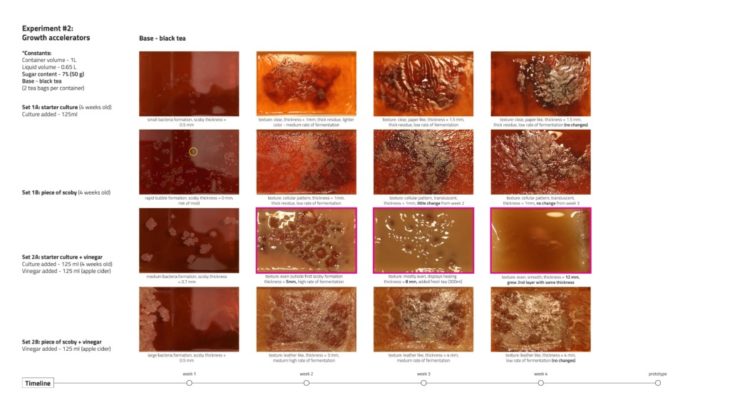

Experiment 2: Growth accelerators (black tea base)

Set 1A: Starter culture Set 1B: Piece of scoby Set 2A: Starter culture + vinegar (apple cider) Set 2B: Piece of scoby + vinegar (apple cider) Results: Set 2A (culture+vinegar) displays fastest scoby growth

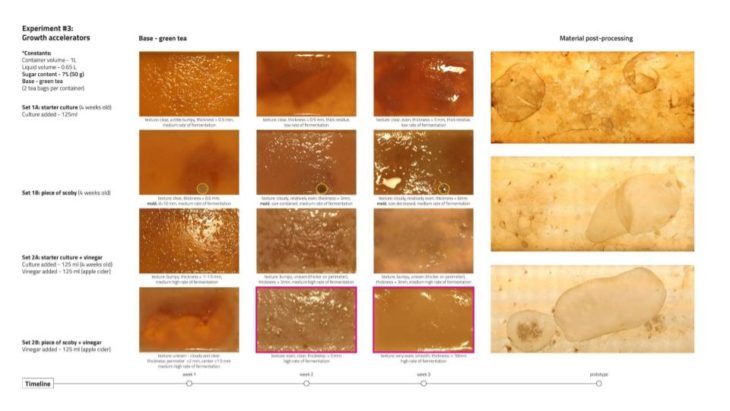

Experiment 3: Growth accelerators (green tea base) Results: Set 2B (piece of scoby + vinegar) displays fastest scoby growth with smoothest texture

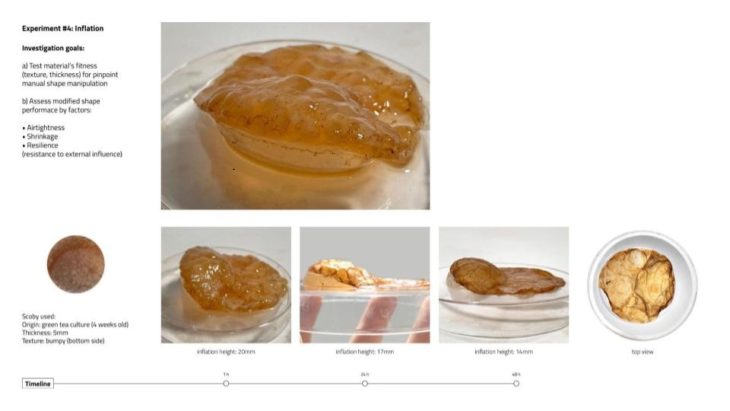

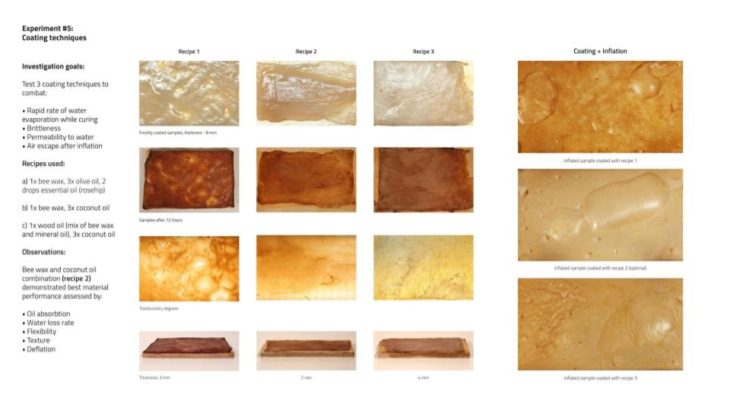

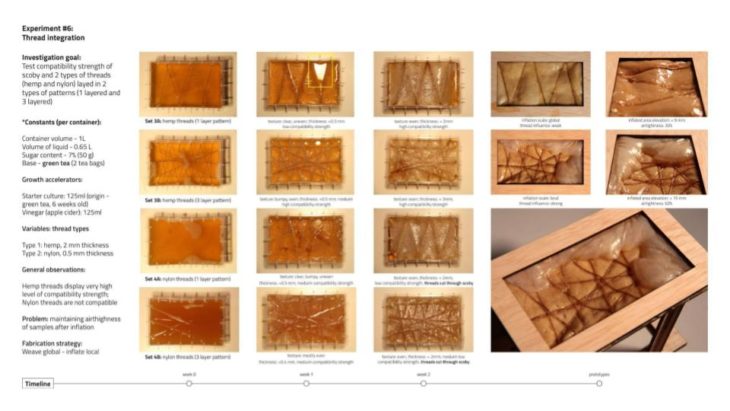

Experiment 4: Inflation

MATERIAL COMPREHENSION: OVERVIEW

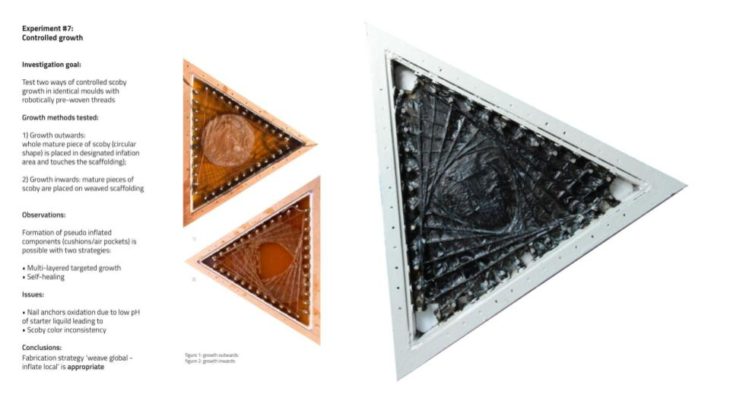

PHASE 02 // HYBRID FABRICATION STRATEGIES: Robotic weaving + Scoby cultivation

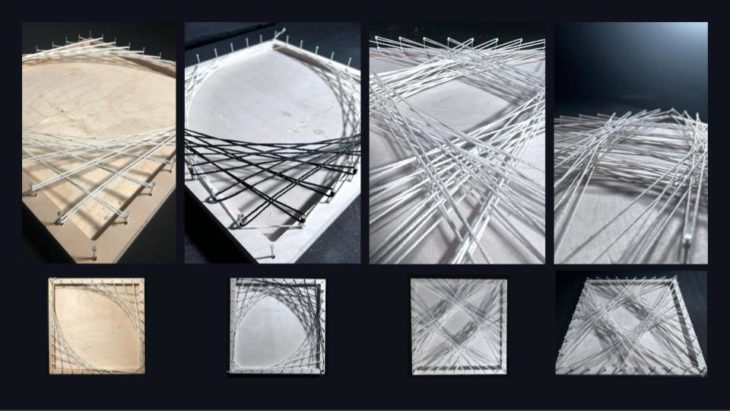

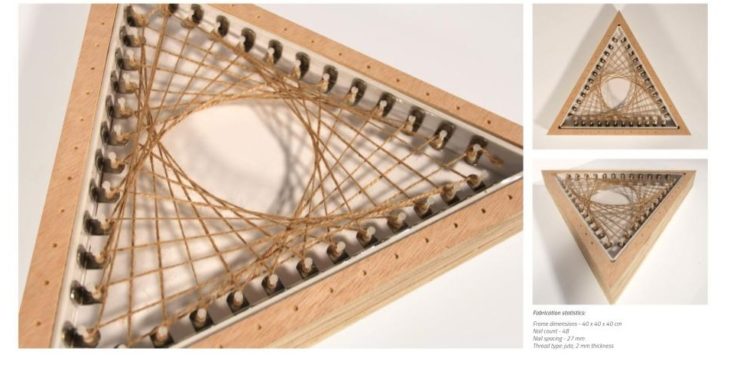

Robotic weaving Experiment #1 Investigation goal: Exercise in robotic weaving using existing fabrication techniques Constants: Frame dimensions – 40×40 cm Nail count – 40 Nail spacing – 40 mm Thread type: cotton, 2 mm

Variables:

- Tool path (weaving pattern)

- Weaving radius

- Spin count around each nail

- Line type (polyline/bezier)

- Clearence plane above threads

(depends on thread thickness)

Optimal parameters:

- Spin count around each nail: 2

- Weaving radius: 15 mm

- Clearance plane: 4 mm

- Robot speed: 35%

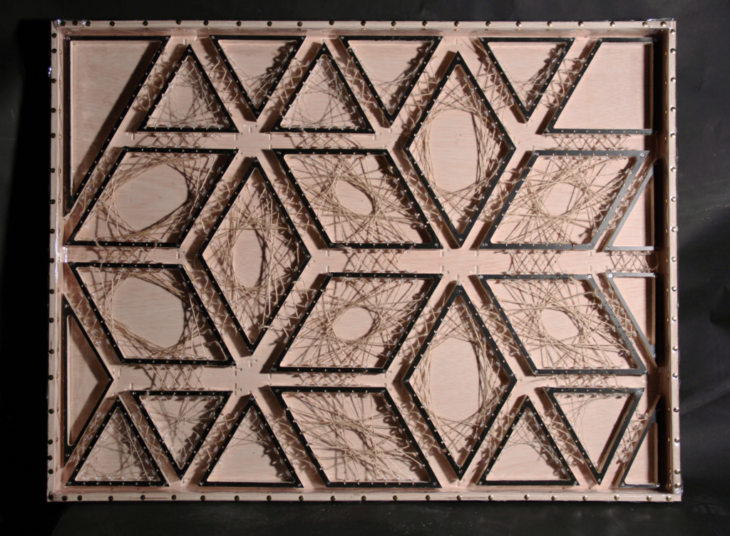

Robotic weaving Experiment #2: Adapted framework Investigation goal: Define maximum weaving resolution

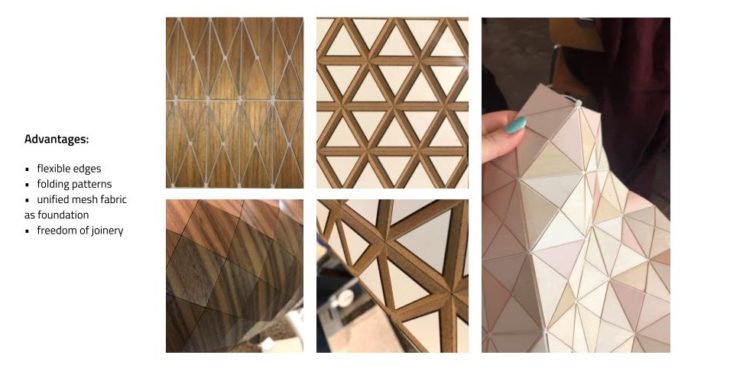

Material Scale-up strategy // 3D Textiles

Proof of concept: Physical prototype

Fabrication statistics: Dimensions: 90 x 110 cm Cell count: 26 Nail count: 758 Thread length: 30 m (jute and hemp, 2 mm) Volume for starter liquid: 13.6 L Liquid used for cultivation: 14.8 L

Growth process: Timelapse over 24 days

Architectural context: Barcelona El Prat Airport Expansion (concept proposal)

Concept render

Tailored Landscape: Exploration of Design potential of Microbial cellulose in Biofabricated Architecture is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in C.Biom-A Thesis Studio in MAA02 programme 2021/22 by Student : Elizaveta Veretilnaya Thesis advisors: Marcos Cruz & Ricardo Mayor