Earth is over the capacity to support the rate of material consumption, especially by the construction industry. Concern for the environment has reached new levels, but more must be done to come up with new materials and methods to mitigate the crisis.

Despite the development of new construction materials, such as nanotechnology, there is a huge gap between research and practice. A new paradigm in engineering is required to be able to calculate the structural integrity of new materials and systems.

Developments on the field of Computational Desing allow for building forms that were not possible in the past, and make it possible that designers make decisions with early design drivers, creating buildings in more efficient ways. But, as these new forms can be very organic

and are therefore more difficult to apply traditional engineering techniques to.

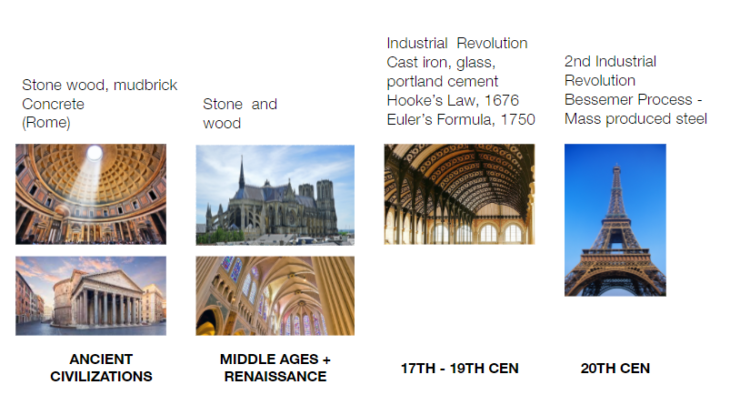

History of Structural Materials Systems

Through history of civilizations, material development has shaped the building environment, by pushing the constructions to the limit of what is possible.

Clay and mud were ideal early building materials because they can be easily harvested and moulded by hand into shelters. As humans made better tools to cut wood and learned more efficient woodworking methods, wood became an incredibly useful building material. Due to its abundance, wood has long been a popular construction resource in North America and parts of Europe.

Early Roman concrete was very cheap and easy to make as it was produced from only rubble and water. Concrete’s cheap and durable nature makes it a versatile building material that is still used to this day.

In 1849 the mix of water, cement and aggregates was first combined with steel to create reinforced concrete. Reinforced concrete has been used in foundations, bridges and highways since its conception.

The industrial revolution paved the way for invention, innovation and large-scale construction. By the nineteenth century, steel was being mass-produced and was being used for beams and in reinforced concrete.

Using scale models made of chains or weighted strings, Gaudí’s upside-down physical models took him years to build but gave him more flexibility to explore organic designs, since every adjustment would immediately trigger the “physical recomputation” of optimal arches. He would turn the model upright by the way of a mirror placed underneath or by taking photographs.

Structural Materials

Nanotechnology

While nanotechnology has attracted attention in many fields of science and technology, including chemistry, electronics, medicine, or biology, its application in civil engineering, up to date, remains limited.

Nanomaterials such as nano-alumina, nano-titania, nano-silica, nano-magnesium oxide, nano-zinc oxide, silver nanoparticles, carbon nanotubes, or graphene derivatives may have enhanced hydration, microstructure, porosity, and thus mechanical properties and transport-related properties of cementitious composites.

Moreover, nanoparticles can also ensure completely new capabilities of structural composites, namely self-cleaning, self-sensing, and antimicrobial activities. Recent nanotechnological developments in civil engineering open up new avenues for the technological applications of nanomaterials in high-performance cement composites as well as in structural health monitoring. However, of significant importance is to focus on new solutions, which will facilitate the use of nanotechnology in real industrial-scale applications.281 / 5.000

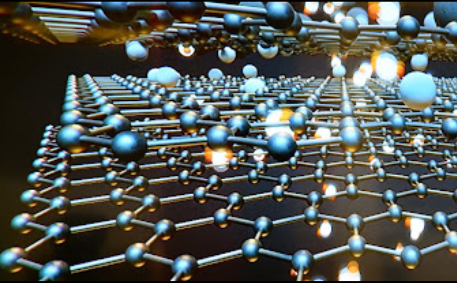

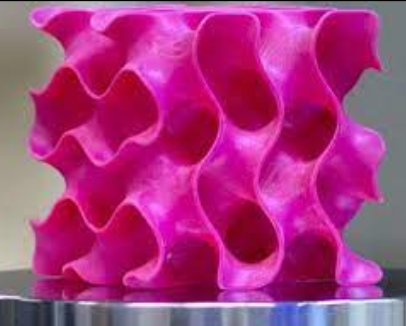

3D Graphene

Graphene is one of the crystalline forms of carbon, as are diamond, graphite, carbon nanotubes and fullerenes. The term graphene was proposed as a combination of graphite and the suffix -ene by Hanns-Peter Boehm. He was the one who described carbon sheets in 1962.

In 2013 researchers developed a production unit that produces continuous monolayer sheets of high-strength monolayer graphene.

There are also bilayers, and the Superlattices. A three-dimensional honeycomb of hexagonally arranged carbon was termed 3D graphene, by MIT is ten times as strong as steel. It’s incredibly strong and has unique electrical, thermal, optical, and chemical properties,has only five percent of the density of steel. , these shapes allow the two-dimensional graphene to form strong structures in the same way that sheets of paper can be folded and rolled into much stronger forms, including cylinder and corrugations, that can hold substantial loads.

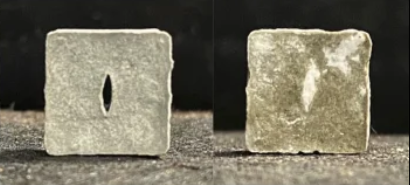

Wool Bricks

Wool bricks are made by adding wool fibers to the regular clay material used to make bricks, then combined with an alginate conglomerate, a natural polymer extracted from the cell walls of seaweed. They are naturally dried (rather than the energy-intensive and polluting process of firing) and the result is a brick that is less prone to cracking and less likely to warp.

Modular Bamboo

Innovative bamboo structural system developed by the Beijing-based Chinese firm Penda. It has a modular base and does not use nails or screws to interconnect the different building elements. Instead, the system uses ropes to establish structural connections and allows for the easy addition of prefabricated modules to the main building.

Self Healing Concrete

Concrete is the most used material in civil construction, being composed of a mixture of water, cement and aggregates. The main enemy of concrete structures is tension, as due to the nature of the material, it cracks and deteriorates over time. The new material uses concepts from biology and engineering aiming to be a solution that can regenerate itself.

The idea was to use dormant microorganisms that were able to survive a high pH environment (such as concrete).

Bacteria are activated when they detect the presence of moisture in the environment. This occurs precisely in a situation of cracks or cracks, which allows water to enter the structure.

Conclusion

New engineering methods are required in order to efficiently use new structural materials, since traditional practices limit innovation. Perhaps resources and education could be used to develop these new methods, leading to the modernization of building techniques, which have become somewhat stagnant.

Structural Materials is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Computation for Architecture and Design in 2021-2022 by Students: Shelley Livingston, Barbara Villanova and Faculty: Jane Burry