1.) Community Centre, Reinosa, Spain. 2. G3 Shooping Centre, Vienna, Austria 3. SCS Warehouse in Philippsburg, Phillipsburg – Huntenheim, Germany. 4.) Hall 10 Der Messe Stuttgart, Germany. 5.) Factory Building in Bobingen, Germany. 6.) Garage and Vehicle Workshop in Andelfingen, Switzerland.

01 – STRUCTURAL SYSTEMS

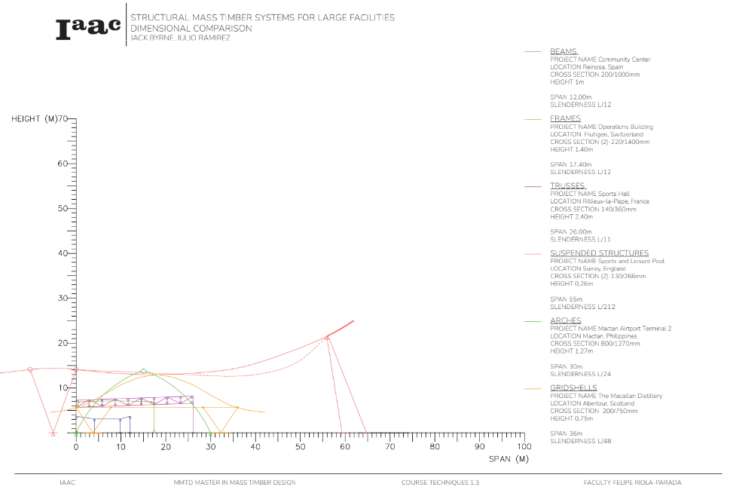

A beam is a structural element, with small cross section dimensions in comparison to length. Beams play a prominent role in how the weight is transferred and ensures that a building’s foundation is firmly planted into the ground. The most common beam types include over-hanging, fixed, trussed, continuous and supported beams. A beams function is to provide a safe and efficient load path that effectively distributes weight throughout the foundation of a building. Beams support the load by resisting being bent under the load’s pressure. Beams resist this force in a lateral way as the force is applied to the axis. In most situations, the load pattern includes a slab, beam, column and foundation. Our focus this semester was predominantly on single span and continuous beams. Single span beams are supported at only two points whereas continuous span beams are supported at three or more points along their length.

02 – REFERENCE PROJECTS

1.) Community Centre in Reinosa

Location : Reinosa, Spain

Architects : RAW/deAbajoGarcia

Construction Year : 2017

2.) G3 Shopping Resort

Location : Vienna, Austria

Architects : ATP Architects Engineers

Construction Year : 2012

3.) SCS Warehouse in Philippsburg

Location : Phillipsburg – Huntenheim, Germany

Architects : Gumpp.Heigl.Schmitt Architekten

Construction Year : 2011

4.) Hall 10 Der Messe Stuttgart

Location : Stuttgart, Germany

Architects : Wulf Architekten

Construction year : 2018

5.) Factory Building in Bobingen

Location : Bobingen, Germany

Architects : Florian Nagler, München

Construction Year : 2001

6.) Garage and Vehicle Workshop in Andelfingen

Location : Andelfingen, Switzerland

Architects : Rossetti+Wyss Architekten, AG, CH–Zollikon, Mark Aurel Wyss

Construction Year : 2015

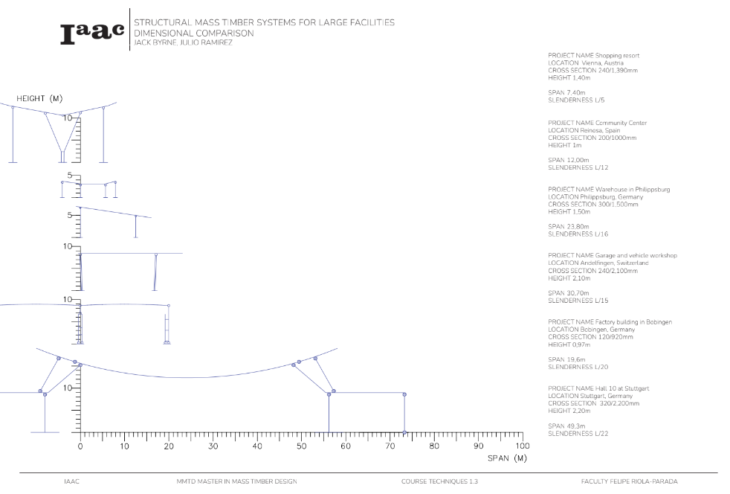

03 – SPANS

The building with the largest span is the “Hall 10 in Stuttgart”, with a 49.3m span. The building with the smallest span is the “G3 Shopping Resort in Vienna” at 7.4m. Most of the spans range from 12m to 30.7m, with the only exception being the Hall 10 in Stuttgart, where we find the largest spanning beam. Most of the beams are single spanning but there is one exception with the shoping resort beam being a continuous beam.

04 – SUPPORTING CONDITIONS

In the majority of cases, the columns are connected using fixed supports to the foundation. However, the Factory building in Bobingen utilizes pin joints while the Hall 10 in Stuttgart utilizes both fixed and pin jointed connections.

Hall 10 in Stuttgart – Image sourced – Detail Magazine

05 – MATERIALS

1.) The Community Centre in Reinosa is predominantly constructed using Glulam beams in conjunction with some steel columns and supports.

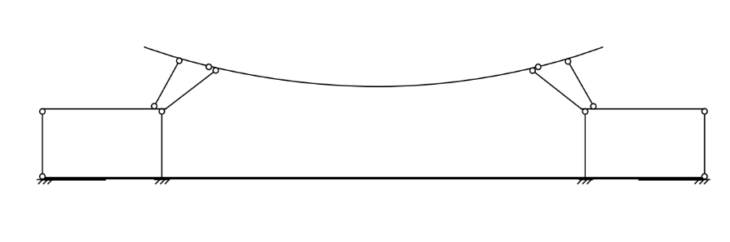

2.) The G3 Shopping Resort utilizes CLT to create the giant wave form roof. The roof is then supported by glulam beams which are supported on reinforced concrete external columns, and Y-shaped steel central columns.

3.) SCS Warehouse in Philippsburg utilizes relatively short glulam beams to span the warehouse bays. However, the beams above the access and loading zones are all simply supported beams spanning 24 or 27 metres.

4.) Hall 10 Der Messe Stuttgart employs a steel structure comprising gerberettes and columns carries the roofs of the two side naves and the central nave. The latter rests on a total of 47 glued laminated timber beams,68 m long and with a span of approximately 50 m, which were each delivered to site in three pieces, lifted into place by crane and the pieces connected together.

5.) Factory Building in Bobingen uses laminated softwood roof beams which connect to laminated timber columns at 6-metre centres are constructed in the form of Vierendeel trusses.

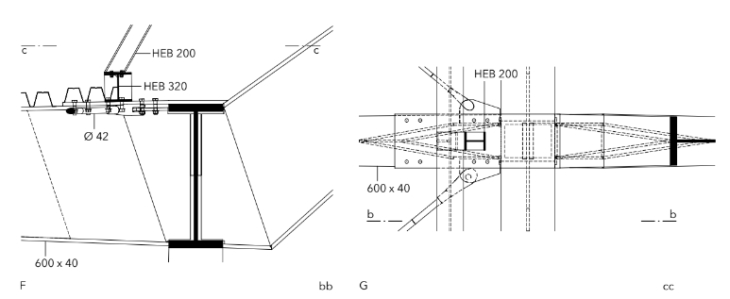

6.) Garage and Vehicle Workshop in Andelfingen uses glulam beams with the 32 m long main supporting beam over the entrance doors playing a key role in the loadbearing structure. The 2 m high, 24 cm thick beam spans the 25 m wide wall opening and has to carry almost half of the roof load.

06 – CROSS SECTION AND SLENDERNESS

The height of the beam varies with the smallest beam being utilized at the Community centre in Reinose, with a height of 1000mm. The highest beam can be found at the Hall 10 in Stuttgart where it has a depth of 2200mm.

The slenderness of each case studies vary with the smallest being L/5 and the largest being L22.

When comparing all the case studies beam slenderness, they are all possess similar slenderness characteristics, even with completely different design and construction concepts. The G3 shopping resort in Austria has the smallest span and also the most slender beam. As the span increases, the slenderness of the beam must be sacrificed to accommodate the additional loads required of it. The Hall 10 in Stuttgart has the largest spans as well as the least slender beam due to its structural requirements.

Hall 10 Beam Layout

07 – BRACING

1.) The Community Centre in Reinosa uses steel cables and columns for its bracing and stability.

2.) The G3 Shopping Resort utilizes a number of methods to brace the structure. Where the structure is not connected to the reinforced concrete columns, steel nodes connect the three part beams by means of steel plates let into the timber with elongated holes for steel dowels so that changes in length can be accommodated without restraint. In addition, there are transverse beams that function as tension and compression members and are positioned along the edge of the roof on the axis of the reinforced concrete columns and in the middle of where the roof aligns with the tops of the columns.

3.) The SCS Warehouse in Philippsburg used solid timber sections instead of trusses, which are complicated to assemble and erect. The designers had to devise a uniform construction configuration for the different structural situations. To do this, they specified glulam beams with approximately identical cross-sections on all main longitudinal grid-lines, functioning as continuous beams supported on the reinforced concrete columns. At the top of each column the support is in the form of a fork, providing lateral restraint to the beam, but the beams at the lower level are ‘threaded’ through a slot formed in the columns. The 12 to 24 metre long roof beams span between the reinforced concrete columns or run from the longitudinal beams to posts

supported on the longitudinal beams at the lower level. Transverse beams spanning between the roof beams form the supporting structure for the roof decking and at the same time provide lateral restraint to the roof beams. On the outer longitudinal grid-line, the buckling length of the roof beams above the loading zone has been shortened by installing diagonal struts. They form a type of inclined truss that provides additional stability for the building.

4.) Hall 10 Der Messe Stuttgart’s structural form is that of a gerberette, an arrangement whereby the bearing force on the facade is never in tension, but remains in compression in all load cases. The green roof construction on the side naves makes a particular contribution to achieving this loading condition. It weighs about three times the weight per unit area of the foil roof over the main nave. The need to avoid tensile loads on the facade columns was because they have an F30 coating, which does not have approval for use on tension members. The cross section of the gerberettes varies in height and width to suit the bending moment envelopes. A 508 mm diameter circular hollow section beam running longitudinally rests on the gerberette cantilever heads and picks

up the loads from the timber roof. The timber central hall is stiffened by the steelwork. The diaphragm action of the timber roof is ensured by cross bracing in the middle and the partial diaphragm effect of the cladding. In the longitudinal direction, the horizontal loads from the longitudinal tubes are transferred via the gerberette cantilevers into the side naves. The gerberette cantilever bays

are also braced with diagonals over the hall doors and the forces in them are transferred to the longitudinal transfer beam. The beam rests on the reinforced concrete structures at the ends of the hall. The southern end resists horizontal forces; the northern end allows longitudinal movement. Horizontal bracing at the edge structure would have been too long. The inner columns are therefore built into socketed foundations, diagonal bracing in the roof plane of all the side naves bays transfers the horizontal loads.

5.) Factory Building in Bobingen’s roof construction is supported by a series of slender laminated roof trusses at two-metre centres. Longitudinal bracing is provided by steel crosses in the long facades, by laminated sheeting in certain areas of the roof, and by the longitudinal beams and gantry rails.

6.) Garage and Vehicle Workshop in Andelfingen is assembled from 36 glued laminated timber wall members with interlocking corner halving’s, the construction very closely

resembles that of a traditional log cabin. Interlocking corners, the largest ever manufactured, secure the structure against overturning and longitudinal displacement. Kept in place by vertical steel pins, the logs are slightly off-set to one another so that the building widens with height. Drip notches are routed into each projecting edge on site, allowing rain water

to drip off as it does from shingle cladding. The narrow lengths of wall on each side of the door elevation stabilize the structure in the longitudinal direction and reduce the span and therefore the structural depth of the timber beam over the door opening.

Garage and Vehicle Workshop in Andelfingen – Interlocking corners

Hall 10 – Stuttgart steel bracing

08 – SUMMARY DIAGRAMS

Beams span and height comparison

Beams comparison

Structural Mass Timber – Analysis of Large Facilities – Beams is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at MMTD in 2021/2022 by students Julio Ramirez & Jack Byrne. Faculty: Felipe Riola Course: Techniques 1 – Module 3