STRAWSHAPE

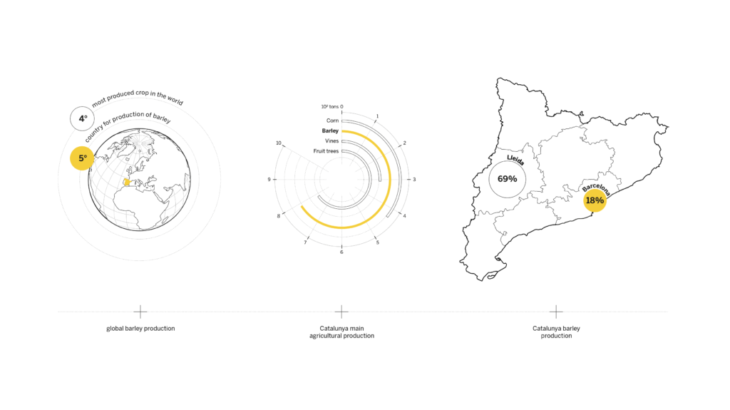

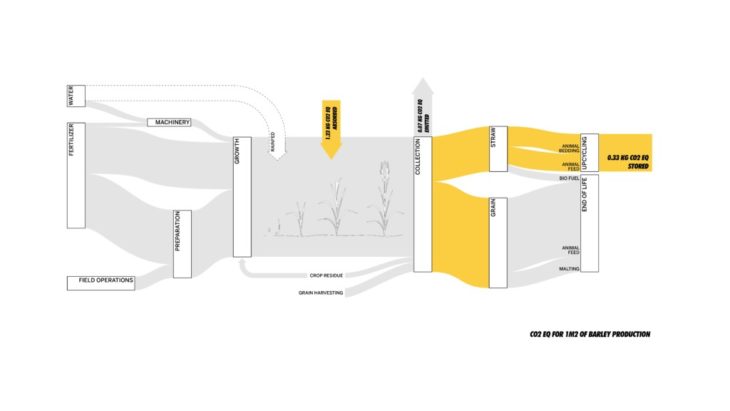

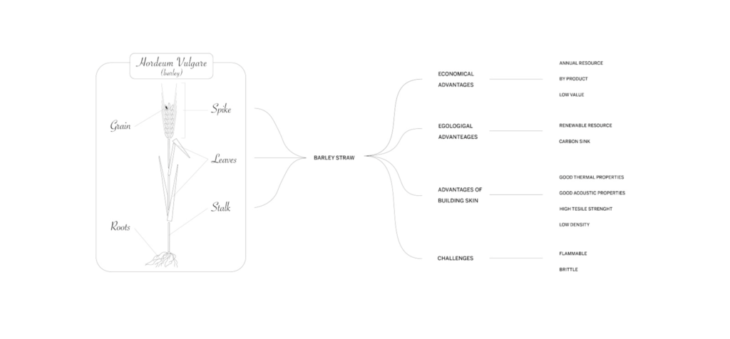

Straw is an agricultural by-product of grain production that is currently not sufficiently valorised. Spain is the 5th country in the world for production of barley, which is the 4th most produced crop in the world. In Catalonia specifically, for every square meter of grain production, 272.725 tonnes of straw is being generated annually. The main uses of such straw is for animal bedding and feed but it’s lifetime can be extended by using it as a building material.

Straw has been used in construction worldwide for over 100 years, but despite it being an annual carbon sequestering resource with low environmental impact, low density and good thermal insulation properties its use has not been widespread and only limited to single house constructions with a contained shape possibilities.

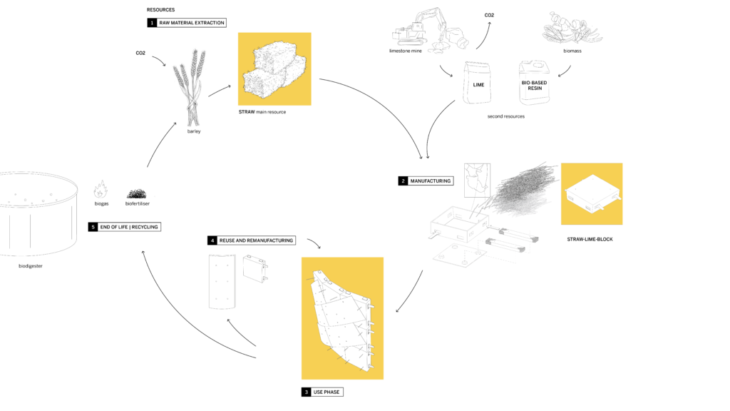

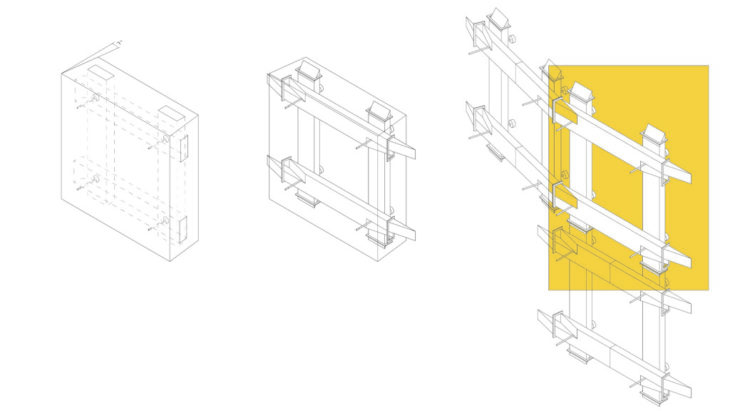

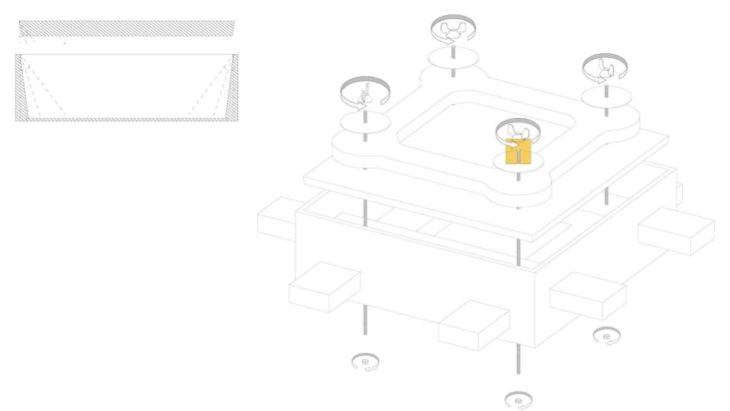

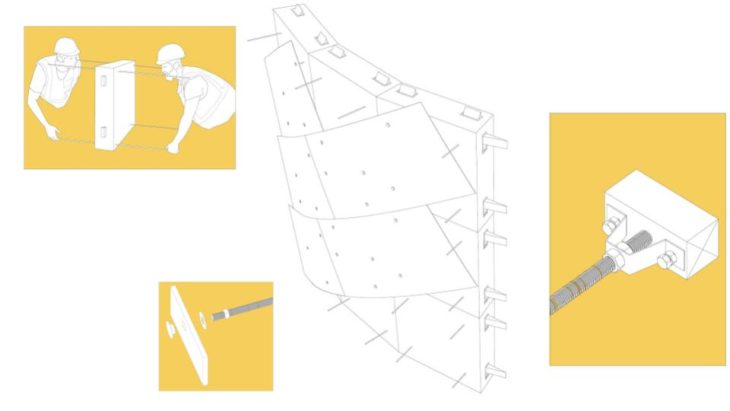

The proposed material system will allow for the implementation of straw as a building material for larger scale constructions by allowing more geometrical freedom in the form of the building skin. This is achieved through a material system composed of an outer layer of composite straw panels with a natural resin that are bolted to a lime-straw insulative layer.

MATERIAL PROPERTIES

MATERIAL SYSTEM LIFECYCLE

FABRICATION METHOD

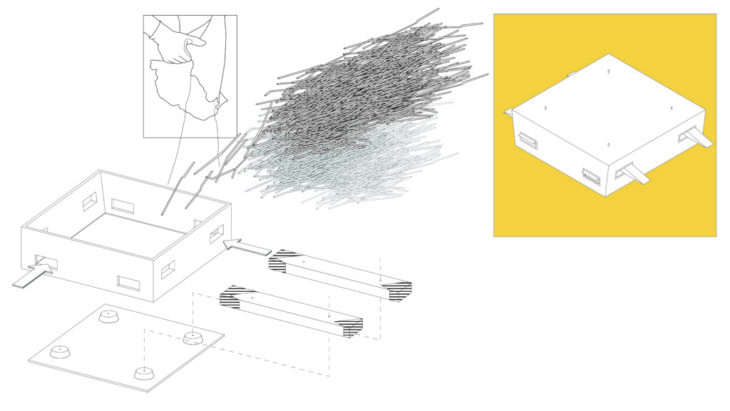

The straw and lime layer is molded with a wooden structure inside that holds the joints between the panels. A lid is placed on top that is compressed with the use of bolts that will later on be used to attach the external straw-resin layer.

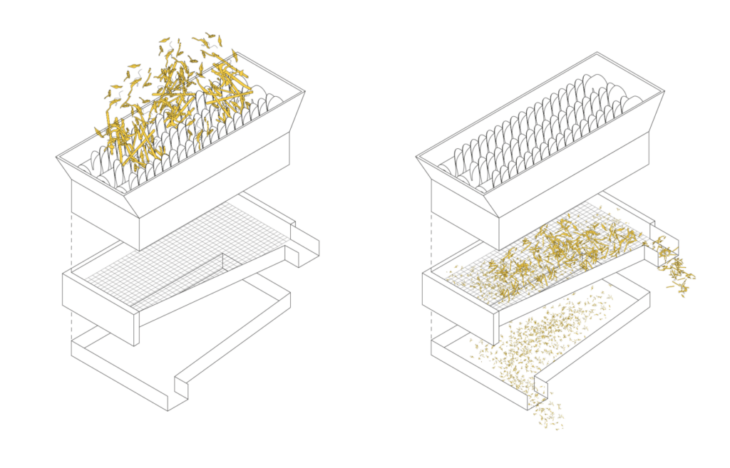

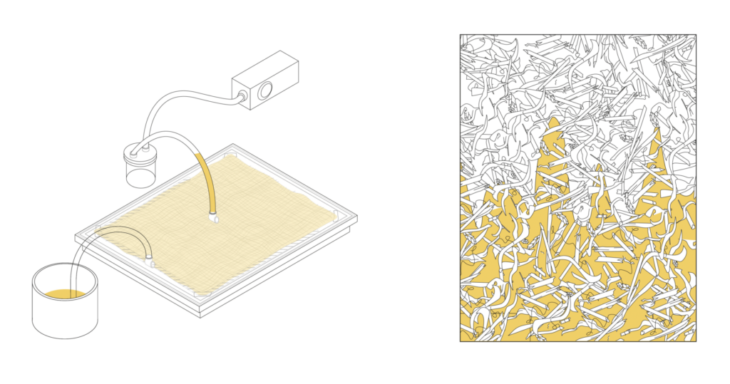

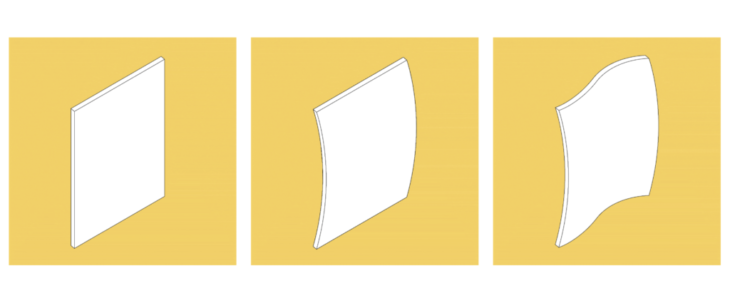

The external composite panel is fabricated by shredding and sifting the straw into various lengths and then it is vacuum infused with the resin. During the curing time of the resin the panels are being shaped into the required curvature.

PROPOSED MATERIAL SYSTEM

is a project of IAAC, the Institute for Advanced Architecture of Catalonia, developed during the Master in Advanced Architecture (MAA01) 2020/21 by students: Mira Housen, Alex Ferragu, Taimur Mian, Mara Muller-de Ahna; faculty: Areti Markopoulou, David Andrés León; faculty assistant: Nikol Kirova; fabrication advisor: Eduardo Chamorro; student assistant: Alexander Dommerhausen