SPIRAL CRATERS

Introduction to Digital Fabrication

The goal of this project was to create an acoustically performative panel using CNC milling. The designed panel had to act as a sound absorber in a reverberant studio space.

The two main criteria’s in this project were :

1. To design the sound absorbing panel with minimum wastage (Design Strategy) and

2. To have an efficient milling strategy that doesn’t take a lot of time (Milling Strategy).

1.Design Strategy

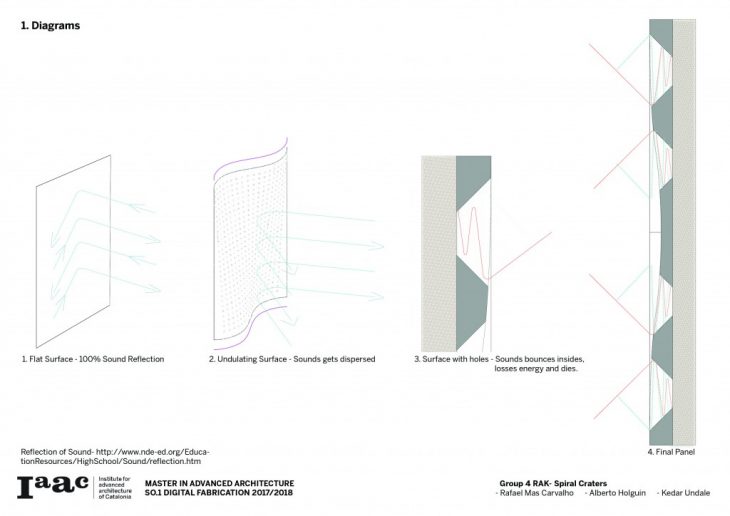

The design started with understanding, what material to use and how to make it sound absorptive.

We found that to make a material highly sound absorptive, it should have an undulating surface and should be porous in order for sound energy to die inside.

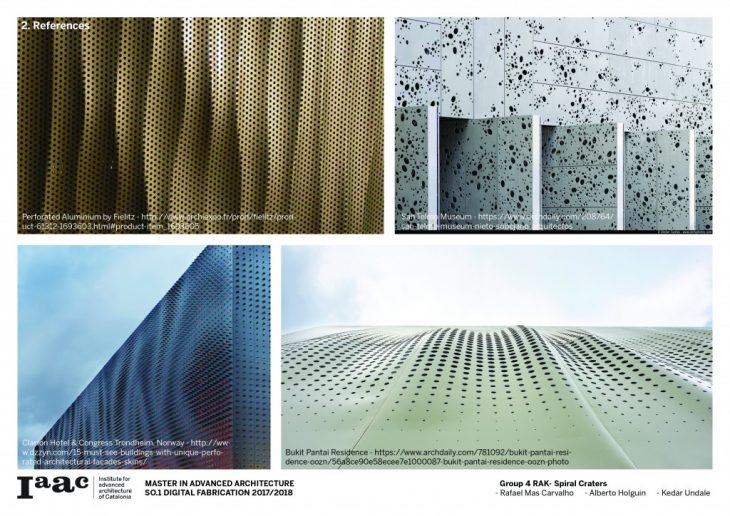

A few references were searched in order to develop the design.

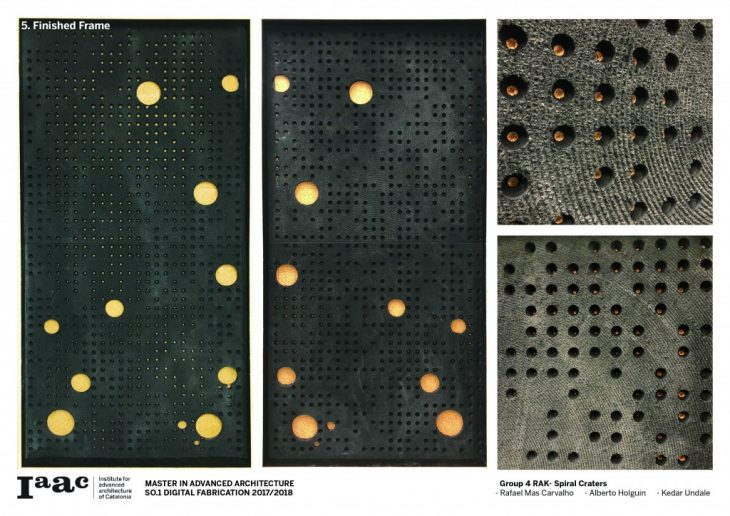

After referring few images, we finally decided to have a waveform on the surface with holes of different sizes

For the material, we went with Ethylene-vinyl Acetate(EVA) foam and a cork sheet. The EVA foam already has few pores, which makes it more sound absorptive and the cork sheet also absorbs sound but mainly acts as a structural sandwich between the two sides of the panel.

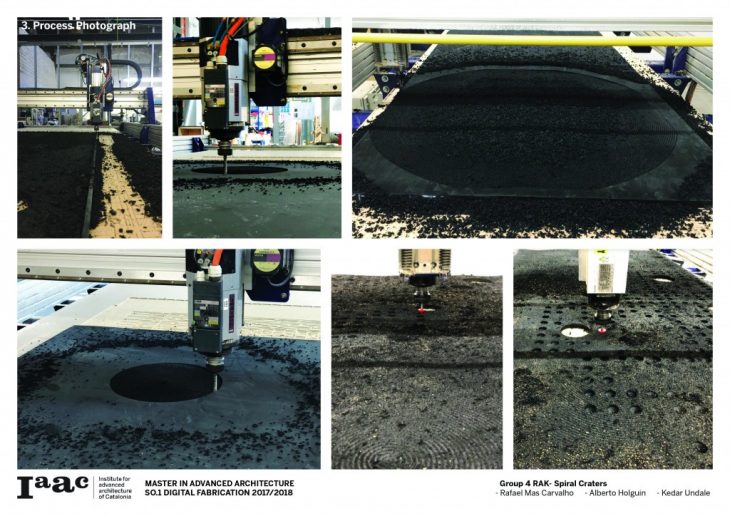

2.Milling Strategy

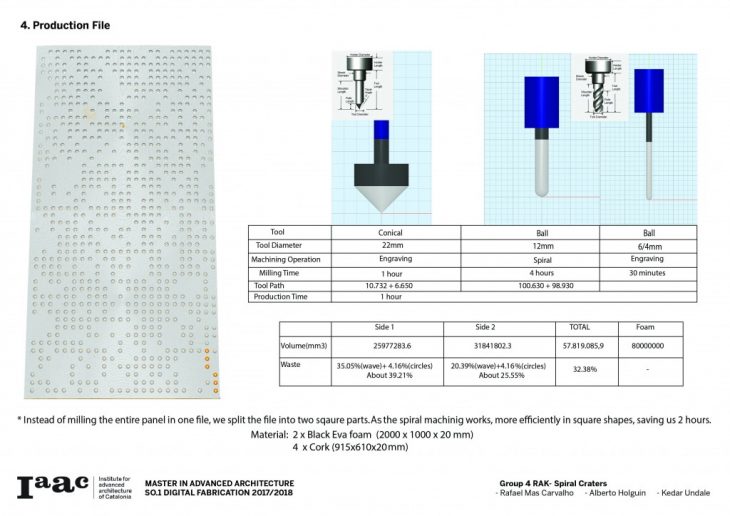

In order to reduce the time and to have more texture on the panel, we went with the spiral engraving using a 12mm ball bit. This helped us to cut down the time by 2hours.

For the holes, we went with the 22mm conical milling bit, which made different sizes of holes depending on the waveform of the surface.

Final Panel

Spiral Craters is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture, MAA 01 in 2017 – 2018 of the Studio SO.1 – Introduction to Digital Fabrication by :

Students: Rafael Mas Carvalho, Alberto Holguin and Kedar Undale

Faculty: Alexandre Dubor, Raimund Krenmueller, Ricardo Valbuena and Kunaljit Singh Chadha.

Support: Ks Sujal, Shyam and Ricardo.