Spaces OffCuts

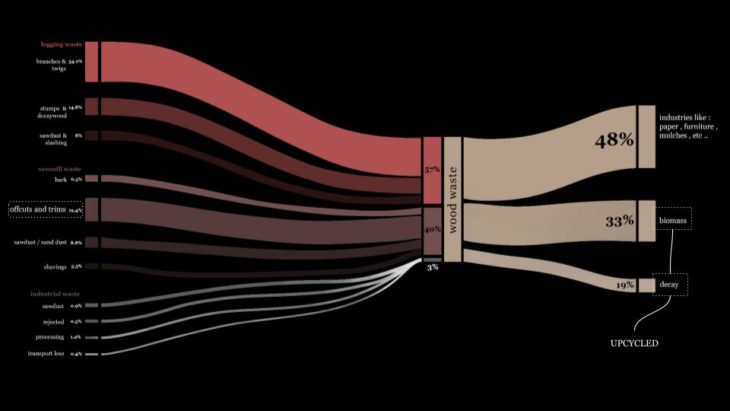

Through the process of lumber production, a large quantity of wood is discarded as waste. Only 40-50% of forested wood is recovered as processed lumber. The waste is generated in sawmills and CLT production while creating standardized sized timber pieces, due to the the shape and profile of logs and the variation in cross section. Most of it is discarded as unusable pieces and often converted into wood chips to be used or used as biomass. With the increase in proposals for mass timber architecture, the amount of wood waste will increase proportionally. Recently, French president macron has pledged that all state-funded buildings in France must contain at least 50% organic materials. These policy changes would affect the production of timber for production, and in turn the waste generated.

Can wood waste be up cycled to create meaningful spaces as a secondary skin for existing – built infrastructure? Instead of converting them into chips, we propose upcycling the discarded pieces by using them for a building skin that adds value to urban fabric by spacemaking.

The objective of this research is to identify and investigate the discarded waste wood, and its classify into suitable elements that will make up the structural and programmatic elements of a building façade. This will aim to solve pressing problems from different façade types from; restricted balcony access, commercial glass buildings with high levels of solar gain, high pollution areas, areas with limited social activities.

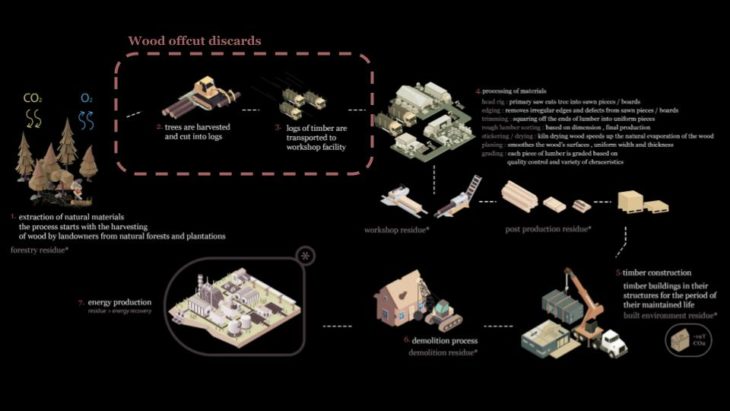

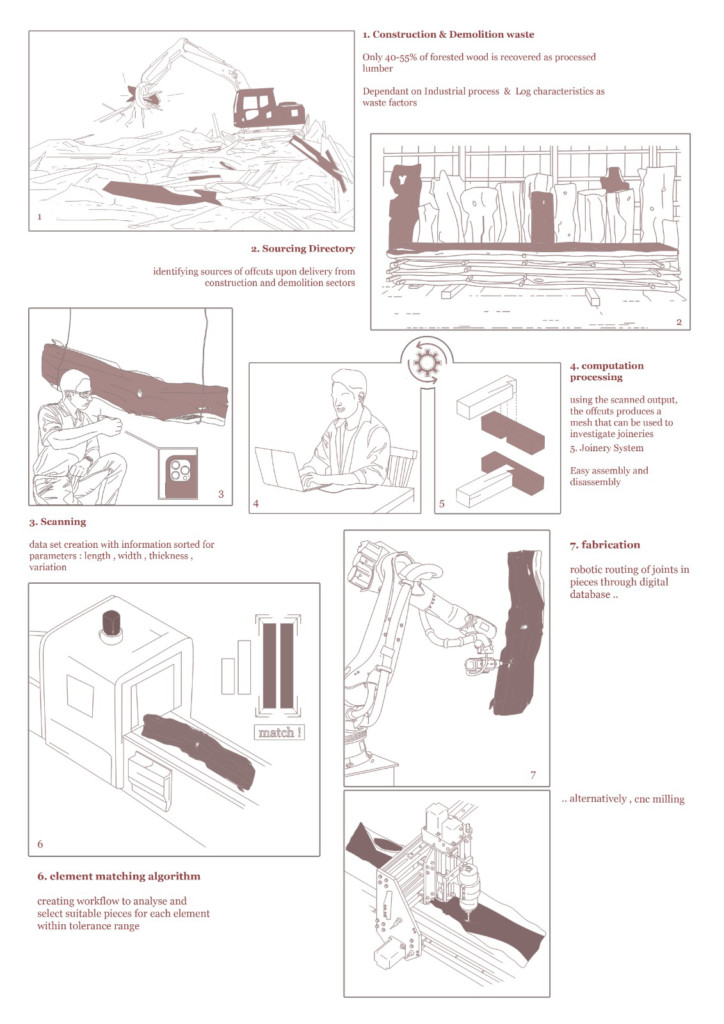

Lifecycle

Waste Sankey diagram

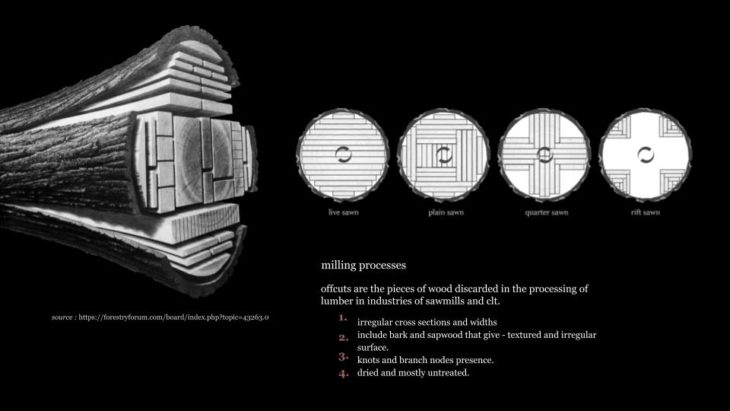

Understanding Wood waste

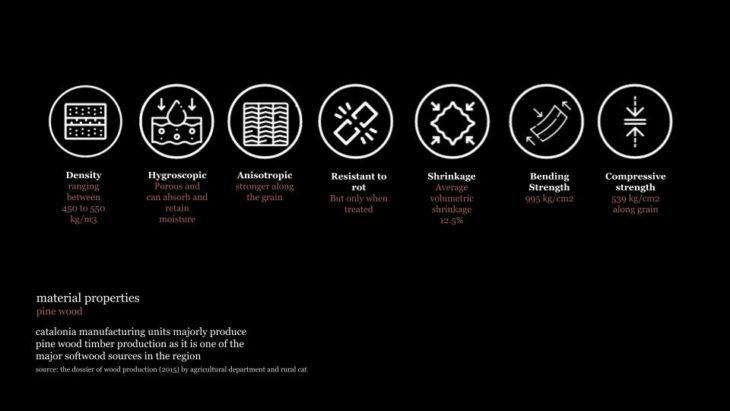

Catalonia majorly produce pine lumbers as Catalonia has forests of pine wood. The wood waste for the project was obtained from Valldaura labs. therefore, pine wood properties were studied. Offcut properties were taken into account to form an understanding of the material.

Further explorations to understand the specificities of the irregular pieces made by scanning all the pieces to form a library . The pieces were sorted and classified according to parameters like length, width, thickness, variation in these , knots, densities etc.

Process – Global system generation

The intent of the process is to create a system – which facilitates the usage of wood waste offcuts from an available library stock. Focus is on minimizing fabrication and cutting of pieces to generated least waste. Effort would be made to utilize the waste as they are without regularizing their size – length, thickness or width. The classification of these pieces would inform the contribution in the design and where it can fit into the designed system.

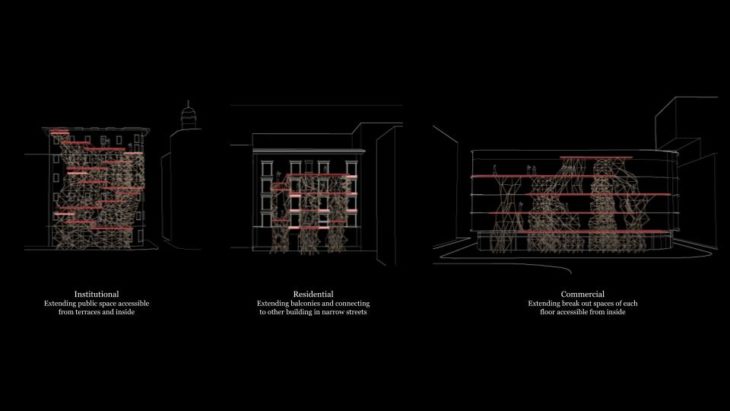

Typical facades

Our typical facades lack connectivity with outside. The system doesn’t allow or accommodate human’s connectivity with the outside or with each other. The monotonous building envelops often form a rigid threshold between the exterior and interior.

these facades though could have intermediate spaces where people can interact within themselves and also be a part of outside. these spaces could facilitate a better and more productive outlook as well as a place to step out to connect with the external environment. These spaces could be interconnected or disjoint dependent on design decisions and form a system of visual or/ and physical connectivity

Spacemaking Parameters

The generation of these spaces can be inform of platforms as a secondary skin. The sizes, typology, location of these platforms can vary defendant on different parameters specific to the building envelop, context, location and building typology.

Platform generation dashboard

The system of space generation can be global where inputting these parameters can generate the platforms that have to supported by the wood lattice

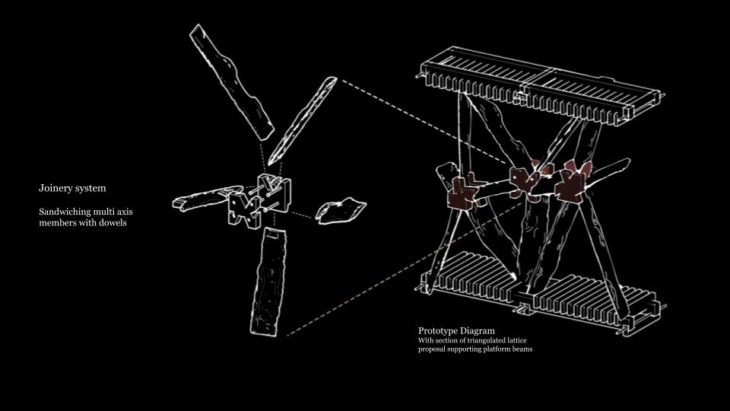

Wood lattice – structural system unit

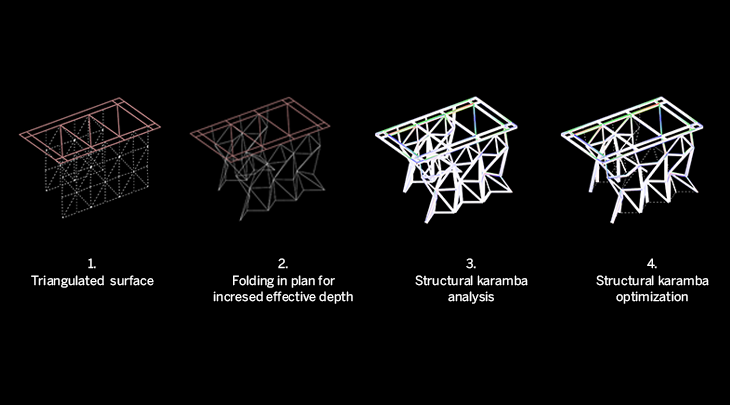

The lattice is formed out of response to a light weight optimized structural system. It increases it is effective depth of cross section by its folding in plan. The triangulating in its surface as well as in plan helps to form a system which can effectively support the generated platforms by using lesser number of elements than a traditional scaffolding system.

The lattice members can be altered to find and match elements from the available stock of wood waste available. this element matching system would ensure minimum fabrication to alter the existing pieces to fit into the regular structural system. Thus the structural system adapts to embrace the irregularity of the available waste.

The structural system can further be optimized by digitally analyzing the model by karamba structural plugin and thereafter optimizing the system to reduce the number of elements from the system.

Wood lattice – system development

System as adapted on different façade typologies

the system can adapt and be generated on all facades takin in mind the platforms that were generated on it. factors like fenestrations, context, orientation and activities on ground floor can drive the growth of the lattice

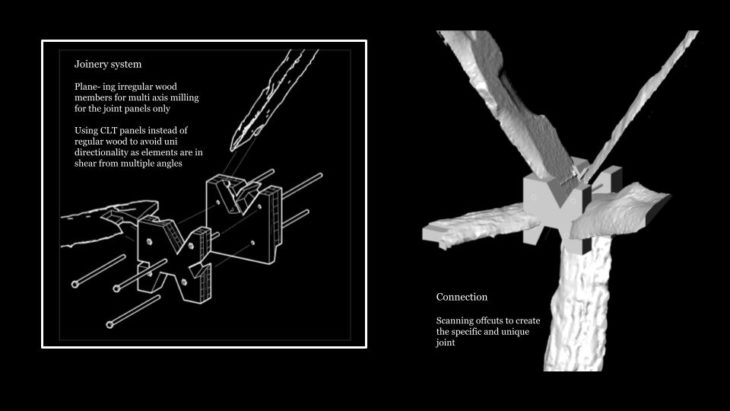

Joinery System

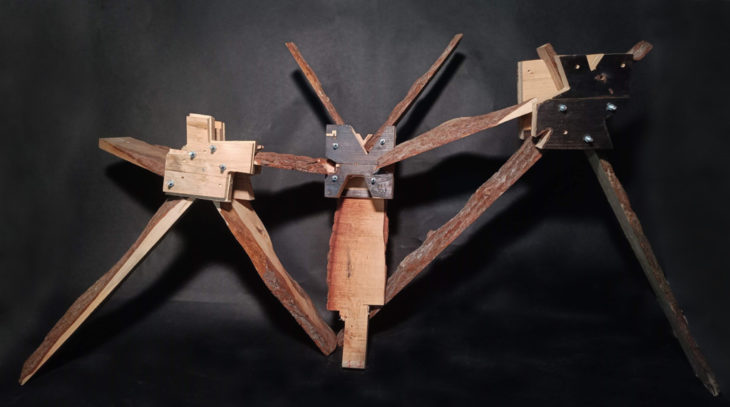

The Joinery system takes in to account the multi axis and directional elements. The proposal is sandwiching pieces by compressing from two sides of the connection. the sandwiching helps in taking into account strength required for the shear. CLT panels instead of regular wood enforces this.

The prototype demonstrates the basic system of t2- way triangulated system that forms the lattice. the pieces were scanned, logged and sorted to form the lattice. the choice of intersection between joinery panels and lattice members is made in a manner that multi axis milling only has to be carried out on the CLT panels and not on each waste offcut wooden pieces. This ensures a workflow where time is saved and complexity reduced for fabrication.

Spaces OffCuts is a project of IAAC, the Institute for Advanced Architecture of Catalonia, developed during the Master in Advanced Architecture (MAA01) 2021/22 by students: Jeremiah Oonyu, Vasudha Karnani and Aaron Perriera; Faculty: Areti Markopolou, David Leon; Faculty assistant: Nikol Kirova, Eduardo Chamorro Martin; Student assistant: Alexander Dommershausen