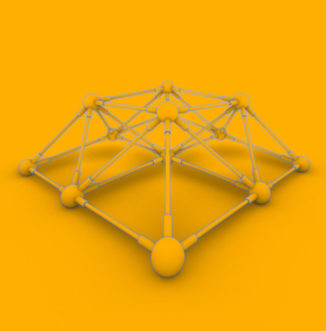

Concept

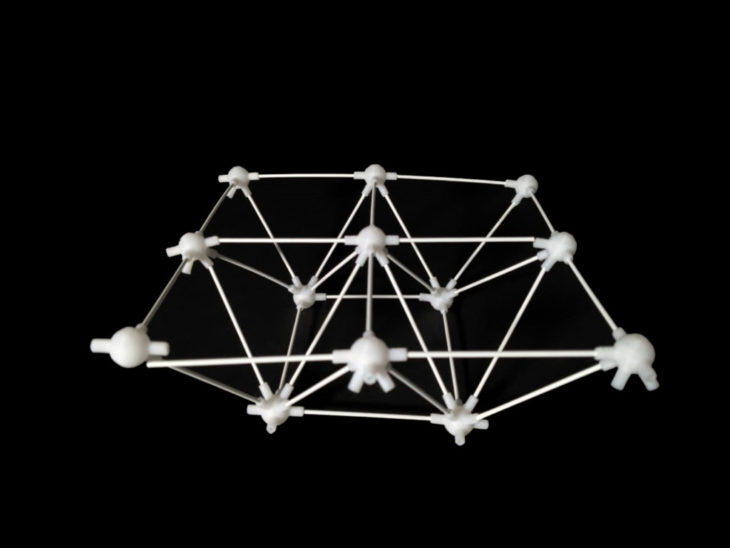

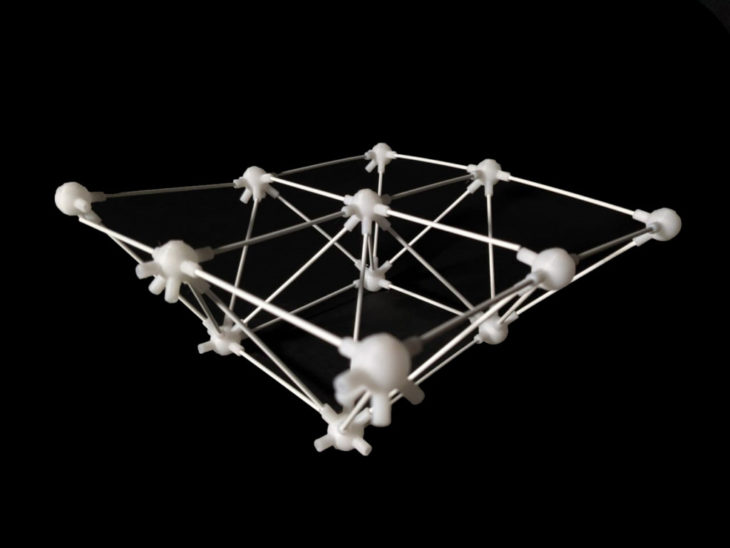

Space Frame was a design that explores the potential of additive manufacturing for architectural applications. This design was 3D printed using nodes that are composed of sphere junctions and legs that deliver the rods. These leg-extensions respected thicknesses of the rods that, in the end, conveyed the desired truss appeal. The rods get shorter to achieve a curved platform.

Space Frame

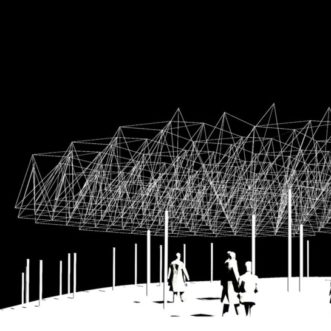

Inspiration

Space Frame is a recursive design that aims to aggregate and proliferate just as the case of the Gallery of Belvedere which has a web of space frames as a pavilion roof.

Gallery of Belvedere – Remstal Pavilion / Barkow Leibinger – 29

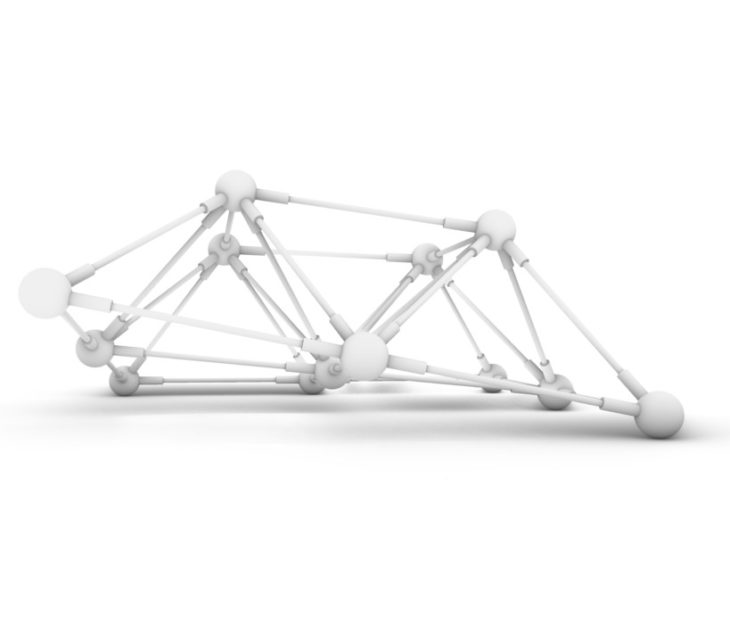

Model

Space Frame: Curved Platform

Space Frame: Curved Platform

Metrics

Material: Fiberglass Rods 2.0 mm/ Technique: 3D Printing/ Joint Type: Nodes/ Machine: Zortax M200/ Nozzle Diameter: 0.4/ Layers Thickness: 0.19/ Infill Density: 0%/ Printing Time: 4 Hours/ Optimization: Mixed/ Nodes: 12/ Dimensions: 18 mm x 13 mm/ Rods Spacing: 2.5 mm

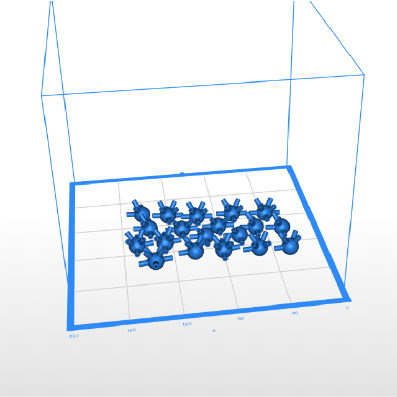

Production File

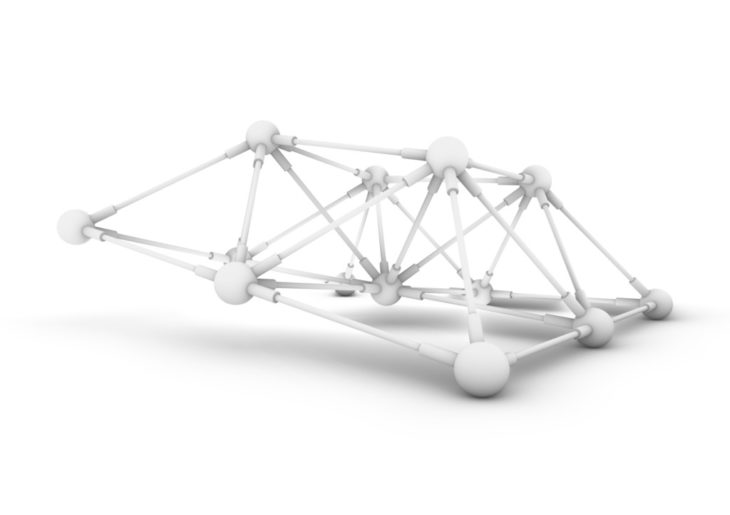

Model

Space Frame: Printed

Space Frame: Printed

Space Frame is a project of IAAC, the Institute for Advanced Architecture of Catalonia, developed during the Master in Advanced Architecture (MAA01) 2020/21 by students: :Michael Groth,Perniyal Waseem, Stanislas Naudeau,Vaibhav Toshniwal ; faculty: Shyam Zonca, Lana Awad, Marielena papandreou, Ricardo Mayor; faculty assistant: Karthy Vijaya, Ilaena Napier