Abstract

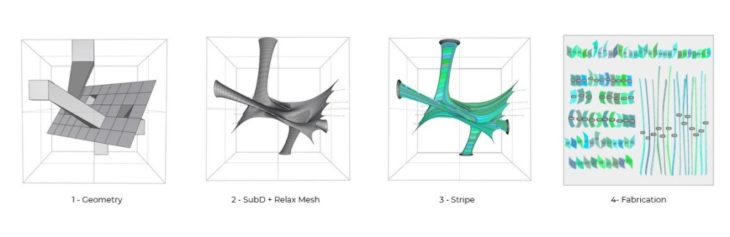

The focus of this studio is to explore mesh geometries and how they affect mesh topologies. For the first step, the team explored two kinds of minimal surfaces and different mesh subdivisions within. This study was crucial to understanding the effects of subdivisions to the mesh relaxation as well as the striping.

Concept

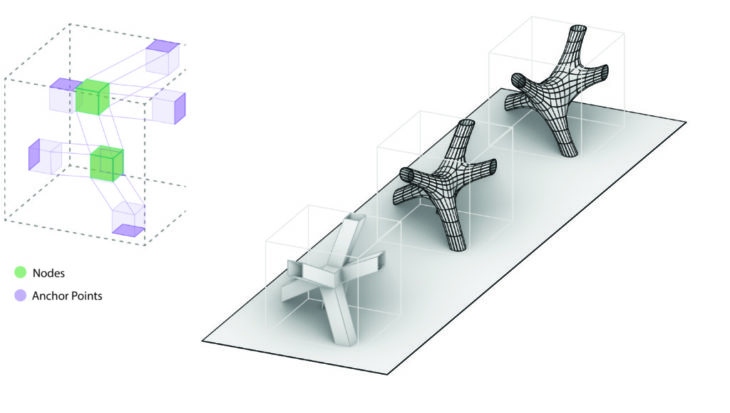

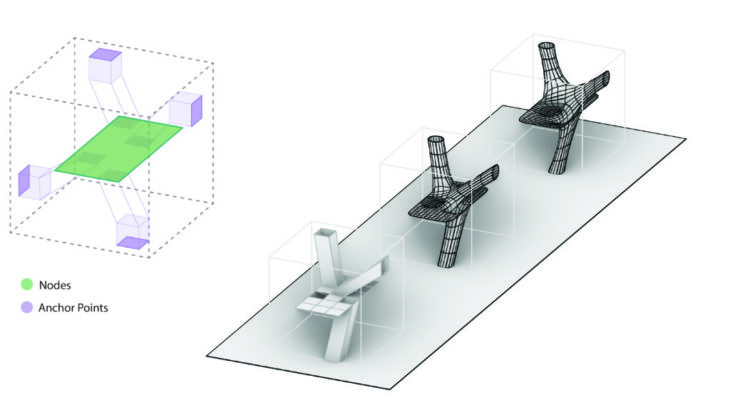

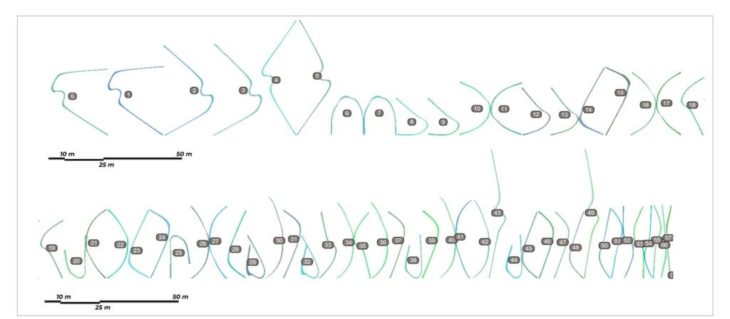

We use the kangaroo plug-in as a tool for mesh relaxation, within which we define the edge length parameters and anchor points. The project moves forward with the concept of different anchor points being connected by a node. The first set of mesh geometries are solid-to-solid connections between these anchor points.

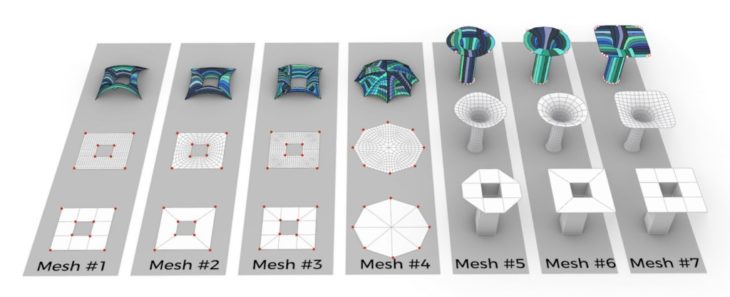

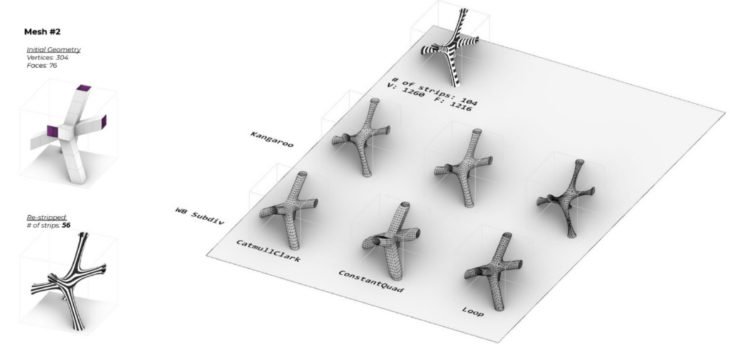

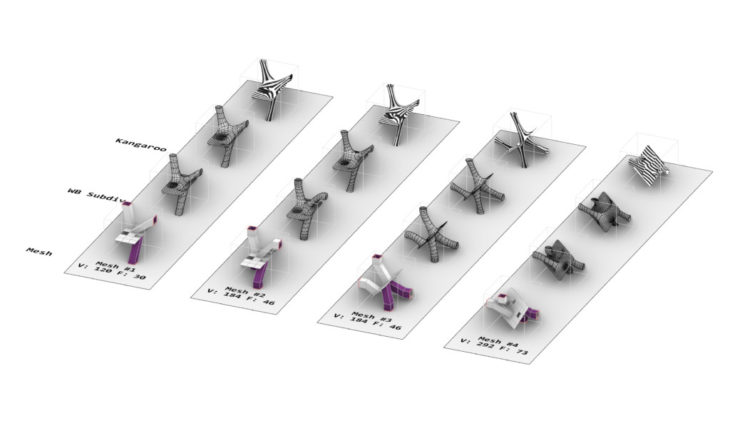

Mesh Geometry Studies

Solid to Solid

The limitation of solid-to-solid connections is that the mesh geometry is revealed in the striping process. There are only two possibilities of face topology iterations that could be explored in the striping of these geometries.

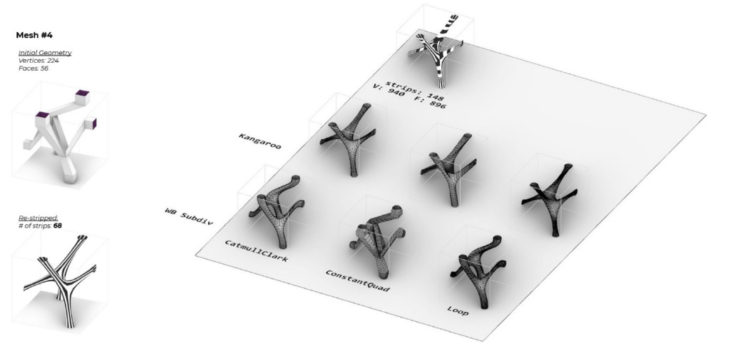

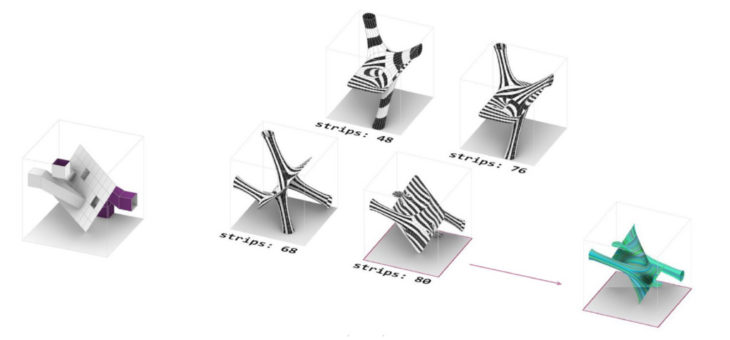

This called forth another study of mesh geometries, a surface-to-solid connection.

Solid to Surface

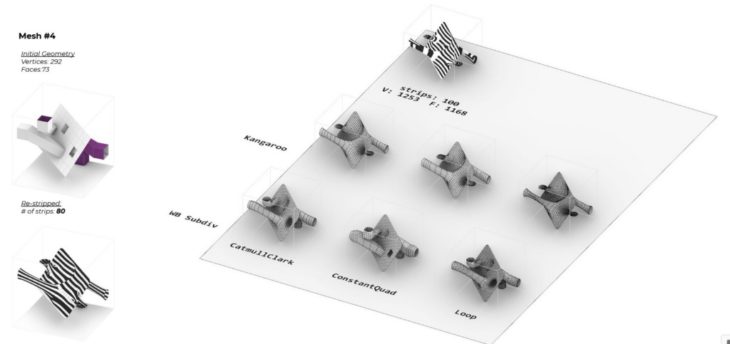

Mesh Geometry 4 was chosen for it being the closest to the desired geometry.

Mesh Geometry 4 was chosen for it being the closest to the desired geometry.

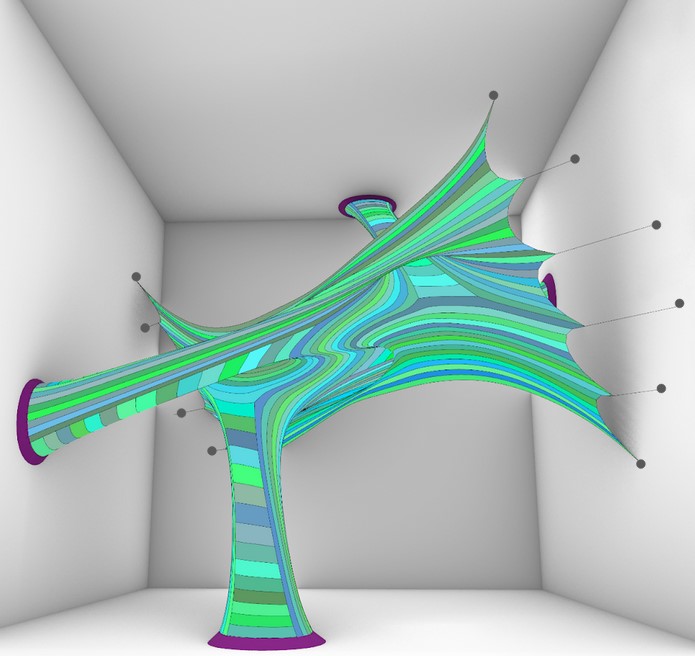

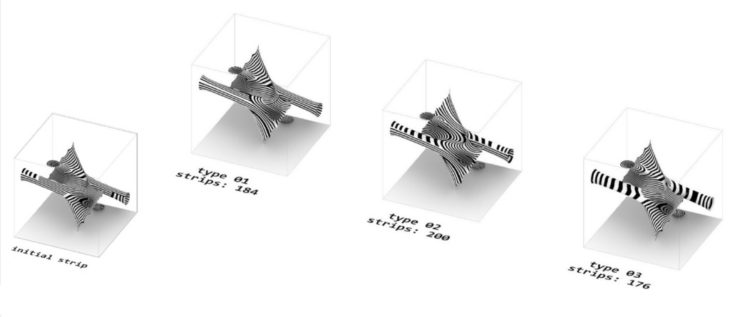

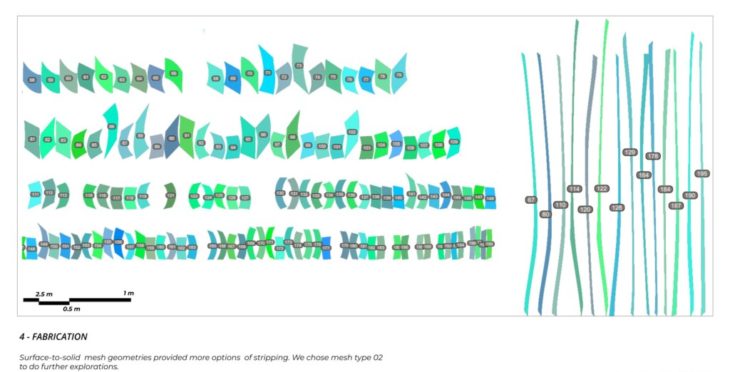

Mesh #4 of the surface-to-solid geometries were chosen to further investigate different methods of striping. Multiple iterations are possible with this definition, unlike the limits faced in solid-to-solid geometries.

Stripes + Fabrication

What stripe typology should we develop?

This question is intricately tied to the matter of fabrication. For example, if we choose to pair or group the strips with consideration of using soft material (with the potential of stitching), we would be choosing type 02.

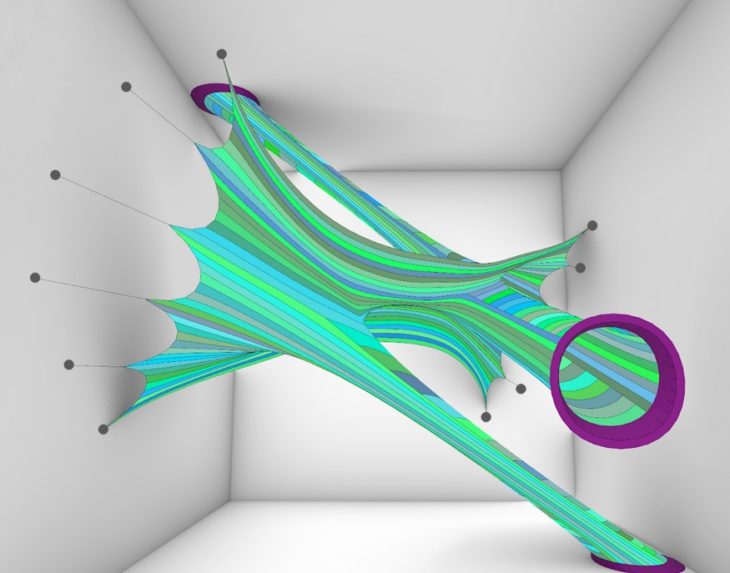

Number of grouped strips - 17 Longest Strip - 9.1mDifferent angles of stripe type 2

Different perspectives of stripe type 2 within architectural space

However, if the material being used for fabrication is aluminum, it is a less ideal choice. We took type 2 and nested the unrolled strips in grasshopper to study the repercussions. The strips were unrolled into a planar geometry and nested according to their lengths.

During the process we realized that more than the length of the strip, the width is what matters for production. Since the standard available width of the aluminum roll is 1.2m~1.5m, we reconfiguring our nesting to fit the industrial standard, we figured that 157 of the 206 strips fit in a size of 1.2mx63.8m aluminum roll.

157 of the 206 strips fit in a size of 1.2mx63.8m aluminum roll.

SOFTer Skin// Software I is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at the Master in Robotics and Advanced Construction in 2021/2022 by:

Students: Yeo Jeong Kim, Andrea Najera, Shamanth Thenkan

Faculty: Andrea Graziano

Faculty Assistant: Eugenio Bettucchi