The final project brief for the Master in Advanced Ecological Buildings requests a maximum 18 m2 prototype ecohouse to be completely designed and constructed within 4 months by the students on a site near Valldaura Labs.

Apart from striving for self-sufficiency, another key requirement is that the model should be equally applicable to similar settings, possible to transport by truck and generally suited to broader commercialization.

Because architectures must be specifically optimized for local conditions in order to function ecologically, these two demands appear at first contradictory – how can a building be both contextually dependent and adaptable to other yet to be determined settings?

The answer, intuitively, comes from nature itself: the seed!

Project team.

Arrival of The SEED to diverse ecosystems around the globe!

The SEED contains all essential components for a house, and grows into a specific home depending upon the inhabitants preferences and in response to local conditions.

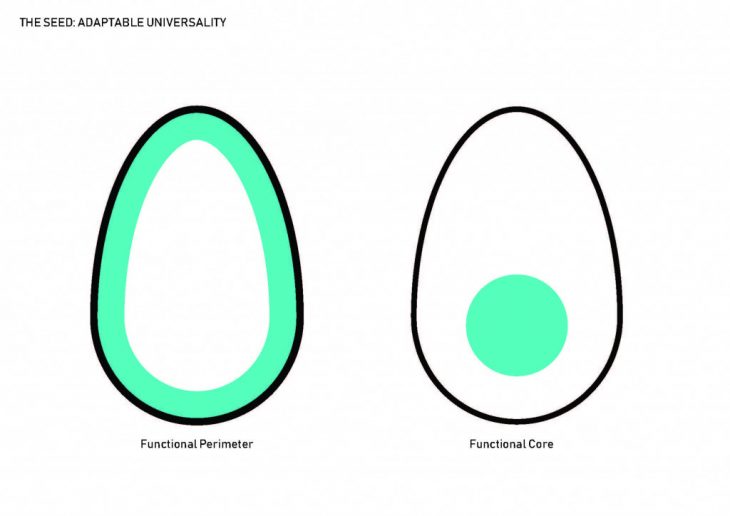

By choosing a functional core plan rather than the more conventional functional perimeter, universal necessities can be concentrated in a contained, replicable unit – The SEED – freeing the skin to adapt to the local conditions.

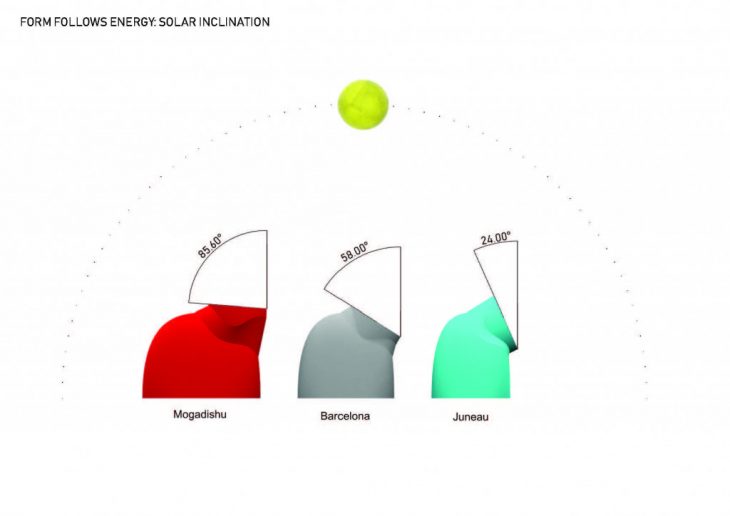

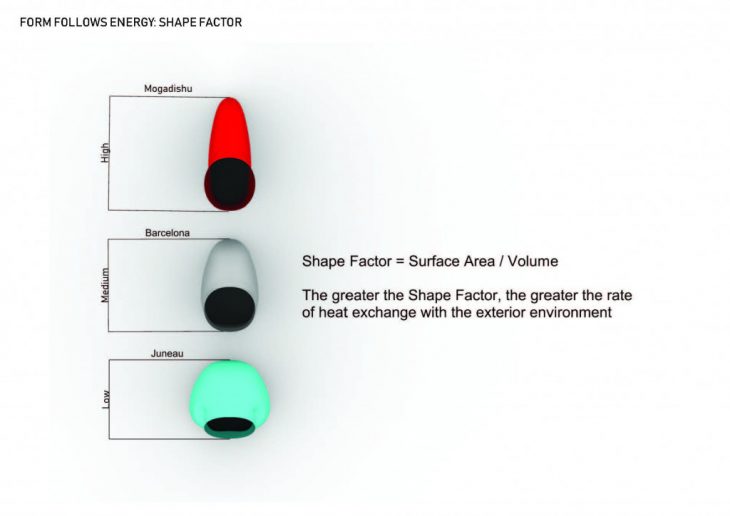

The general form of each SEED ecohouse is a responsive combination of the relevant solar angle, the core containing all universal necessities and the footprint.

The PV surface is angled according to locally specific solar regimes.

The footprint is adjusted to provide the shape factor optimal for the specific location of installation.

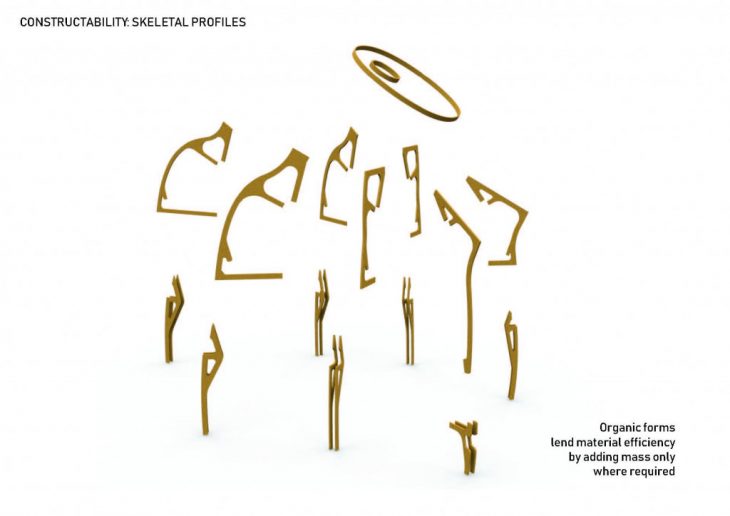

The cross-laminated timber (CLT) structure of The SEED ecohouse radiates from the heart of the home, core and solar surface, and is organically profiled for material efficiency – locating mass only where necessary. Such organic profiles are easy to achieve using CNC milling.

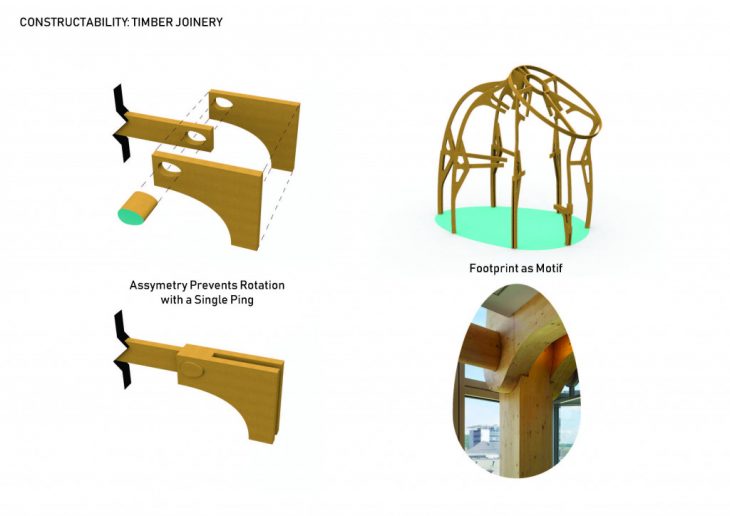

The unique footprint of each SEED Ecohouse, tuned to provide the locally optimized shape factor, is then used as a motif in all the timber joints, lending each ecohouse individuality in the details. The asymmetry of the footprint means that a single pin is sufficient to prevent rotation. Joints using only timber pins rather than conventional screws or nails are advantageous in terms of reducing the amount of embodied energy, carbon and water in the structure, but also in terms of performance; rather than transferring stresses from the CLT into the few discrete points where the steel fasteners are inserted, the mono-material joint deforms uniformly, working together as a flexible system of load distribution, thus extending the structure’s lifetime.

When attached to the central core, which serves as the primary load-bearing column, the structure becomes fully stable.

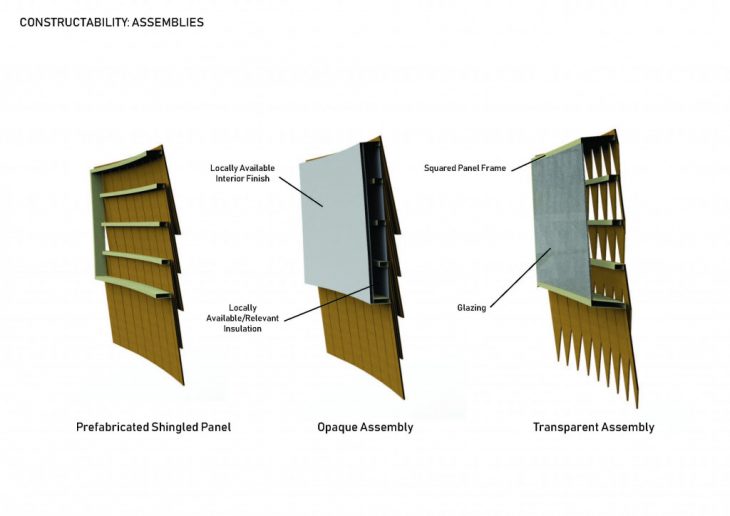

For ease of installation, repair and disassembly, the purlins supporting the facade are panelized in modules inserted between the structural members.

The structural members, combined with the core as the primary load bearing column and the panelized purlins.

The panelized purlins carry wooden shingles which overlap to form a watertight skin, or can be cut to allow light and air to pass through where desired. The interior edge of the frames can either enclosed with a finish maintaining the roundness of the form, or squared off to host standard materials like glass for windows.

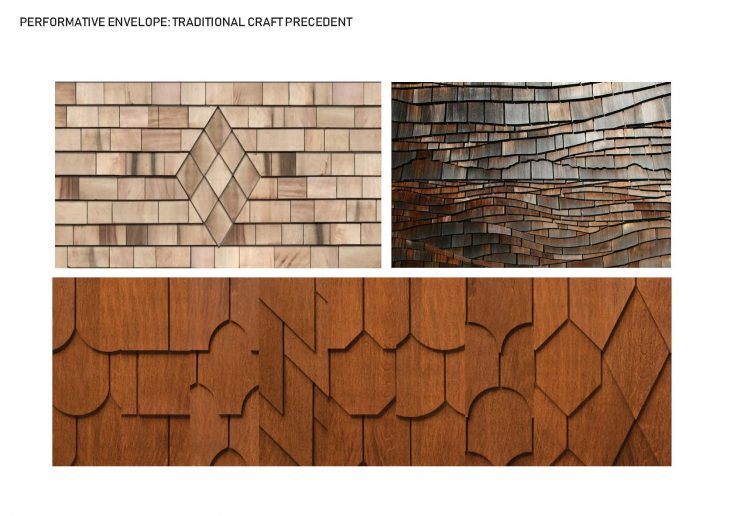

Wooden shingles are proposed because of their adaptability in terms of patterning and their ability to clad complex curvatures, as well as due to the availability of pine and oak from the forest surrounding Valldaura.

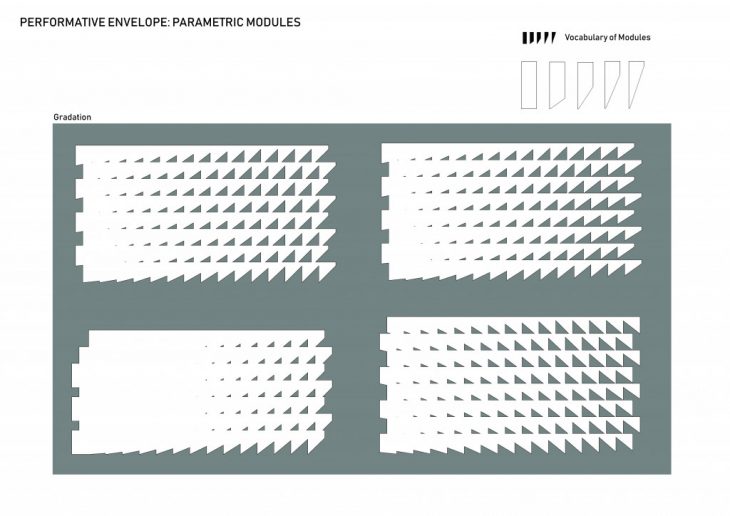

Using parametric software and CNC milling, the shingles can easily be profiled to overlap for full water-tight coverage where necessary, or cut back to create porosity for air and light to pass through when desired, lending an aesthetically captivating gradient to the facade system. Therefore, the architectural skin functions in the same way as a biologic skin – acting both as barrier and permeable membrane.

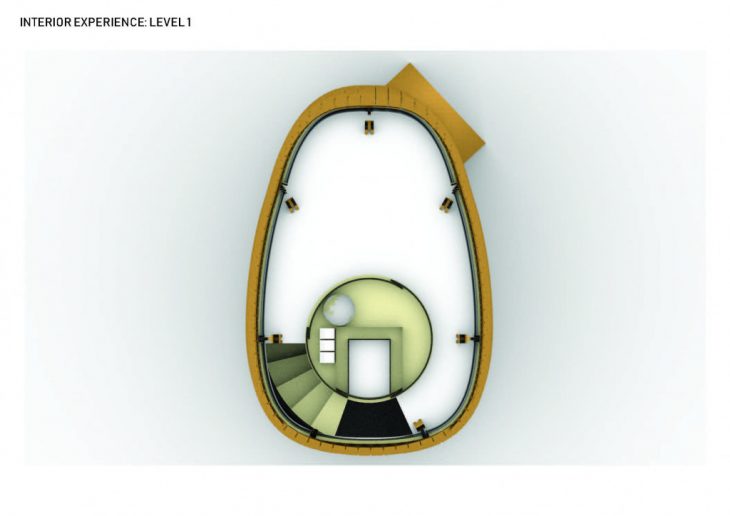

Essential functions are congregated in the SEED core, leaving the majority of the plan open for free use. Level 1 hosts kitchen facilites, as well as a toilet room and washing machine.

Level 2 hosts closet space and a shower.

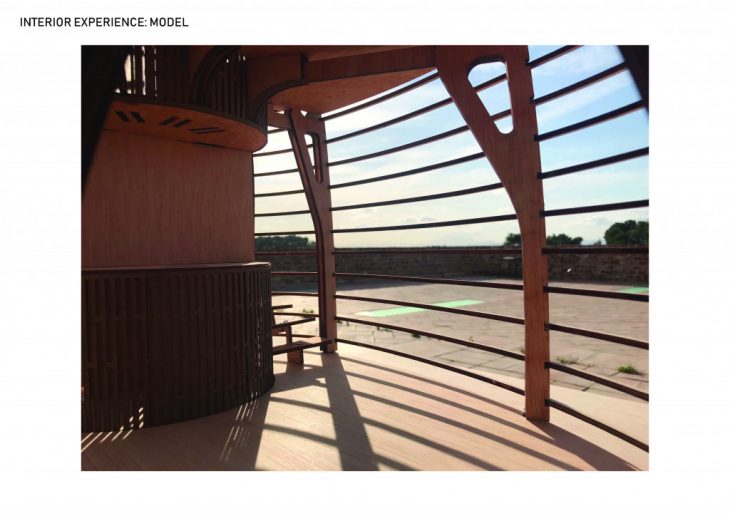

Interior view from the 1:10 scale model prior to the application of the shingles.

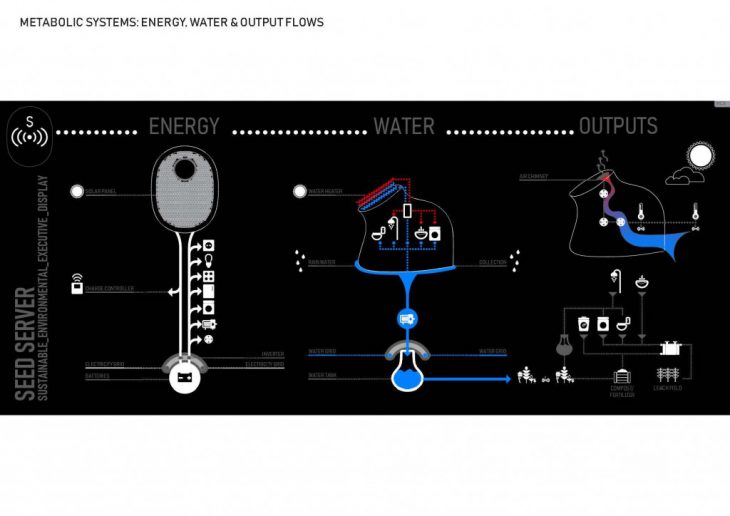

The SEED Ecohouse provides all of its own energy via photovoltaics, and all metabolic systems are designed to optimize efficiency by recycling gray water, combining space and water heating systems and providing users comprehensive feedback on system performance.

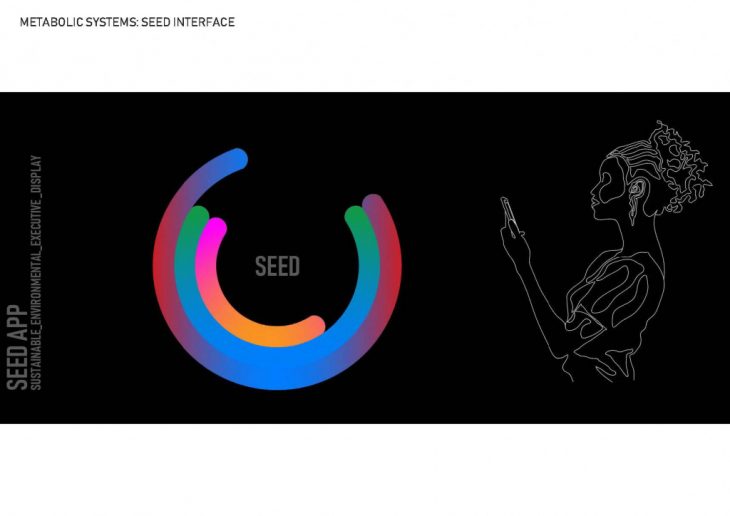

All information relating to the metabolic systems is communicated to users via an intuitive graphic app.