IAAC – Master in Robotics and Advanced Construction

Studio I

–

Faculty: Alexandre Dubor

Assistant Faculty: Raimund Krenmueller

ROBOTIC CRAFT

Syllabus

Taming catalan wood in non-standard construction

Industrial timber processing is aiming at standardization and predictability, taking out as much as possible of the inhomogeneities and particularities of the raw wood. This rather brutal way of taming a grown material is tightly connected to the constraints of the tools involved in wood construction, from the sawmill to the design software.

On the other end of the production chain, there is a big demand for thermally improving (and/or spatially extending) existing buildings through retrofitting elements. Wood offers a sustainable solution in such applications, but in catalunya, this demand cannot be met with locally sourced raw material: Due to its diversity and heterogeneity, catalan wood is used mainly in the production of low-quality products such as pallets or shredded and pressed into pellets for heating.

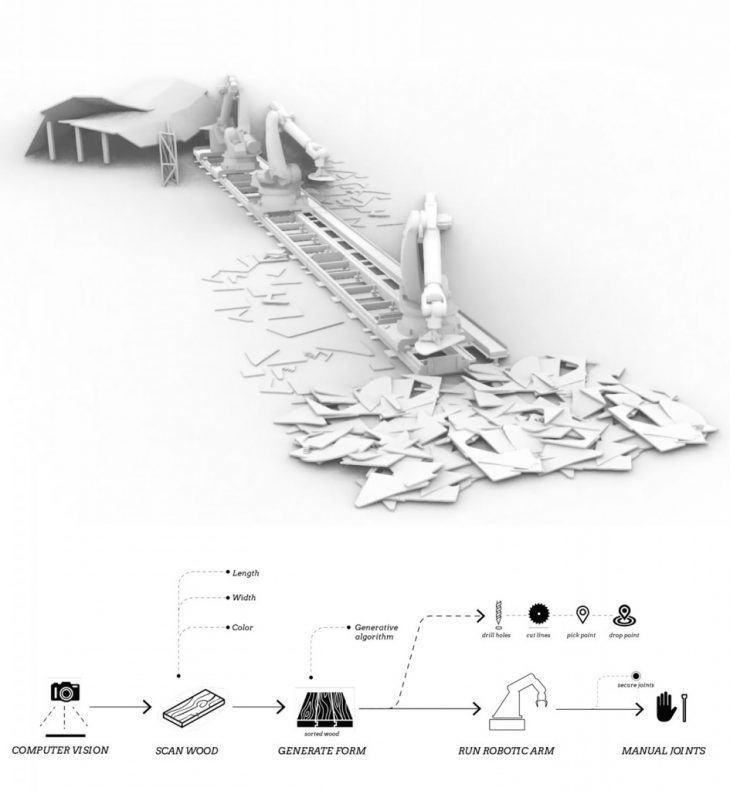

However, thanks to computational design and robotic fabrication, it is now possible to reintegrate the original properties of natural materials in their full complexity, and also to create designs with customizable non-standard geometries that can adapt to specific conditions on the building site.

This emerging paradigm in working with natural materials is as much related to industrial mass-production, as it is to the knowledgeable craftsman. For catalunya, this opens up new opportunities of working with local wood in high-quality, customized products.

In this edition of the robotic craft studio, we strive to improve the students’ ability to conceptualize, develop and envision a conclusive project of a digital design and production process, and to anticipate its possible impacts on the catalan wood construction industry. The studio will be conducted in continuous exchange with industry representatives, in order to maintain a close connection to the real world and to create a valuable contribution that is ecologically and economically beneficial, in catalunya and beyond.

METHODOLGY

CONCEPT

based on a thorough analysis of the established wood processing chain, from the tree to the final building, as well as the state of the art of experimental and industrial wood fabrication processes, the students are asked to propose a novel robotic application based on the particularities and requirements in the context of the catalan wood industry.

DEVELOPMENT

The students are asked to show the feasibility of their application using the machines available at iaac. The development will reach a proof-of-concept stage, which involves building or adapting existing tools, the programming of the machine, the simulation of the process, as well as dealing with aspects relevant to the design, such as material properties, geometry, structure, joinery, assembly sequence etc.

VISION

The >big picture< and the design possibilities of the project will be elaborated using drawings, simulations and animations, videos, renderings etc.. This should be rooted in what has been developed in the concept and proof of concept stage, but go beyond what is achievable to physically realize in the framework of the studio – it should represent the comprehensive vision of the project, on the level of design and impact.