Robot-Assisted Interior

How can robotic technologies be used to benefit the interior industry ?

ABSTRACT : Robots are being used in increasing numbers in manufacturing throughout the world. The expanded use of industrial robots in manufacturing and the increased projections of greater numbers in the future has resulted in a greater interest by the construction and interior fitout work industry. As a key technology, construction robots are expected to improve working conditions, reduce accidents, and increase construction productivity. Robotics in the construction industry is a young and fast growing interdisciplinary field.

Photo : Interior of London flagship store by 3D printing of recycled plastic.

KEYWORDS : Robotics, Interior fitout, Automation, Advanced construction, technologies.

INTRODUCTION : While the application of robots in the manufacturing is now well established, the range is continually expanding into construction field. The application of robotics in construction has been very active. Robotics in the construction industry is a young and fast-growing interdisciplinary field, in which many researchers are challenging to create productive, cost efficient, and smarter machines. Although the construction industry so far has managed to develop highly productive systems without the help of robots, but there are specific areas of application that the industry would benefit from robots application. The main ones are the application of robots in interior fitout work which can produce better quality with faster production. Another application area is in hazardous work environment that would be dangerous for a human operator. The robots can be also used to perform construction tasks that are boring or tiring for the human operators.

There are Four key requirements for a successful application of robotics in construction industry : increase in productivity, technological feasibility, quality improvement and meeting the needs of the contractors or subcontractors. The objective of this basic research is to introduce some of practical robots developed in the construction industry. Currently research is in progress in many Building Construction activities to improve the process more smoothly and accurate. This book describes some of the successful robots and their activities in interior fitout work.

METHODOLOGY : Method of the Study : The study consisted of the following stages:

? Reading and discussing of existing knowledge with reference to the system explored .

This comprised the following sources:

a. Books, papers, symposium proceedings , trade periodicals in the field of robotics.

b. Books, manuals, specifications and- other publications on construction technology.

c. Communications with experts in the field of robotics

d. Communications with robots manufacturers, major construction firms, distributors of

construction equipment.

? Examination of the present state of robot technology in view of building construction and

interior needs

? Examination of the building construction methods in view of the robotic performance

capacity

? Specification of robot requirements with reference to major types of construction activities

? Examination of robots implementation needs in building construction and interior work.

? Economic evaluation of robots applications to building construction.

INTERIOR WALL, PARTITIONS, PANELS AND CLADDING :

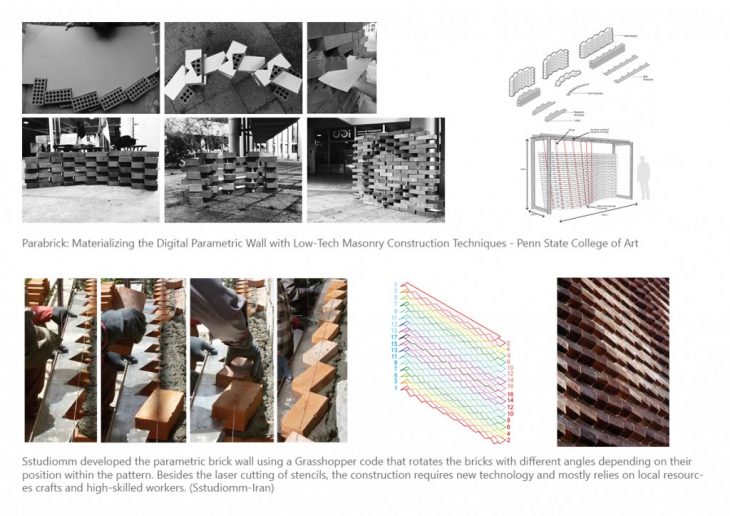

The overall parametric geometry of these elements was difficult to be conceived, represented and

materialized without the help of digital technologies. Trying to build an irregular brick structure

without parametric tools, it is very difficult for a human to understand and translate it from 2D

drawings and 3D models into a certain physical structure.

Architecture has changed because of the computer; thanks to technological development, designers

can do complicated parametric forms that would have been difficult to draw by hand and impossible

to build. In addition to that thanks to robotic masonry fabrication techniques, the robot can

naturally read all the different spatial coordinates describing each brick’s position and orientation

and, then, pick and place them correctly in space.

Photo : Parametric Brick Facade – Using Traditional Craft Techniques

Photo : Parametric Brick Facade – Using Robotically Assembled Techniques

PLASTERING, SURFACE FINISHING AND PAINTING :

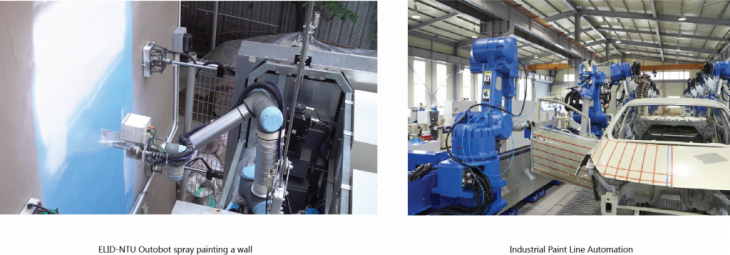

These type of robots are automatic sprayer for wall painting that can perform spray coating on walls.

Its main purposes are: sealer coating, material spraying, and top coating. It can cope with materials

to be sprayed and the finish patterns of the main materials. Furthermore, it needs only one operator

on the floor and provides an enhanced production rate about five times that of conventional

methods. It gives an excellent finish comparable to skilled workers.

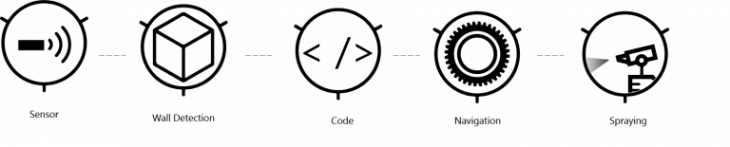

Also another type of Autonomous robotics painting explores the possibility of autonomous

navigation to detect and repair damaged patches on any wall, which can be repaired through

spraying paint. The robot does so, by exploring an alien frontier/ environment, all the wile mapping

and avoiding obstacles to isolate and recognise walls which need repairing. The rover/robot with its

sensors, manoeuvre the mounted paint gun to spray on the damaged wall to give a clean finished

surface.

Some of the references for the research include the Industrial Paint Line in the automotive industry

and a research project at ELID-NTU, Singapore. Where there is a clear lack of autonomy through the

lack of sensors in the prior, while the former despite ints autonomy lacks the ability to navigate

freely. Therefore the areas of interventions of our research were:

Other possible applications of the same process can be recreated in:

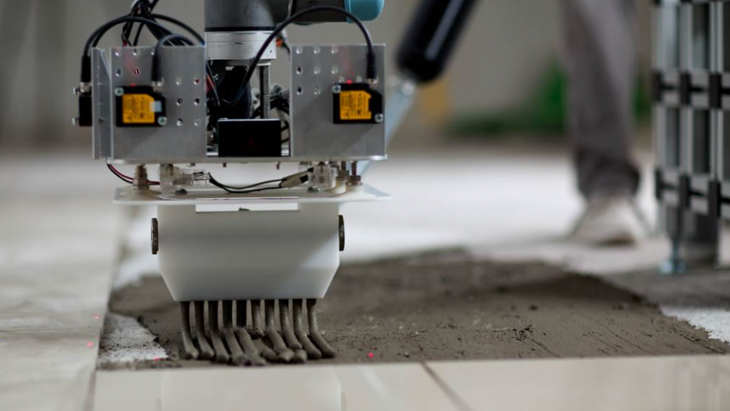

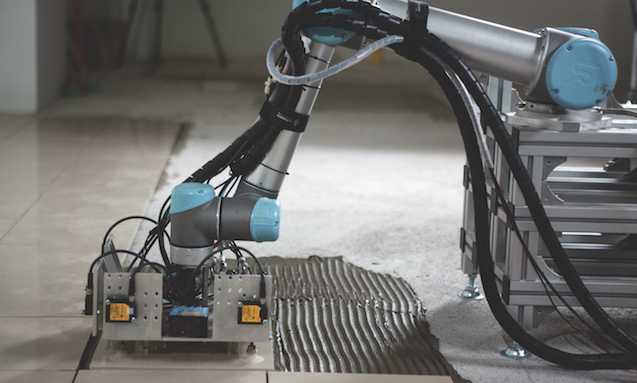

FLOORING : Tiling work, in particular, is suited for robotic automation. It is a well-defined subdomain of construction with clear interfaces that can easily be singled out. Furthermore, it is a repetitive task and features no complex joinery. Automating this process is expected to benefit the construction industry as a whole as the robotic co-worker can safely work alongside humans without employing additional security measures. It is to be integrated to the existing construction workflow, lowering the entry barrier for adopting new technologies in the building industry.

The expected outcome of the project is to realise an automated tiling process which demonstrates

the feasibility of applying a mobile robotic system for planning and executing onsite tiling work. An

essential benchmark for the project is its ability to compete against manually executed work in

terms of quality, time, and costs.

CONCRETE FLOOR FINISHING ROBOT Concrete floor finishing work consists of leveling, wood

floating, and trowel-finishing steps. The final trowel finishing step is the most difficult for the

worker because the worker must push a trowel on the wet concrete floor in an awkward posture for

a long period of time. Furthermore, the number of skilled workers for concrete floor finishing work is

decreasing. So, it has been difficult to gather enough skilled workers at construction sites.”

The robot can be operated by radio remote manipulation. The hardness of the concrete surface to

be finished is not uniform in the finishing area. The parameter of the robot should be changed

according to the hardness of the surface, which is difficult to measure, therefore, a remote-control

system was adopted.

The main features of this device are its fine finishing accuracy, close contact between the trowel and

concrete face, and the trowel load can properly be adjusted according to how much the concrete

has grown hard. The angle between the concrete surface and the trowel can be adjusted by a cam

mechanism. This angle is changed according to the hardness of the concrete surface to be finished.

Other features of this machine are that it is easy to install, operate, and clean it away.

CEILING PANEL FALSE CEILING : Ceiling construction for office buildings, hotels, and other commercial buildings interior is accomplished by using plaster board panels, which are made of plaster and covered with paper. The plaster board ceiling construction method accounts for about 70% to 80% of the ceiling construction market. A typical mid-size office building, for example, with 8 floors and 5,000 m 2 (53,820 ft 2″ requires 400 panels for each floor, totalling 3,200 pieces which must be set one by one.

The procedure for ceiling construction requires temporary scaffolding to be erected all over the floor and then be cleared away for the next procedure. Human workers must assume an undesirable posture for the panel setting work. The workers must raise heavy and large sized panels over their heads for placement against the hanging ceiling flat bars. Repetition of this work over a long period of time exhausts the workers. Sometimes ceiling construction results in a delay of the total building construction period because of the shortage of skilled panel setting workers. The CFR-1 is a typical robot developed for ceiling panel positioning which consists of a panel carrier which can be separated easily when transported. The CFR-1 has four degrees of freedom, 300 kg (660 lb) weight, carrying capacity of 20 panels, work capacity of 25 panels/hour, and working travel speed of 3 m/min (10 ft/min). Ceiling construction work using the robot is accomplished as follows. The fully loaded panel carrier is attached to the robot (about 20 panels), and the robot is positioned under the location where the panel will be set. The robot uses the panel holder to remove one panel from the panel carrier and lifts it into position among the hanging ceiling flat bars. The robot places the panel in correct position using the X-Y horizontal table automatically assisted by the compliant mechanism. Then, a worker fixes the panel using an air screw driver. The robot travels to the next position to set the next panel.

CONCLUSIONS : The goal of this research in developing construction robot is to build robots which are more flexible, adjustable, and able to cope with constantly changing construction environments. Research and development in construction robots is intended to extend present capabilities of conventional equipment to an integrated and fully automated system. An ancillary benefit of this type of research

is an understanding of the key problems that need to be solved in construction and interior firout work.

As with any technology, new solutions bring new problems. One of the most serious problems currently facing automation in the construction industry is the integration of information. This integration must occur in a cost effective and productive manner without loss of current construction functionality. These robots represent the integration of many different ideas and technologies into a working system. The challenge of building construction robots is a challenge of integrating not only robot components, but also of integrating construction experiences, ideas, and technology.

ACKNOWLEDGEMENT : I would like to thank Ricardo Devasa for providing all the necessary and valuable information that this book is developed based on it. I would also like to acknowledge the contributions of MRAC Course Director`s Alexandre dubor, Aldo Sollazzo, Jury member Mathilde Marengo, MRAC Colleagues and visiting people Shajay Bhooshan, jelle feringa, Wes McGee, Fabio Gramazio, Johannes Bruhmann and roland Snooks . i would also like to thank the authors of the books and paper i refer for basic research reading.

REFERENCES :

A Construction Robot for Autonomous Plastering of Walls and Ceilings, by Johan Forsberg, Roger

Aarenstrup and Ake Wernersson.

Integrating automation into construction to achieve performance enhancements

(CIB World Building Congress, April 2001, Wellington, New Zealand, Paper: HPT 27)

David w cobb, David Cobb Associates, Walnut Tree Cottage, Aldbury, Herts, UK, HP23 5SL,

Robotics in Construction, IQP Final Report , 3/24/2016 , An Interactive Qualifying Project Report.

Advanced Robotics in Civil Engineering and Construction, Roozbeh Kangari, Associate Professor,

School of Civil Engineering, Georgia Institute of Technology, Atlanta, Georgia, USA.

FutureHome, 2000b. Economic Interest Group website: www.city.ac.uk/futurehome

Takada, H. et al, 2000. “Study on assembly methods for large-scale structure using an innovative

and intelligent field factory”. Paper presented at the International Symposium on Automation and

Robotics in Construction (ISARC 17), Taiwan, September 2000. pp983-989.

Application of Robotics to Building Construction, by Abraham Warszawski, Professor, Department

of Civil Engineering, Carnegie Mellon University Pittsburgh, Pennsylvania.

Wong, T.C.K 1997 “Repair and maintenance of tall residential buildings” Paper presented at ICE

seminar “Working at Height” 6 March 1997, 8pp, London

Construction automation and robotics in the 21st century, ISARC 2006, by Yukio Hasegawa,

Professor Emeritus, Waswda University, Japan.

Web-to-Real Application for Artistic Robotic Surface Processing of Natural Stone, Sven Stumma,

Matthias Neuhausa , Johannes Braumanna,, Jan Brüninghausa , Sigrid Brell-Cokcan,

Robotic Fabrication in Architecture, Art and Design 2018 by Jan Willmann, Philippe Block, Marco

hutter, Kendra yrne, Tim Schork Editors.

Robot-Assisted Interior is a basic research project conducted of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction (M.R.A.C.) in 2019 by,

Students: Subhash Prajapat

Faculty: Prof. Ricardo Devesa