//ReJoin: A digitally fabricated pure timber joineries system for modular construction

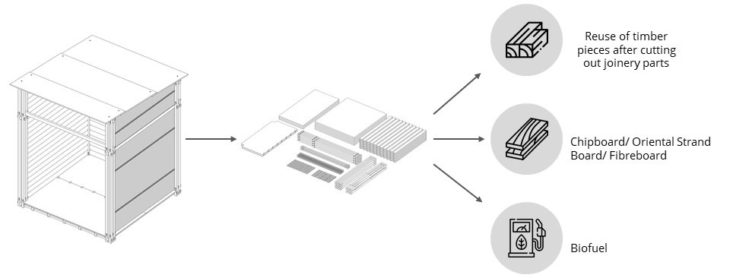

Exploring the revival of traditional timber connections, ReJoin aims to develop a light frame and modular system of pure timber construction. This digitally fabricated system which is designed for rapid assembly and disassembly, also aims to reduce the embodied energy of the structure as well as prolong the life cycle of the timber used. A key factor of this project is that it has been designed without the use of any adhesives or embedded metal fasteners, enabling disassembly and reassembly.

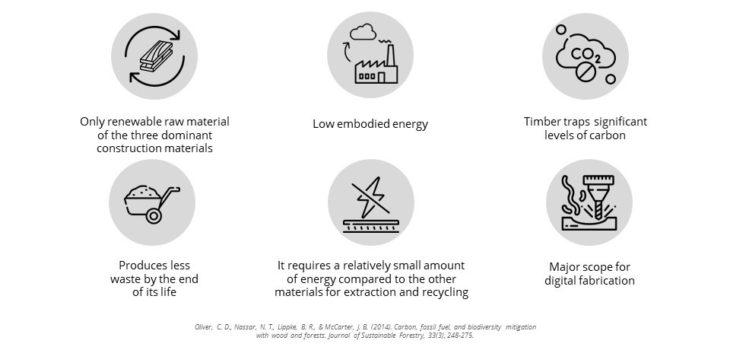

//Timber as a Construction Material

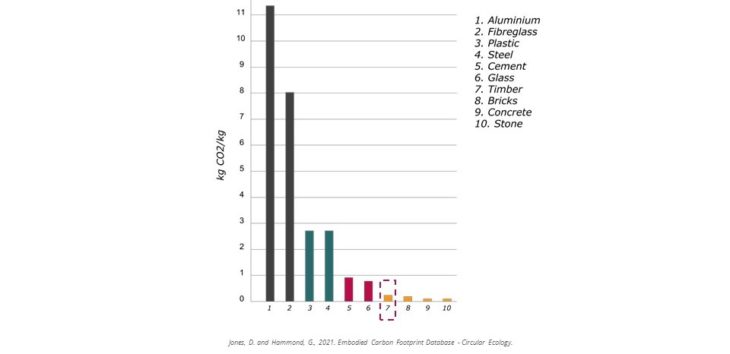

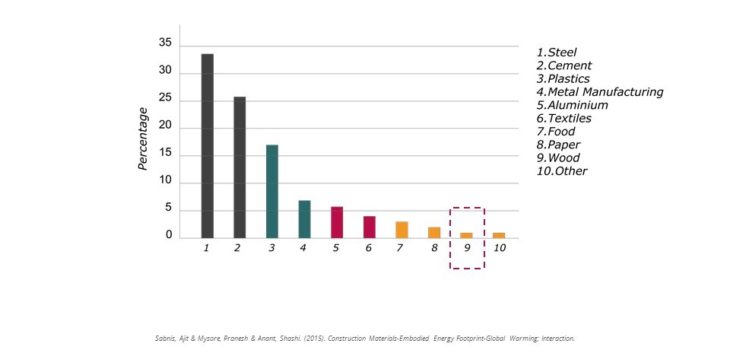

//Embodied Energy and CO2 Emissions of Construction Materials

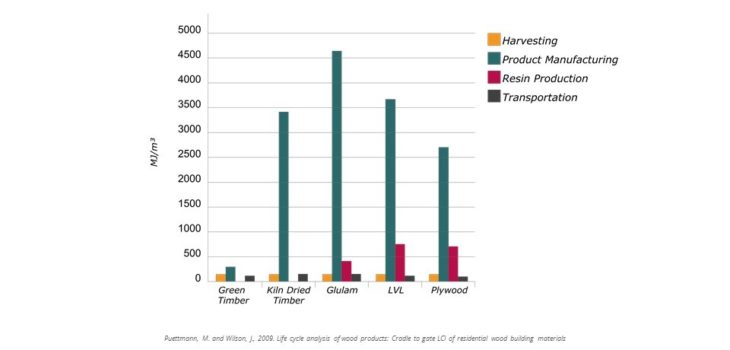

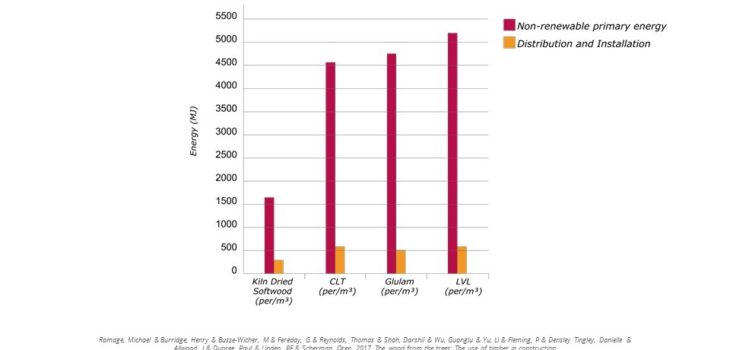

//Embodied Energy and Energy for Manufacture of Construction Timber Products

//Timber Joineries

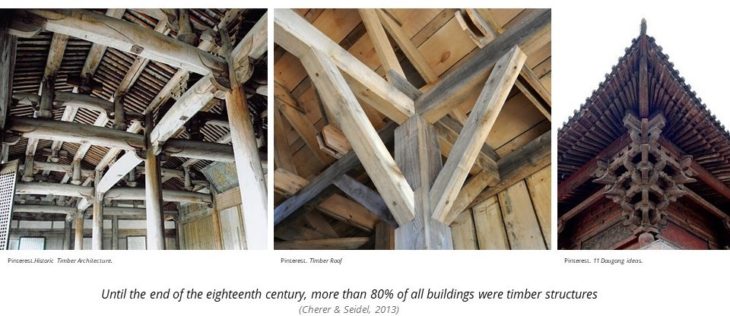

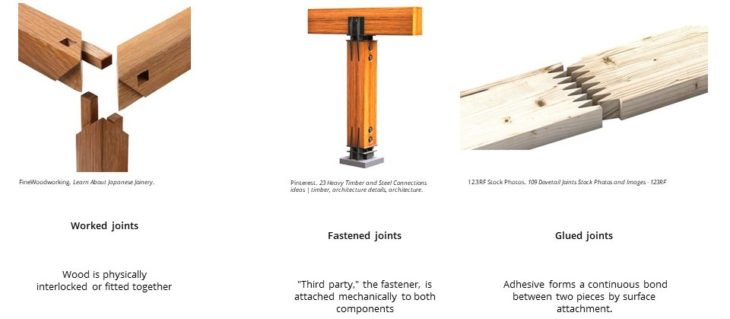

Timber joineries are a method of geometrically interlocking timber elements prevalent in historic cultures around the world. In the preindustrial times, the heterogeneity of wood was effectively utilized and the intricate structural differences in the raw material were employed for specific building elements through manual wood-working techniques. These slow yet ingenious fabrication methods, which were developed and adapted over hundreds of years, took advantage of the material and its specific characteristics. This was also the time when labour was cheap but material was expensive.

With the dawn of industrialization, the predominance of wood architecture became increasingly challenged by synthetic materials like iron and steel.

The historic transition from joinery to fasteners arose out of the efficiency afforded by fasteners to join standardized timber elements, compared to the time and labor required to carve joinery geometries out of each timber element.

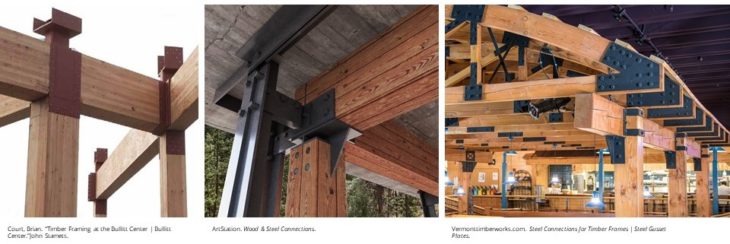

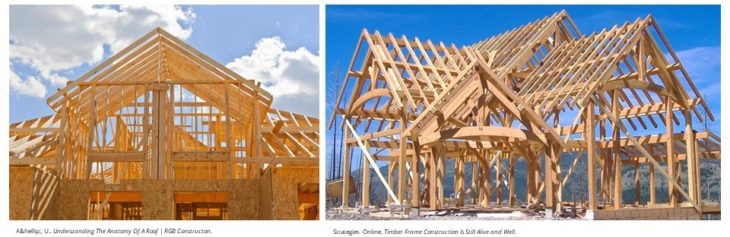

Over the past couple of years, timber frame construction like this has become very common. It looks sustainable since the primary construction material is timber.

But this timber is filled with nails and screws which are time consuming and a laborious task. Hence, this wood ends up in landfills. Even if nails removed, the nail holes lower the grade of timber.

//Wood Waste Management

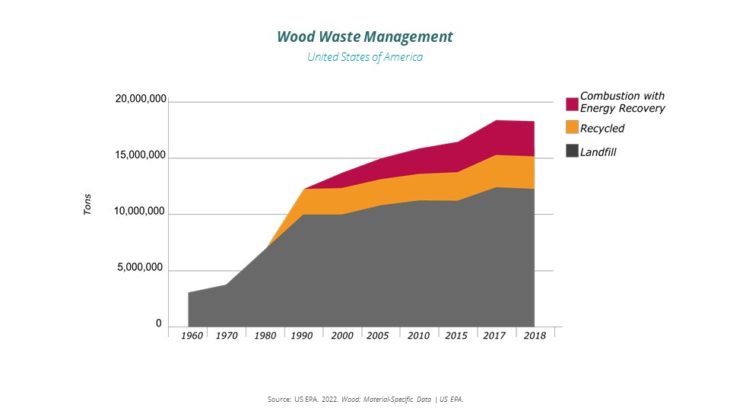

This data is from 1960 to 2018 from USA, shows the total number of tons of wood generated, combusted with energy recovery, recycled and landfilled. In 2018, landfills received 12.2 million tons of wood. This was 8.3 percent of all Municipal Solid Waste landfilled that year

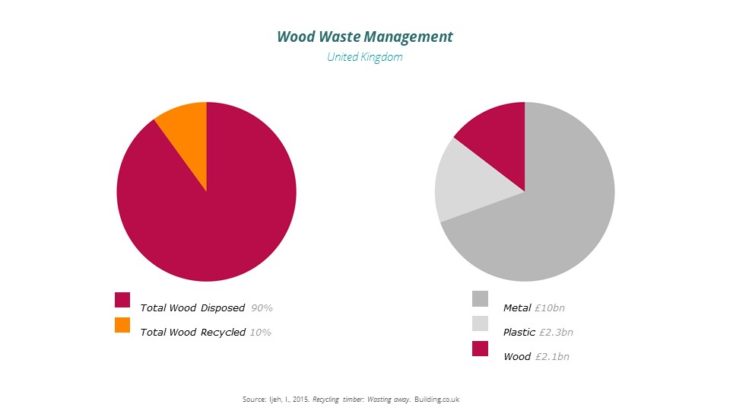

Every year the UK disposes of 10 million tons of wood, but only 1 million tons of this is recycled. According to this report from 2015, this amounts to a commodity value of 2.1bn pounds being wasted, the third highest of all materials sent to landfill after metals and plastics.

//Research Framework

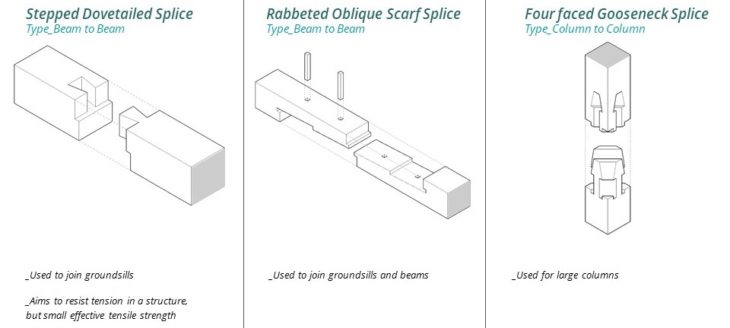

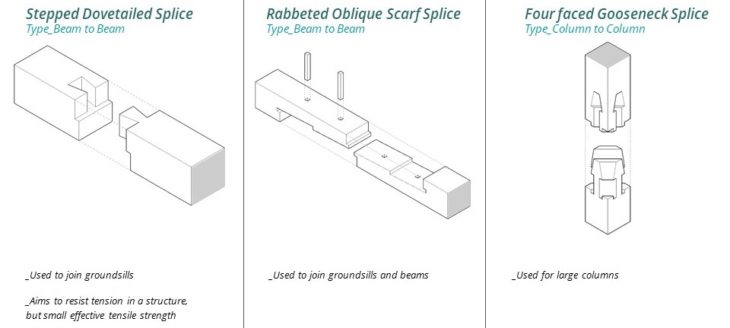

//Types of Joints

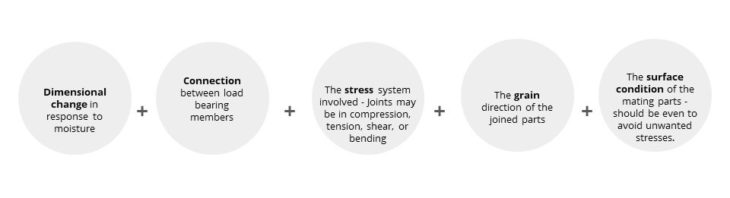

//Element of Joints_Success of Joints

//Joint Catalogue

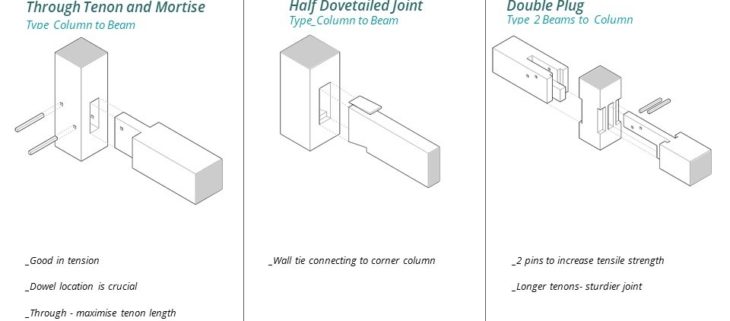

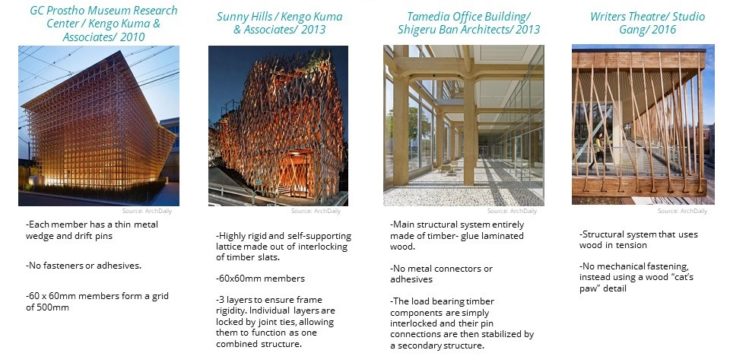

//State of Art

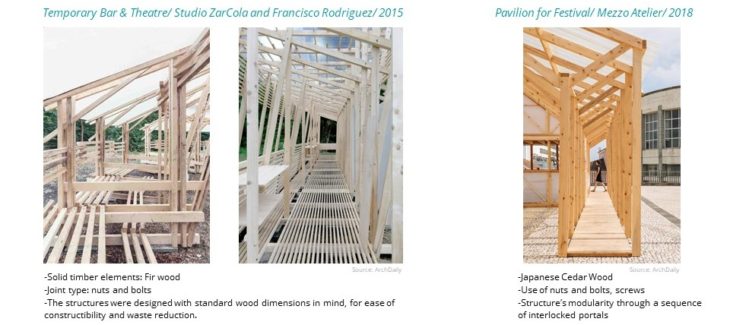

Projects showing the current developments in digitally fabricated timber joineries on an architectural scale

Projects pertaining to the building scale pertaining to my thesis topic

//Digital Fabrication_3 Axis CNC Milling

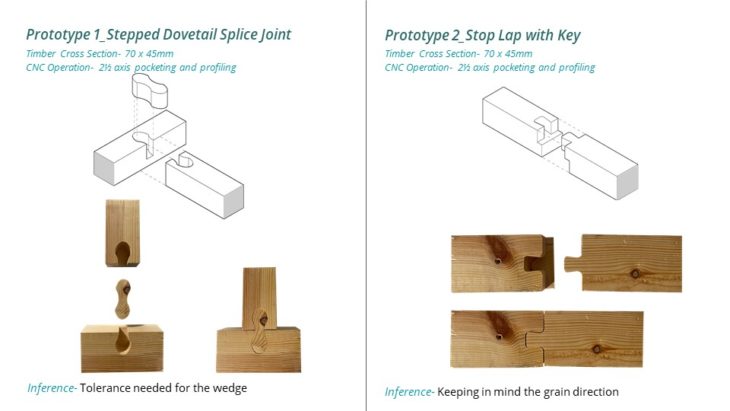

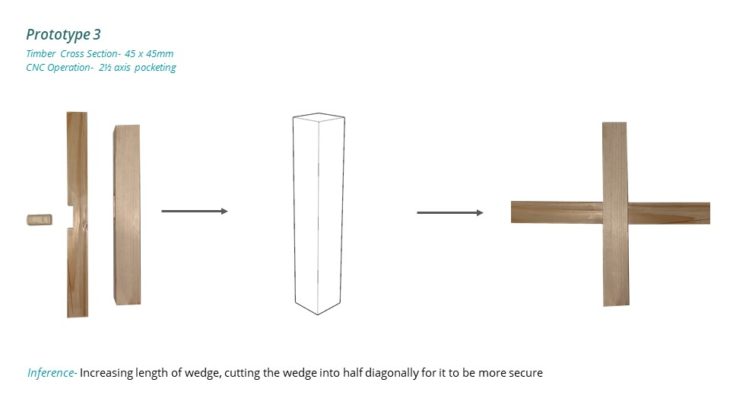

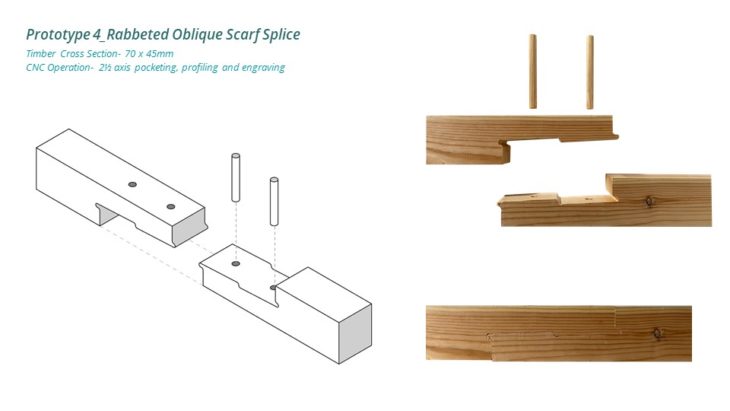

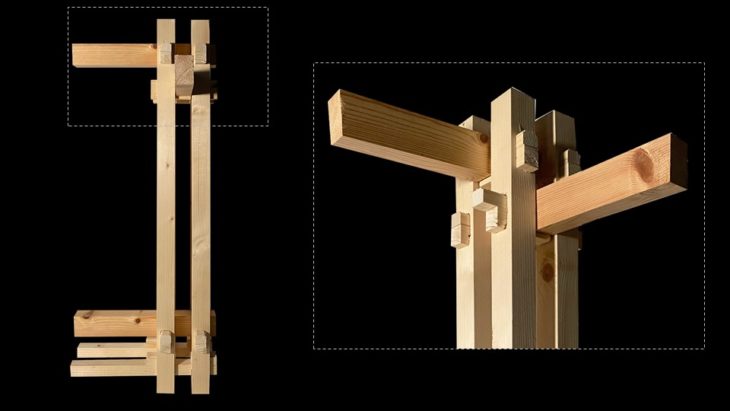

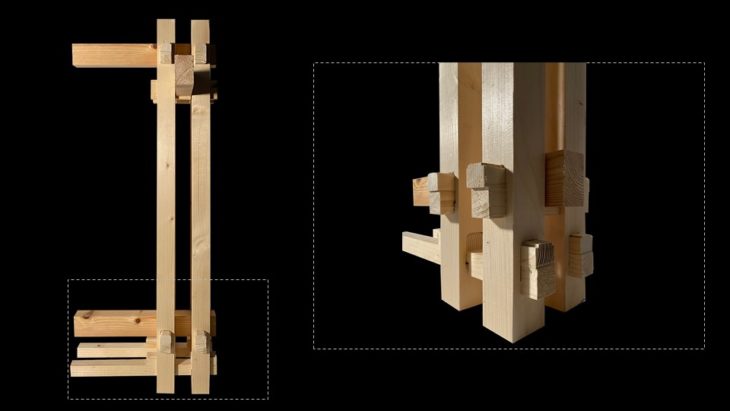

//Fabricated Test Prototypes

//Design

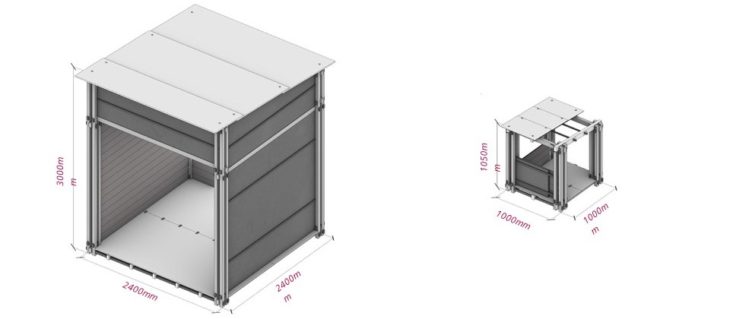

//Attributes of Modularity

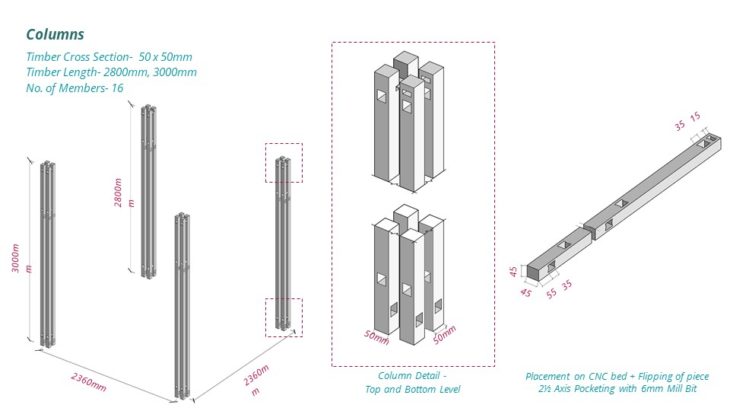

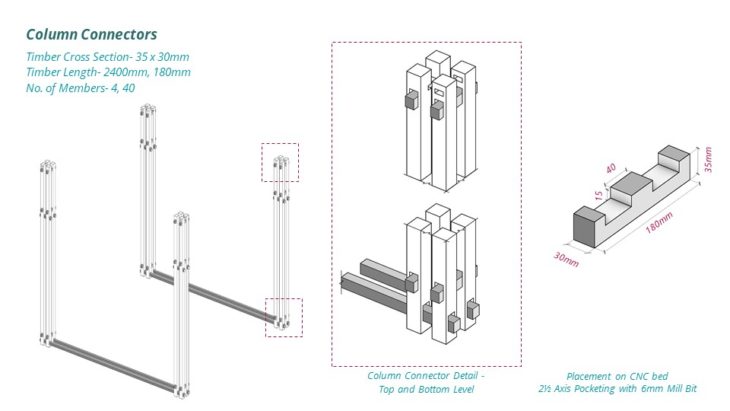

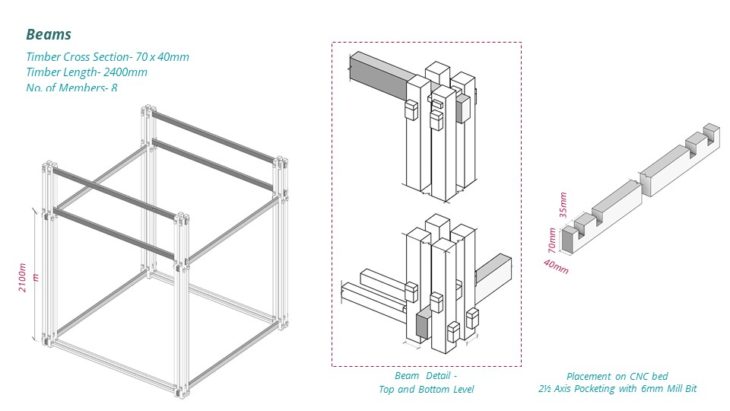

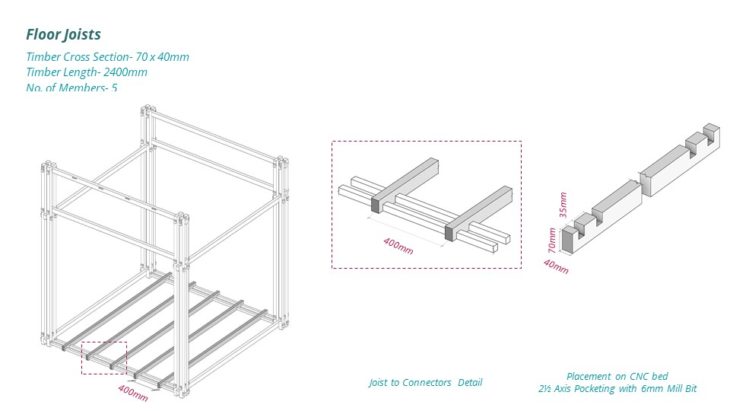

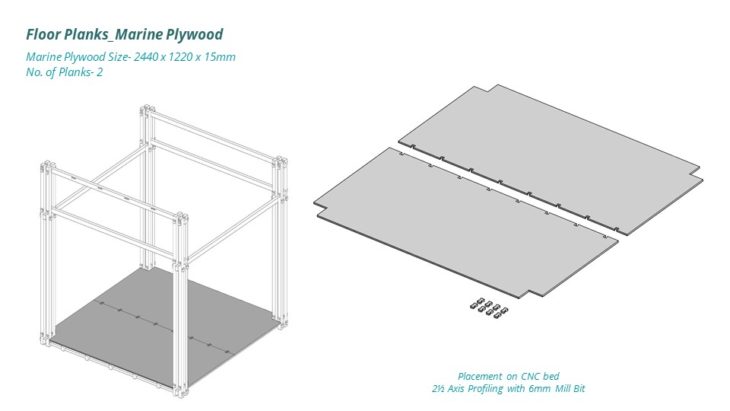

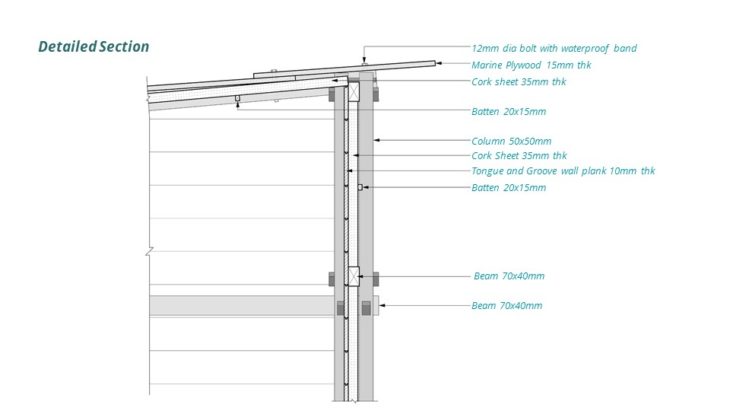

//Elements of One Module, Fabrication Details

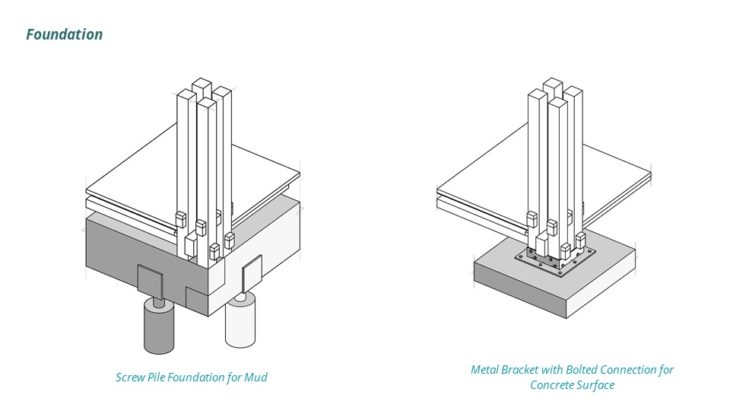

//Hierarchy of Assembly of Structural Frame

- 4 Columns

- Column Connectors

- Wedges for Column Connectors

- Beam

- Wedges for Beam

//Assembly of Flooring System

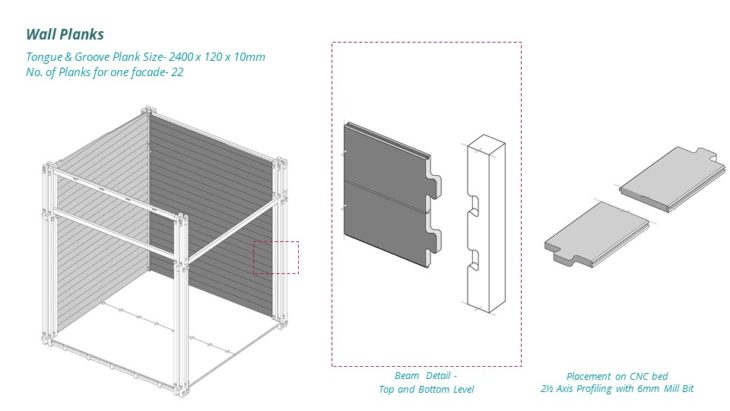

//Assembly of Tongue & Groove Wall Planks

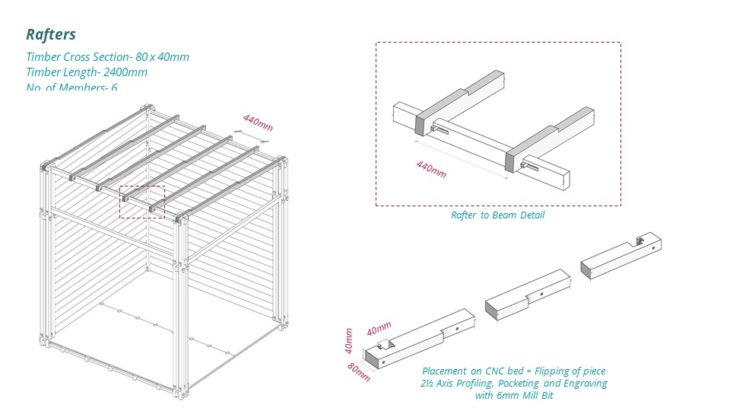

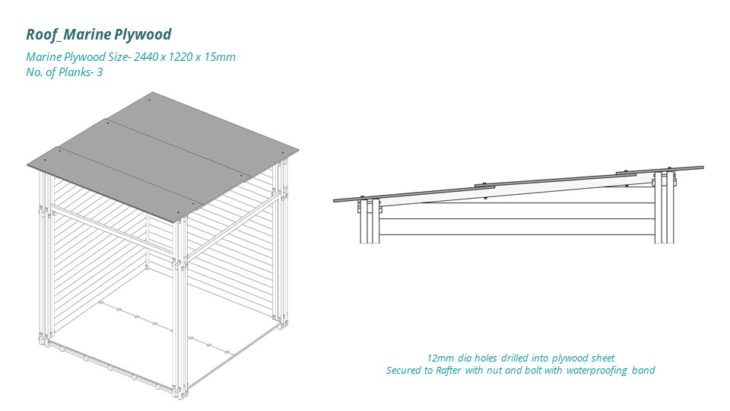

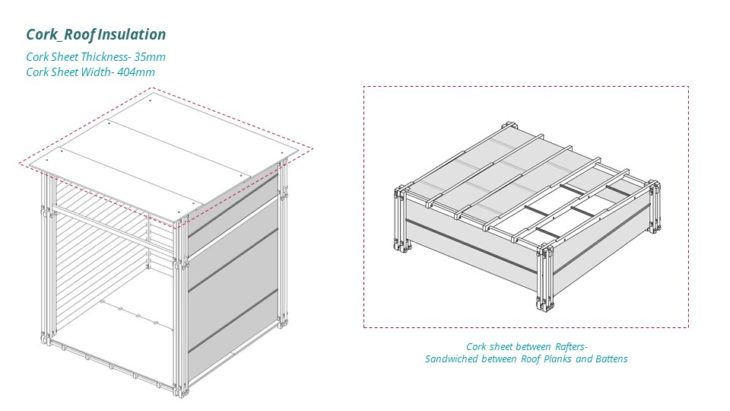

//Assembly of Roof System

//Hierarchy of Structural Frame Assembly

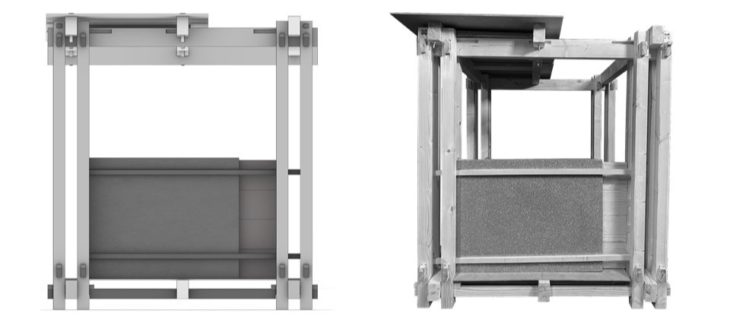

//One Module Visuals

//Prototype Fabrication

//Digital Model vs. Physical Model

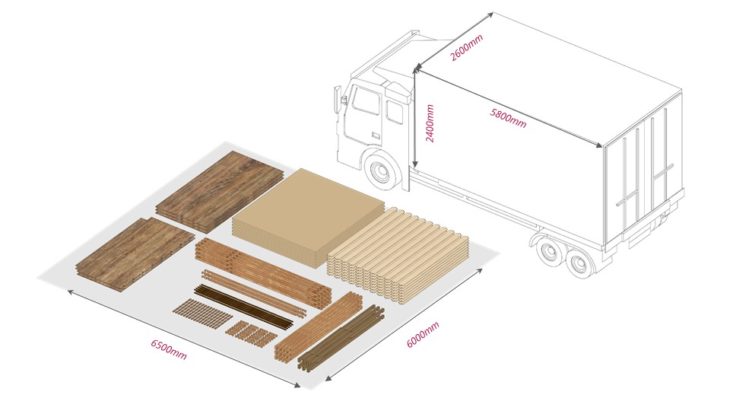

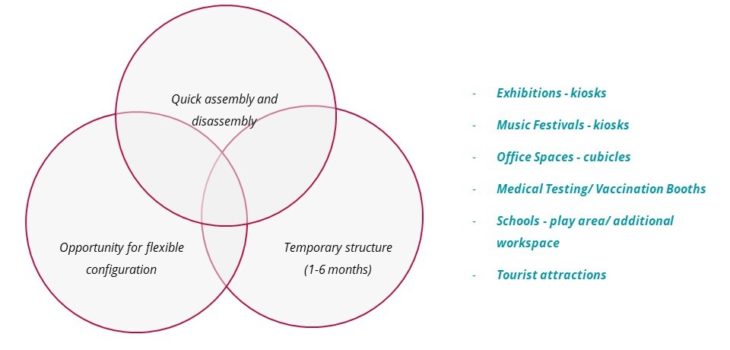

//Application of Digitally Fabricated Timber Modular System

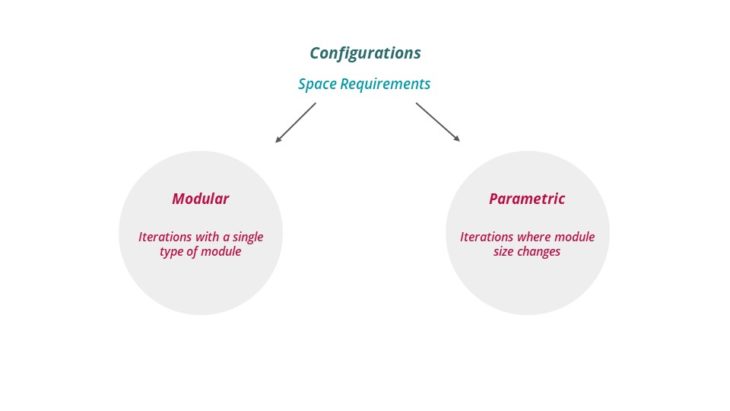

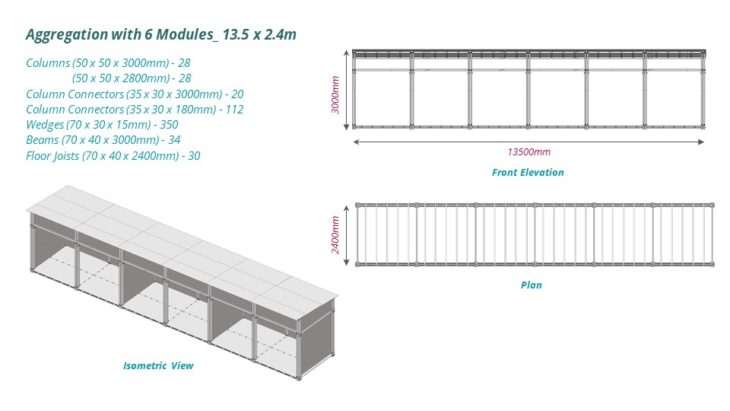

//Spatial Configurations

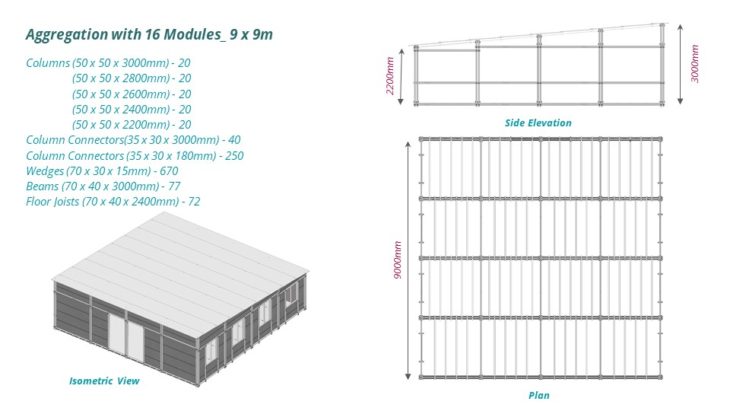

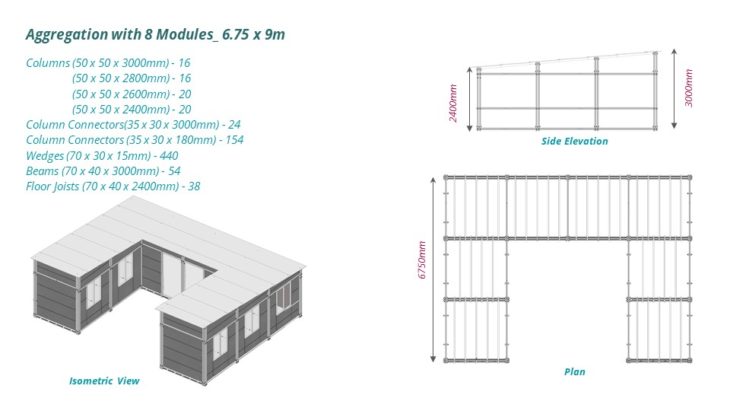

There were two ways to go about the spatial configurations: in a Modular or Parametric approach. A Modular approach enabled the reuse of timber components because of defined sizes where as a parametric approach would require different sizes of timber components. This project explored the modular approach with this system.

// The Future

//Material Recycling

//Future Steps

ReJoin is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master of Advanced Architecture 2021/22 by: Student: Hairati Tupe and Faculty: Vincent Huyghe and Gabriele Jureviciute.