PREFABRICATED CONSTRUCTION: A REVIEW

Street in Barcelona being used to store construction material

Abstract

Construction projects inherently involve a disruption to the area they surround. There are different kinds of nuisances a construction site generates on the residents. In literature and reports, these impacts are rarely addressed over the cost or time considerations of a project. Financial and resource management considerations are critical to players involved in the construction process, however the social and environmental costs of a project are becoming more important in innovating construction techniques for urban areas. I investigate the themes, benefits and limitations that an increased amount of prefabricated construction can provide to the neighbourhood of a given site.

Introduction to prefabricated construction

Terms such as offsite construction, prefab, and modular construction are used interchangeably and cover a range of different approaches and systems. These systems vary depending on the complexity of the elements being brought together. The simplest are single elements that are clipped together using standard connections and interfaces. From an operational standpoint, the more components a prefabricated design involves, the longer it will take to finalise design and install on site.

How might the activities change for a prefabricated build?

The construction industry plays an important role in advancing cities. Onsite construction activities in urban areas cannot be dismissed when a project is underway. However, one important way to reduce the adverse impact of a construction project on its surrounding area is by increasing the amount of prefabricated components. Prefabricated buildings are lauded for improving quality and productivity in the building industry; however, studies have shown emissions from vehicle movements servicing prefabricated building sites reduced by up to 60%, and significant reductions in noise and dust pollution.4

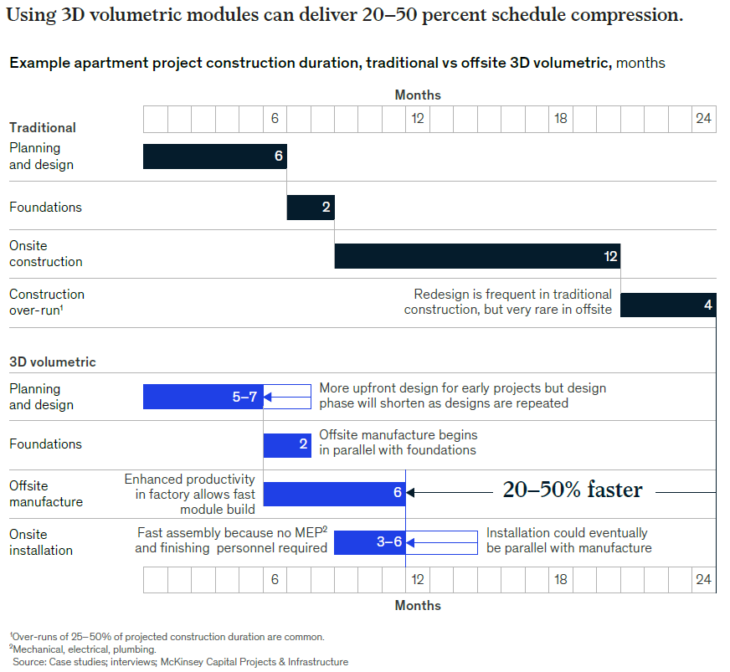

Involving a large portion of prefabrication in a construction project reliably accelerates the schedule, and inherently, reduces the time spent building onsite significantly. A portion of this time is transferred to manufacturing offsite. Below is an infographic in Mckinsey’s Modular construction: From projects to products that illustrates some of the differences in time between a traditional or offsite apartment project. (Figure 1). For this example, the time projected for a prefabricated project’s onsite activities may vary between 5-8 months as opposed to a possible 18 months. This can have a significant impact on reducing the nuisances caused by a neighbouring construction site.

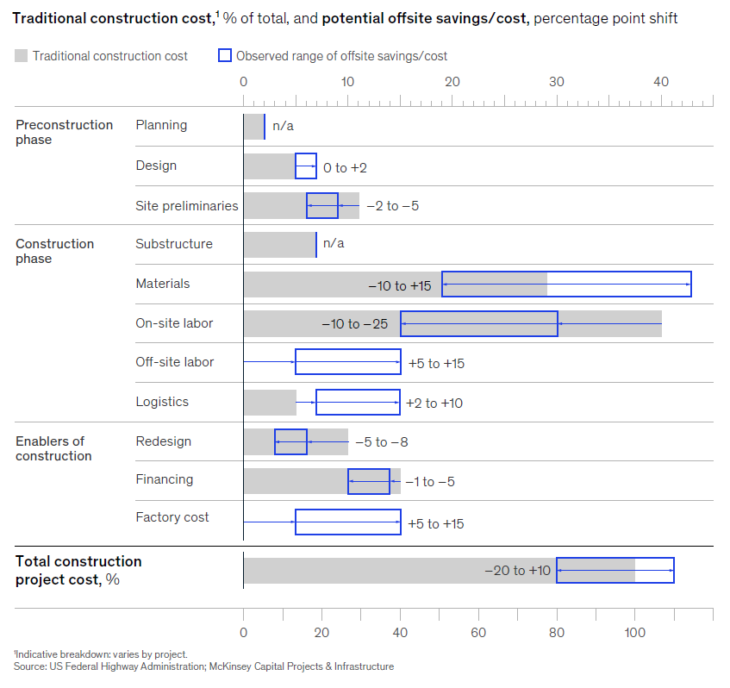

Not only is time significantly reduced when prefabricated components are assembled on-site, it is also used more efficiently. There is typically a trade-off for reducing labour onsite for an increase in logistics and offsite labour costs. For the same example on time savings, Figure 2 shows the potential differences in cost across a project. Cost is a driving factor for developers and, although there are cost and time savings observed across the construction cycle, there are not enough prefab factories for these techniques to be more widely adopted yet.

Figure 1: Timeline comparing the a traditional vs. offsite construction of an apartment building. Source: Mckinsey & Company

Figure 2: Cost comparison between traditional vs. offsite construction of an apartment building. Source: Mckinsey & Company

Benefits and limitations of prefabricated construction

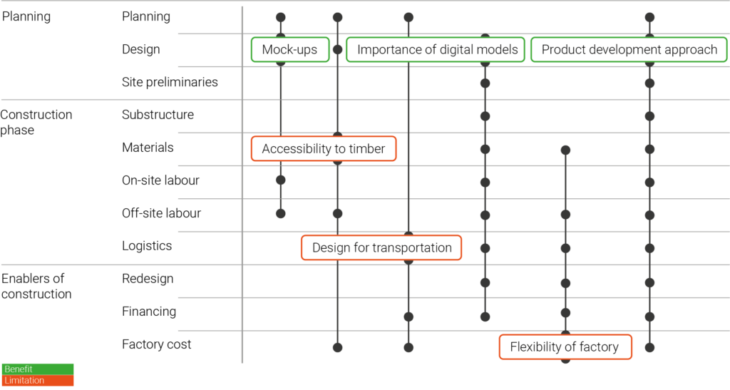

The process structure of Figure 2 was used as a starting point to map out the benefits and limitations of prefabricated construction (Figure 3). Using semi-structured interviews, key themes were deduced based on comments made from the different participants. There is no theme that arose, that affects only one aspect of a construction process. A sorting of whether they generally are perceived as a Benefit or a Limitation. A more extensive analysis, both qualitative and quantitative, would be required to understand the impact and priority they may have to increase the uptake of prefabricated projects.

Figure 3

Figure 3

Timber as a prominent material in prefabricated construction

Although steel and precast concrete have prefab solutions, timber is most widely sought for prefabricated construction. Timber as is inherently a prefabricated material, and is seen as easier to machine and transport than its counterparts.

“A lot of these timber products are inherently digital or fabricated materials. You don’t grow a sheet of CLT, you always make it. And because it always has to be made, there can always be variation on how you make it”.

–Luis Orozco, ICD Associate

There are however concerns with the accessibility to timber for construction – sourced wood has to be of a high grading in order to be used for construction–, for those regions that don’t have a prominent timber industry.

Suppliers and fabricators of engineered wood products (EWPs) are a key enabler for a project because of their ability to determine feasibility of a design and having the right facilities for manufacturing. These fabricators are predominantly located in countries with an important timber industry, hence a project outside of these countries would have a bigger trade-off to consider with the transportation logistics.

Mock-ups are a very important tool to support/develop the design

By definition, a mock-up is used to experiment or learn. Although it is a higher investment upfront, it reduces the amount of redesign and can be instructional for efficient fabrication and assembly.

“It’s a feasibility study. We do complex buildings and very often the decision-makers have problems taking a decision for the next stages. Mock-ups give a lot of confidence for the project. It helps a lot for making fast-passage decisions.”

–Kai Strehlke, Head of Digital Processes at Blumer Lehmann

Optimising the design for transportation, is as equally important as Design for Manufacturing and Assembly (DfMA)

Logistics play a critical role in a project meeting its budget or timeline. Depending on how large the prefabricated components are, coordinating the transportation and installation of modules can be costly, especially in a dense urban area.

“[4m] is the maximum length you can have without needing a police car. If you needed one, you get super expensive logistics exploding the transportation costs”

–Joan Artes, CEO of La Casa por el Tejado

Digital models aren’t just to communicate between collaborators.

As digital fabrication techniques become widely adopted, digital models go from being a deliverable for understanding the design, to a necessary component in the construction workflow. Models can be exported into different formats, and different collaborators will find different formats useful or redundant. In some cases, not delivering the right format can be problematic to a project, but

“In Industry 4.0 workshop the model/drawing becomes productive. It becomes information directly to fabricate”

–Javier Peña, Architect

“Models are about interfaces, they clearly define boundaries between collaborators”

–Fabian Scheurer, managing partner at Design to Production

Flexibility of factory

Manufacturing construction components for predominantly prefabricated buildings requires factories that can meet the demand, and have the expertise to do so. Fabricators, such as Blumer Lehmann or ERNE, have large facilities and expertise to handle a vast range of projects. However, their activity outside of their surrounding regions is only attainable to few developers, because of the larger budgets needed. In the long-term, having a network of smaller factories and specialised workshops is more desirable across different regions for a higher uptake of prefab construction.

“[Arrival] build a small factory in every country, engage local supply chains, and customise products. Microfactories that employ digital workflows, but include traditional and local building”

–Vincent Huyghe, Design for Manufacturing expert, IAAC staff

“When working with a fabricator that is far away, you can’t make a mistake for a second. Having a fabricator closer makes it easier to tackle manufacturing challenges.”

–Javier Peña, Architect

Product development approach

Since the fabrication of components for prefab are carried out in factories, the mindset associating it to a product development cycle has been commented on since its revival in the 1990s 7. Conceptually, there is a divide associating a building as a product or a project. The following is a well put distinction:

“Builders who work in a project model are enabled by their setup. Certain number of employees or tools are able to reorganise them or redistribute them to work on any project that walks through the door. Product model fabricators on the other hand seem to be restricted by their setup. They have a production workflow or processing line, and as long as it fits on that line they can produce any variation, but if it is a different shape or typology of wall all together, it isn’t going to work”

–Luis Orozco, ICD Associate

Traditional construction falls into ‘project model’ thinking. The above distinction is particularly rigid, whereas there are players in the industry that lie in between both conceptual models. There are fabricators and design consultancies that are attempting to build a production system of components that can adapt to any project an architect proposes. Two examples are: Bryden Wood, who designed a ‘platform-based’ system of components capable of producing configurations that do not seem prefabricated; another is La casa por el Tejado who specialise in ‘drop-top’ prefabricated flats. They demonstrate how a more product model leaning approach can produce prefabricated builds that steer away from the common misconceptions that off-site construction is a stack of boxes/shipping containers. Switching towards a product model is a paradigm shift that affects all the supply chain involved.

Highlight of different models being attempted

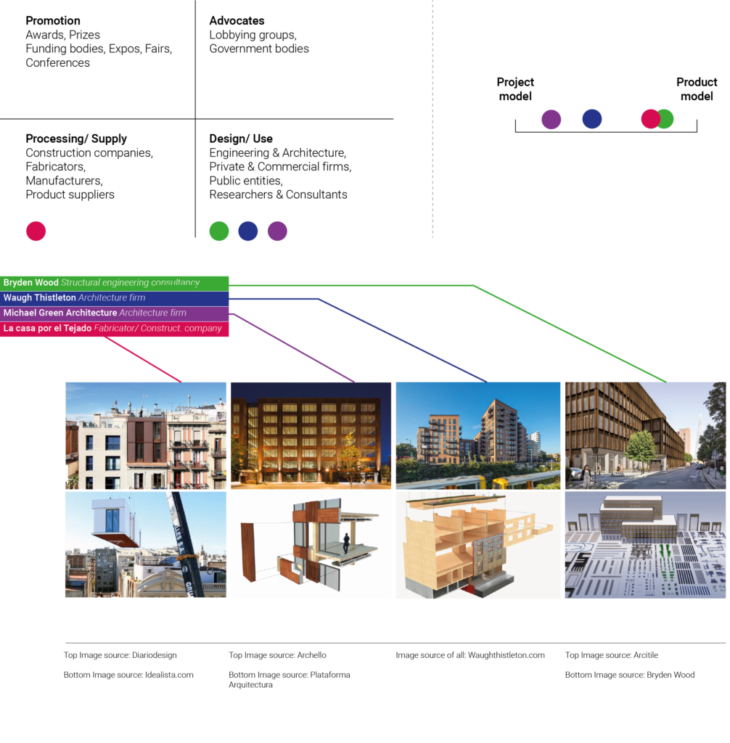

The next step was to get an understanding on what are players disrupting in prefabricated construction. For mapping purposes, a categorisation on the timber industry was used, composed of four sections 3: Promotions (Examples: Awards, grants, expos), Advocates (Examples: Lobbying groups, government bodies), Processing/Supply (Examples: Construction companies, fabricators, manufacturers), and Design/Use (Examples: Engineering/Architecture, researchers). A player can be better understood with respect to the brodar system through this categorisation.

In Figure 4, the highlighted players lie mostly in the Design/Use. The motivation for this selection was to discover prefabricated systems that enable a high-value design to an urban site. There are attempts to make prefabricated buildings highly repeatable –for example Blockable, or Factory OS. This selection looks at players that take advantage of a repeatable construction system, while delivering unique designs for every project.

In addition to La casa por el Tejado and Bryden Wood, Michael Green Architects (MGA) and Waugh Thistleton were chosen as architecture firms that push the envelope in the prefab construction process. As none of these are vertically integrated players, they are examples of how smaller, more specialised players can succeed. MGA is an example of a firm which focuses on the technology development for timber prefab structures, while Waugh Thistleton has published material on design for timber prefab that is recognised within the industry. They use projects to advance their construction techniques at a design-level. This is largely in part of the partnerships they have built over the years. In MGAs example, they became a design partner for Sidewalk Labs and Katerra– two businesses that attempted to be disruptive vertically-integrated construction/development companies.

Conclusions

In this investigation, reasons to believe that prefabricated construction is becoming a more attractive option to traditional construction. While there are limitations with scaling up these emerging processes –to a degree where it becomes an at-scale shift from the traditional construction process–, they are likely to be overcome, as there is mounting proof that a prefabricated build can have better value for cost-time of a project. These drivers will incentivise players to disrupt the industry; however, the byproduct will be an improved onsite experience. Prefabrication construction techniques are to become more prevalent because:

Figure 4

The technology is ready

Prefabricated construction is demonstrating to surpass expectations on delivering higher quality builds than traditional construction. Prefab relies more on digitalisation, and as more workers in AEC become familiar with digital tools, smaller players will be able to access prefab urban projects more easily. The above models/firms are examples of this.

Simpler may be better

The workflows produced from prefab construction techniques, makes AEC reconsider the complex and difficult parts that have been holding it back, such as liability issues. General contractors might be obsolete in this new shift, however this simplified process is most noticeable in the important onsite time reduction these projects have.

References

- ‘How the Residents Are Affected from Construction Operations Conducted in Residential Areas’. Procedia Engineering 161 (1 January 2016): 394–98.

https://doi.org/10.1016/j.proeng.2016.08.580.

- Bertram, Nick, Steffen Fuchs, Jan Mischke, Robert Palter, Gernot Strube, and Jonathan Woetzel. ‘Modular Construction: From Projects to Products’. Capital Projects, n.d., 34.

- DigitalFUTURES world. Platform-Based Robotic Timber Architecture: DAY 3-Session 1, 2020.

https://www.youtube.com/watch?v=XJrChXiUfao.

- ‘Rethinking Timber Buildings’. Accessed 6 June 2022.

https://www.arup.com/en/perspectives/publications/research/section/rethinking-timber-buildings.

- ‘Modular vs Traditional Construction’. Definition; Guidance; Research, Development and Innovation.

https://www.designingbuildings.co.uk.

Accessed 7 June 2022.

https://www.designingbuildings.co.uk/wiki/Modular_vs_traditional_construction.

- Mass Timber City. Mass Timber at Design to Production – Fabian Scheurer – Design to Production – March 9, 201, 2021. .

- Eastman, Charles M. Building Product Models: Computer Environments, Supporting Design and Construction. CRC Press, 1999.

Prefabricated construction: A review is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction, in 2021/2022 by:

Jordi Vilanova

Faculty: Mathilde Marengo