By internalizing the logic of discrete / procedural assemblies we can create a composite fabrication system which lends itself to the production of composite material systems.

Figuratively layering different processes as part of a standard operating procedure for a new class of material fabrication systems.

[Fast] Mass customization.

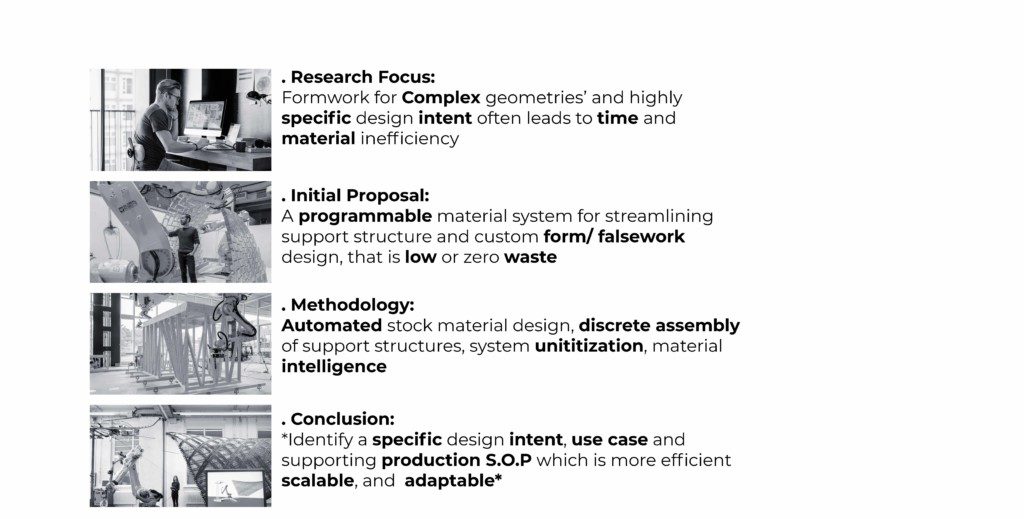

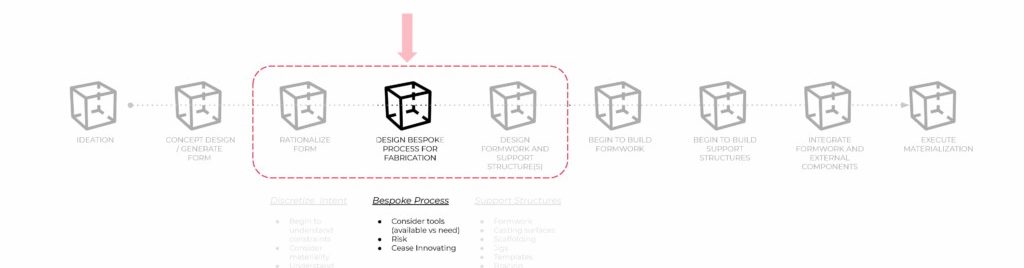

The bulk of the project exists within this bucket, focusing on developing a bespoke fabrication process.

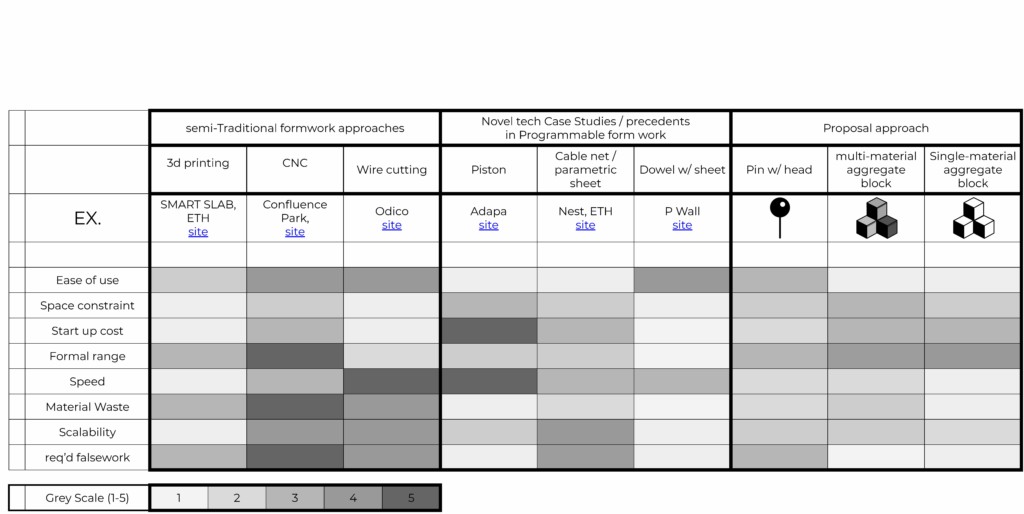

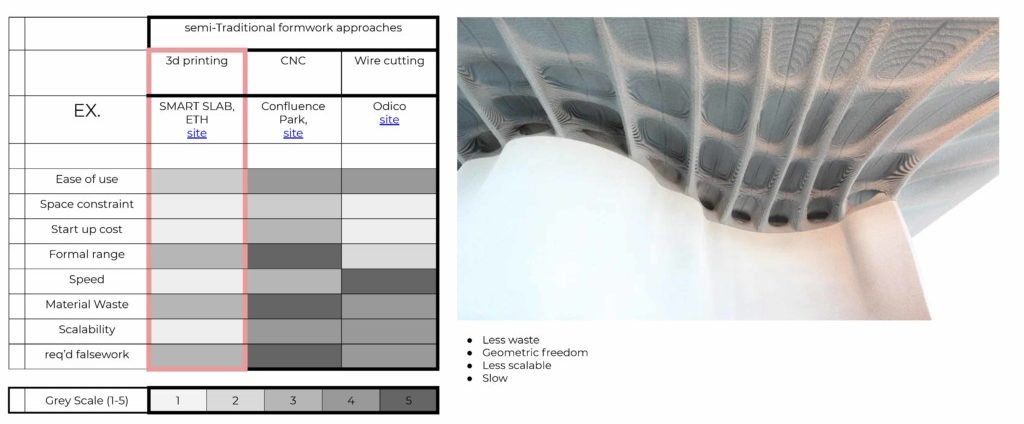

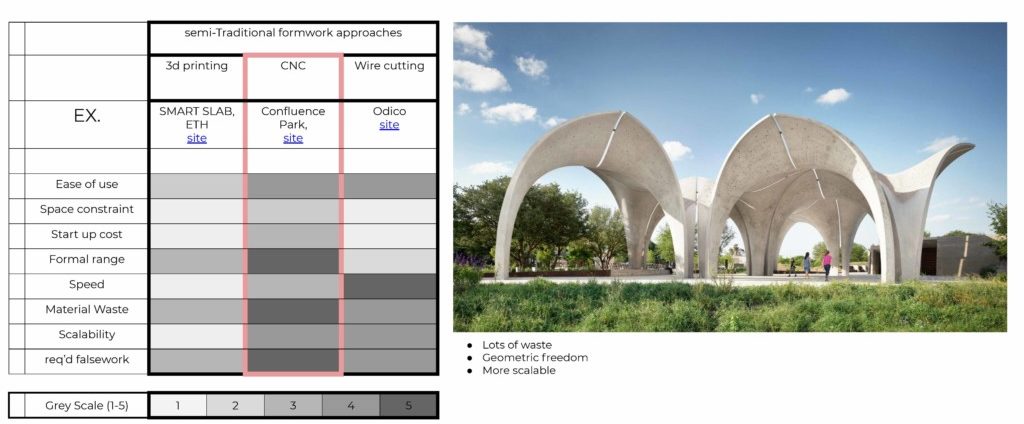

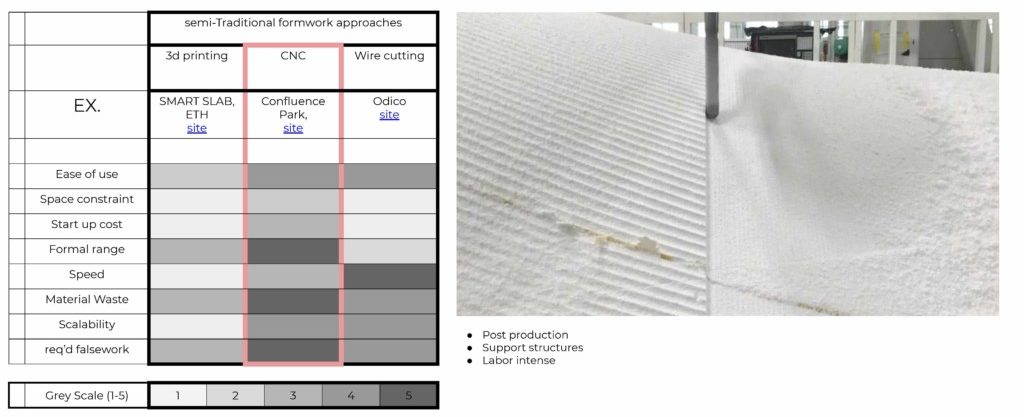

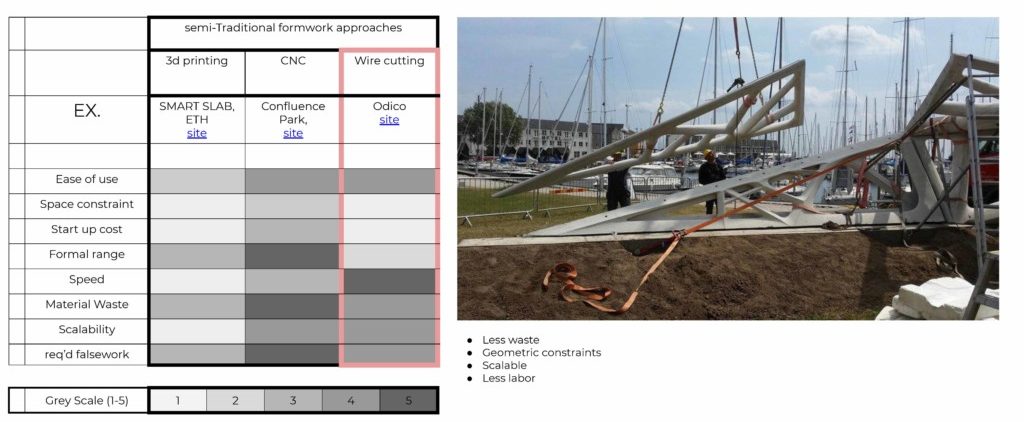

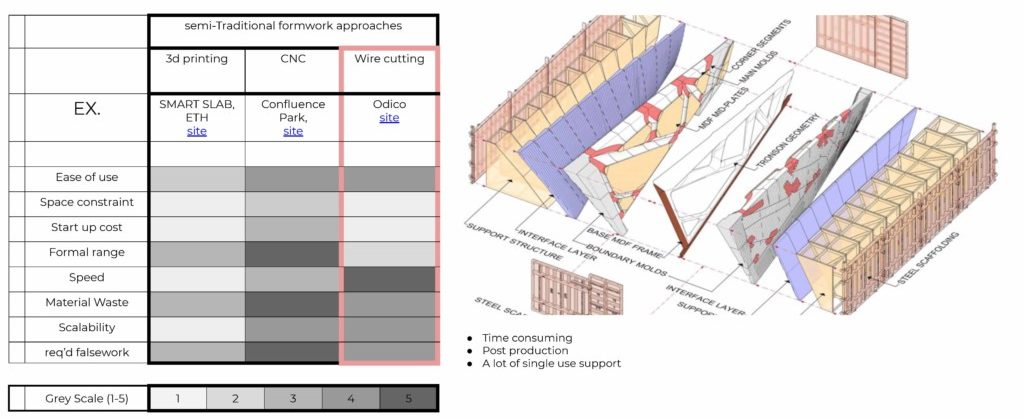

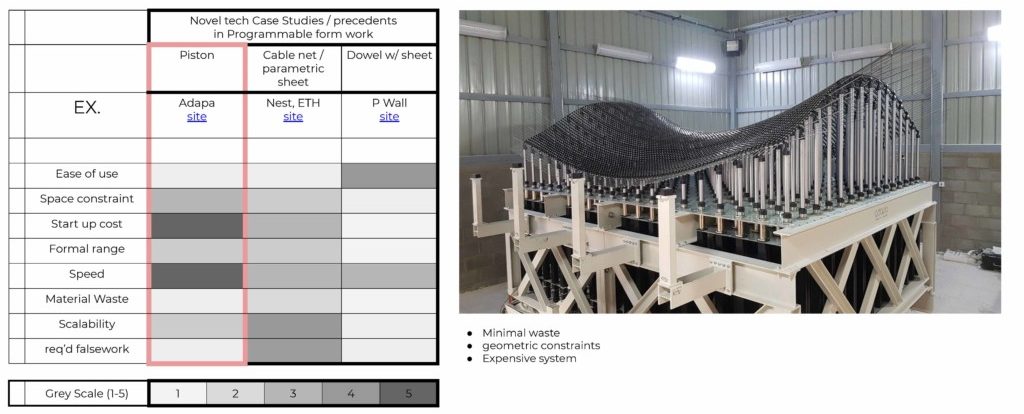

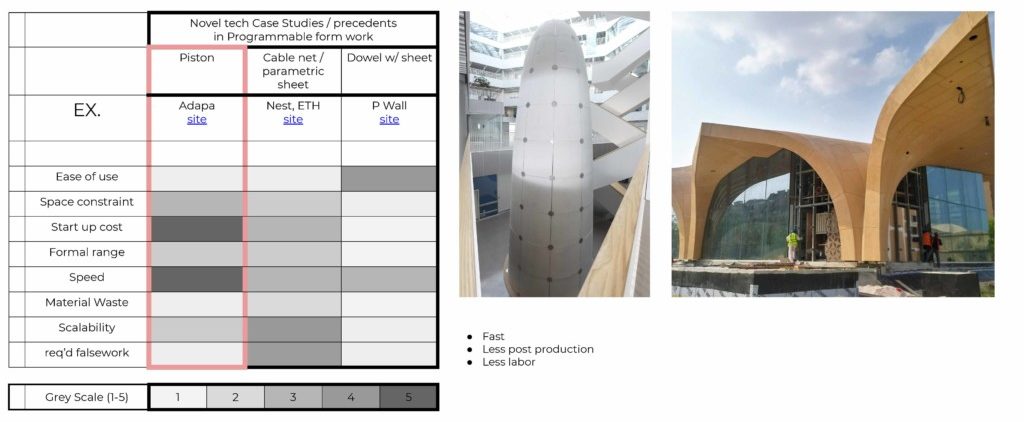

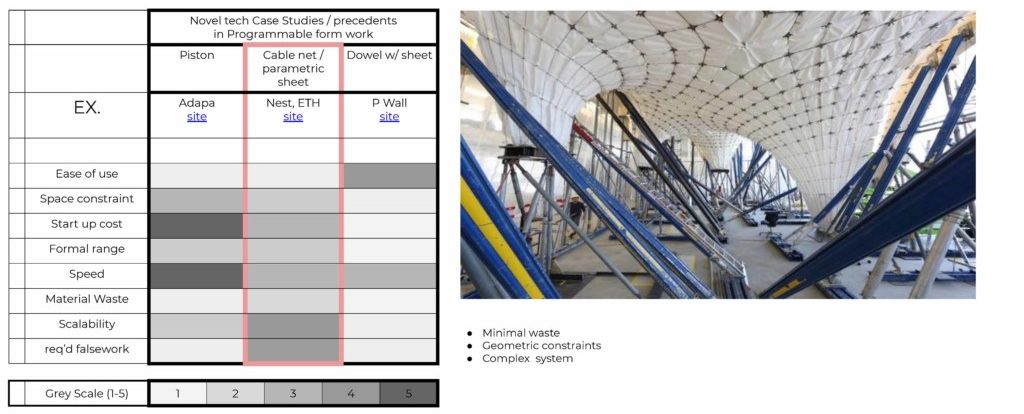

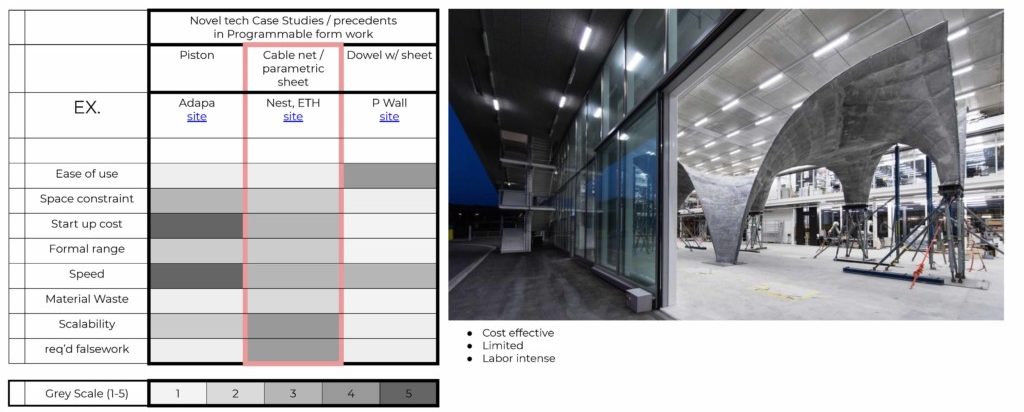

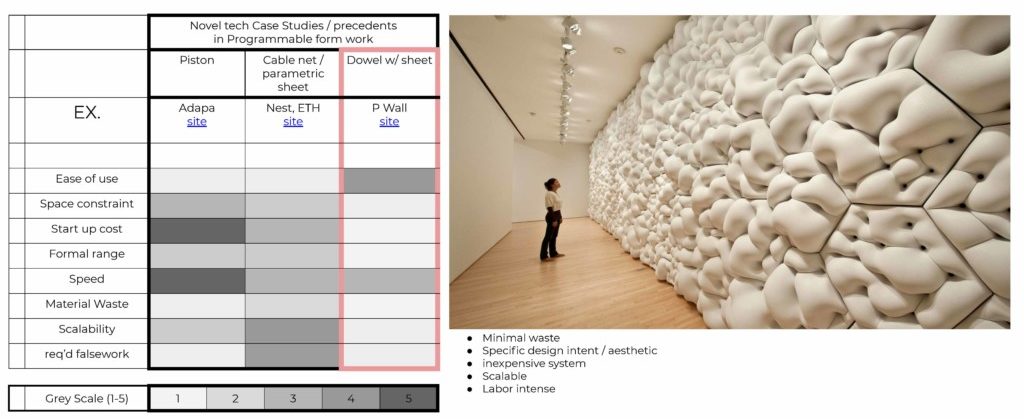

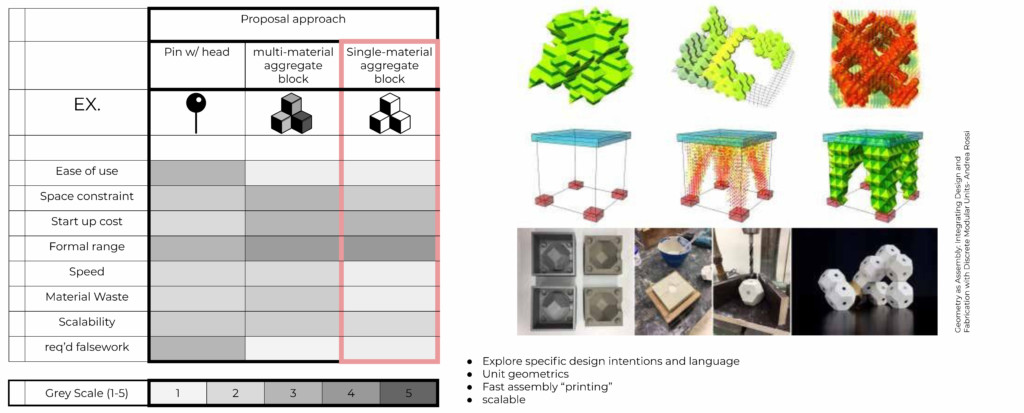

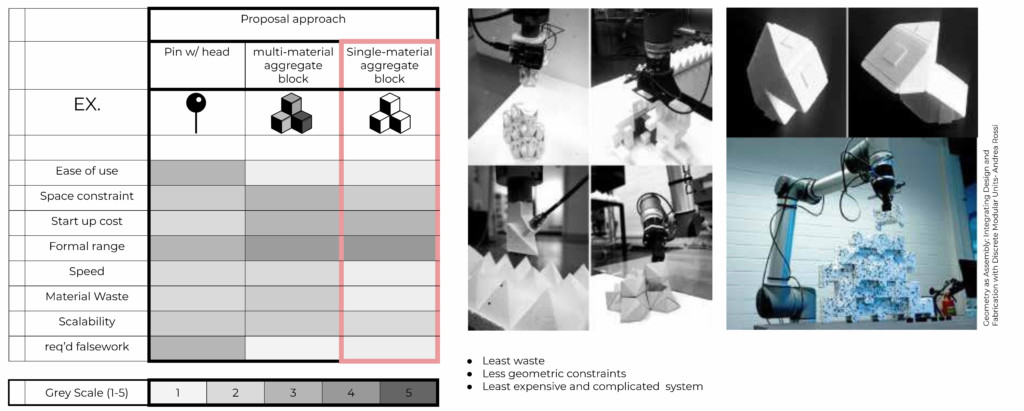

Chart describing a set of formwork case studies or precedents and ranking them qualitatively. The Last set of three are early ideas for experimental approaches initially considered for this research.

The following case studies illustrate points of reference in the various domains of on site of of site concrete formwork, using novel / programmable technology or more standard digital fabrication tools. I’m analyzing these case studies for weaknesses which can be improved as well as to gain an understanding of where / how my proposed tool may be able fit within the market.

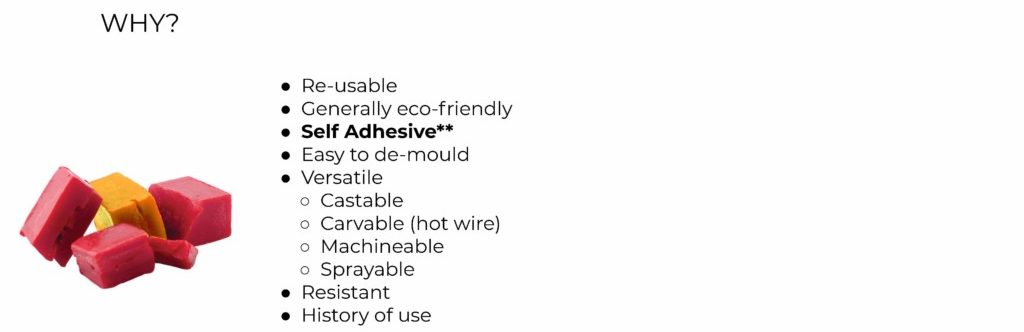

Wax is the first viable material I intend to experiment with to achieve the desired results, for these reasons.

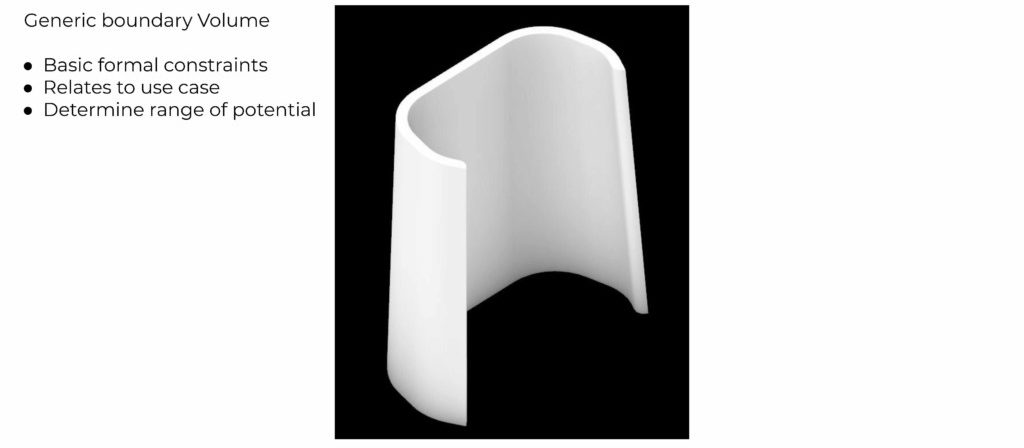

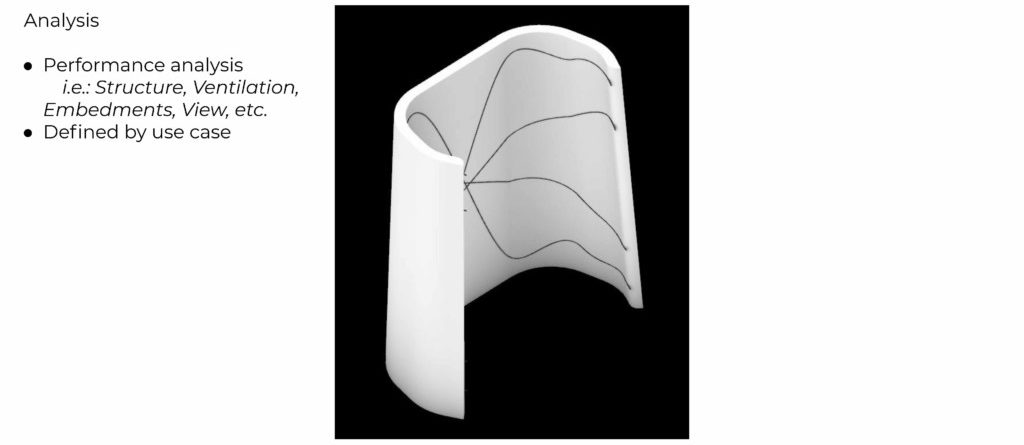

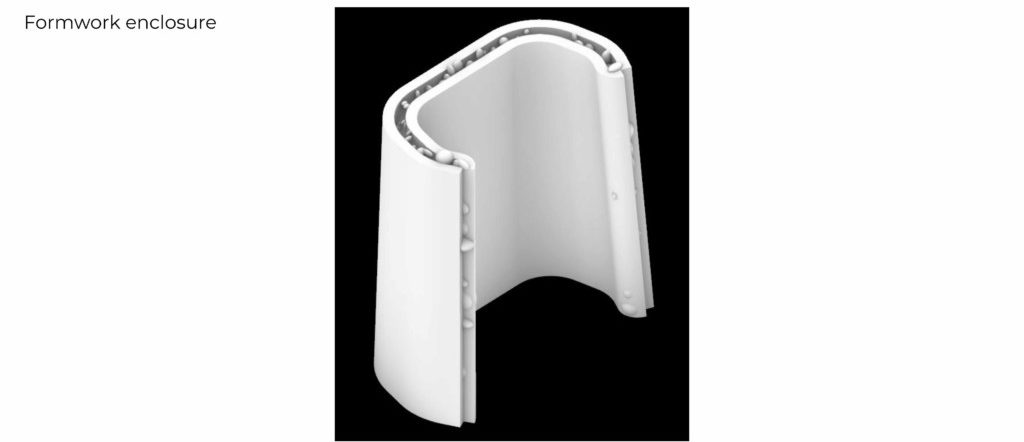

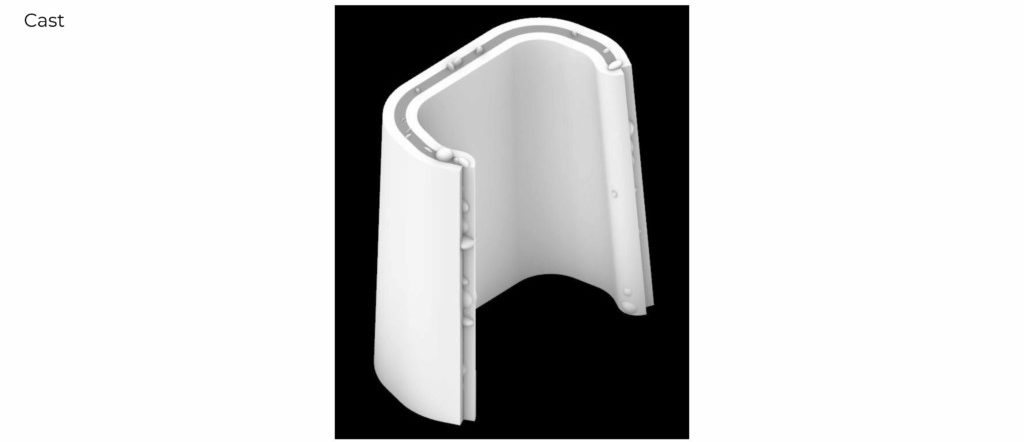

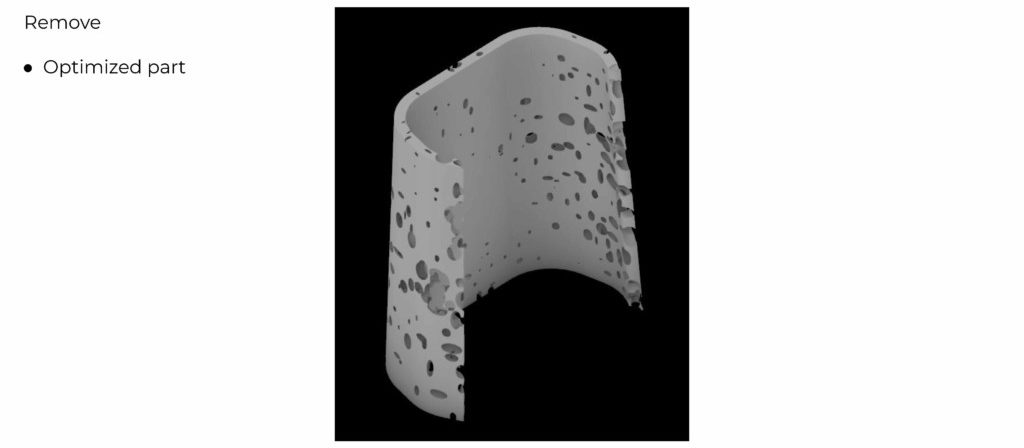

Below is a draft proposal for the conceptual work flow, working from a generic volume, through analysis, pick n’ place tool path and casting.

Research Thesis- wip- Porous concrete via novel formwork is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master of Robotics and Advanced Construction in 2021/22 by student: Michael DiCarlo and faculty: Alexandre Dubor and Aldo Sollazzo