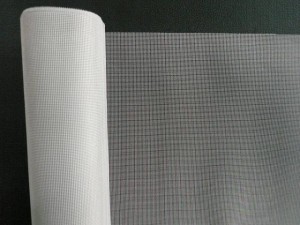

Scientific Name: Poly(ethylene terephthalate) Formula/ Chemical Composition: C10H804 It is made of many substances that contains compounds derived from living matter, making the material organic. Its biochemical composition thus consists of highly polymerized esters of fatty acids that are waxy and water repellant substances in plant cuticles, called Cutin. To put it simply, it controls the movement of water, solutes and gases. Living matter (e.g. plants) depend on these barriers that provide an interface with the environment. Furthermore, the main ingredient is a derivation of petroleum, called ethylene. Material Description: The object of study is a mosquito net which is made from polyester, sometimes referred to a Terylene if it is used as fibre. A mosquito net is a net that usually hangs across a door, a window or around a bed to keep mosquitoes away in most tropical and hot climate, preventing the increase of diseases such as malaria, dengue fever, yellow fever amongst others. Polyester is a good material to fight against mosquitoes and other insects because it is small enough to exclude the insects without preventing the passage of air into a place, nor impeding the ability to see. In addition, if it is treated it is more effective in the prevention of tropical diseases. Extraction Process: In a process known as polymerization, dimethyl terephthalate reacts with ethylene glycol at a temperature between 150-210 C, together with a substance that increases the rate of reaction, resulting in a chemical combined with terephthalic acid and is thus raised to a temperature of 280 C. A clear and molten substance is shaped to form long ribbons. This is polyester. Once the long ribbons have cooled down and are brittle, they are cut into tiny pieces and are completely dried to prevent irregularities in consistency. Afterwards the small pieces are melted down into a solution which is forced through a spinneret, to form a single strand. As it spins other chemicals are added resulting in a product which is flame retardant, antistatic and easy to dye. After this process fiber are textured or twisted to create duller, or softer fibre. Basic Properties:

- Compressive strength : 20 kN/m squared

- Tensile strength : 120 N

- Stiffness (n/m2) : < 10 GPa

- Density (kg/m3) : < 1.4 g/cm cubic

- Carbon footprint (average, KGC02E/ kg) : 4

- Recyclable : Yes

- Laser : Yes

- Small Laser : Yes

- Milling : Yes

- 3d Printing : Yes

Advantage in the context of digital fabrication: This material in conjunction with the fast and more economical nature of 3D printing is a great alternative to machining, in creating models that help determine if a design meets a client’s concept and expectations. In addition it can help to create prototypes of parts, testing them for fit, form and function in relation to other components of an assembly. Material suppliers: Eastman (South Carolina Operations) –

http://www.eastman.com/Company/Worldwide/our_sites/Pages/UnitedStates_SouthCarolina.aspx

PET Resin Association (PETRA) –

http://www.petresin.org/

Price: Materials World/ Servei Estacio –

http://www.mwmaterialsworld.com/es/textil/mosquitera-tela-poliester.html

3.94 EUROS per 150 cm.