This project explores the intersection of biology, computation and design to rethink the potential for new spaces of cultivation and consumption of Spirulina within a urban/domestic environment.

By decoding the behaviour of Spirulina and the operation of photobioreactors, the micro-properties of this algae were hacked through synthetic biology, influencing its macro flows through local design solution.

We want to bring the algae production inside the urban culture, within a hyperlocal context, placing the production spots within the consumption spots, challenging the way we think about how microorganisms can be integrated and celebrated in the built environment and gastronomy culture.

</p>

INTRO

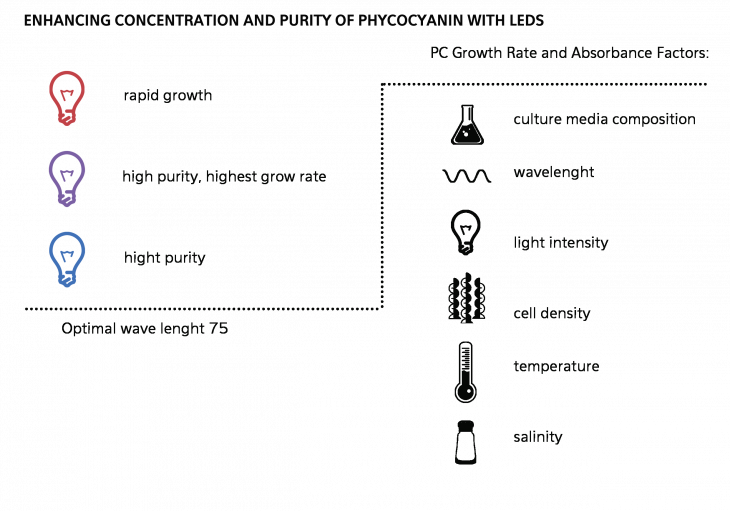

This study applies a Spirulina cultivation method using combinations of red, blue and purple light-emitting diodes under different intensities to maximise the quantitative content and purity of phycocyanin for application to gastronomy.

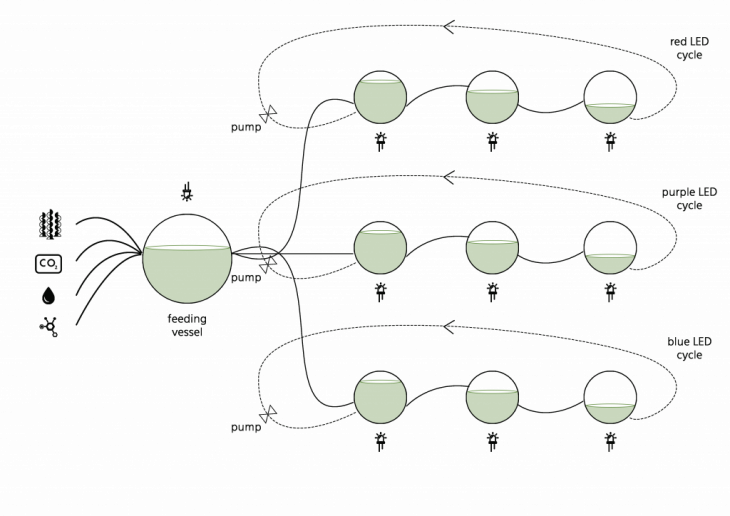

A material system consisting of three isolated loops running in parallel has been developed with separate LED light exposures. The output is three separate culture conditions that are used to optimise synthetic characteristics for yields of either pigment, nutrition or production speed.

The results provide a prototype for development of a full scale photobioreactor that can be used to harvest food-grade phycocyanin, which is a photosynthetic pigment found in Spirulina platensis, for applications in popular gastronomy culture.

GENETIC OPTIMISATION

Genetic characteristics have been identified in Spirulina platensis that may be favourable to generating popular culture around its consumption. Phycocyanin is a water-soluble light-harvesting pigment with a high nutritional content of protein and antioxidants. Recent advances in synthetic engineering are producing high yields of the photosynthetic pigment for applications in the food industry. Studies reveal that market demand is predicted to double the next three years (Lee, 2015). Its aesthetic and nutritional appeal presents an opportunity to pair rapid advances in production with the rise in popularity of Gastrophysics in food culture.

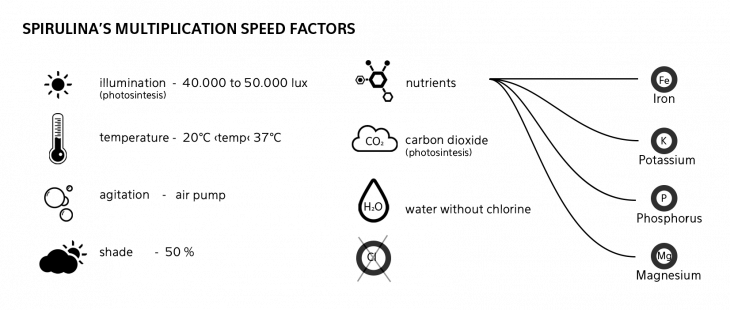

As a photosynthetic microorganism, Spirulina’s fertility is directly correlated with properties of light absorption. The growth rate of Phycocyanin is therefore a function of light intensity as well as the wavelength. While many research papers explore the optimisation of light conditions during the cultivation of Spirulina, little attention has been given to how this light can affect the purity and concentration of phycocyanin specifically to optimise results for kitchen gastronomy.

SYNTHETIC BIOLOGY

This study sets out to prototype a material system that implements research method (Lee, 2015) in a controlled environment to cultivate food-grade phycocyanin for harvest in kitchen applications.

When spirulina cells don’t have enough light they will straighten themselves so that they can absorb more light. When the sun is too intense, they will become more spirally, each turn of spiral providing some shade to the rest of the filament.

If the light goes above 120,000 lux the spirulina cells are under photostress and are lysing. The culture becomes yellowish and foaming. Spirulina releases toxins such as microcystins (BMAA) upon cell death or lysis. Microcystins cause gastro disturbances or liver damage.

When the culture is dense enough, with a Secchi disc reading of 3 cm or less, S pirulina will shade each other enough and you don’t need to have any other type of shading on the tank. Here the agitation of the water column is crucial because the light will not penetrate deep.

PHOTOBIOREACTOR MORPHOLOGY

The morphology of PhycoLights was shaped according to the special lighting system and split cycles of harvesting needed to obtain the three different cultures mentioned before.

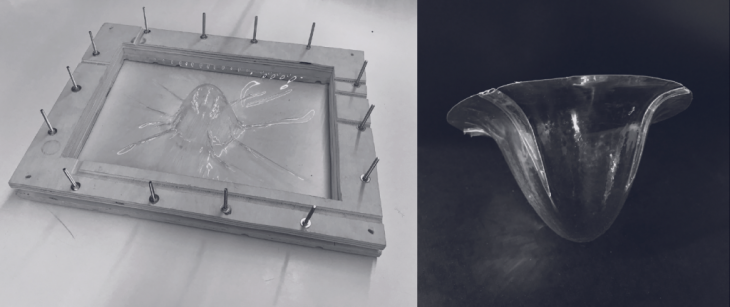

The other mandatory input is the photosithesis, therefore, transparent material is necessary. We chose acrylic for this reasons and elastic fabric to protect the Spirulina contamination, at the same time allowing it to ventilate.

The spatial configuration resembles to a brain that contains all the mechanics necessary for working, the nutrients and feeds three independent cycles. This branch hierarchy allows a growth of the system according to the user’s needs.

FUNCTIONING

The first sample of spirulina is grown in the first vessel until it reaches at least 1500ml within the optimum concentration to be split. Once reached this stage, the sample can be divided into the three separate cycles.

Due to the necessity of not mixing the different samples once they were hacked with the specific LED, the Spirulina running in each cycle doesn’t return to the first vessel. The amount of time of function of each cycle depends of the concentration, nutrients, temperature and light exposure.

THERMOFORMING PROCESS

PHOTOBIOREACTOR

lights off lights on

Intro Studio project developed at Master in Advanced Architecture, 2017/2018

Students: Luciana Teodózio, Nikoleta Nikolova, Deepak Sivadasan, Ewald Jooste.

Faculty: Claudia Pasquero, Carmelo Zapulla.