OTF program takes advantage of the technology and breaks the boundaries of design by exploring the possibilities that 3D-printing offers in the field of architecture and construction. Furthermore, the program chooses to work with sustainable, eco-friendly materials, such as clay as its main building material and Km-0 found additive solutions to enhance its structural properties.This year the research aims to achieve a sustainable and structurally stable construction system using km-0 robotic additive manufacturing. The research will employ continuous printing and cantilever geometries to enhance the structural capacities and spatial qualities of its expected results.

The tools employed consist of a combination of computational methods, robotic manufacturing, custom made material solutions and performance- based design. During the 6-month exploration, the research will produce several scaled models and a final construction of a complex design, printed in different scales and materials.

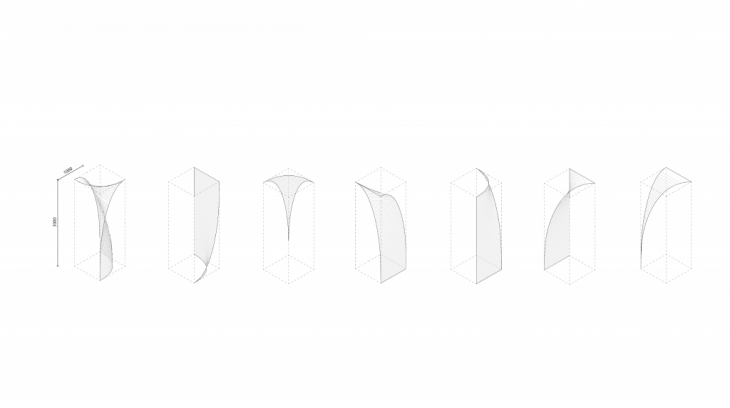

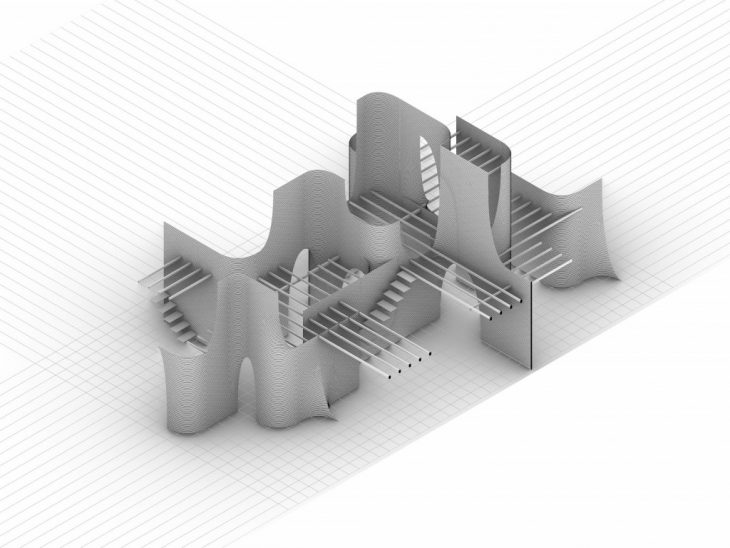

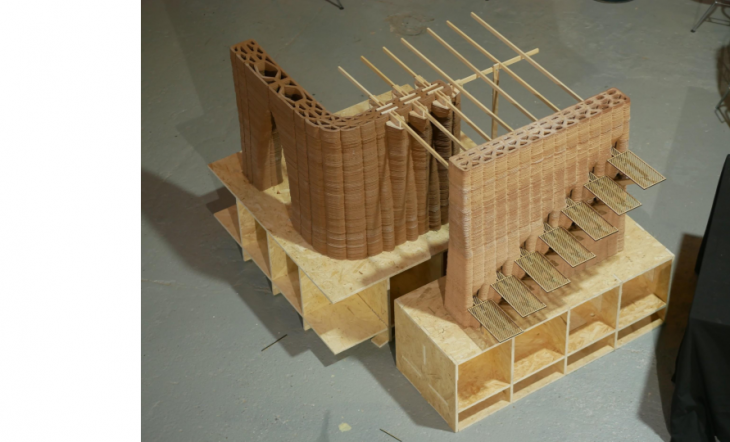

The design process of the final prototypes followed a path from abstraction to specificity. Based on the structural research conducted before the finalization of this step, 7 modules of various qualities were produced. This modules acted as the connecting pieces between the abstract design and the technicalities of the new technology. They were combined, manipulated, twisted and deformed in order to create spatial solutions in the form of series of rooms and single architectural elements, such as stairs, openings and columns. The final results can be observed both on paper and in reality.

Based on our surface geometry catalogue, we selected 7 modules that has the same tangency but different degree of curvature and shape, as our design basis. The tangency allows us to connect the modules seamlessly, and forming a series of architectural elements such as walls, columns, rooms, and opening.

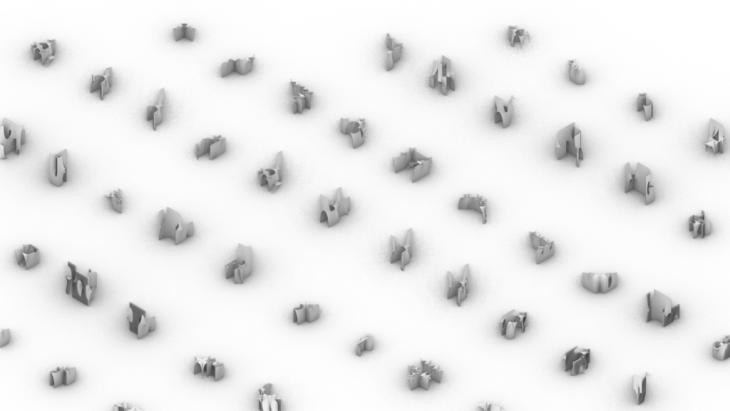

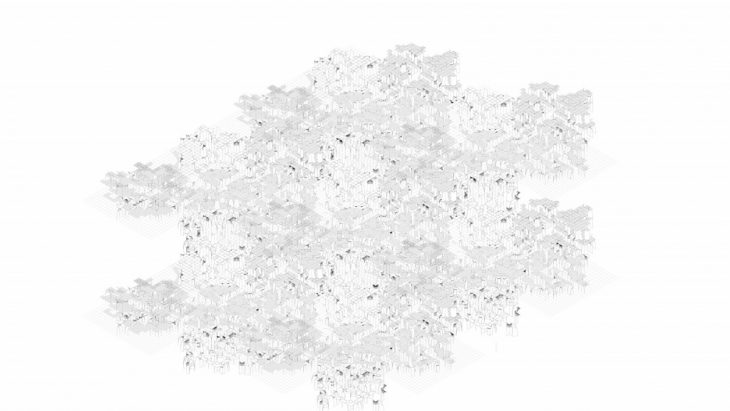

These moments, each with its specific functions and spatial qualities expand into an endless city carpet that has no boundaries.

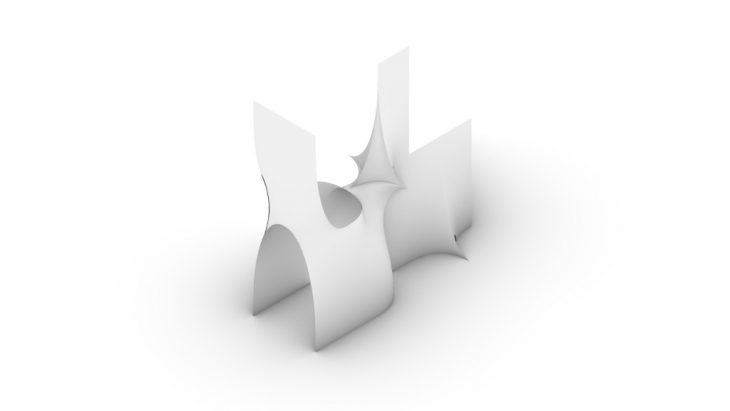

From the endless carpet, one house is extracted. The main design focus is blurring the distinction between the interior and exterior, creating a smooth transition between the ground and first level, also between the horizontal and vertical direction. Surfaces fold in and out to create openings and guides the way of circulation.

For the abstract house to become 3D printable with clay, volume and infill are added according to structural stability and functional purposes. It has the potential to create a new kind of spatial experience.

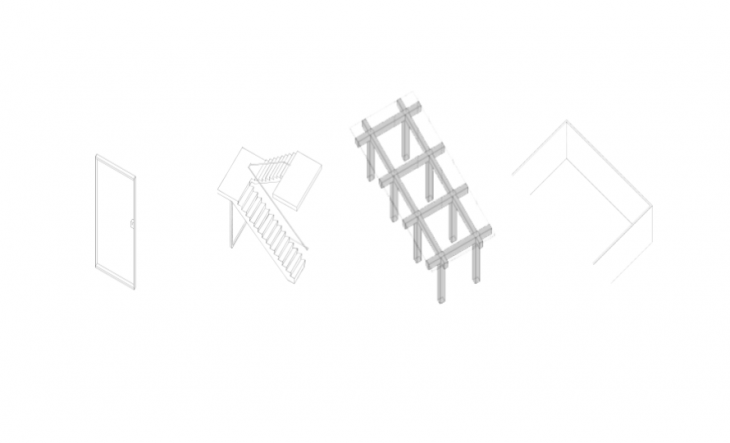

Inspired from the endless house, we rethink our current building system. What is actually defining the space quality in our modern buildings. The answer will probably be the span between pillars. In 20th century, modernism architects has clearly distinguished all the architecture elements such as floor slab, pillar, wall and staircase, a typical prototype is the domino system as we all known.

Since then, components of building are fabricated separately and assembled fast. We have achieved rapid,standard,mass production, but we’ve somehow lost flexibility and humanity in our living space.

What if we incorporate these components all together becoming one piece? It may give us an opportunity to break our existing construction rule and space forming rule.

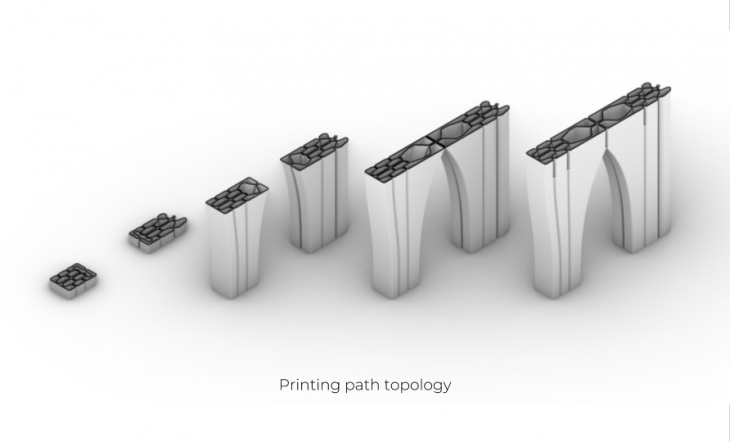

So from the endless house, we have selected several typical architecture elements as our structure-prototype to fabricate. One is to connect horizontal spaces, which is arch opening. One is to connect vertical spaces, which is staircase and the cantilever that is used to receive beam on top covering spaces. Here these architecture elements are not isolated and clear anymore. They are able to be integrated into wall (or we would prefer calling it continuous surface) and they are created with space in one go. This is a big advantage of 3D printing technique in architecture field.

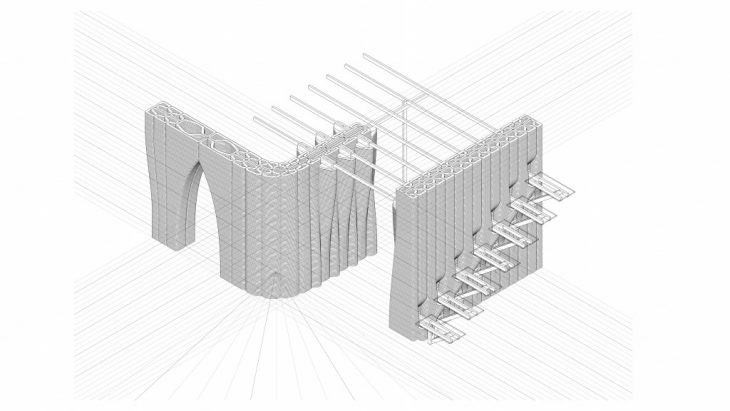

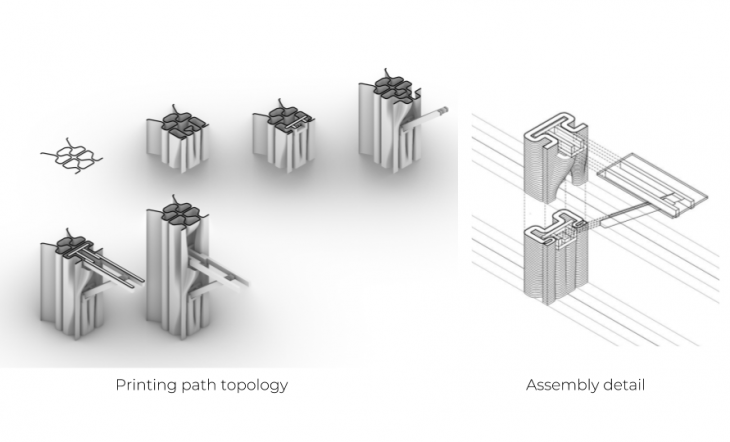

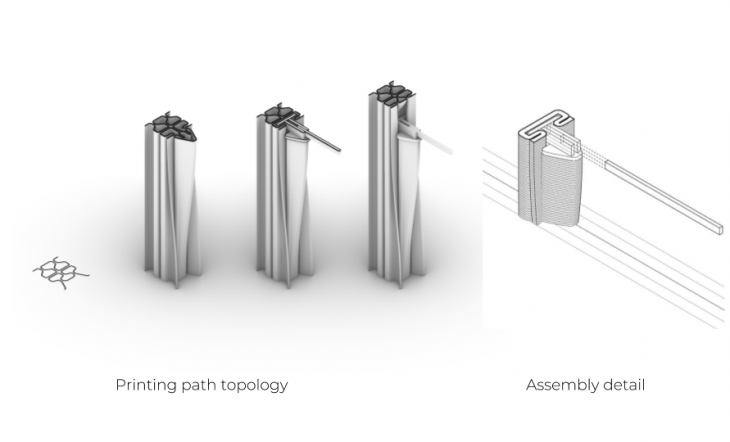

In the section below of one unit detail design, one can notice some complex geometry changes happening behind the facade. The goal is that we can digest both structure needs and assembly needs in a sequence of continuous printing lines.

From the detail diagram below you can see how the curve topology goes. Form a simple basic curve structure to a complex pattern, and they are lofted in one go.

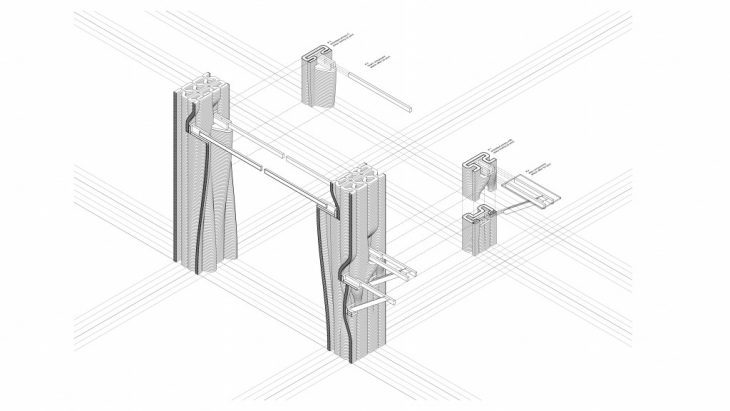

For the staircase detail, we have designed two embedded seats for the wooden joinery, so these two wooden joinery were placed during 3D print. And the rest of components including diagonal rod and step tread are attached after 3D print. For the lower wooden joinery, the clay mass behind resists the horizontal component-force that comes from diagonal component, and the upper joinery is blocked by the clay in front in order to prevent the step going out while there’s force loading on top.

For the beam detail, we have designed an embedded wooden plate to distribute the force of floor, and attach the wooden beam after print.

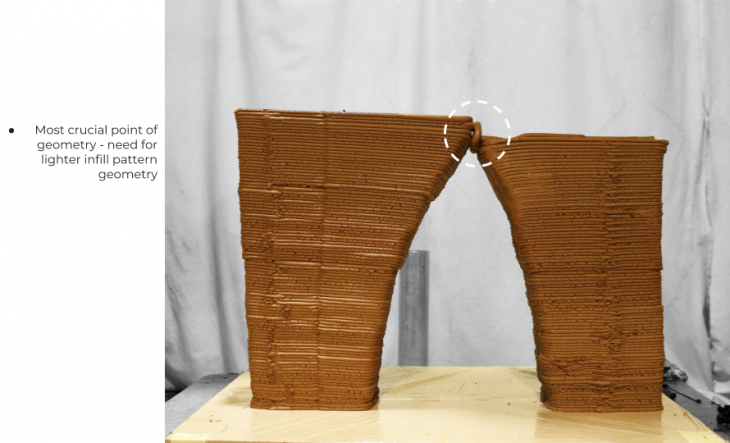

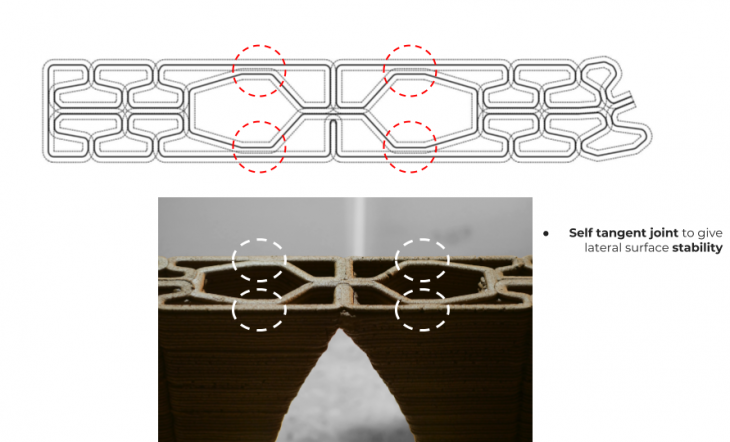

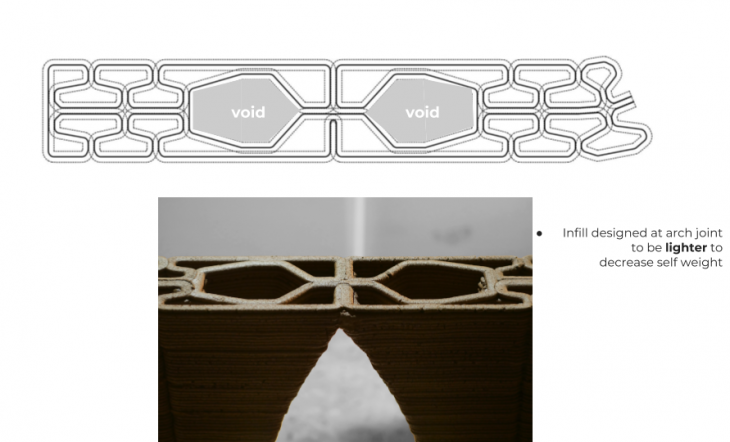

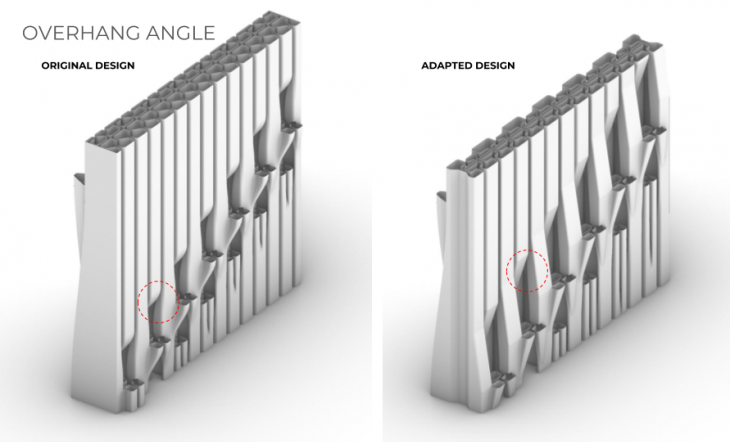

For the arched doorway, we configured the infill density according to its self weight balance, you can see the pattern grows up becoming an envelope in front and the mass is gradually shifting backwards, holding the envelop. at the same time, the inner layer has the impact of reinforcing the lateral clay in order to increase local inertia.

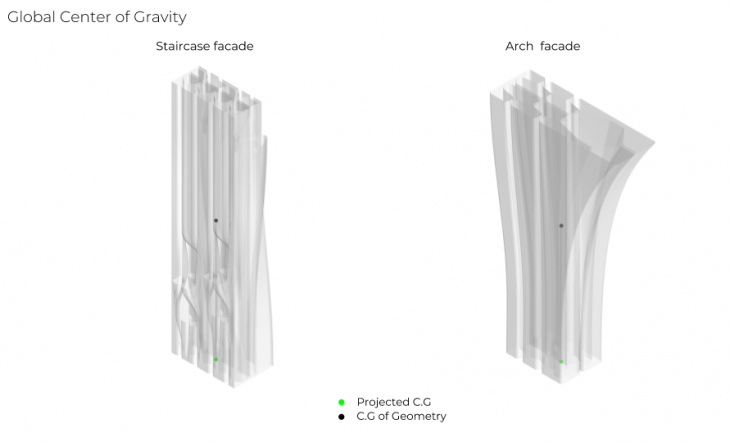

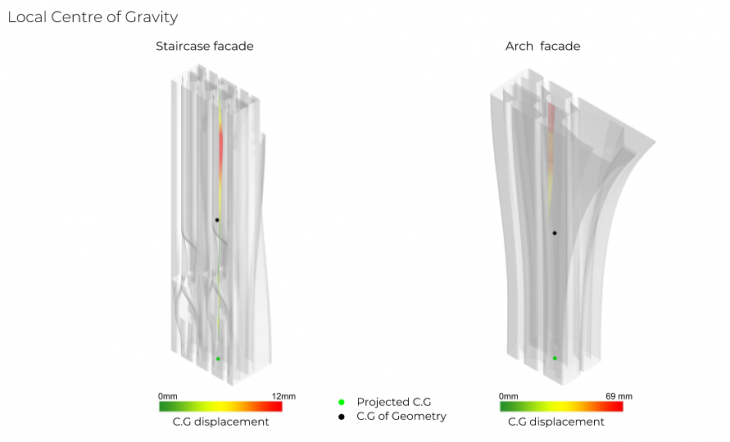

During the design phase, we were also using some structural analysis toolkit to visualize some crucial issues.

For example, below is the global center of gravity of the whole geometry. We can anticipate if the C.G goes beyond the geometry support base.

Center of gravity of every single layer affects the center of gravity of whole geometry as well. These subtle changes actually can be seen in our real fabrication process and also affect our printing strategy. for the arch design it is very key to us, it can visualize how the infill balance back the self weight of entire geometry while the cantilever goes further away.

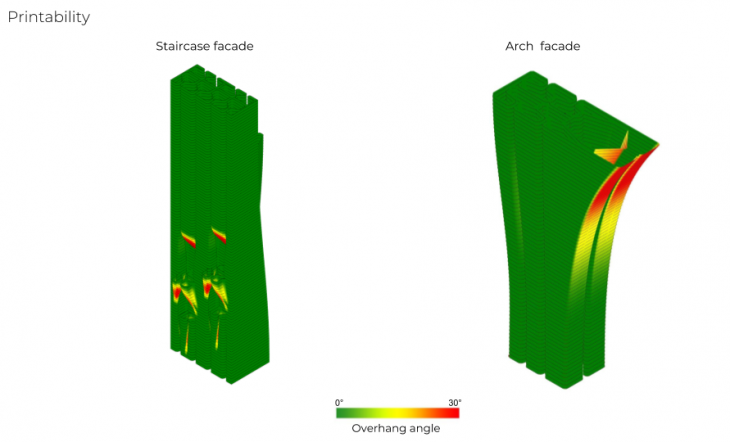

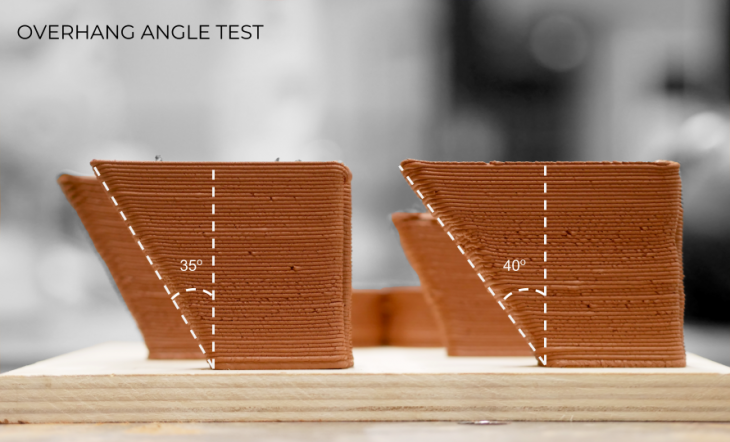

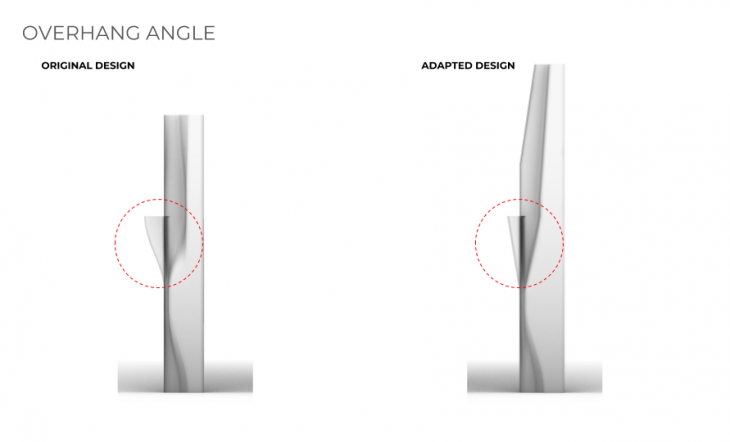

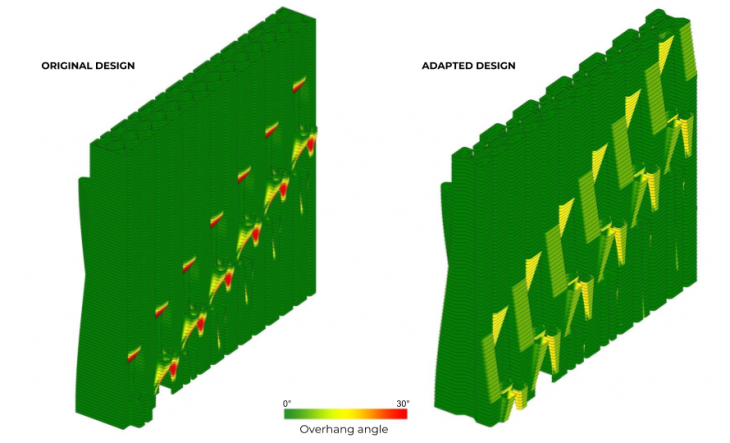

Below is the overhang angle analysis. The record of printable overhang angle in OTF last year is 30 degree, and this year we have happily refreshed the record as 37 degree relying on the infill design.

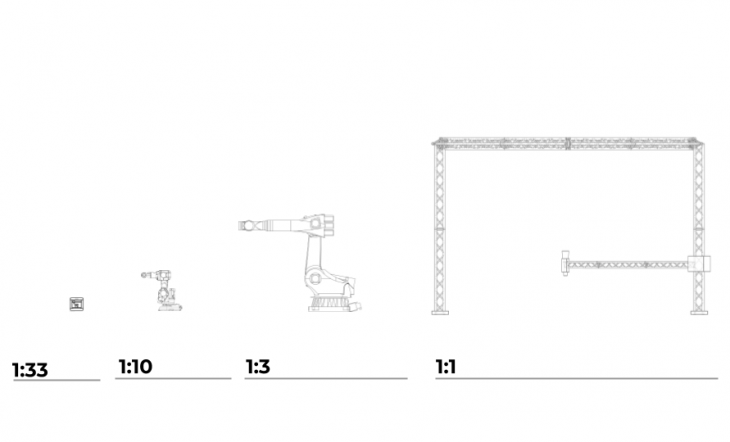

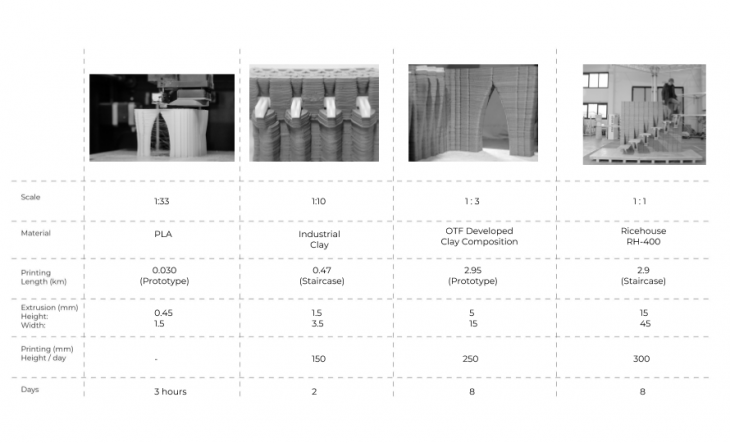

After an intensive design phase we decided to start prototyping at different scales to understand how the design and geometry work with different materials and different printing technologies.

The first testing we started for the prototype was on a basic PLA-extrusion 3D printer to test the aesthetic value of the geometry and design. For the same we created a custom 3D-slicer to mimic the printing process that would take place on a larger-scale machine. The scale of this model was at the 1:33 scale.

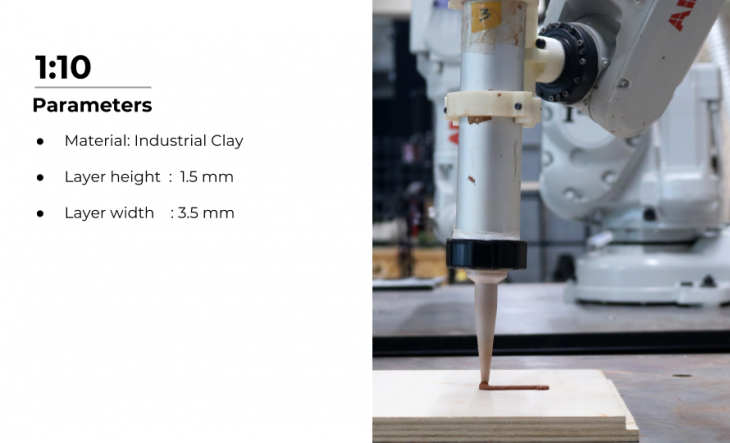

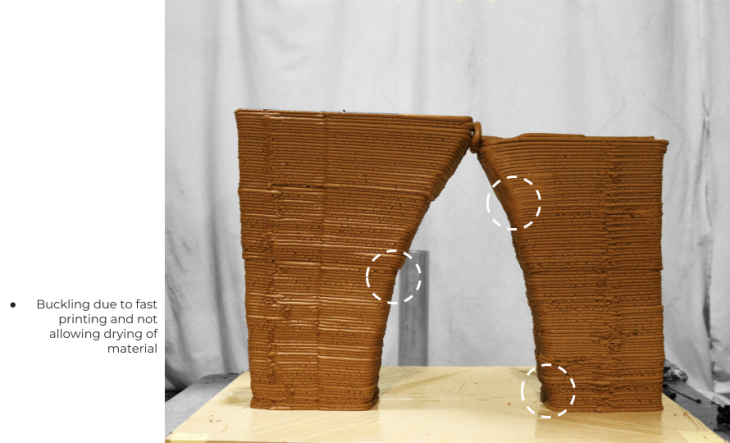

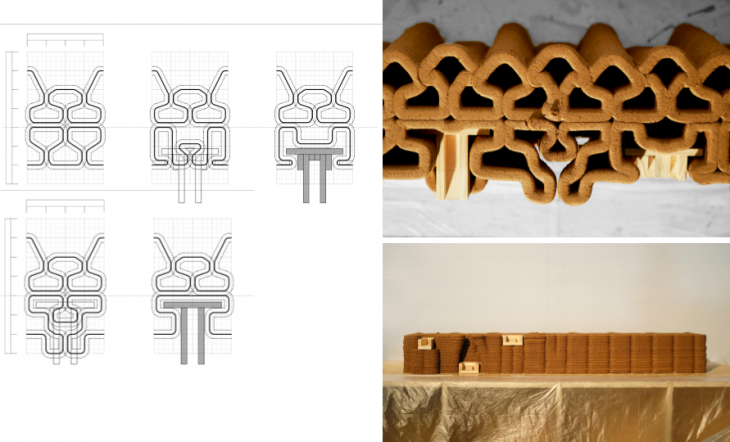

The next stage of our prototyping was at a 1:10 scale to start understanding and testing the geometry with similar material in industrial clay.

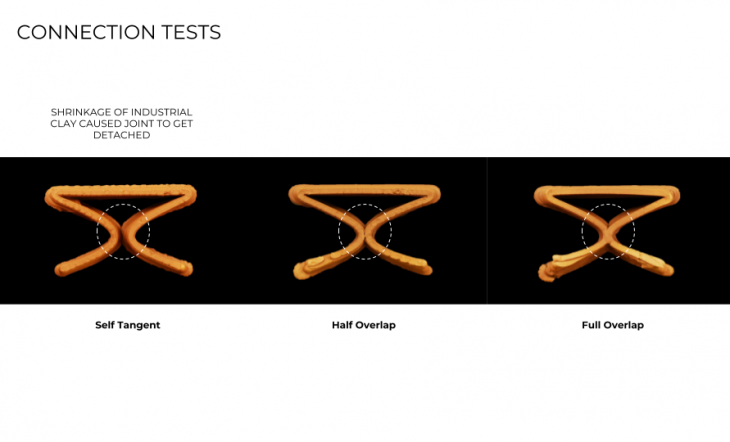

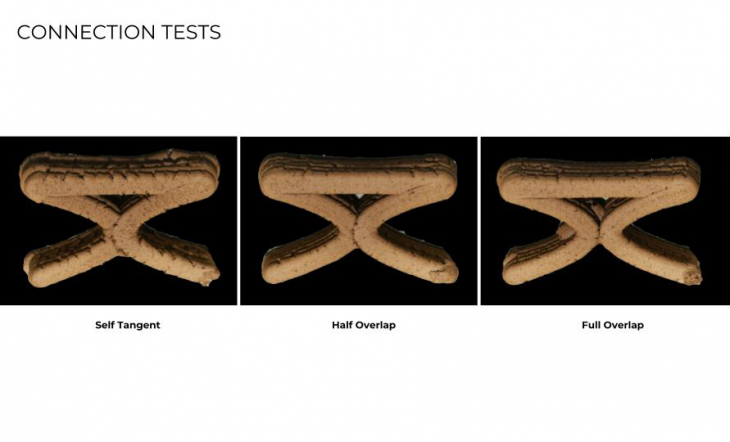

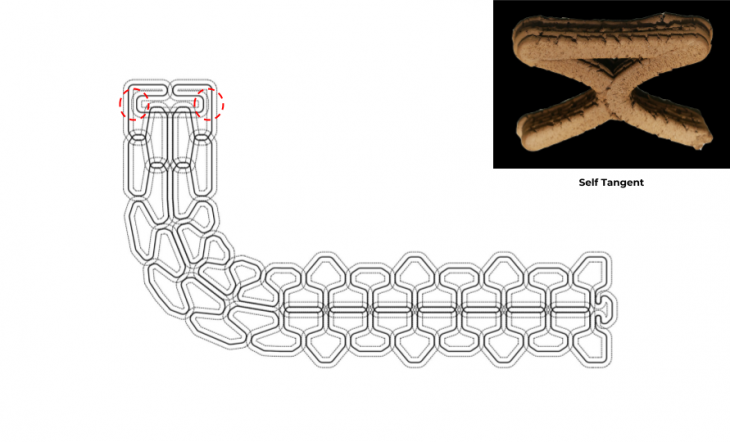

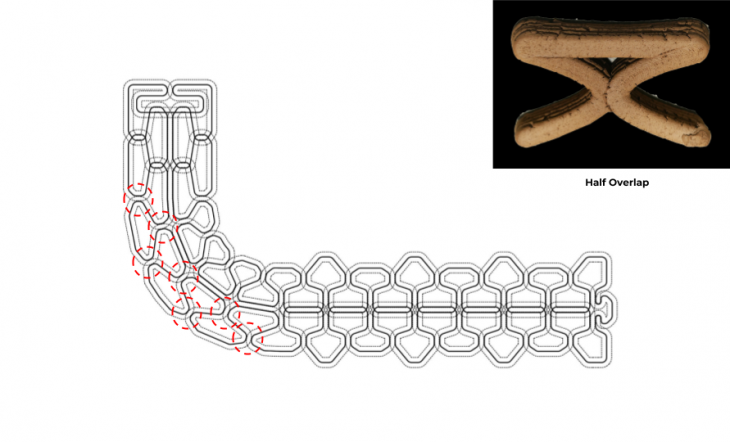

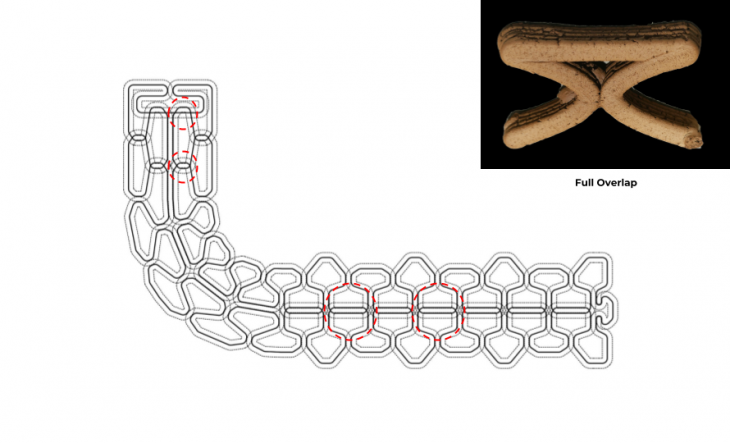

We tested different parameters like the connections in the infill design plus overhang angles that could be achieved.

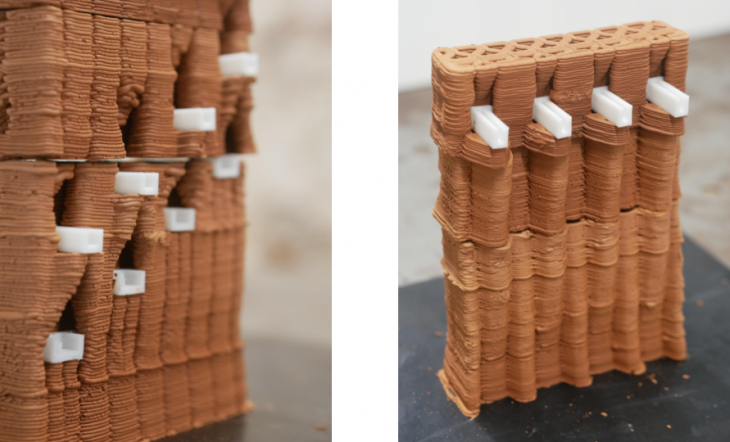

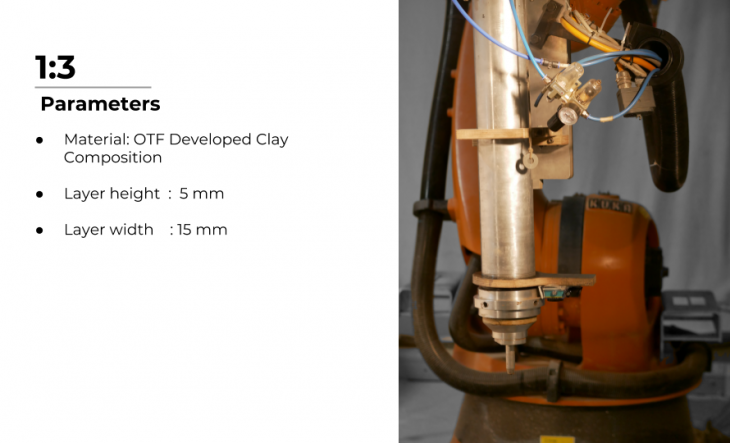

From the knowledge gained at different scales we shifted our attention to the 1:3 scale to get a better understanding of spatial and functional qualities. For the same we used a material which we developed in the program this year. At this scale we tried to have control over both the material and machine itself.

For the connection tests here we realized that every case gave us positive results. Thus we decided to use these different cases smartly for the infill design. This has been shown below in the infill design where for different situations a different form of overlap is implemented.

The final result of this scale gives an understanding of spatial and functional qualities. It also gave us insight about how the logistics would work for such kind of advanced technology.

After all the tests and prototypes at different scale we shifted to the 1:1 scale model in collaboration with WASP in Italy. Here we worked with the km-0 material available which was the Rice house material they used for their GAIA project. Because of shortage of time we decided to only print the staircase wall.

With change in material and machine there were problems related to the overhang angle possible and also the connection joints. Thus the design had to be modified a bit to make the printing possible.

Also with the analysis shown below the red parts which were printable on the 1:3 scale needed to be changed a bit to be printable on the 1:1 scale.

Working on different scales with different materials gave us a deeper understanding of how 3D printing at large-scales changed with different machines. Also the design has to be adapted for every scale not only to make up for change in machinery but also because of material change on every scale. Below the table shows the comparison between these different scales.

OTF Research Credits :

This project is a research of the Institute for Advanced Architecture of Catalonia (IAAC), developed within the Open Thesis Fabrication (OTF) program 2018-19, in collaboration with WASP, UN-Habitat, Windmill, La Salle and Rice House.

Students : Ozgur Cengiz, Yuchen Chen, Ipsita Datta, Yingxin Du, Ashkan Foroughi, Pavlina Kriki, Yi Fan Liao, Bhakti Vinod Loonawat, Shahram C. Randeria, Payam Salehi Nejad, Nusrat Tabassum

Faculty : Alexandre Dubor, Edouard Cabay, Joaquim Melchor, Kunaljit Chadha

Faculty assistant : Eugenio Bettucchi, Sheikh Riaz, Armin Akbari, Ya-Chieh Chang

Collaborators : Lapo Naldoni, Alberto Chiusoli, Massimo Visonà and Francesco De Fabritiis (WASP), Josep Ramon Sole and Joal Juanpere (Windmill), Runze Wang (Un-Habitat), Nadia Soledad and Gloria Font (LaSalle)