INTRODUCTION

The aim of this project was to explore three dimensional recursive geometry that could be materialised and adapted to various digital fabrication tools – Laser Cutting, CNC milling and 3D Printing. The geometry explored towards this purpose was the genus of flowering plants called oxalis.

OXALIS | CNC MILLING

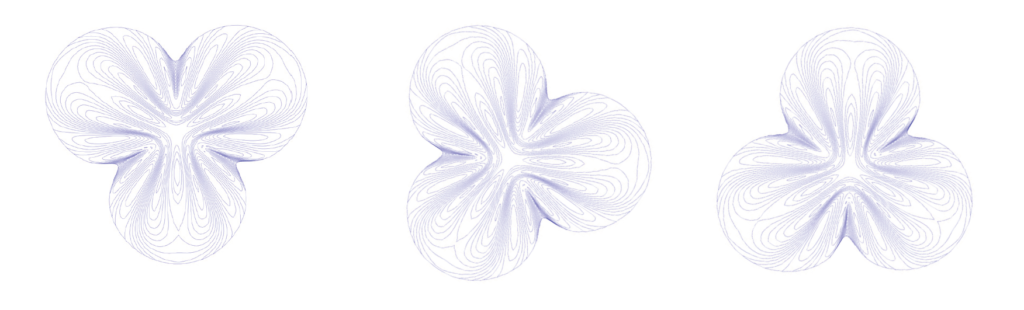

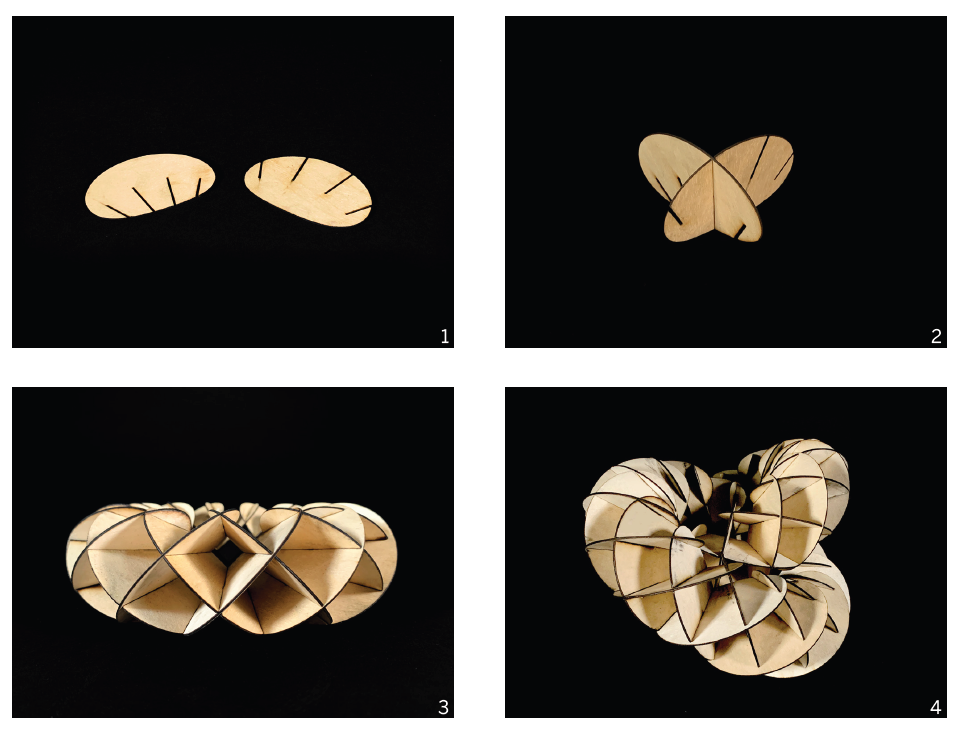

For CNC milling, our design began with a circular mesh deformed (or pinched) with the use of anchor points on each intersection of the folds to form the oxalis geometry. Within the folds there is possibility of aggregating the geometry through alternating rotation vertically and horizontally. For the stock strategy we contained the toolpath on the geometry boundary to opstimise the milling time and limit the amount of stock removal. We used 3-Axis machining. For the bulk material removal we uses horizontal roughing with the tool – upcut 10mm. For our finishing we initially used parallel finishing and realized it was not giving the geometry the desired curvature. We then switched to horizontal finishing with the 6mm ball mill. This finishing strategy was more suited to our geometry because it has steep curves and parts that are more vertical than horizontal. 2 1?2 Axis profiling using 10mm Upcut – we set the cut z depth and created a total of four bridges.

Parameters

Material: plywood

Machine: t-rex(p59)

Post processor: cnc_step_bcn

Workpiece volume: 200x200x30mm

Total mill time: 1.02 hour

CNC milling strategies

1 – Engraving

Flat mill

Flute: 1

Diameter: 10mm

Spindle speed: 12000

Cut direction: upcut

Stepdown control (dz): –

Stepover distance: –

Total mill time: 00.48 minutes

2 – Horizontal roughing

Flat mill

Flute: 1

Diameter: 10mm

Spindle speed: 12000

Cut direction: upcut

Stepdown control (dz): 25%

Stepover distance: 50%

Total mill time: 18.78 minutes

3 – Horizontal finishing

Ball mill

flute: 2

Diameter: 6mm

spindle speed: 12000

cut direction: upcut

stepdown control (dz): 10%

Stepover distance: –

total mill time: 29.53 minutes

4 – Axis profiling

Flat mill

Flute: 1

Diameter: 10mm

Spindle speed: 12000

Cut direction: upcut

Stepdown control (dz): –

Stepover distance: –

Total mill time: 07.59 minutes.

CNC milling process

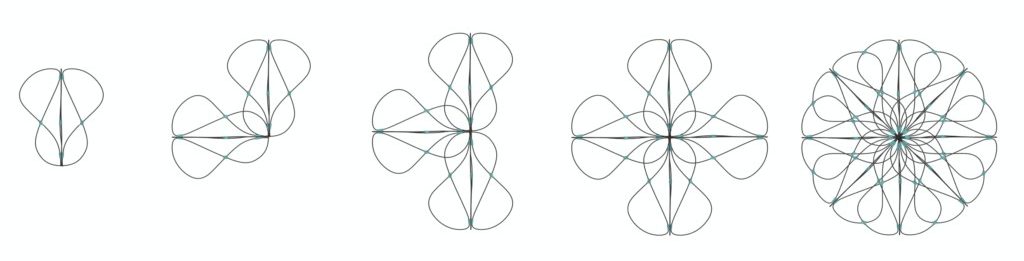

Digital exploration of aggregation strategy

Final Result

OXALIS | 3D PRINTING

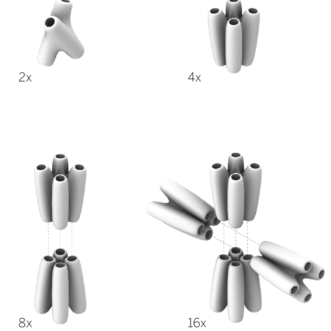

This project operated with the constraints of developing a node that could be integrated into a three dimensional recursive shape constructed of 2mm fiberglass rods. The node design was aimed at obscuring any visible assembling of the rods forming the geometry. As such the final outcome would have seamless continuity. Moreover with only two nodes varying in typology the primary 3D geometry could be aggregated both horizontally and vertically.

Parameters

Material: fiberglass rods 2.0 mm

Technique: 3d printing

Joint type: nodes

Machine: zortrax m200

Nozzle diameter: 0.4

Layers thickness: 0.19

Infill density: 30%

Printing time: 2 hours

Optimisation: mixed

Nodes: 12

Dimensions: 18×13 mm

Rods spacing: 2.5 mm

Digital exploration of aggregation strategy

Final Result

INTERLOCK | LASER CUTTING

The aim of our design for laser cutting was to achieve recursion within the constrains of only 2 dimensional curves. We used waffling strategy in diagonal sections. Materialising the geometry with 1.2mm birch plywood – the final models that resulted were assembled with two simple modules. Two toruses were then produced and interlocked in an to extend the recursion beyond the two intersecting modules.

Parameters

Material: plywood 1.2 mm

Technique: laser cut

Joint type: waffling

Machine: epilog 75 (p59)

Speed: 10

Power: 94

Frequency: 400

Cutting time: 1.45 hour

Dimensions: ø 60 mm

Slices: 26

Grooves: 1.08 mm

Final Result

Introduction to Digital Fabrication – Recursive Geometries is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2021/2022;

Students: Gianmarco Paglierani, Solene Cais, Vishakha Pathak;

Faculty: Shyam Francesco Zonca, Lana Awad and Ricardo Mayor