The PYLOS workshop was based on previous research developed by IAAC Alumni Sofoklis Giannakopoulos between 2013 and 2015. The theme focuses on using clay as a material for 3D Printing, and within the 2 weeks the students tested and discovered the potential of clay and developed an entirely new architectural alphabet of design parameters, that led to structural strategies and form finding techniques.

Towards creating architectural elements at a 1:1 scale there was a continuous series of trial-and error processes. The students were divided into 4 teams, each focusing on a specific topic, and in the end there were 2 larger teams united, in order to create an optimized design.

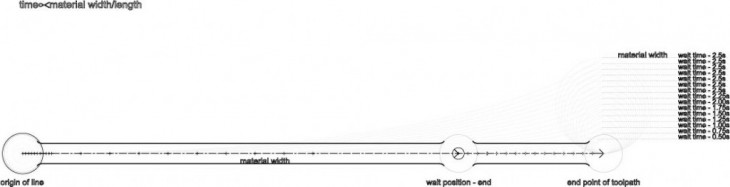

- The lines team focused on determining an optimum ratio between lines width and length. Then these lines were subjected to various degrees of rotation that generated overlapping, intersections, continuous lines and symmetry in order to maximize the cleanliness of the models.

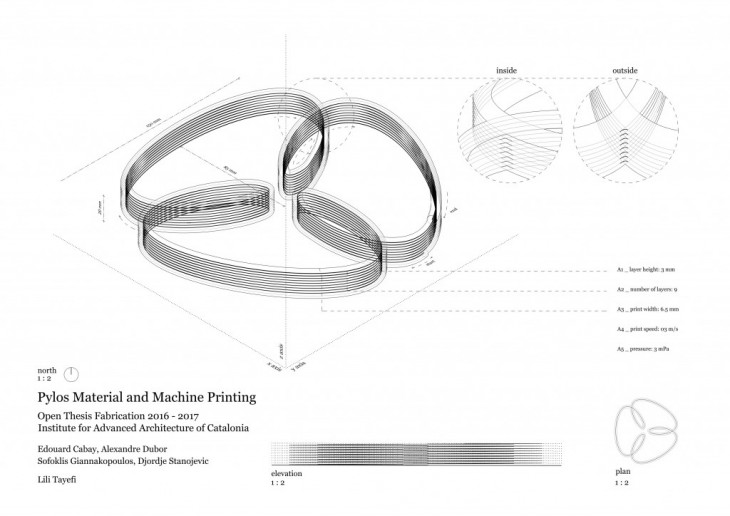

As a first example, in order to obtain branching, a series of methods was tested. The first one had a Boolean intersection in the top, but the bottom was hollow and had many cantilevers, which was a strategy that failed.The second geometry wasn’t exactly branching, but meant to create an opening and a single contour line. A relationship between inside and outside was established, with a crossing intersection, so it opens where it touches itself. This type of intersection was also picked from previously 8 tested types of intersection, that each could be appropriate in a different type of geometry. However, while the intersection worked, the prototype was uneven due to chosen pressure and speed.The third model’s surface is a lot more consistent because of the adding of cantilevers. The ridges are even, and speed and pressure are optimized for further use. In the fourth model, a different material was used with the perfected parameters, therefore a form that permitted two types of intersection was created– one that crosses and one that allows modules to touch each other.

As a first example, in order to obtain branching, a series of methods was tested. The first one had a Boolean intersection in the top, but the bottom was hollow and had many cantilevers, which was a strategy that failed.The second geometry wasn’t exactly branching, but meant to create an opening and a single contour line. A relationship between inside and outside was established, with a crossing intersection, so it opens where it touches itself. This type of intersection was also picked from previously 8 tested types of intersection, that each could be appropriate in a different type of geometry. However, while the intersection worked, the prototype was uneven due to chosen pressure and speed.The third model’s surface is a lot more consistent because of the adding of cantilevers. The ridges are even, and speed and pressure are optimized for further use. In the fourth model, a different material was used with the perfected parameters, therefore a form that permitted two types of intersection was created– one that crosses and one that allows modules to touch each other.

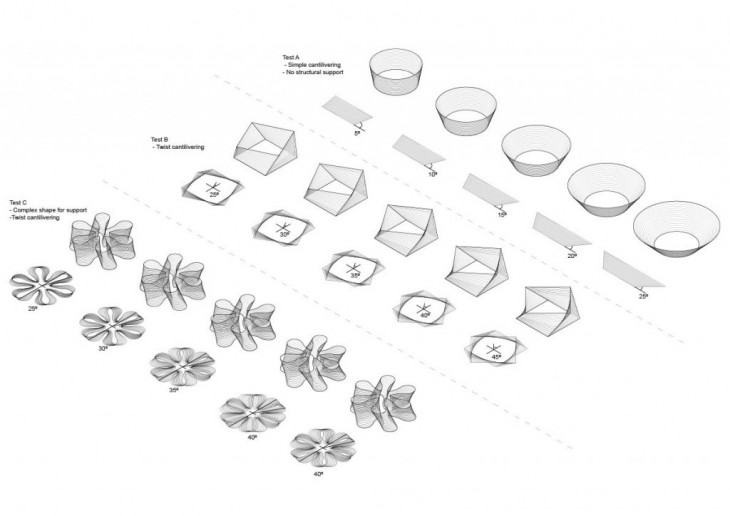

- The cantilever group focused on the issue of cantilevers and overhangs and how far they can be pushed. The material was under-tested in order material to find the safest way, not only the most risky one.

The experiments began with the primordial shape – the circle. After it was tested the limits of the cantilevers a circle derived geometry can resists, the basic shape was switched, in order to test other support systems. This followed in the creation of an actual architectural prototype, which presented openings, since light and shadow are basic architectural needs. Tunnels and arches could safely be added due to previous tests and the understanding of material behavior.

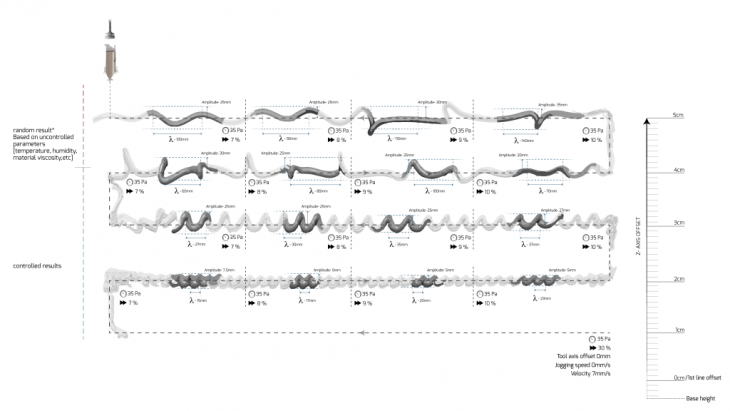

- The third team had the topic of printing lines in space, which circumstantially created a series of patterns and textures depending on the variation of print height from the surface.

The forms started with a 2D approach, with shifted and switched patterns, but in order to avoid a strictly ornamental result it was discovered that texture could be used as a structural element. It was a sculptural, hands-on approach, that implied continuously testing types of lines in order to derive the curvature of the lines into a structural element. Texture bumps became place holders for the curve’s seam, undulating shapes were given a context within architectural elements such as columns, material served form, form served purpose.

The forms started with a 2D approach, with shifted and switched patterns, but in order to avoid a strictly ornamental result it was discovered that texture could be used as a structural element. It was a sculptural, hands-on approach, that implied continuously testing types of lines in order to derive the curvature of the lines into a structural element. Texture bumps became place holders for the curve’s seam, undulating shapes were given a context within architectural elements such as columns, material served form, form served purpose.

- The fourth group dealt with the more technical issue of on and off. This focused on creating a good length for when the material is pushed in order to create the first line, and on optimum placing of the seams.

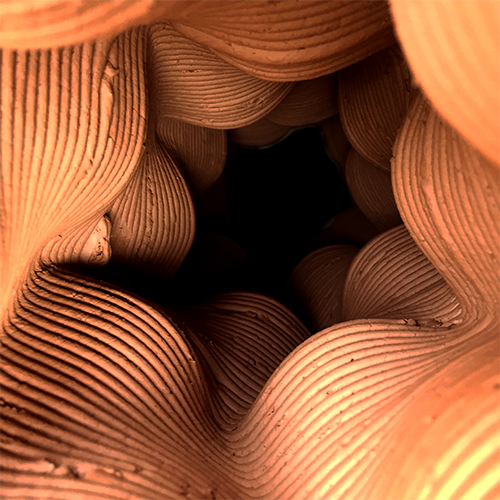

For the column exercise, the challenge was intersecting in planimetry two identical shapes, and place the seam and On and Off command on the inside of the structure, so that it will hide fabrication flaws, since in architecture and design the manufacturing process’s importance and flaws succumb to the importance of the final, clean product. The two basic intersecting squares were than derived – the edges were fileted, to create an organic shape. A route was applied for the form in the vertical direction that would permit them to come apart and then intersect. Along this Z direction curve, the shape were scaled, bigger towards the bottom and leaner towards the tip, for structural purposes, and were rotated in XY plane, to create a twisted effect.

For the column exercise, the challenge was intersecting in planimetry two identical shapes, and place the seam and On and Off command on the inside of the structure, so that it will hide fabrication flaws, since in architecture and design the manufacturing process’s importance and flaws succumb to the importance of the final, clean product. The two basic intersecting squares were than derived – the edges were fileted, to create an organic shape. A route was applied for the form in the vertical direction that would permit them to come apart and then intersect. Along this Z direction curve, the shape were scaled, bigger towards the bottom and leaner towards the tip, for structural purposes, and were rotated in XY plane, to create a twisted effect. Pylos /// Material and Machine Printing Workshop

Pylos /// Material and Machine Printing Workshop

Tutors: Sofoklis Giannakopoulos, Djordje Stanojevic

Program Directors: Edouard Cabay, Alexandre Dubor

Research Advisor: Areti Markopoulou

Students: Abdullah Ibrahim, Sameera Chukkapalli, Tanuj Thomas, Lili Tayefi, Chenthur Raaghav, Iason Giraud, Lidia Ratoi.