OTF – OPEN THESIS FABRICATION

FIRST PHASE FINAL PRESENTATIONS

The IAAC program Open Thesis Fabrication 2017-18 (OTF) proposes to design and construct 1:1 architectural elements that take advantage of the latest computational tools, additive manufacturing process and the great thermodynamic properties of adobe to achieve passive performative system for a bioclimatic architecture.

(check the Program here)

In the first phase (September – December) the program was based on ?three? ?lines? ?of? ?exploration?: Design Studio, Techné and Scientific Research. The research lines provided design, technical en engineering skills to the students, who worked in 3 groups exploring the design potential as well as the structural and environmental properties of the material, and then systematizing their knowledge in a scientific paper.

The results were presented on Tuesday 5th December 2018

In the studio, groups of 3 students worked on the design of a passive habitat constructed with clay printing in three different contexts: the dense urban environment of the Barceloneta and the Valldaura natural park in Spain, as well as the emergency housing situation of the Kakura refugee camp in Kenya.

// Site 1 – Barceloneta

Gelder Graaf van Limburg Stirum, Ghazal Refalian, Filipp Sevostianov

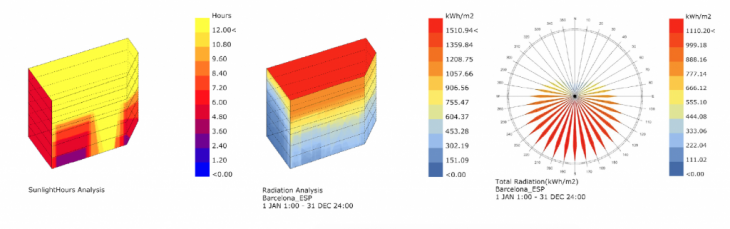

Particular aspects of the Barceloneta are dense neighborhood, narrow streets, consequently low light and high humidity, which is mostly addressed by climatic patios and porosities in facades.

The site is affected by sea breezes from May/June to September and winds from the west and northwest in winter. Taking advantage of breezes from the sea to the land gives a possibility to create micro-climates inside the building.

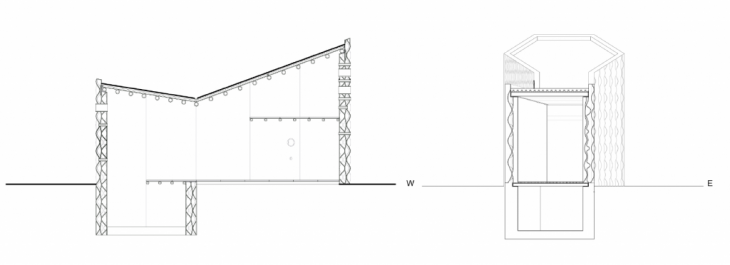

The objectives of the fabrication approach are to optimize Robot placement and extruding path related to plan, to use wood supports to be combined with adobe regarding horizontal parts like floors or lintels. The strategy was based on using 3 axis moving frame with robot attached on it, wooden floors and wooden supports for windows

Fabrication Strategy

Climate analysis

// Site 2 – Equatorial Africa – Kakuma (Kenia)

Ya-Chieh Chang, Daniele Fiore

The Equatorial Africa site is the Kakuma Refugee camp in Kenia. It represents the world’s largest UNHCR refugee camp with a current population of 142.000 people. The site is located at the latitude of 3.71° N, only slightly north from the Equator, featured by hot and arid climate, with low amount of precipitation.

The aim of the project was to define a derivative construction system working with adobe printing technology for housing systems that leave no trace, as required in refugee camps.

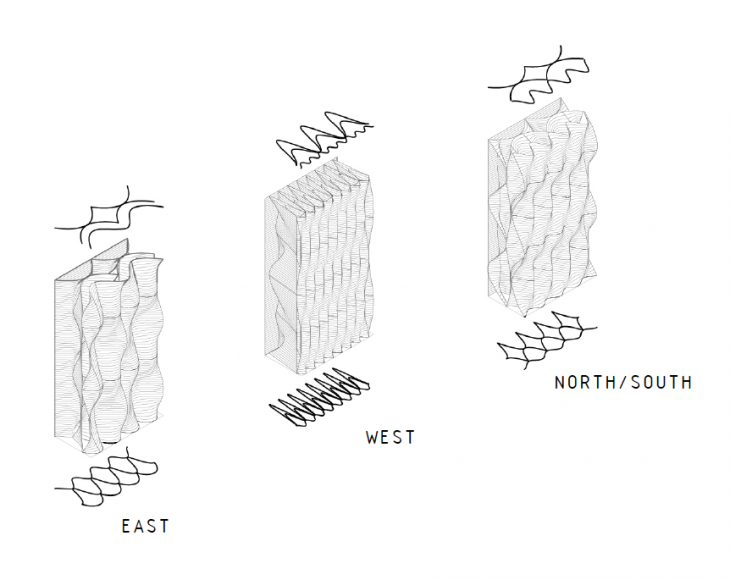

Climatic conditions especially in terms of the constantly high solar radiation required the housing design to be integrative of a series of geometric aspects, including the placement of the house in relation to the ground, the surface area exposed to the radiation, and the roof shape. The wall system design changes according to sun radiation, with a different geometry and distribution of layers: structural clay, clay filling, insulation filling.

Wall system variation

Wall system variation  Architectural section

Architectural section

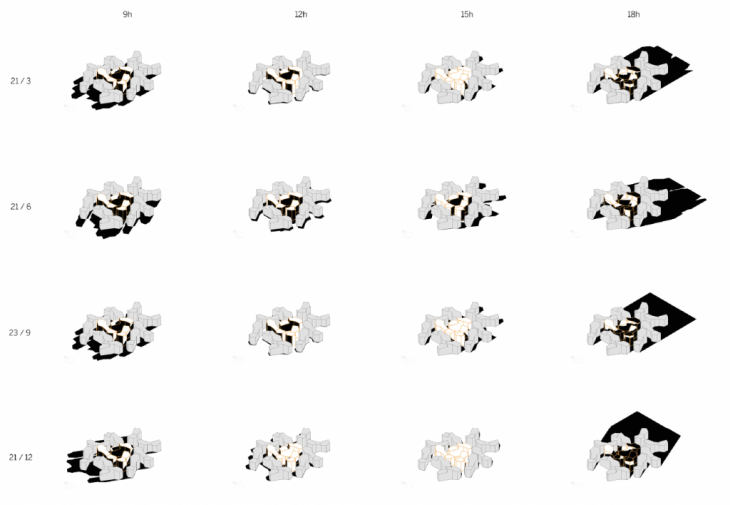

Following the vernacular local architecture, the individual shelter represents the unity of a modular system where the aggregation allow shading and climatic control.

Aggregative model

Aggregative model

// Site 3 – Valldaura natural park – Barcelona (Spain)

Sheikh Rizvi Riaz, Quan LI, Dongliang Ye

The site 3 is the Valldaura natural park, a mountain location in Barcelona characterized by a humid climate with a mild, humid winters and warm to hot summers. The proposal is an individual habitat embedding food production system in the architectural design.

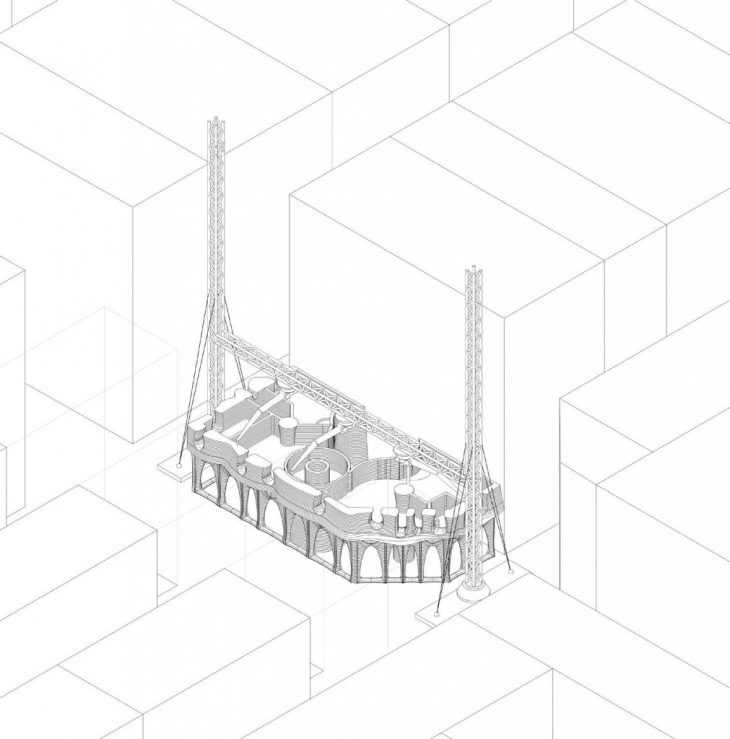

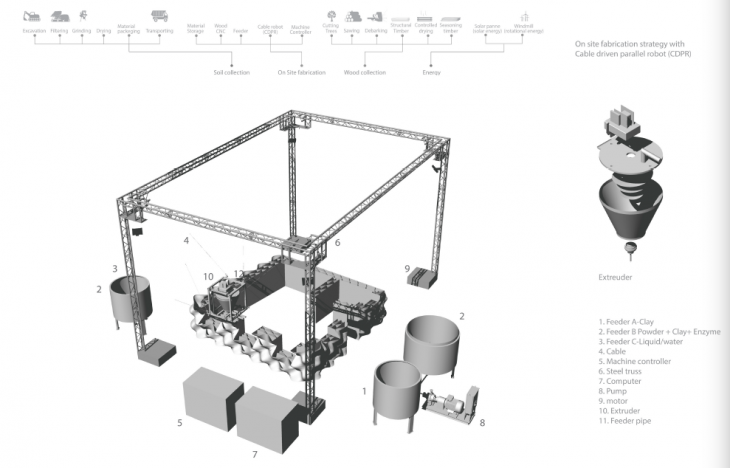

The fabrication strategy is based on the use of a Cable Robot with an integrated CNC control to automate the movement of a 3D extruder, using a composition of local earth as printing material.

Fabrication strategy

Fabrication strategy

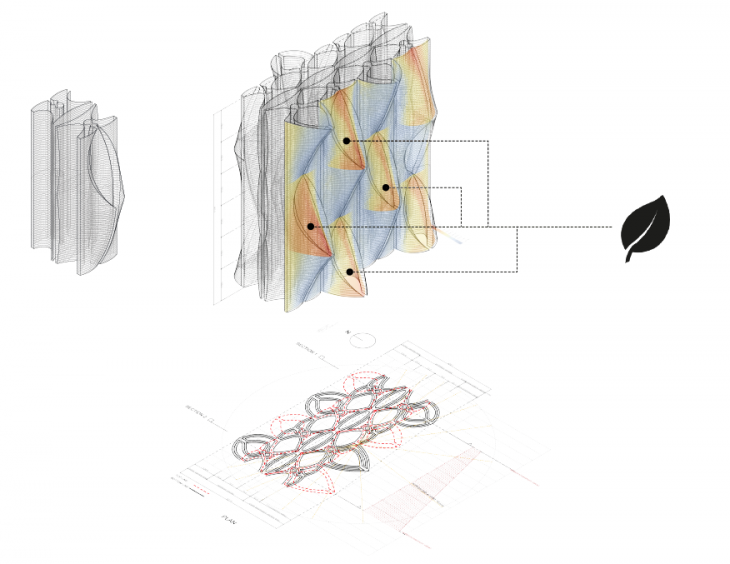

Wall system

Wall system