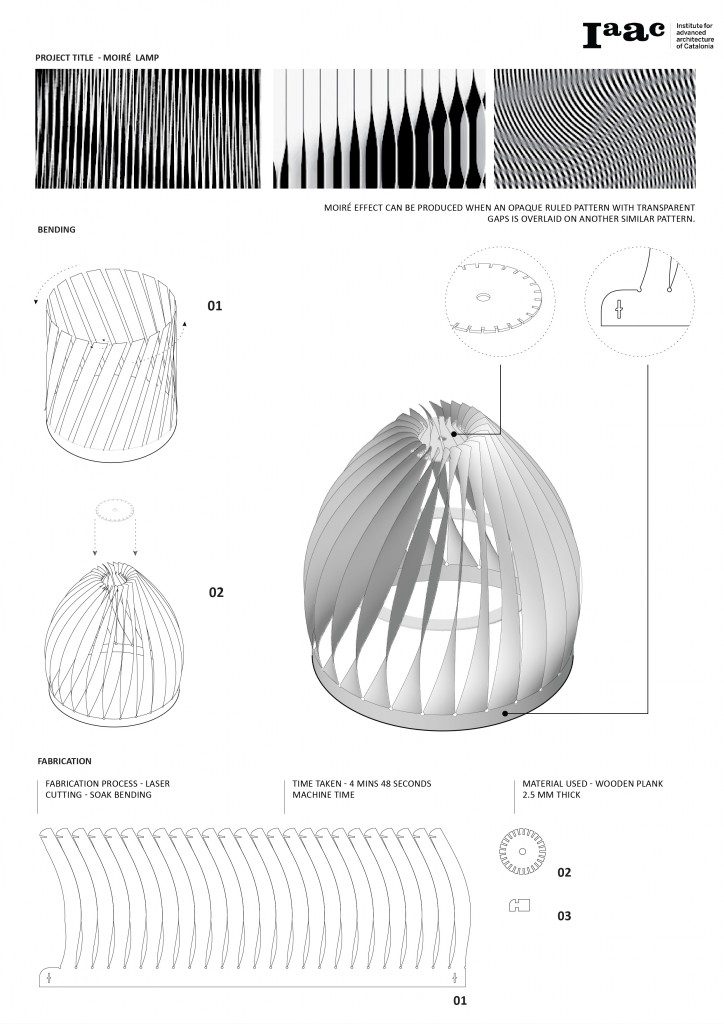

STARTED AS AN IDEA TO EXPERIMENT WITH THE QUALITY OF LIGHT AND TEST THE LASER CUTTINGTECHNIQUE TO THE FULLEST POTENTIAL. WE FOCUSED ON EXPLOITING : JOINTS, MATERIAL, ANGLES AND STRUCTURAL STABILITY.

WE CAME ACROSS AN EFFECT – ” MOIRÉ “ WHICH REALLY INSPIRED US. THE MAIN OBJECTIVE OF OUR DESIGN PROCESS WAS TO TWIST THE WOOD TO THE MAXIMUM POINT AND CREATE HETEROGENEOUS, NONLINEAR LIGHT PATTERN.

FOR OUR TEST PRINT, WE HAD A MODULE. ONCE IT WAS CUT AND SOAKED, HAVING DISCUSSED FURTHER, WE REALIZED THE AMENDMENTS AND IMPROVED THE FORM FURTHER BY WORKING WITH PROPORTIONATE ANGLES AND STRENGTHENING OUR JOINTS.

FINALLY, CAME THE FORM, COMPLETELY TWISTED AND LAYERED.

Moiré effect:

http://whatis.techtarget.com/definition/moire-effect

FABRICATION PROCESS – LASER CUTTING – SOAK BENDING

TIME TAKEN – 4 MINS 48 SECONDS MACHINE TIME

MATERIAL USED – WOODEN PLANK 2.5 MM THICK

MOIRÉ LAMP is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2016 by:

Students: Montakan Manosong, Malavika Mehta, Ricardo Mayor Luque

Tutors: Alexandre Dubor, Djordje Stanojevic