ML FOR FIBRO_SKIN is a project by MRAC 01 students Yeo Jeong Kim, Mit Patel, Beril Serbes during the SOFTWARE III seminar of the third term. SOFTWARE III was taught by IAAC faculty Mateusz Zwierzycki and Nikol Kirova.

This project focuses on a material with least unpredictable nature while fabricating double curvature geometry. Investigating fabrication of synthetic fiber composite panels took the research towards carbon fiber panels. Carbon fiber is a material with many material benefits that are interesting for architectural world. Since it is a toxic and an expensive material, architecture cannot take advantages of these benefits. ML FOR FIBRO_SKIN begins by investigating fabrication of bio-composite fiber panels to bring the material benefits such as high strength, lightweight, form freedom.

===OBJECTIVE===

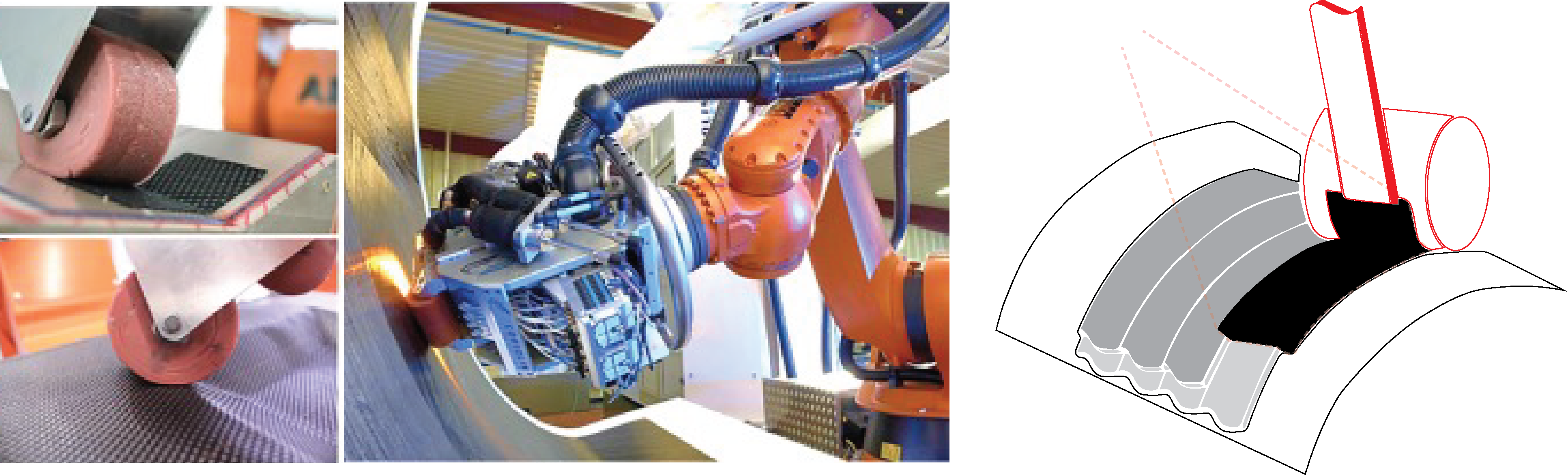

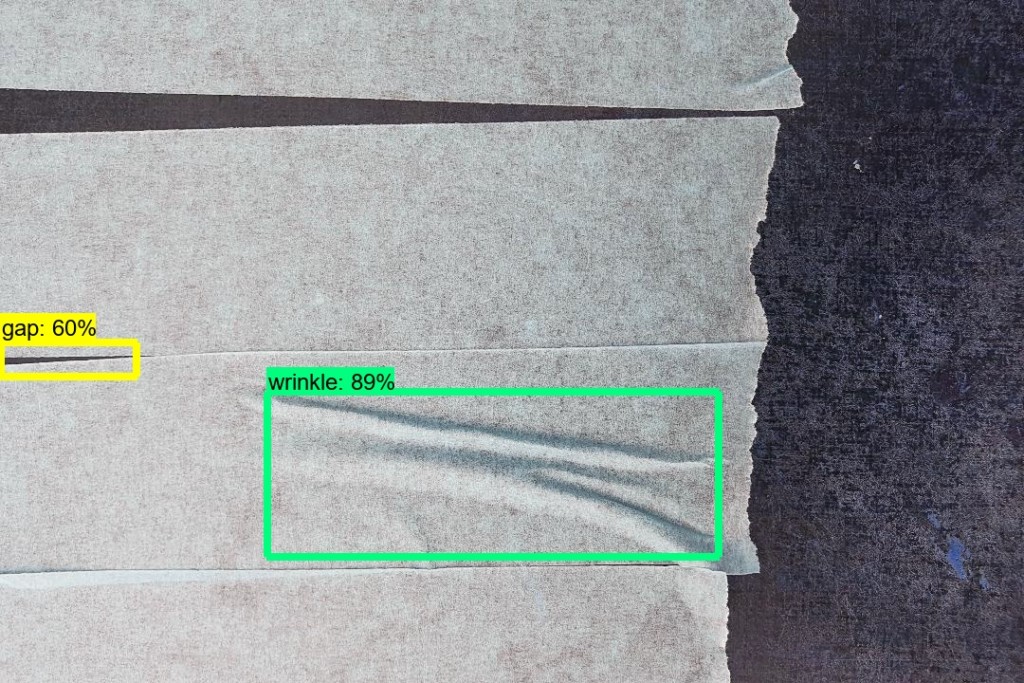

In the production of carbon fiber panels, tape laying and fabric laying is a popular process. For quality check purposes, defect detection for Automated Fiber Placement (AFP) is a developing research for additive carbon fiber manufacturing.

Fibers are more textured and less even on bio-composite tapes, as they are newer to the industry. The interest behind ML FOR FIBRO_SKIN begins in constructing a detection model for laying flax fiber tapes.

===THE PROCESS===

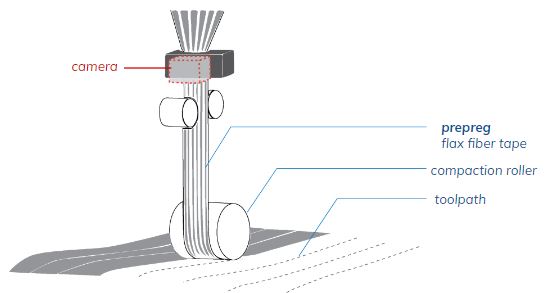

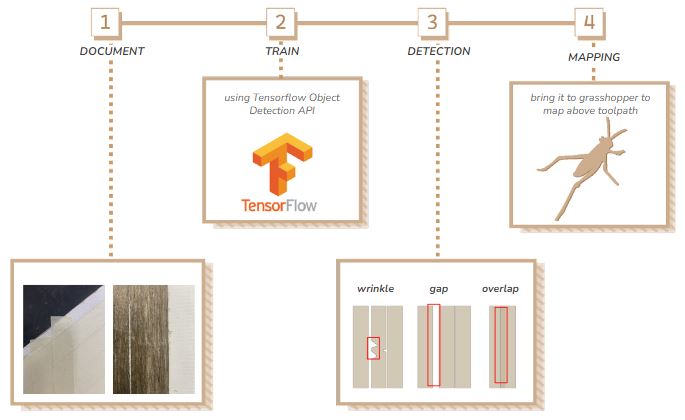

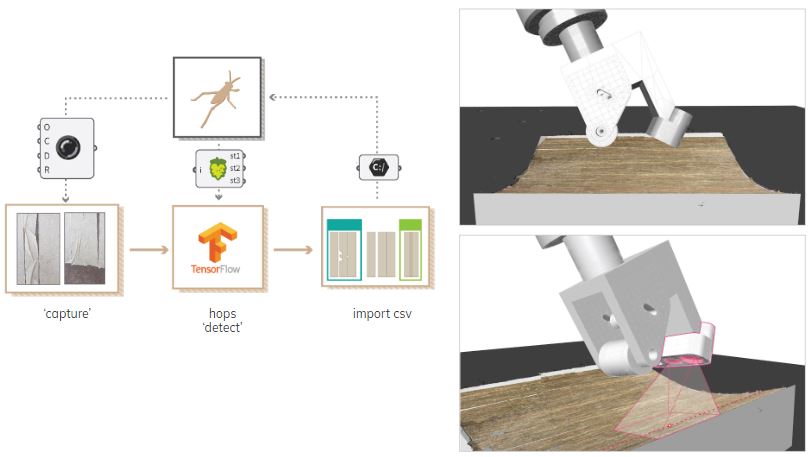

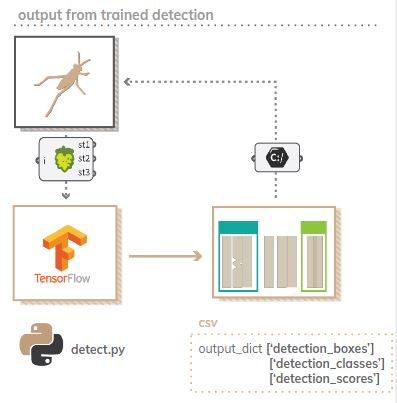

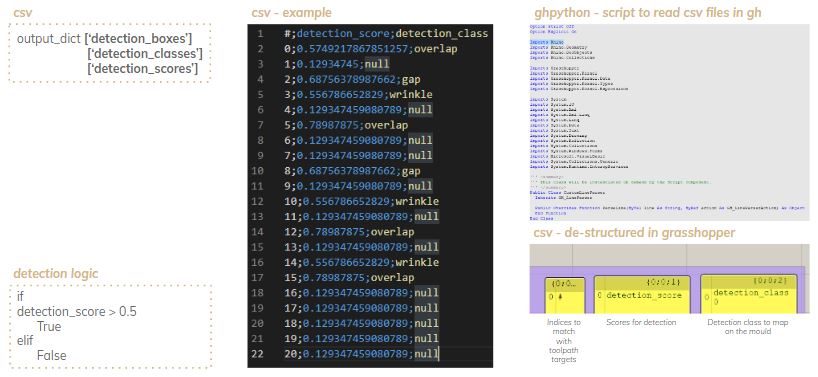

The aim is to have the detection trained by tensorflow object detection API, and the mapping of the detection to occur in grasshopper.

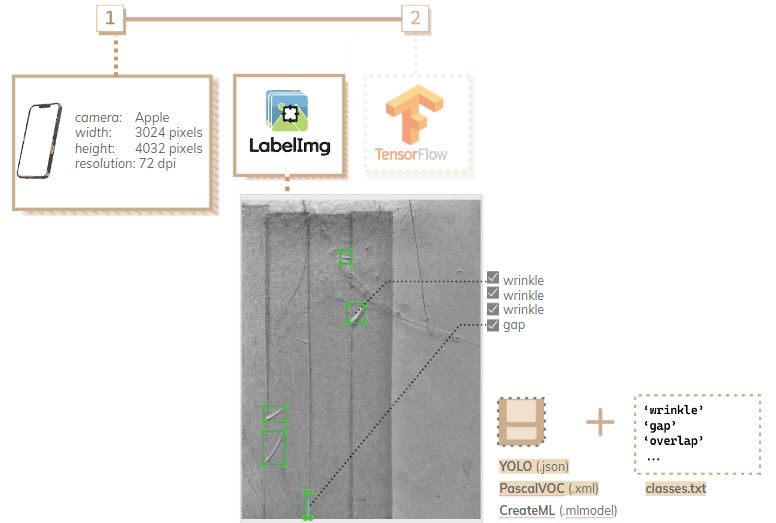

===THE LABELING===

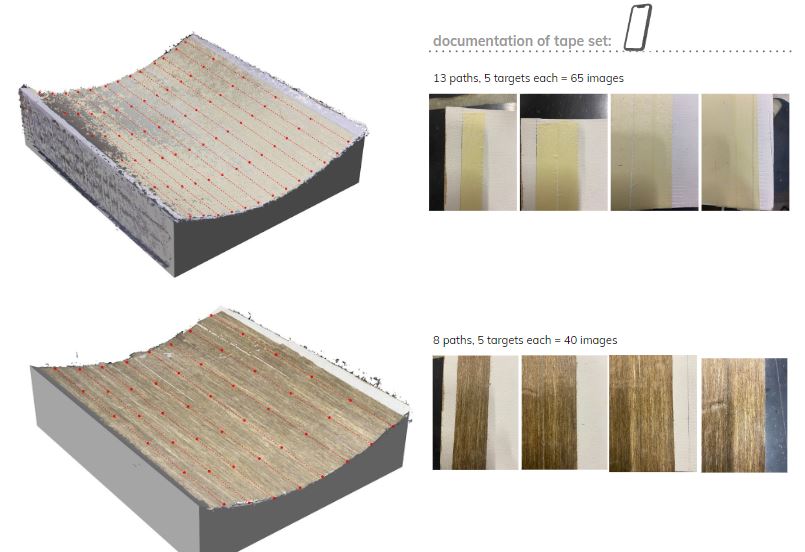

Prior to setting up the training, we performed the documentation with iPhone camera, labeling with LabelImg.

===TRAINING SET===

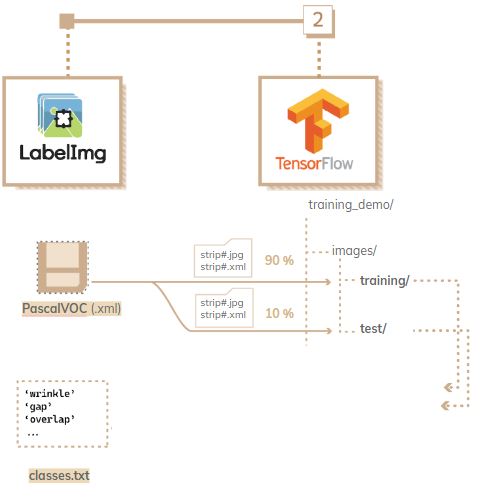

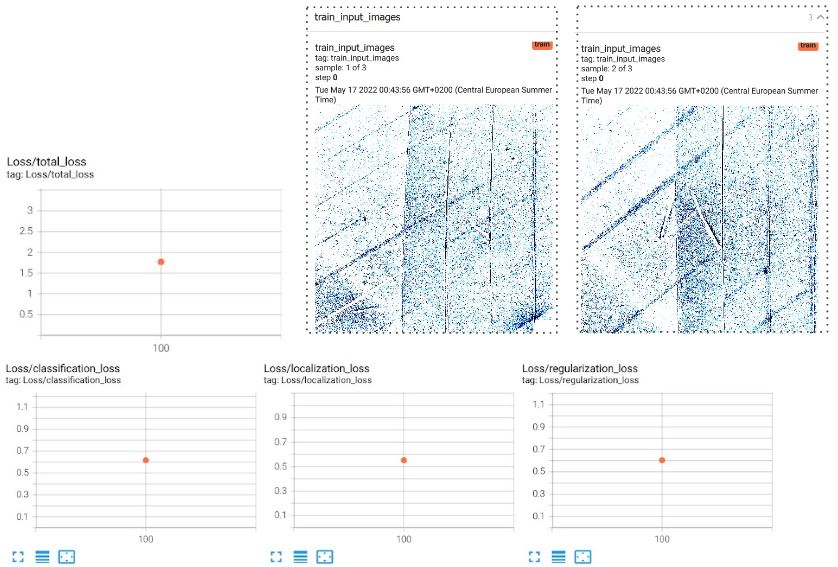

The labels in xml files will be split into training set (90%) and test set (10%), and they need to be iterated into a .record file for the training model to recognize.

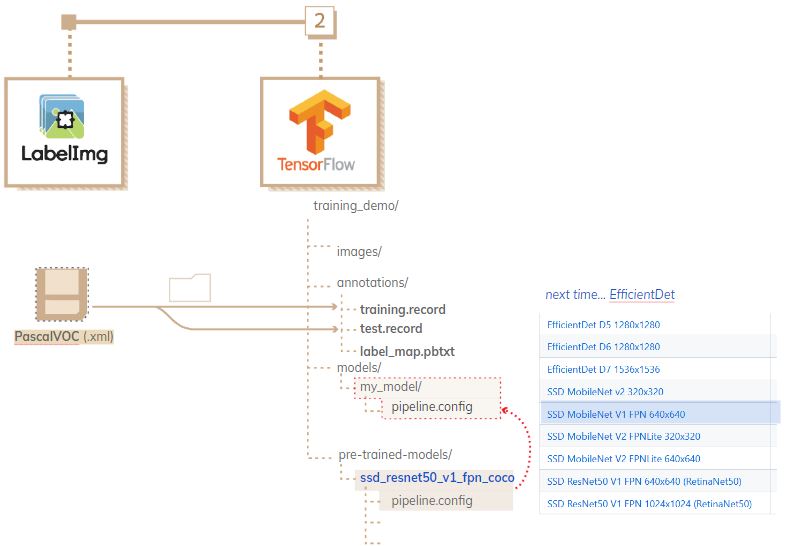

===CONFIGURATION===

The configuration for training is defined in the pipeline.config. A pre-trained FPN model is used to copy its architecture.

===TRAINING DATA SETS===

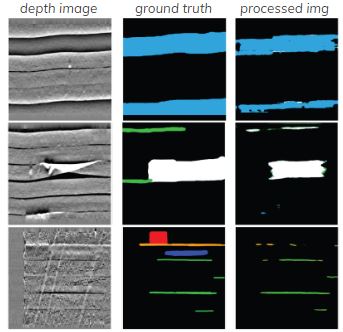

SET 1 – original color // SET 2 – opencv filter // SET 3 – variety

Set 1 Results:

batch size: 64 num_of_epochs: 1

miss detection, identifying wrinkles on walls and other flat areas.

Set 2 Results:

batch size: 12 num_of_epochs: 1

no loss, no gain

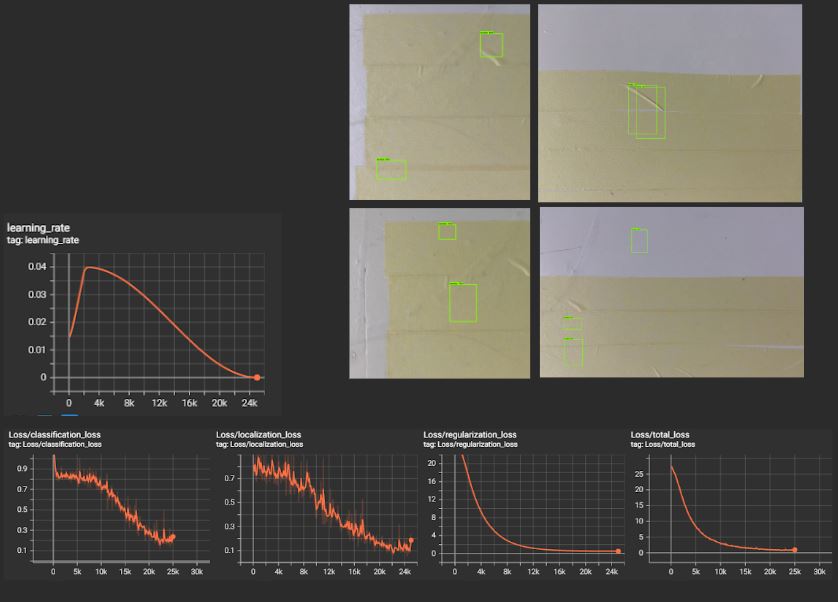

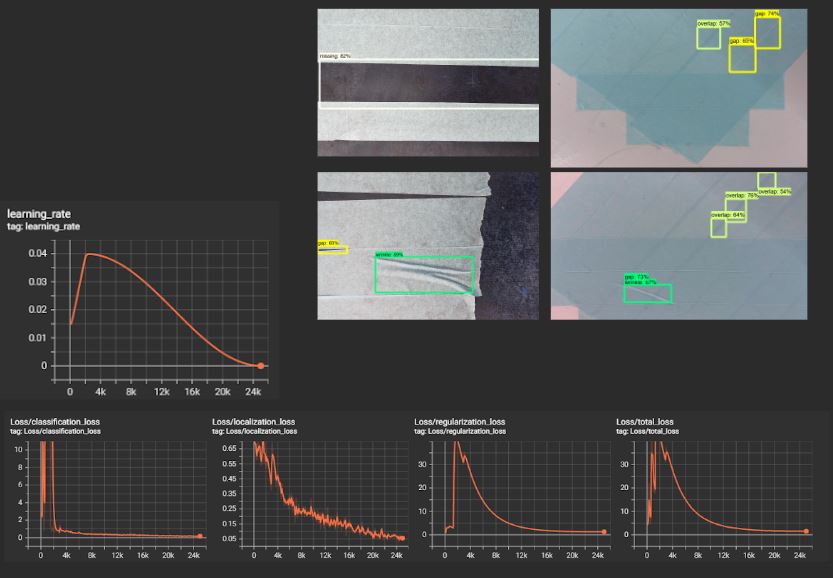

Set 3 Results:

batch size: 64 num_of_epochs: 1

gap confidence: 50 – 81%

wrinkle confidence: 50 – 98 %

missing confidence: 78 – 85%

===THE WORKFLOW===

Having the toolpath in grasshopper, the goal is to have everything triggered and imported to gH.

===TEST WITH SET 3===

tape_orig: 65, tape_prepreg: 40

As documentation was performed manually with phone camera, we tried to map the documentation into a toolpath.

detect.py plots detection box. the class, and the confidence score.

===MAPPING===

Prepreg showed over-detection as well as mis-detection. More training with more variety of textures, at constant distance and consistent image size is needed.

ML FOR FIBRO_SKIN is a project of IAAC, Institute for Advanced Architecture of Catalonia

developed at Master in Robotics and Advanced Construction,

in 2021/2022 by:

Students: Yeo Jeong Kim, Mit Patel, Beril Serbes

Faculty: Mateusz Zwierzycki and Nikol Kirova